Comprehensive Guide to Mercury 25 HP Parts Diagram

In the realm of small engines, comprehending the various elements that contribute to their operation is essential for maintenance and repair. This section delves into the intricate relationships between the numerous components that work in harmony to ensure optimal performance. By familiarizing yourself with these essential parts, you can enhance your understanding and troubleshooting skills, ultimately prolonging the lifespan of your engine.

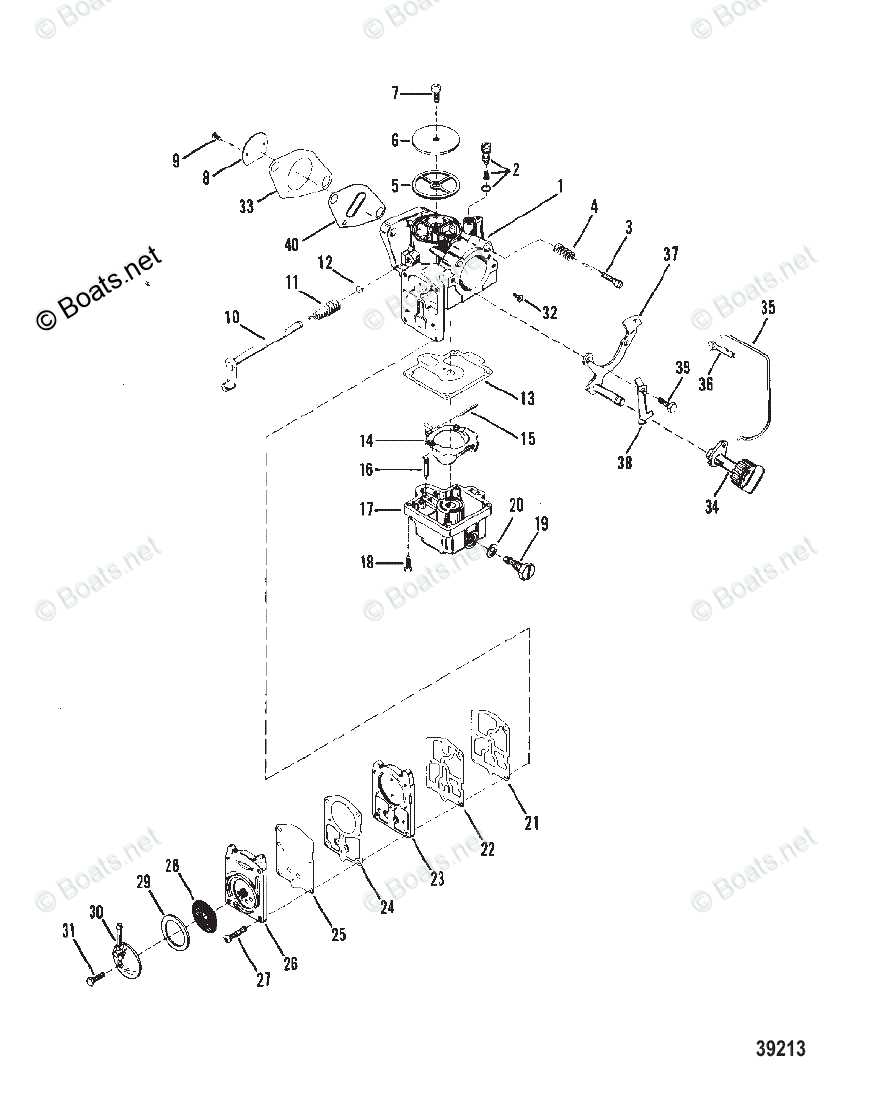

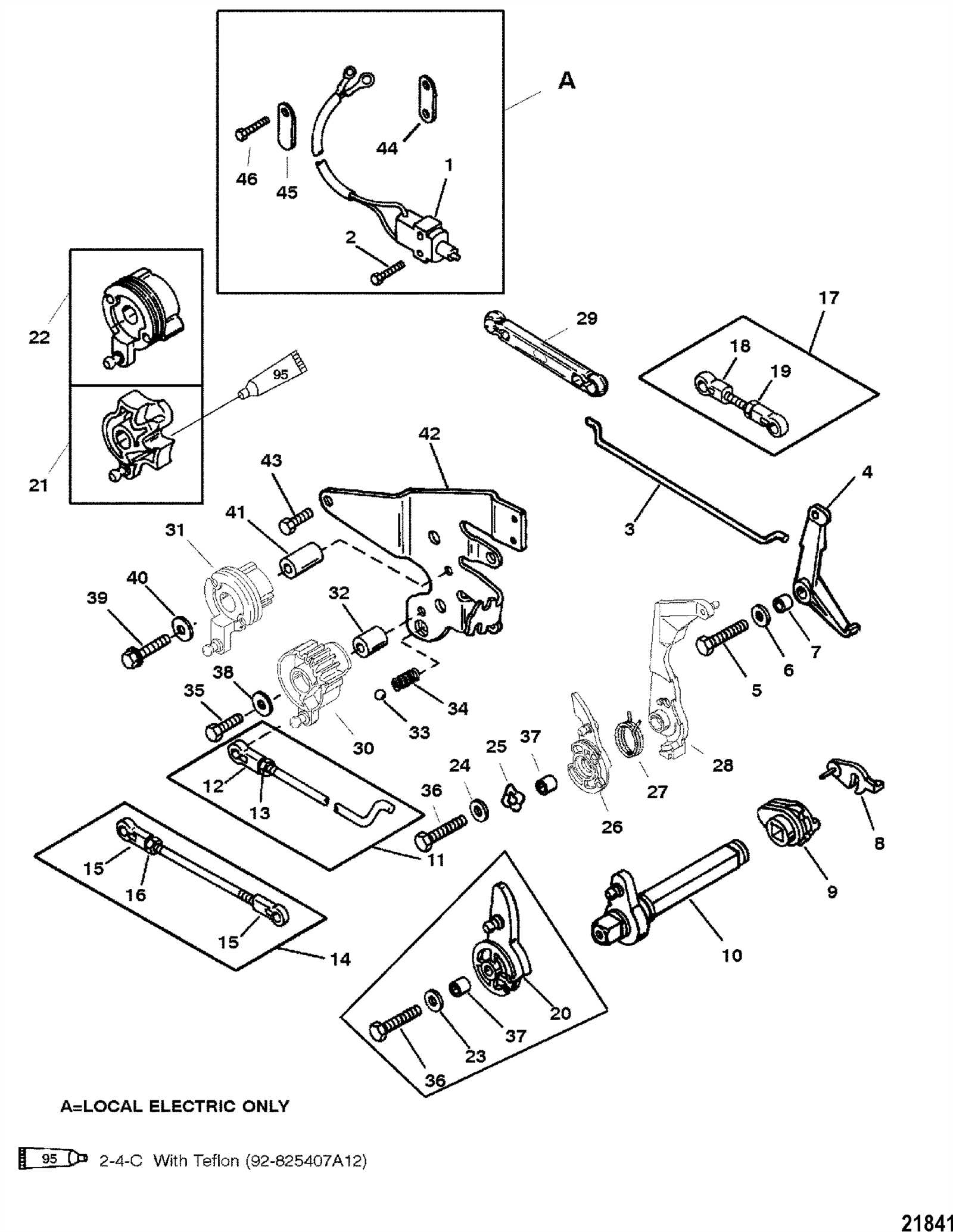

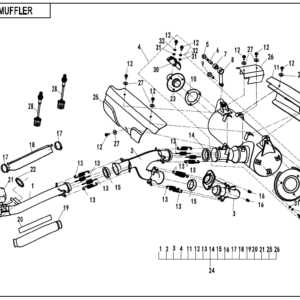

For those engaged in the upkeep or restoration of a 25 horsepower engine, visual aids can prove invaluable. Detailed illustrations that showcase the layout and functionality of each component provide insights into how they interconnect and operate. This knowledge empowers users to diagnose issues more effectively and to conduct repairs with greater confidence.

Whether you are a seasoned technician or a hobbyist, exploring the arrangement and roles of the various elements within this engine type is crucial. Gaining a clear view of these components not only aids in efficient repairs but also fosters a deeper appreciation for the engineering behind these powerful machines. With the right resources at your disposal, maintaining and optimizing your engine can become a straightforward task.

Understanding Mercury 25 HP Parts

This section aims to provide a comprehensive overview of the various components that make up a 25 horsepower outboard engine. Understanding these elements is crucial for both maintenance and repair, ensuring optimal performance and longevity. Each element plays a significant role in the overall functionality, contributing to the efficiency and reliability of the engine.

Key Components and Their Functions

The following table highlights essential components commonly found in a 25 HP engine and their primary functions:

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and facilitates combustion. |

| Piston | Moves up and down within the cylinder, compressing fuel-air mixture. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Fuel Pump | Delivers fuel from the tank to the engine for combustion. |

| Ignition System | Creates a spark to ignite the fuel-air mixture for combustion. |

Maintenance Tips

Regular upkeep is essential for ensuring the efficient operation of a 25 HP outboard engine. Here are some tips to keep in mind:

- Check and change the oil regularly to prevent engine wear.

