Understanding the Components of a Maytag Neptune Washer

Every appliance, no matter how advanced, is made up of various interconnected elements that work together to ensure efficient operation. When looking to maintain or repair a washing machine, it is essential to be familiar with the internal structure and layout of its key sections. Understanding how each component fits and functions can help diagnose issues more effectively and ensure the machine runs smoothly.

Knowing the layout of the internal mechanisms, from the central controls to the smallest moving pieces, provides clarity when performing maintenance. Whether you are troubleshooting or simply looking to upgrade parts, having a clear guide to the arrangement of these elements will make the task much easier.

In this article, we will explore the intricate design and functions of each critical section of the appliance, ensuring that you gain a comprehensive understanding of how they contribute to the overall performance. This knowledge is crucial for anyone looking to keep their system in optimal condition or carry out specific repairs.

Overview of Key Components in Maytag Neptune

Understanding the essential elements of this specific appliance model is crucial for maintaining optimal performance and ensuring efficient operation. Each element plays a significant role in the overall functionality, contributing to the durability and effectiveness of the machine. Below, we’ll explore some of the most critical features and systems involved in this household equipment.

Primary Control System

The control system serves as the central hub, managing the various functions of the machine. It handles tasks such as regulating water temperature, cycle settings, and timing. Ensuring the integrity of this system is vital for proper machine operation.

Mechanical and Moving Parts

The core mechanical components are responsible for movement and the execution of different cycles. This includes the drive system, responsible for rotating internal elements, and other mechanisms that ensure proper function. Regular upkeep of these components helps avoid performance issues.

Common Issues with Internal Mechanisms

Over time, many household machines that provide critical daily functions may experience problems within their internal components. These issues can range from minor malfunctions to more significant failures that disrupt operation. Regular wear, along with other external factors, often leads to complications that require attention and, sometimes, part replacement.

Wear and Tear on Key Components

One of the most frequent concerns involves the gradual degradation of essential elements due to regular use. Mechanical parts, such as motors, belts, and other moving sections, can deteriorate or loosen, leading to reduced performance. It’s crucial to monitor these elements for early signs of damage, which include unusual noises, slower operation, or inconsistent functionality.

Electrical System Failures

Another prevalent issue arises from disruptions in the electrical systems. Faulty wiring, worn connections, or malfunctioning sensors can lead to operational inconsistencies. In many cases, these failures manifest as unexpected shutdowns, incomplete cycles, or error messages. Identifying and addressing such electrical faults promptly helps to prevent more significant damage to the overall mechanism.

Understanding Electrical Connections and Wiring

To ensure that a device functions correctly, it’s important to have a clear grasp of how its electrical components interact with each other. The wiring system serves as the backbone for distributing power and signals across various internal mechanisms. Proper connections are key to maintaining the efficiency and safety of the unit, making it crucial to understand the basic principles of wiring configurations and connections.

Key Components of the Wiring System

Wiring systems are composed of various elements that work together to transfer electrical power and communication signals. These elements include cables, connectors, and terminals, each designed to perform specific tasks. Understanding the role of these components can help troubleshoot and ensure that the system operates efficiently.

Safe and Efficient Wiring Practices

Maintaining proper connections is not only about functionality but also about safety. Incorrect wiring can lead to malfunction or, worse, hazards like electrical shorts. Always ensure that connections are secure, cables are intact, and that the right type of wires are used to handle the electrical load.

