Comprehensive Guide to Scotsman Ice Machine Parts Diagram

In the world of commercial refrigeration, comprehending the intricate components of your equipment is essential for optimal performance and longevity. This section delves into the various elements that contribute to the efficient functioning of your cooling unit, highlighting their roles and interconnections.

Grasping the layout of these crucial elements not only aids in troubleshooting but also enhances your ability to perform routine maintenance. By familiarizing yourself with the structure and function of each component, you empower yourself to address potential issues before they escalate.

Whether you are a technician or a business owner, having a clear understanding of your cooling apparatus will lead to improved efficiency and reduced downtime. This knowledge serves as a foundation for effective management and care of your equipment, ensuring it operates smoothly in demanding environments.

Understanding Scotsman Ice Machines

This section provides an overview of a popular type of equipment used in food and beverage service, focusing on its components and functionality. Gaining insight into these systems helps users maintain efficiency and troubleshoot potential issues effectively.

Key aspects to consider include:

- Types of equipment available

- Common features and functionalities

- Maintenance requirements for longevity

- Typical problems and their solutions

Users should familiarize themselves with the essential elements that contribute to optimal performance. Understanding the roles of various components is crucial for effective operation.

- Compressor: Responsible for circulating refrigerant.

- Condenser: Helps release heat from the system.

- Evaporator: Facilitates the freezing process.

- Water reservoir: Stores the liquid needed for production.

By recognizing how these parts interact, operators can ensure their systems run smoothly, leading to improved service and customer satisfaction.

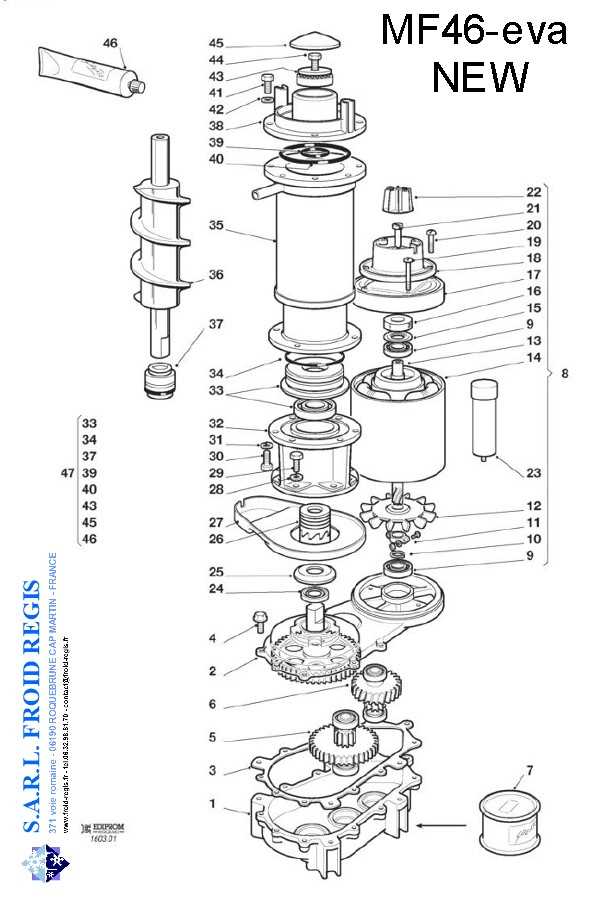

Key Components of Ice Makers

Understanding the essential elements that contribute to the functionality of freezing devices is crucial for effective maintenance and optimal performance. These integral components work together to create and dispense frozen water, ensuring a consistent supply for various applications.

Refrigeration System

The refrigeration system plays a pivotal role in the freezing process. It consists of a compressor, condenser, and evaporator, which work in unison to lower the temperature of water. The compressor circulates refrigerant, while the condenser releases heat, allowing the evaporator to absorb heat from the surrounding environment, thus facilitating the freezing cycle.