- Inspect the fuel system for leaks and blockages.

- Clean the cooling system to avoid overheating.

- Examine the ignition system for reliable starting.

Importance of Parts Diagrams

Visual representations of components play a crucial role in various industries, providing clear guidance for assembly, maintenance, and repair tasks. By offering a detailed view of individual elements and their relationships, these illustrations serve as essential tools for technicians and enthusiasts alike, facilitating efficient workflows and minimizing errors.

Enhanced Understanding

One of the primary advantages of such representations is their ability to enhance comprehension. Users can quickly identify and locate specific components, enabling them to understand how each piece fits into the overall structure. This clarity reduces the likelihood of mistakes during assembly or servicing, as individuals can reference the visual guide to ensure accuracy.

Streamlined Maintenance

Another significant benefit lies in the efficiency it brings to maintenance procedures. When dealing with intricate systems, having a visual guide simplifies troubleshooting processes. Technicians can easily pinpoint potential issues and access the required components for repairs, ultimately saving time and effort. This streamlined approach contributes to improved productivity and overall operational effectiveness.

Key Components of the Engine

Understanding the essential elements of a motor is crucial for both maintenance and performance optimization. Each component plays a vital role in the overall functionality, contributing to the efficiency and reliability of the machine.

Cylinder Block: The foundation of the engine, it houses the cylinders where combustion occurs. This component must withstand extreme temperatures and pressures while maintaining structural integrity.

Piston: Moving within the cylinder, the piston converts the energy from fuel combustion into mechanical motion. Its design influences the engine’s power output and efficiency.

Crankshaft: This rotating shaft translates the linear motion of the pistons into rotational force, ultimately powering the propeller or other attachments. It is a critical element for the engine’s operation.

Valvetrain: Comprising various components such as valves, springs, and camshafts, the valvetrain controls the intake of air and fuel and the expulsion of exhaust gases. Proper timing is essential for optimal performance.

Fuel System: This system delivers the appropriate mixture of fuel and air to the combustion chamber, ensuring efficient ignition and power generation. Its components include fuel injectors, filters, and pumps.

Cooling System: To prevent overheating, this system circulates coolant through the engine, absorbing excess heat. Key elements include the radiator, water pump, and thermostat, which work together to maintain optimal temperatures.

Electrical System: Providing the necessary power for ignition and other electronic functions, this system includes the battery, alternator, and wiring. A well-functioning electrical system is vital for reliable engine start-up and operation.

Locating OEM Replacement Parts

Finding original equipment manufacturer components is essential for maintaining the performance and longevity of your marine engine. These authentic items ensure compatibility and reliability, which is critical for optimal operation. Whether you’re addressing a minor repair or a significant overhaul, sourcing these components effectively can save time and enhance the overall efficiency of your vessel.

Start by consulting your engine’s manual for a list of necessary items and specifications. This document typically includes part numbers and descriptions, providing a solid foundation for your search. Additionally, many online platforms offer extensive catalogs of original items, often searchable by model and year, making it easier to pinpoint the exact component you need.

Local dealers and authorized service centers are invaluable resources for acquiring genuine components. These establishments often maintain a stock of frequently requested items and can place special orders for less common ones. Moreover, their staff can provide expert advice on compatibility and installation, further ensuring the success of your repair.

Participating in online forums and communities dedicated to marine engines can also yield helpful insights. Fellow enthusiasts often share their experiences with sourcing components, recommend reputable suppliers, and may even offer alternatives when certain items are difficult to obtain.

Lastly, consider checking for warranties or return policies when purchasing. This practice ensures you receive quality items and provides peace of mind in case the components do not meet your expectations or requirements.

Reading the Parts Diagram

Understanding the visual representation of components is crucial for anyone looking to perform maintenance or repairs on their equipment. These illustrations serve as a roadmap, guiding users through the various elements involved and highlighting their relationships. A thorough grasp of this visual guide enhances the ability to identify individual sections and facilitates the replacement or adjustment of necessary items.

First and foremost, familiarize yourself with the layout. Each section typically features labeled numbers or letters, corresponding to specific components. These identifiers allow for quick reference, making it easier to locate the required items without confusion.

Additionally, pay close attention to the accompanying legend or key, which provides essential details about each labeled element. This reference is vital for understanding the function and compatibility of each component, ensuring that you select the right parts for your tasks.

