Complete Guide to Mercury 40 HP Parts Diagram

For anyone who owns a 40 HP outboard engine, having a clear visual representation of its components can significantly enhance maintenance and repair processes. Whether you are a seasoned marine technician or a novice boat owner, familiarity with the intricate layout of the engine can lead to better decision-making and a deeper understanding of its functionality.

Identifying individual elements within the machinery is crucial for troubleshooting issues and conducting routine checks. With a comprehensive overview, you can easily locate essential pieces, ensuring that everything runs smoothly and efficiently. This knowledge not only helps in immediate repairs but also contributes to the longevity of your engine.

In this guide, we will explore a detailed overview of the key components of a 40 HP outboard motor, providing insights that empower you to maintain your equipment with confidence. By delving into the specifics, you will be equipped to tackle various challenges and keep your vessel performing at its best.

Understanding Mercury 40 HP Engine Components

Familiarizing oneself with the various elements that make up a specific outboard motor is essential for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance, reliability, and longevity. A comprehensive understanding of these pieces can aid in troubleshooting, repairs, and enhancements.

Key components of this engine include:

- Powerhead: The heart of the engine, housing the combustion chamber and other critical systems.

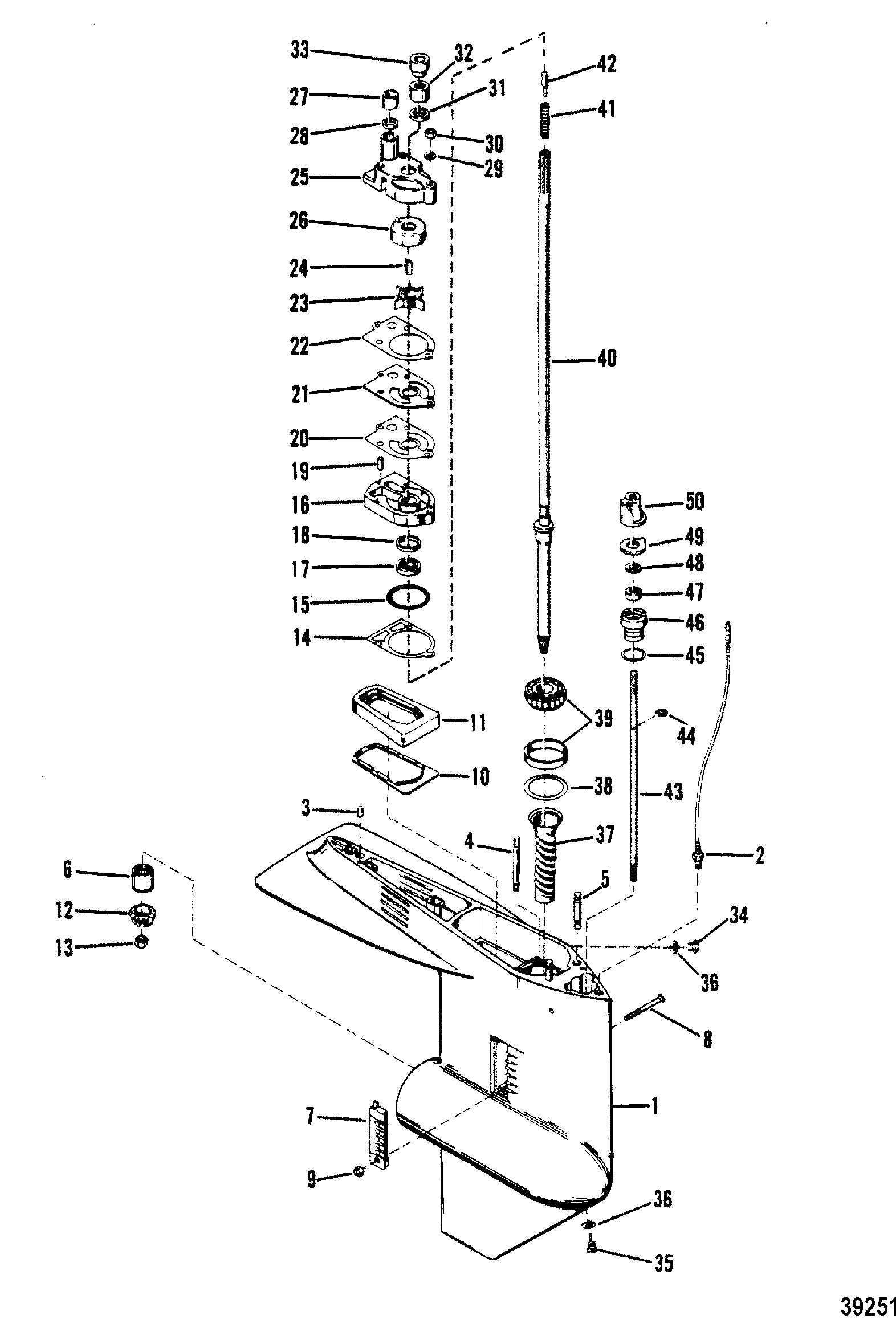

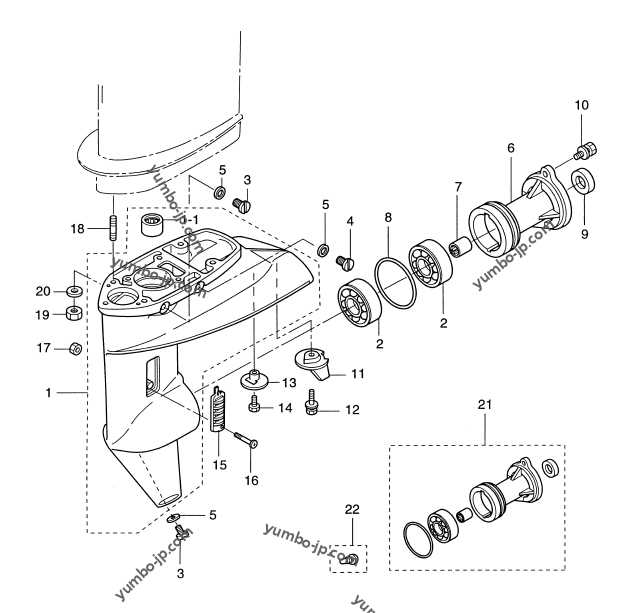

- Lower Unit: This part is responsible for the propulsion and contains the gear system.

- Fuel System: Essential for delivering the necessary fuel to the engine for combustion.

- Cooling System: Ensures that the engine operates at safe temperatures to prevent overheating.

- Electrical System: Powers the ignition and other electrical components vital for operation.

Each of these elements contributes to the overall functionality. Regular inspection and understanding of their roles can lead to improved performance and proactive maintenance strategies.

To dive deeper into the specifics, consider the following components:

- Ignition System: Controls the spark that ignites the fuel-air mixture.

