Understanding the Mercury 115 Elpto Parts Diagram for Better Maintenance

In the realm of marine mechanics, the ability to navigate through the complexities of various engine elements is crucial for optimal performance. This section explores the essential components that work in harmony to ensure efficiency and reliability in watercraft propulsion systems.

By examining the layout and interactions of these integral parts, enthusiasts and professionals alike can gain deeper insights into maintenance and troubleshooting. The visual representation of these elements not only aids in comprehension but also highlights the ultimate significance of each component within the broader system.

Whether you are a seasoned technician or a novice exploring the fundamentals, understanding the configuration of these mechanical pieces is vital. It serves as a gateway to delving into the technical nuances that can elevate your expertise in engine repair and enhancement.

Understanding Mercury 115 Elpto Parts

Exploring the components of a specific marine engine can greatly enhance maintenance and performance. Each element plays a vital role in ensuring smooth operation, contributing to the overall efficiency of the vessel. Familiarity with these elements can aid in troubleshooting and optimizing functionality.

Key Components

- Powerhead

- Lower unit

- Fuel system

- Ignition system

- Steering mechanism

Maintenance Tips

- Regularly inspect and replace worn components.

- Ensure proper lubrication to prevent damage.

- Check fuel quality to maintain performance.

- Keep electrical connections clean and secure.

Overview of Mercury 115 Elpto Model

This section provides a comprehensive examination of a specific outboard motor variant, emphasizing its features, functionality, and applications. The design is tailored to meet the needs of both recreational and professional users, showcasing innovation and reliability in marine propulsion.

The model is characterized by its robust construction and efficient performance, making it a preferred choice for boat enthusiasts. It integrates advanced technology to enhance fuel efficiency and reduce emissions, ensuring an environmentally friendly operation.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke engine designed for optimal power output. |

| Fuel System | Innovative fuel injection system for improved efficiency. |

| Power Rating | Capable of delivering substantial horsepower for various vessels. |

| Weight | Lightweight design facilitates easy handling and installation. |

| Applications | Suitable for both recreational boating and professional use. |

Overall, this model exemplifies the blend of power and practicality, making it an ideal option for a wide range of maritime activities.

Importance of Parts Diagrams

Understanding the structure and components of any mechanical system is crucial for effective maintenance and repair. Visual representations offer a clear insight into the relationships and functions of each element, enabling users to troubleshoot issues more efficiently. This clarity fosters confidence and enhances overall performance.

Enhancing Efficiency

Having a visual guide simplifies complex assemblies, allowing technicians to identify and locate each piece swiftly. This efficiency minimizes downtime, ensuring that operations run smoothly and effectively.

Facilitating Communication

Visual aids also serve as a common language among team members, promoting better collaboration. When everyone can reference the same illustration, discussions become more focused and productive, leading to quicker resolutions.