Lastly, take note of any annotations or supplementary notes included in the illustration. These notations often contain valuable insights regarding assembly, disassembly, or potential issues to watch for, empowering users to tackle projects with greater confidence and efficiency.

Common Issues with Mercury Outboards

Outboard motors, known for their reliability and performance, can occasionally encounter various challenges that may hinder their operation. Understanding these common problems can help boaters maintain their equipment more effectively and ensure a smoother experience on the water.

Frequent Problems

One of the most prevalent issues faced by users involves fuel-related complications. Contaminated fuel can lead to poor engine performance and may even cause complete shutdowns. Another common challenge is electrical system failures, often manifested through issues with ignition or battery connections. Overheating engines, due to blockages in the cooling system, can also pose significant threats to the longevity of the motor.

Maintenance Tips

Regular maintenance is crucial in preventing these issues. Routine checks of the fuel system, electrical connections, and cooling components can help identify potential problems before they escalate. Additionally, following the manufacturer’s guidelines for servicing can enhance the durability and efficiency of the motor.

| Issue | Symptoms | Solutions |

|---|---|---|

| Fuel Contamination | Poor acceleration, stalling | Replace fuel, clean filters |

| Electrical Failures | Engine won’t start, misfiring | Check connections, replace battery |

| Overheating | Engine warning lights, steam | Inspect cooling system, clear blockages |

How to Order Mercury Parts

Acquiring components for your outboard motor can be a straightforward process when you follow a systematic approach. Knowing where to source the required items and understanding the specifics of your engine model will ensure you receive the correct items efficiently.

First, identify the exact specifications of the engine you own. This includes noting the model and serial number, as these details are crucial for matching the correct items to your motor. Having this information at hand can greatly speed up the ordering process.

Next, explore reputable suppliers that specialize in marine equipment. Many vendors offer comprehensive catalogs that include a variety of items for different models. Utilize these resources to find the specific components you need. Make sure to read customer reviews and verify the credibility of the seller to ensure a reliable purchase.

When placing an order, it’s advisable to use an online platform that provides a user-friendly interface. Most websites have a search function where you can input your engine’s details, allowing you to easily locate the necessary components. Additionally, check if the supplier offers assistance via customer support to address any questions or concerns you might have.

Finally, once you’ve selected the required items, proceed to checkout. Review your order to confirm that everything is accurate before completing the purchase. Keep an eye out for any promotional offers or discounts that may be available, as this can help reduce costs.

In summary, gathering the right information, choosing a reliable supplier, and carefully reviewing your order will facilitate a smooth procurement experience for your motor’s components.

Maintenance Tips for Longevity

Ensuring the enduring performance of your marine engine involves a combination of regular care and proactive measures. By adhering to essential maintenance practices, you can enhance the durability and reliability of your vessel’s power system. This section provides valuable insights into effective upkeep strategies that will keep your engine running smoothly for years to come.

Regular Inspections

Routine examinations are crucial for identifying potential issues before they escalate into significant problems. Check essential components, including fuel lines, electrical connections, and the cooling system. Pay close attention to signs of wear and tear, such as leaks or corrosion. Early detection allows for timely repairs, preventing costly breakdowns and extending the life of your engine.

Fluid Management

Maintaining proper fluid levels is vital for optimal performance. Regularly check and change the oil, coolant, and fuel to ensure they meet the manufacturer’s specifications. Using high-quality fluids not only enhances efficiency but also reduces wear on internal parts. Additionally, consider adding fuel stabilizers to prevent degradation and ensure clean combustion.

By implementing these maintenance tips, you can significantly enhance the longevity of your engine, ensuring it remains a reliable companion on the water.

Tools Needed for Repairs

When undertaking maintenance or repairs on marine engines, having the right equipment is essential for achieving optimal results. Proper tools not only streamline the repair process but also enhance safety and efficiency. Below is a list of necessary implements that can aid in effectively addressing various mechanical issues.

1. Wrenches and Sockets: A variety of wrenches, including adjustable and socket types, are crucial for loosening and tightening fasteners. Ensure that you have a complete set to accommodate different sizes.

2. Screwdrivers: Both flathead and Phillips screwdrivers are indispensable for accessing and securing components. A magnetic tip can also be beneficial for handling small screws.

3. Pliers: Needle-nose pliers, along with regular pliers, can assist in gripping, twisting, and cutting wires or hoses that may need adjustment or replacement.

4. Torque Wrench: This tool is vital for applying precise force when securing bolts to specified tension, preventing damage from over-tightening.