Water Delivery and Control Mechanism

A reliable water delivery system ensures that the correct amount of liquid is available for freezing. This system typically includes a water reservoir, pump, and float switch. The control mechanism regulates water flow and timing, ensuring that the freezing process occurs efficiently and without interruption.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any equipment. Neglecting maintenance can lead to a decline in performance, increased wear and tear, and ultimately, premature failure. By implementing a consistent maintenance schedule, users can prevent minor issues from escalating into significant problems, thereby preserving functionality and reliability.

Enhancing Efficiency

Proper care not only extends the life of devices but also improves their efficiency. When components are clean and well-maintained, they operate at optimal levels, reducing energy consumption and minimizing operational costs. Efficiency directly impacts productivity, making it crucial to prioritize regular check-ups and servicing.

Preventing Costly Repairs

Investing time and resources into routine maintenance can significantly decrease the likelihood of expensive repairs. Identifying potential issues early allows for timely interventions, saving both money and inconvenience. Prevention is far more cost-effective than reaction, reinforcing the value of a proactive approach to care and management.

Common Issues in Scotsman Units

In the realm of commercial refrigeration units, various challenges can arise that affect their performance and efficiency. Identifying and addressing these problems promptly is crucial to ensure optimal functionality and longevity of the equipment. This section will explore frequent concerns encountered in these systems, along with potential solutions.

Cooling Inefficiencies

A prevalent issue is the lack of sufficient cooling, which can lead to inadequate product preservation. This problem may stem from factors such as poor ventilation, clogged filters, or faulty thermostats. Regular maintenance, including cleaning air intakes and ensuring proper airflow, is essential to mitigate these issues.

Unusual Noises and Vibration

Another common concern is the generation of abnormal sounds or excessive vibrations during operation. This may indicate underlying mechanical issues, such as loose components or worn bearings. It is advisable to inspect the unit periodically, tightening any loose fittings and replacing worn parts to maintain smooth operation.