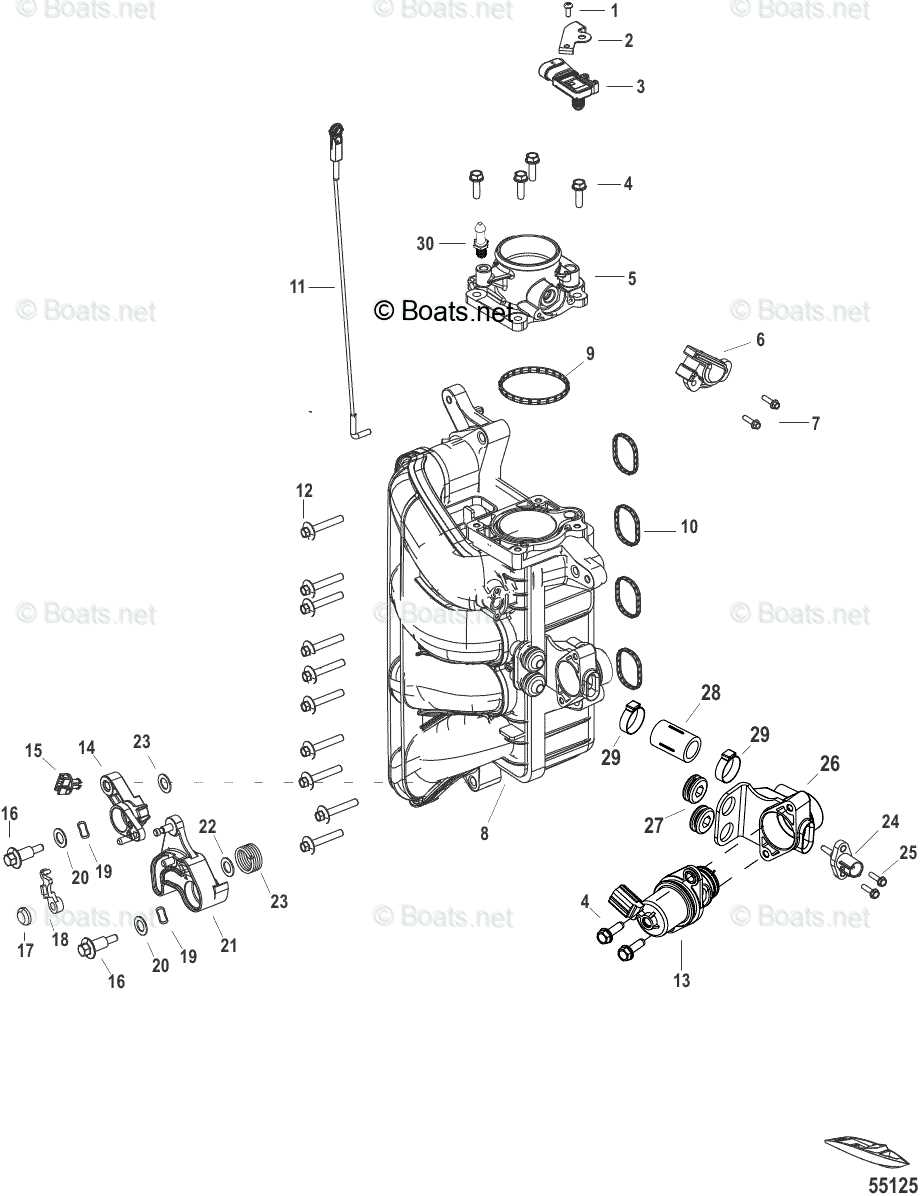

Key Components of the Engine

Understanding the essential elements of an outboard motor is crucial for effective maintenance and optimal performance. Each part plays a significant role in ensuring the smooth operation of the overall system.

Major Elements

- Cylinder Block

- Piston Assembly

- Crankshaft

- Fuel Delivery System

- Ignition System

Supporting Structures

- Cooling System

- Lubrication System

- Exhaust System

- Power Head

Each of these components contributes to the ultimate functionality and longevity of the engine, highlighting the importance of regular inspection and upkeep.