5. Multimeter: A digital multimeter is essential for diagnosing electrical issues, allowing you to measure voltage, current, and resistance within the system.

6. Oil Filter Wrench: If your maintenance includes changing oil, an oil filter wrench is necessary to remove and install filters with ease.

7. Cleaning Supplies: Keep brushes, rags, and cleaning solvents handy for maintaining cleanliness and ensuring that components are free of debris before reassembly.

Equipping yourself with these tools will greatly enhance your ability to perform repairs effectively and efficiently, ensuring your engine remains in peak operating condition.

Identifying Parts by Serial Number

Understanding how to accurately recognize components based on their unique identification codes is crucial for effective maintenance and repair. These numerical sequences serve as a key to unlocking detailed information about each item, allowing users to ensure compatibility and functionality. By following a systematic approach, one can easily navigate the complexities of various elements and make informed decisions.

First and foremost, locate the serial code, usually found on the manufacturer’s label or stamped directly onto the item. This code typically contains vital information, such as the production year, model, and specific attributes that differentiate it from similar offerings.

Once the identification number is obtained, it can be cross-referenced with official catalogs or online databases. These resources often provide comprehensive details, including specifications, installation guides, and recommended replacements, streamlining the repair process significantly.

Moreover, keeping a record of these codes can aid in future troubleshooting and maintenance, making it easier to order the right replacements when needed. Developing a habit of documenting these unique identifiers not only enhances efficiency but also ensures the longevity and reliability of the equipment.

Aftermarket vs. OEM Parts

The choice between alternative and original components often influences maintenance decisions and overall performance. Each type of product presents distinct advantages and drawbacks, impacting durability, compatibility, and cost. Understanding these differences helps consumers make informed choices tailored to their needs.

Alternative components are typically produced by third-party manufacturers. They offer a range of benefits, including:

- Cost-effectiveness: These products are usually more affordable than their original counterparts.

- Availability: They are often more readily available in various retail outlets.

- Variety: A wider selection allows users to choose features and specifications that meet their preferences.

However, there are potential drawbacks to consider:

- Quality variance: The quality can differ significantly among manufacturers, leading to inconsistencies.

- Compatibility issues: Some may not fit as well or function optimally, causing performance problems.

- Limited warranties: Often, these components come with shorter or no warranty coverage.

Original components, produced by the manufacturer of the equipment, provide their own set of advantages:

- Quality assurance: Typically, they meet stringent quality standards, ensuring reliability.

- Exact compatibility: These items are designed to fit perfectly and function effectively within the system.

- Comprehensive support: Usually, they come with better warranty options and customer support.

On the other hand, original components may present challenges:

- Higher costs: They often carry a premium price tag compared to alternatives.

- Limited availability: Original items might not be as easy to find, especially for older models.

Ultimately, the choice between alternative and original components depends on individual needs, budget constraints, and the specific requirements of the equipment in question.

Installing New Parts Safely

Ensuring the secure installation of new components is essential for maintaining optimal performance and preventing potential hazards. By adhering to proper procedures, one can enhance the longevity of the equipment while minimizing risks associated with improper handling.

Preparation Before Installation

Before beginning the installation process, it is crucial to gather all necessary tools and materials. Ensure that the workspace is clean and organized to avoid losing small items. Additionally, reviewing the manufacturer’s guidelines will provide valuable insights into the correct assembly methods and precautions to take.

Steps for a Safe Installation

When executing the installation, always wear appropriate safety gear such as gloves and goggles to protect against injuries. Handle each item carefully, ensuring they are free from damage or defects. Follow a step-by-step approach, double-checking each connection and fitting for security. Once the process is complete, conduct a thorough inspection to confirm that everything is correctly placed and functioning as intended. This attention to detail will not only ensure safety but also promote the reliable operation of the equipment.

Resources for Further Information

Accessing reliable information is crucial for understanding the intricacies of your equipment. Various sources can provide valuable insights, guidance, and support to help you maintain and enhance your machinery. Exploring these resources can significantly aid in troubleshooting and optimizing performance.

One excellent option is the online forums and communities dedicated to enthusiasts and professionals alike. These platforms often feature discussions, tips, and shared experiences that can help clarify complex topics. Additionally, many manufacturers offer comprehensive user manuals and maintenance guides on their official websites, providing authoritative information and instructions.

For those looking for visual aids, instructional videos on platforms like YouTube can serve as helpful resources. These videos often demonstrate step-by-step processes, making it easier to grasp specific tasks. Finally, don’t overlook the value of local workshops and seminars, where experts can offer hands-on training and answer any questions you may have.