- Carburetor: Mixes air with fuel in the appropriate ratio for combustion.

- Exhaust System: Removes combustion gases from the engine while minimizing noise.

- Propeller: Converts engine power into thrust, propelling the vessel forward.

Understanding these components and their interrelations can significantly enhance one’s capability to maintain and operate the engine effectively, ensuring a smoother and more reliable boating experience.

Importance of Parts Diagrams

Understanding the intricate components of a machine is essential for effective maintenance and repair. Visual representations serve as invaluable tools that guide users through the various elements, ensuring a clearer grasp of how everything fits together. This clarity not only enhances comprehension but also improves the efficiency of troubleshooting and restoration processes.

Facilitating Maintenance

When dealing with complex machinery, having access to visual aids allows technicians and hobbyists alike to identify issues more swiftly. By clearly showcasing the relationships between different components, these resources minimize the likelihood of mistakes during assembly or disassembly. This is particularly crucial when time is of the essence, as it streamlines the repair process.

Enhancing Communication

In collaborative settings, having a common reference point fosters better communication among team members. Whether discussing repairs with colleagues or seeking advice from online forums, being able to refer to visual guides ensures everyone is on the same page. This shared understanding can lead to more effective problem-solving and knowledge sharing.

Key Components of the Mercury 40 HP

The efficient operation of a 40-horsepower outboard motor relies on a variety of essential elements, each playing a crucial role in overall performance. Understanding these components can enhance maintenance practices and improve longevity, ensuring optimal functionality on the water.

Engine Assembly

The heart of the motor is its engine assembly, where the combustion process takes place. This section includes critical elements such as the cylinder block, pistons, and crankshaft. Each part must work harmoniously to generate the power needed for propulsion. Regular inspections can prevent issues that may arise from wear and tear.