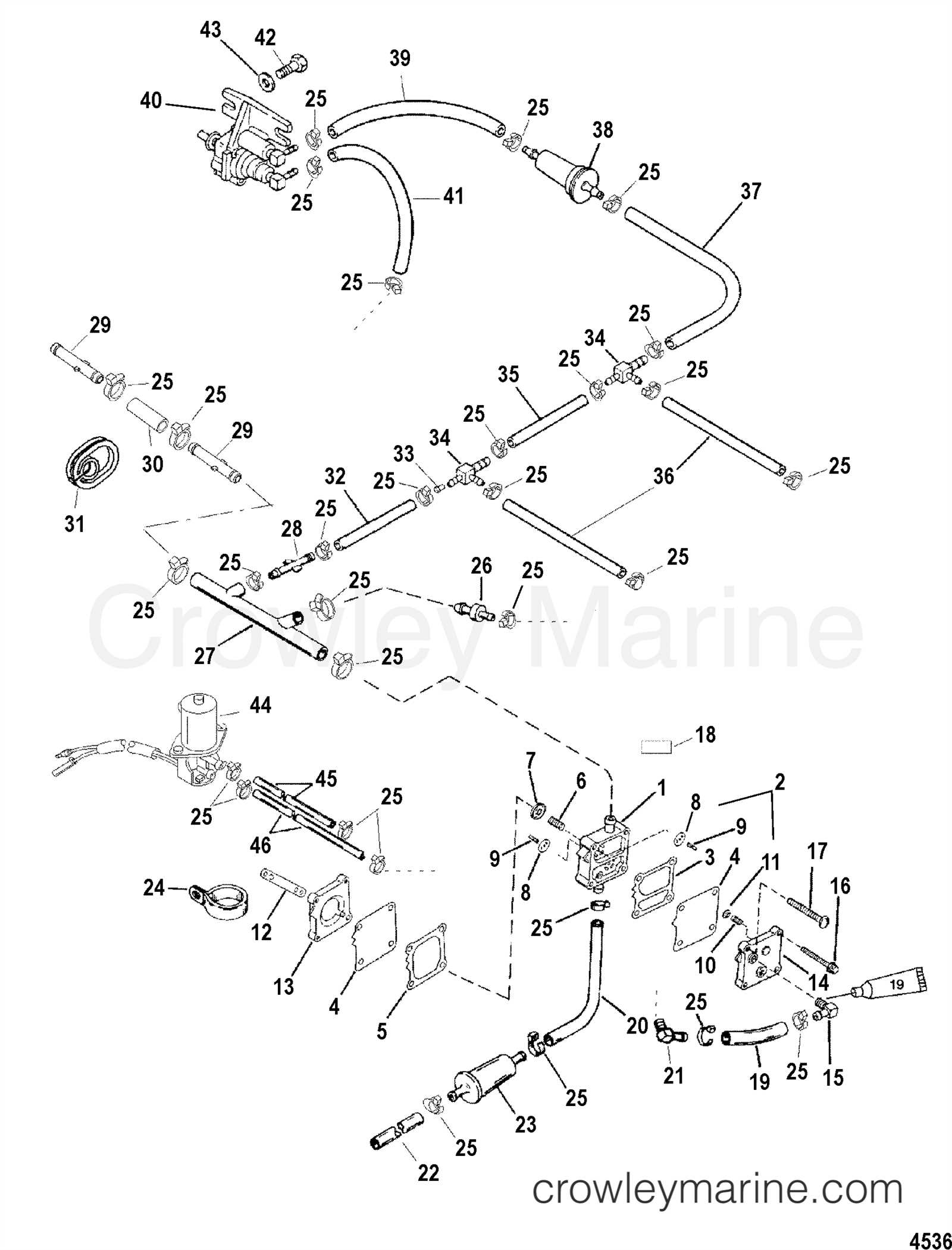

How to Read Parts Diagrams

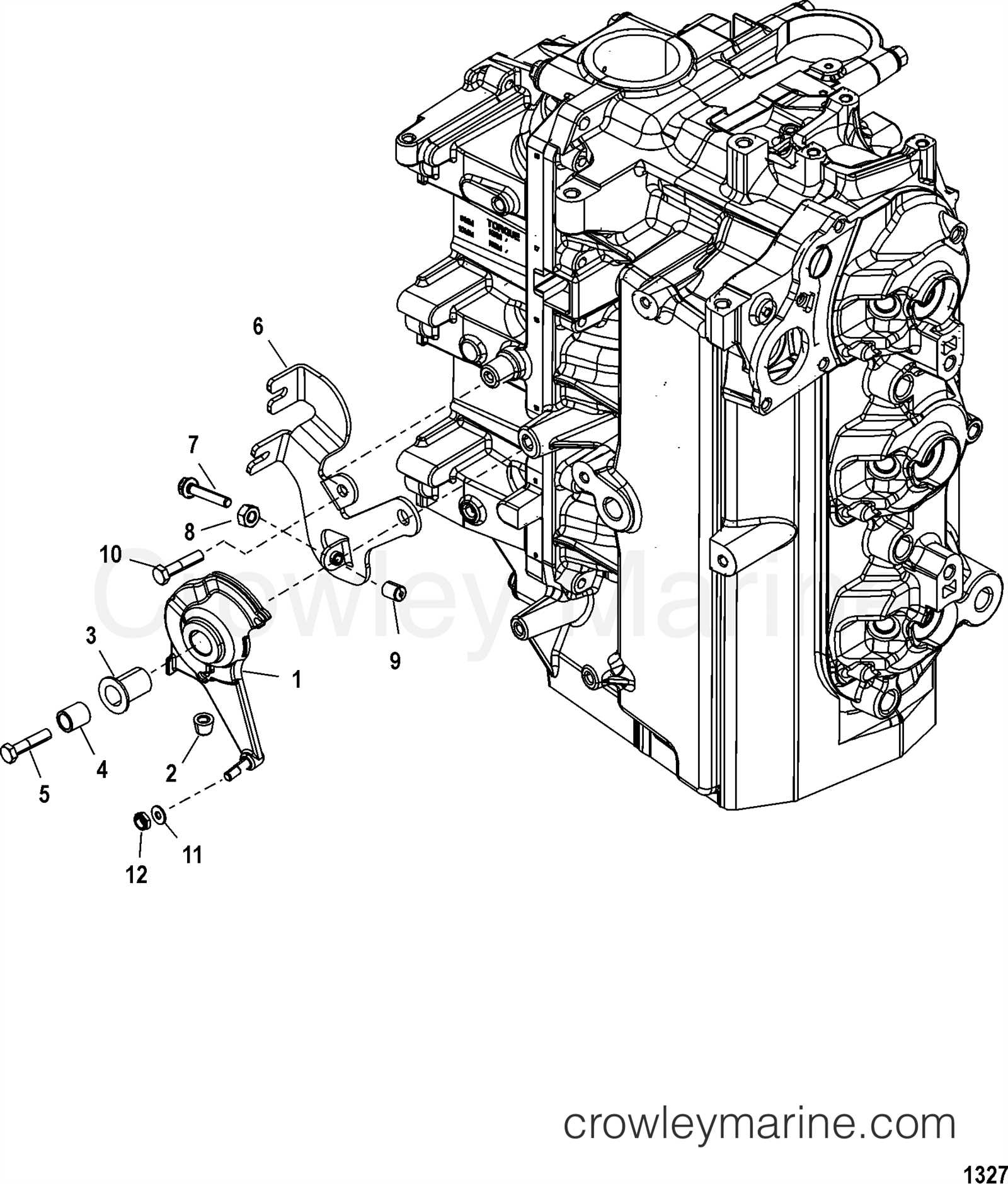

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual guides provide a clear layout of various elements, helping users identify and locate specific items quickly.

Start by familiarizing yourself with the symbols and notations used in the illustration. Each symbol typically represents a different part, and knowing these can significantly ease the process of interpretation.

Next, pay attention to the numbering system often included, as it correlates with a list or key that offers detailed descriptions. This relationship ensures that you can match visual elements with their corresponding information efficiently.

Lastly, practice by cross-referencing the image with actual components. This hands-on approach not only reinforces your understanding but also enhances your ability to navigate similar illustrations in the future.

Common Issues and Solutions

When operating small watercraft engines, users often encounter various challenges that can affect performance and reliability. Understanding these common problems and their respective solutions can enhance the overall experience and prolong the lifespan of the equipment.

Frequent Problems

| Issue | Description | Solution |

|---|---|---|

| Starting Difficulties | The engine fails to start or cranks slowly. | Check the battery charge, inspect the ignition system, and ensure fuel is reaching the carburetor. |

| Overheating | Engine temperature rises excessively during operation. | Inspect the cooling system for blockages, verify water intake, and ensure the thermostat is functioning correctly. |

| Fuel Leaks | Presence of fuel on the ground or around the engine. | Examine fuel lines and connections for cracks or loose fittings; replace damaged parts. |

Maintenance Tips

Regular maintenance can prevent many of these issues from occurring. It is advisable to perform routine inspections, replace filters, and service the engine as recommended by the manufacturer. Keeping a log of maintenance activities can help identify patterns and prevent future complications.