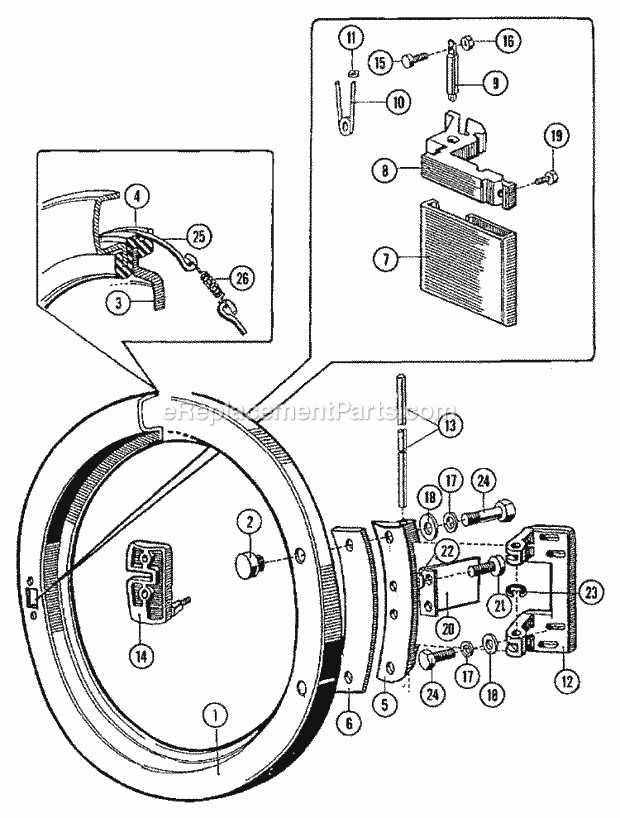

How to Replace Door Parts Efficiently

Maintaining the proper function of the door mechanism is essential for ensuring smooth operation. Whether it’s a worn-out hinge or a faulty latch, knowing the right steps for replacement can save both time and effort. This guide will walk you through the process, helping you tackle the job with confidence and efficiency.

- Gather the Tools: Before starting, make sure you have the necessary tools. Typically, a screwdriver, pliers, and a wrench will suffice for most tasks.

- Remove the Old Components: Begin by carefully unscrewing any visible fasteners. Take care to support the door while detaching it to avoid damage.

- Install the New Components: Align the new hinges or latches with the existing slots and fasten them securely. Make sure everything fits snugly to avoid misalignment.

- Test the Door: After reassembling, test the door’s movement to ensure it opens and closes smoothly without resistance or noise.

- Make Final Adjustments: If necessary, fine-tune the alignment by slightly adjusting the fasteners for a perfect fit.

Following these steps will help you complete the task efficiently and ensure the longevity of your appliance’s functionality.

Locating and Repairing the Water Pump

Identifying the location of the water discharge system in a household appliance is a key step when addressing issues related to water drainage. Over time, blockages or mechanical malfunctions can lead to inefficient water removal, causing performance problems. To maintain optimal operation, it is essential to understand where this critical component is situated and how to access it for routine inspection or replacement.

Steps to Access the Pump

To begin, ensure that the appliance is unplugged for safety. The pump is usually positioned at the bottom of the machine, often behind a rear or front panel that requires removal. Carefully unscrew the designated access panel to reveal the internal components. Once visible, check the hoses connected to the pump for any signs of clogging or wear.

Repair and Maintenance Tips

When you have located the pump, inspect it for any visible signs of damage, such as cracks or obstructions. If the issue involves debris, clean the filter and surrounding areas. In cases of more serious damage, the pump may need to be replaced. Be sure to follow proper procedures when disconnecting and reassembling the parts to avoid further issues.

The Role of Bearings in Performance

In any mechanical system, the efficiency and smooth operation significantly depend on the components that facilitate movement and reduce friction. Among these critical elements, the supporting structures play a pivotal role in enhancing performance by ensuring stability and minimizing wear over time. Their design and material composition directly influence the longevity and reliability of the entire assembly.

Functionality and Importance

The primary function of these supporting structures is to enable rotational motion while maintaining proper alignment. This not only aids in efficient energy transfer but also helps in dissipating heat generated during operation. High-quality components can lead to improved performance, resulting in less energy consumption and reduced operational costs.

Maintenance Considerations

Regular inspection and maintenance of these essential components are crucial to prevent failures and extend the lifespan of the equipment. Identifying signs of wear or damage early can save costs and ensure optimal functioning. Proper lubrication and timely replacements contribute to the overall health of the system.

| Feature | Impact on Performance |

|---|---|

| Material Quality | Influences durability and resistance to wear. |

| Alignment | Ensures efficient energy transfer and reduces vibration. |

| Lubrication | Minimizes friction and prevents overheating. |

Control Board Functions and Troubleshooting

The control board plays a crucial role in managing the operations of various household appliances. It serves as the central hub for communication, processing commands, and ensuring that all components function harmoniously. Understanding its functions and how to troubleshoot common issues can significantly enhance the performance and longevity of your appliance.

This section will outline the primary functions of the control board and provide a guide for diagnosing common problems. Familiarizing yourself with these aspects can empower you to effectively address issues that may arise during the appliance’s operation.

| Function | Description |

|---|---|

| Communication | Facilitates interaction between different components and sensors within the appliance. |

| Control | Manages the timing and execution of various cycles, such as washing, rinsing, and drying. |

| Monitoring | Checks for any malfunctions or irregularities in the appliance’s operations. |

| Settings Management | Allows users to customize and select preferred settings for their specific needs. |

| Power Distribution | Distributes electrical power to various components, ensuring they receive the necessary energy to operate. |

Troubleshooting the control board involves a systematic approach to identify and resolve issues. Begin by observing any error codes displayed on the appliance, as these can provide valuable clues. Next, inspect wiring connections for damage or looseness, as poor connections can lead to malfunction. If problems persist, testing components such as sensors and relays for continuity can help pinpoint the source of the issue.