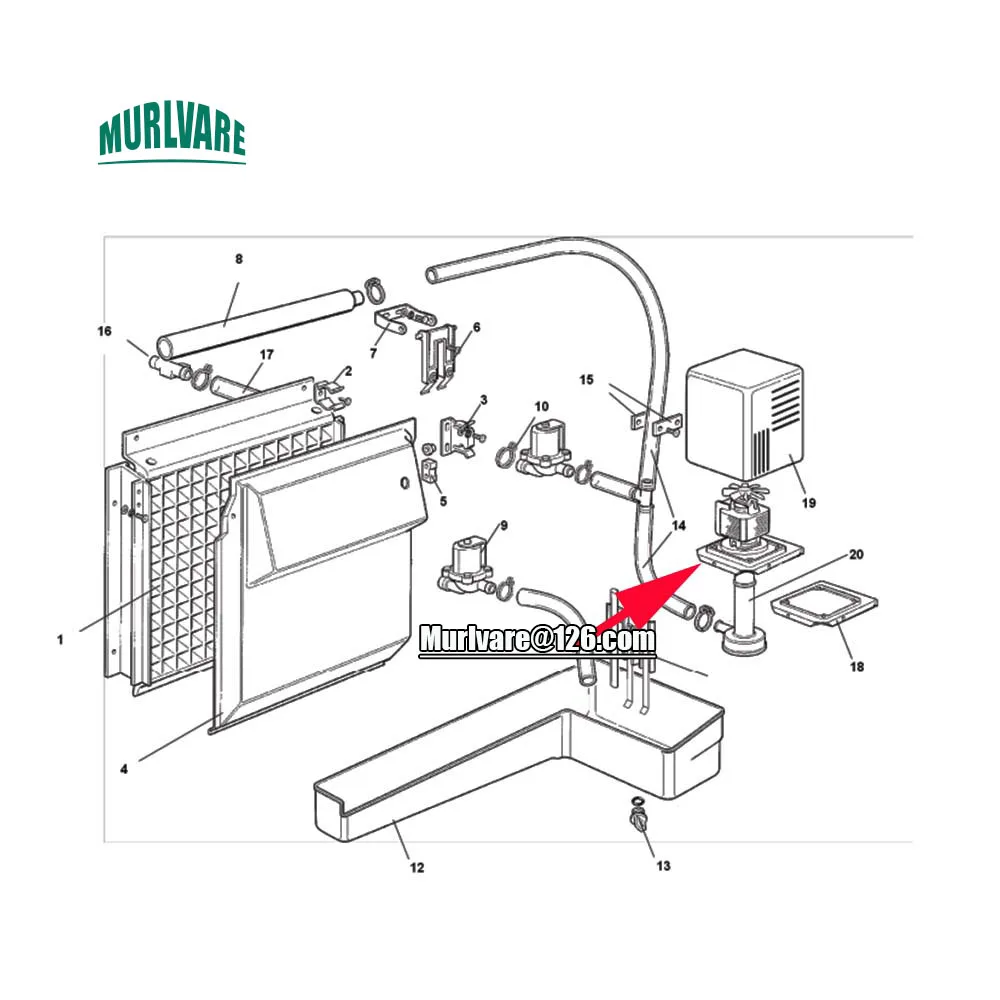

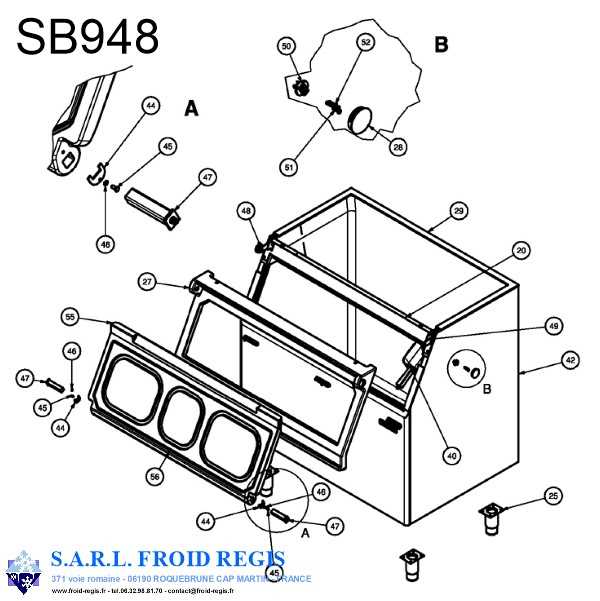

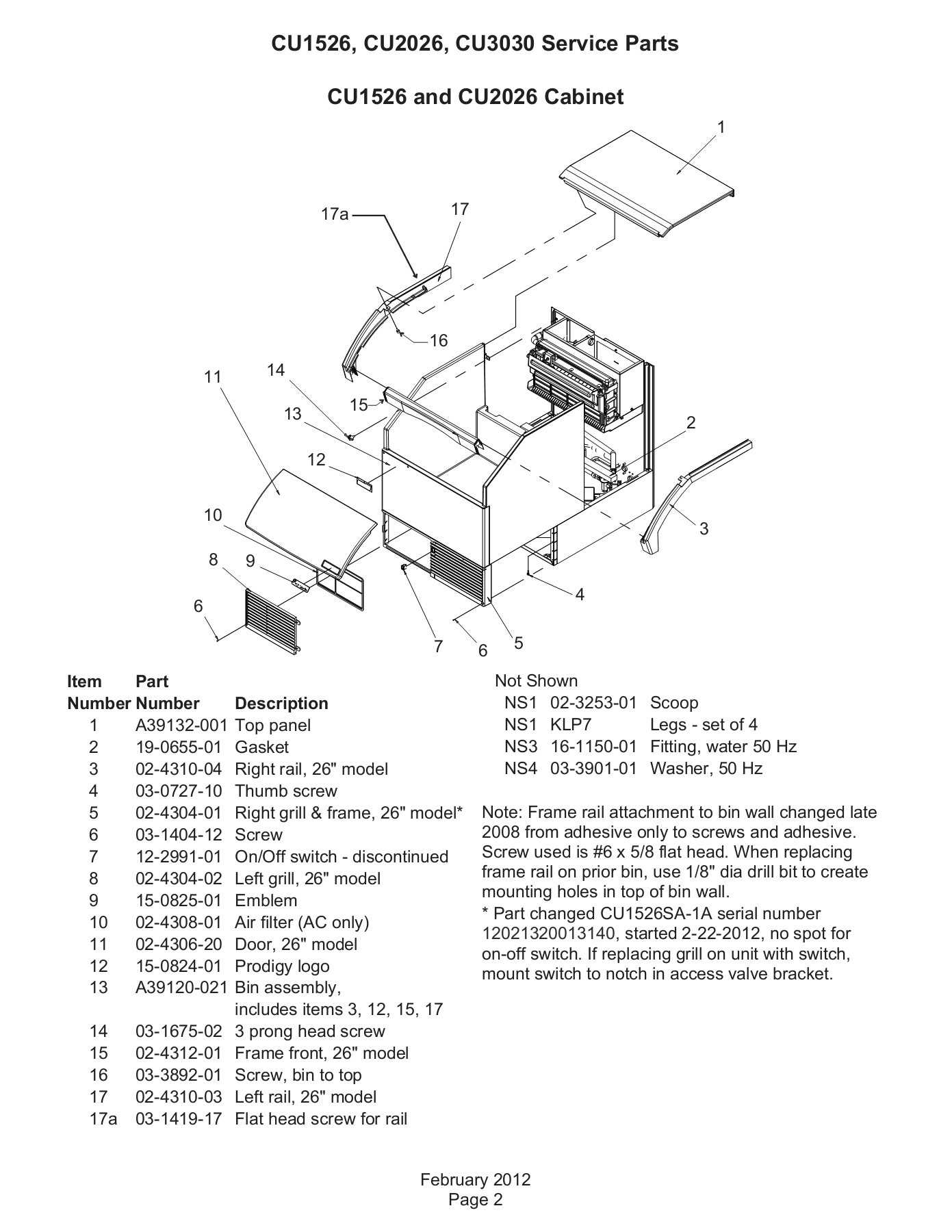

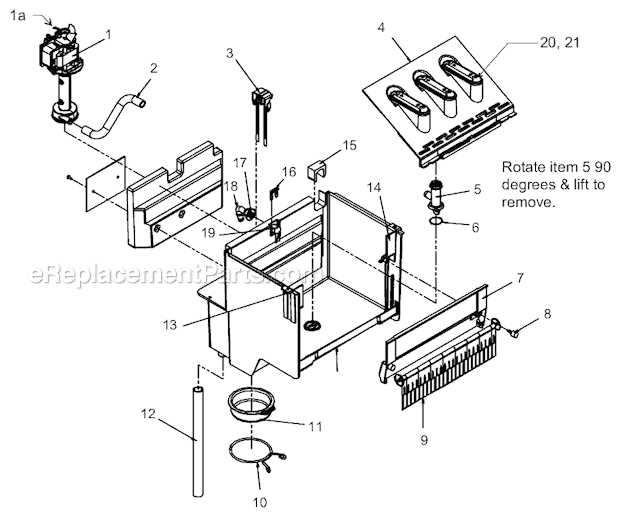

Identifying Parts in a Diagram

Understanding the various components within a visual representation is crucial for effective maintenance and troubleshooting. Each element plays a specific role, and recognizing these functions enhances one’s ability to address issues efficiently.

Key Features: Start by familiarizing yourself with the overall layout. Look for labels that indicate different sections, as these often provide context for the roles each component fulfills. Pay attention to symbols and numbering, which typically help in pinpointing specific elements.