Maintenance Tips for Longevity

Ensuring the enduring performance of your marine machinery requires regular upkeep and attention. By following a few essential practices, you can significantly enhance its lifespan and efficiency, preventing costly repairs and ensuring reliable operation.

Regular Inspections

Conduct frequent checks on key components to identify wear and tear early. Regular inspections help in spotting issues before they escalate, ensuring that everything functions smoothly.

Proper Storage

When not in use, store your equipment in a dry, protected area. This helps prevent rust and corrosion, ultimately preserving its condition and reliability.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Filter Replacement | Every 100 hours |

| Visual Inspection | Monthly |

| Battery Check | Every season |

Replacement Parts: Where to Find Them

When it comes to restoring your aquatic vessel’s performance, sourcing the right components is crucial. Whether you’re looking for essential elements or accessories, knowing where to locate these items can streamline the process and ensure smooth sailing.

Authorized Dealers

One of the most reliable avenues is through certified vendors. They typically offer authentic items that meet quality standards, providing peace of mind for enthusiasts.

Online Marketplaces

The internet is a treasure trove for those seeking components. Websites dedicated to marine supplies often feature a wide selection, allowing you to compare prices and find the best deals. Just ensure that the seller has positive reviews to avoid potential issues.

In conclusion, exploring both physical stores and digital platforms will ultimately enhance your chances of securing the necessary elements for your vessel.

Comparing Different Engine Models

In the realm of marine propulsion, understanding the nuances between various engine designs is crucial for optimal performance and efficiency. Each model presents distinct characteristics, catering to diverse needs and preferences. By examining these differences, one can make informed decisions that enhance their boating experience.

Key Factors to Consider

- Power Output: Varies significantly across models, impacting speed and load capacity.

- Fuel Efficiency: Different designs utilize fuel in unique ways, affecting overall cost.

- Weight: Heavier engines may provide stability but can reduce speed and maneuverability.

- Maintenance: Some models require more frequent servicing, influencing long-term ownership costs.

Popular Engine Types

- Two-Stroke: Known for their lightweight and high power-to-weight ratio.

- Four-Stroke: Offers better fuel economy and lower emissions.

- Diesel: Renowned for durability and efficiency over long distances.

By delving into these factors, users can better align their choice with their boating style and requirements, ultimately enhancing their maritime adventures.

DIY Repairs: Tools Required

When embarking on repair projects, having the right equipment is crucial for achieving success and efficiency. Proper tools not only simplify the process but also enhance the quality of the final outcome. Below is a guide to essential implements that can aid in various tasks.

Essential Tools

- Screwdrivers (flathead and Phillips)

- Wrenches (adjustable and socket)

- Pliers (needle-nose and regular)

- Utility knife

- Measuring tape

Specialized Equipment

- Torque wrench

- Multimeter

- Heat gun

- Flashlight or work light

- Safety goggles and gloves

Expert Recommendations for Performance

To enhance the efficiency and overall functionality of your marine engine, several expert insights can be instrumental. These suggestions focus on optimizing various components and ensuring seamless operation.

Regular Maintenance: Routine check-ups and servicing are crucial. Regularly inspect essential systems to identify wear and tear before they lead to significant issues.

Quality Fuel: Utilize high-grade fuel to ensure maximum combustion efficiency. Poor-quality fuel can hinder performance and lead to engine complications.

Cooling System Efficiency: Maintain optimal cooling conditions to prevent overheating. Clean the cooling passages and ensure the thermostat is functioning properly.

Upgrade Components: Consider upgrading certain elements, such as propellers and ignition systems, to enhance thrust and acceleration. Delve into options that provide the ultimate boost to performance.

Professional Inspections: Engage professionals for thorough evaluations, especially if unusual noises or performance dips occur. Their expertise can pinpoint issues that may go unnoticed.