Regular maintenance and periodic checks can also prevent future complications. Ensuring that the control board is free of dust and debris will promote optimal performance, extending the life of your appliance.

Steps to Identify Motor Problems

Diagnosing issues with the motor in an appliance requires a systematic approach to ensure that the root cause is accurately identified. By following a series of methodical steps, you can determine whether the motor is functioning properly or if it needs repair or replacement.

1. Visual Inspection: Begin by examining the motor and its surrounding components. Look for any visible signs of wear, damage, or loose connections. Ensure that there is no debris or obstructions that could hinder the motor’s operation.

2. Listen for Unusual Noises: Power on the appliance and pay close attention to any abnormal sounds coming from the motor. Grinding, humming, or rattling noises can indicate mechanical issues that need further investigation.

3. Check for Overheating: Monitor the temperature of the motor during operation. If the motor feels excessively hot to the touch, this may suggest that it is working harder than normal due to internal friction or electrical problems.

4. Test Electrical Components: Use a multimeter to test the voltage and resistance of the motor’s electrical components. A lack of voltage or irregular resistance readings can point to electrical faults that require attention.

5. Assess Performance: Evaluate how the motor operates under load. If it struggles to start, stops unexpectedly, or runs inconsistently, these symptoms can reveal underlying issues that may need to be addressed.

Following these steps will help you gain insight into potential motor problems, allowing for timely maintenance or repair decisions to restore optimal performance.

Exploring Drum and Tub Assembly

The assembly of the rotating drum and outer tub is crucial for the efficient functioning of a laundry appliance. This section delves into the various components that make up this essential assembly, highlighting their roles and interconnections. Understanding these elements is vital for anyone looking to maintain or repair their washing unit effectively.

The inner drum, typically designed to hold the laundry during the wash cycle, works in tandem with the outer tub, which contains the water. The interaction between these two parts influences the machine’s overall performance, including washing efficiency and water management.

| Component | Description | Function |

|---|---|---|

| Drum | A cylindrical container where clothes are placed. | Rotates to agitate and clean the laundry. |

| Tub | The outer shell that houses the drum. | Holds water and supports the drum during operation. |

| Bearings | Supports the drum’s rotation. | Reduces friction and wear during spin cycles. |

| Seal | A component that prevents leaks between the drum and tub. | Ensures water remains contained within the tub. |

By grasping the intricacies of the drum and tub assembly, users can better appreciate the engineering behind their laundry appliances. This knowledge not only aids in effective troubleshooting but also empowers individuals to perform maintenance tasks with confidence.

Maintaining the Heating Element for Optimal Use

To ensure peak performance and longevity of your appliance, proper care of the heating component is essential. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Understanding the factors that contribute to wear and tear can significantly impact its operational lifespan.

Key Maintenance Tips

Regular inspection and cleaning of the heating unit are vital steps in maintaining its effectiveness. Accumulation of debris and mineral deposits can hinder performance. Here are some best practices:

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for any signs of damage, corrosion, or excessive wear on the heating element. |

| Cleaning | Every 3 months | Remove dust and debris from the heating area using a soft brush or cloth. |

| Check Connections | Every 6 months | Ensure all electrical connections are secure and free from oxidation. |

Signs of Potential Issues

Being aware of warning signs can help you address problems before they escalate. If you notice any of the following, it may be time to consult a professional:

- Inconsistent heating performance

- Unusual noises during operation

- Burning smells or discoloration

Cleaning and Servicing the Filter System

Regular maintenance of the filtration system is essential for optimal performance and longevity of your appliance. A clean filter ensures that the unit operates efficiently, preventing potential clogs and prolonging the lifespan of various components.

Step 1: Begin by disconnecting the power source to ensure safety during the cleaning process. Locate the filter housing, which is typically situated near the water inlet or drainage area.

Step 2: Carefully remove the filter from its housing. Inspect it for any debris or buildup that may have accumulated over time. A clean filter not only improves functionality but also enhances the overall effectiveness of the system.

Step 3: Rinse the filter under warm water to remove any dirt or contaminants. If necessary, use a soft brush to gently scrub away stubborn residue. Avoid harsh chemicals, as they can damage the filter material.

Step 4: Once cleaned, allow the filter to air dry completely before reinserting it into the housing. Ensuring the filter is thoroughly dry helps prevent mold and unpleasant odors from developing.

Step 5: Reattach the filter securely and restore the power supply. It is advisable to check the system periodically and perform this cleaning routine every few months to maintain optimal performance.

By following these steps, you can ensure the longevity and efficiency of your filtration system, contributing to the smooth operation of your appliance.