Visual Cues: Utilize color coding or distinctive shapes that may highlight critical components. These cues can simplify the identification process, allowing for quicker reference during repairs or replacements.

Finally, consulting the accompanying documentation can further clarify the purpose and interaction of each element. A thorough understanding not only aids in maintenance but also fosters a deeper knowledge of the entire system’s operation.

How to Read Ice Machine Diagrams

Understanding technical schematics can be challenging, yet it is essential for effective troubleshooting and maintenance. These visual representations provide valuable insights into the structure and functionality of equipment. Familiarizing yourself with the elements of these illustrations will empower you to navigate through complex systems with ease.

Start by identifying the key components. Each illustration typically labels various elements, such as the compressor, evaporator, and control systems. Recognizing these parts allows you to comprehend how they interact within the overall framework.

Next, pay attention to the connections. Lines and arrows often indicate the flow of refrigerants and electrical signals. Understanding these pathways is crucial for diagnosing issues and implementing effective repairs.

Additionally, refer to the legend or key that accompanies the schematic. This guide explains symbols and notations, which are vital for accurately interpreting the information presented. Familiarity with common symbols will enhance your understanding significantly.

Finally, practice makes perfect. The more you engage with these visual tools, the more proficient you will become at reading them. Regularly reviewing various schematics will build your confidence and technical knowledge.

Replacing Worn-Out Components

Maintaining optimal performance requires attention to various elements that may degrade over time. Regularly assessing and substituting these elements is essential for ensuring efficiency and prolonging the lifespan of the equipment. Understanding the signs of wear and the appropriate methods for replacement can greatly enhance functionality.

Identifying Signs of Wear

It is crucial to recognize the indicators that suggest a component may need replacement. Common symptoms include unusual noises, reduced efficiency, or visible damage. Monitoring these signs helps prevent larger issues from developing, which can lead to costly repairs or replacements.

Steps for Replacement

Once worn elements have been identified, the next step is to gather the necessary tools and replacement items. Following a systematic approach can streamline the process. Begin by disconnecting power sources to ensure safety, and then carefully remove the affected part. Install the new component, ensuring it fits securely, and reconnect the power source. Testing the functionality afterward is vital to confirm successful installation.

Regular Maintenance

Establishing a routine maintenance schedule can help identify potential issues before they escalate. Regular inspections and timely replacements not only enhance performance but also contribute to the longevity of the overall system.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining optimal performance. Whether you’re dealing with a malfunction or simply planning a routine upgrade, knowing where to source these items is crucial. Various avenues can provide access to high-quality alternatives, ensuring your unit operates smoothly.

Online Retailers

One of the most convenient options is to explore online vendors. Numerous websites specialize in providing a wide range of components, often featuring detailed descriptions and specifications. Many platforms allow you to filter results based on brand compatibility, making the search process more efficient. Customer reviews can also guide you in selecting reliable options.

Local Distributors and Service Centers

Another effective strategy is to visit local suppliers and authorized service centers. These establishments usually have knowledgeable staff who can assist in identifying the right components for your specific equipment. Additionally, purchasing locally can often expedite the process and provide immediate solutions to any pressing issues you may encounter.

Benefits of Genuine Scotsman Parts

Using authentic components for your equipment brings a multitude of advantages that enhance performance and longevity. These original items are designed specifically for optimal compatibility, ensuring that your unit operates at its best and minimizes the risk of breakdowns. Investing in high-quality replacements means you are supporting the integrity of the entire system.

One significant benefit is reliability. Genuine items are subjected to rigorous testing and quality control standards, which means they are less likely to fail under pressure. This reliability translates into reduced downtime and maintenance costs, allowing you to focus on your core operations rather than worrying about repairs.