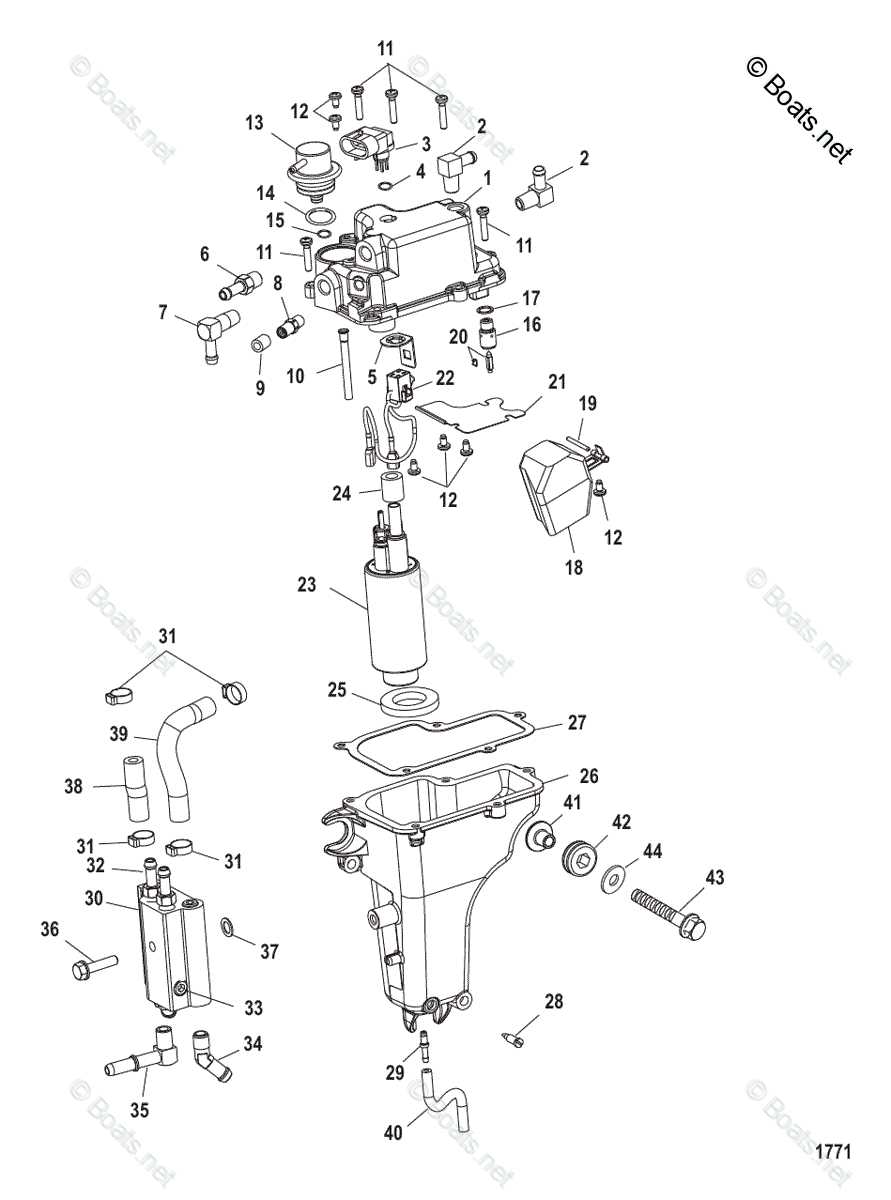

Fuel and Ignition Systems

Equally important are the fuel delivery and ignition systems, which ensure the correct mixture of fuel and air reaches the combustion chamber. Components like the carburetor and spark plugs are vital for maintaining efficiency and performance. Proper tuning of these systems can significantly enhance responsiveness and reduce fuel consumption.

Common Issues with Engine Parts

Engines are complex machines, and various components can encounter difficulties that affect overall performance. Understanding these common challenges can help in maintaining optimal function and prolonging the lifespan of the engine. Regular inspections and timely interventions are essential to mitigate potential problems.

1. Wear and Tear

Over time, components can degrade due to friction, heat, and exposure to various elements. Piston rings and valves are particularly susceptible to wear, leading to decreased efficiency and potential engine failure. Regular checks and replacements can prevent minor issues from escalating.