Moreover, original components often come with warranties that safeguard your investment. This added layer of protection not only provides peace of mind but also reflects the manufacturer’s confidence in their products. When you opt for these verified elements, you are ensuring that you are using materials that have been engineered to work seamlessly together.

Finally, choosing authentic components contributes to the overall efficiency of your system. These elements are designed with precision, allowing for improved energy consumption and better performance metrics. This efficiency can lead to cost savings in the long run, as your unit operates more effectively and consumes less energy.

Safety Precautions During Repairs

When undertaking maintenance tasks, prioritizing safety is essential to prevent accidents and ensure a secure working environment. Proper precautions can help mitigate risks associated with handling tools and equipment.

- Always disconnect the power source before beginning any repair work to avoid electrical shocks.

- Use personal protective equipment (PPE), including gloves, goggles, and appropriate footwear, to safeguard against injuries.

- Familiarize yourself with the equipment’s manual and safety guidelines to understand potential hazards.

- Keep your workspace organized and free of clutter to minimize the chance of tripping or accidents.

Additionally, it’s crucial to be aware of the tools and materials you are working with:

- Inspect tools for any damage or wear before use, as faulty tools can lead to accidents.

- Use the correct tools for the job to ensure efficiency and safety.

- Store hazardous substances properly and handle them according to safety protocols.

By adhering to these guidelines, individuals can significantly reduce the risk of injury and create a safer repair environment.

Troubleshooting Common Ice Problems

Addressing issues with frozen products can be challenging, but understanding typical malfunctions can simplify the process. Identifying symptoms and implementing effective solutions ensures smooth operation and quality output.

1. Insufficient Production: If you’re experiencing a lack of frozen cubes, check the water supply. Ensure that the inlet valve is functioning properly and that there are no blockages in the water line. Additionally, assess the temperature settings; if they are too high, the creation process may be hindered.

2. Irregular Shapes: When the frozen products have inconsistent shapes, it may indicate a problem with the freezing cycle. Examine the thermostat for accuracy and inspect the evaporator for any buildup of debris that could impede proper freezing.

3. Cloudy Appearance: A cloudy look often signifies impurities in the water supply. Consider using filtered water to improve clarity and quality. Regular cleaning of the water reservoir can also help maintain a clear output.

4. Excessive Noise: Unusual sounds can be a sign of mechanical issues. Listen for grinding or rattling noises, which may indicate loose components or worn parts. Inspect and tighten any loose fittings and check for proper alignment of the operational elements.

5. Melting Problems: If the frozen products are melting too quickly, check the ambient temperature around the storage area. Ensure it is kept cool and that the ventilation is adequate. Additionally, verify that the insulating materials are intact and functioning as intended.

By systematically addressing these issues, you can enhance the efficiency and reliability of your frozen product creation process. Regular maintenance and prompt troubleshooting will lead to improved performance and longevity.

Optimizing Performance of Ice Machines

Enhancing the efficiency and functionality of freezing devices is essential for ensuring consistent output and longevity. By focusing on various aspects of operation and maintenance, users can achieve better results while minimizing energy consumption and downtime.

- Regular Maintenance: Frequent inspections and cleaning help identify potential issues before they escalate. This includes checking filters, water supply, and interior components.

- Temperature Management: Maintaining optimal ambient temperatures can significantly affect performance. Ensure that the surrounding environment is conducive to effective operation.

- Water Quality: Utilizing purified water prevents mineral buildup, which can hinder performance. Regularly testing and treating water supply ensures better quality output.

In addition to these foundational practices, consider implementing advanced monitoring systems that provide real-time data on operational metrics. This proactive approach allows for immediate adjustments, further enhancing overall efficiency.

- Establish a routine maintenance schedule.

- Monitor and control environmental conditions.

- Utilize high-quality water sources.

- Implement advanced monitoring technologies.

By adopting these strategies, users can not only improve the effectiveness of their freezing units but also extend their lifespan, ultimately leading to cost savings and superior performance.