2. Fuel System Problems

Issues within the fuel delivery system can lead to poor performance and increased emissions. Clogged fuel injectors and dirty filters often result in inadequate fuel flow, causing misfires or rough idling. Maintaining a clean fuel system is vital for optimal engine operation.

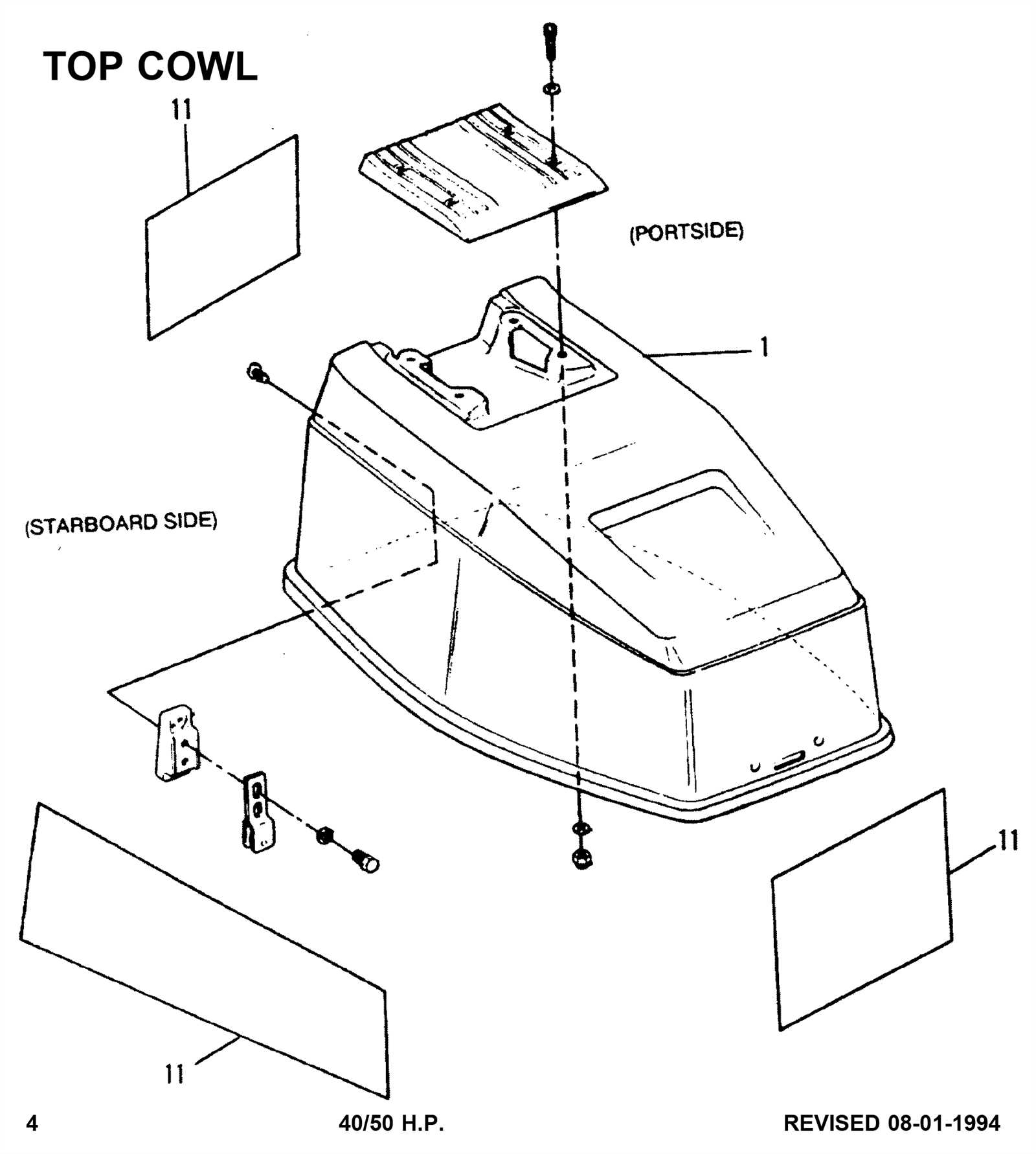

How to Read a Parts Diagram

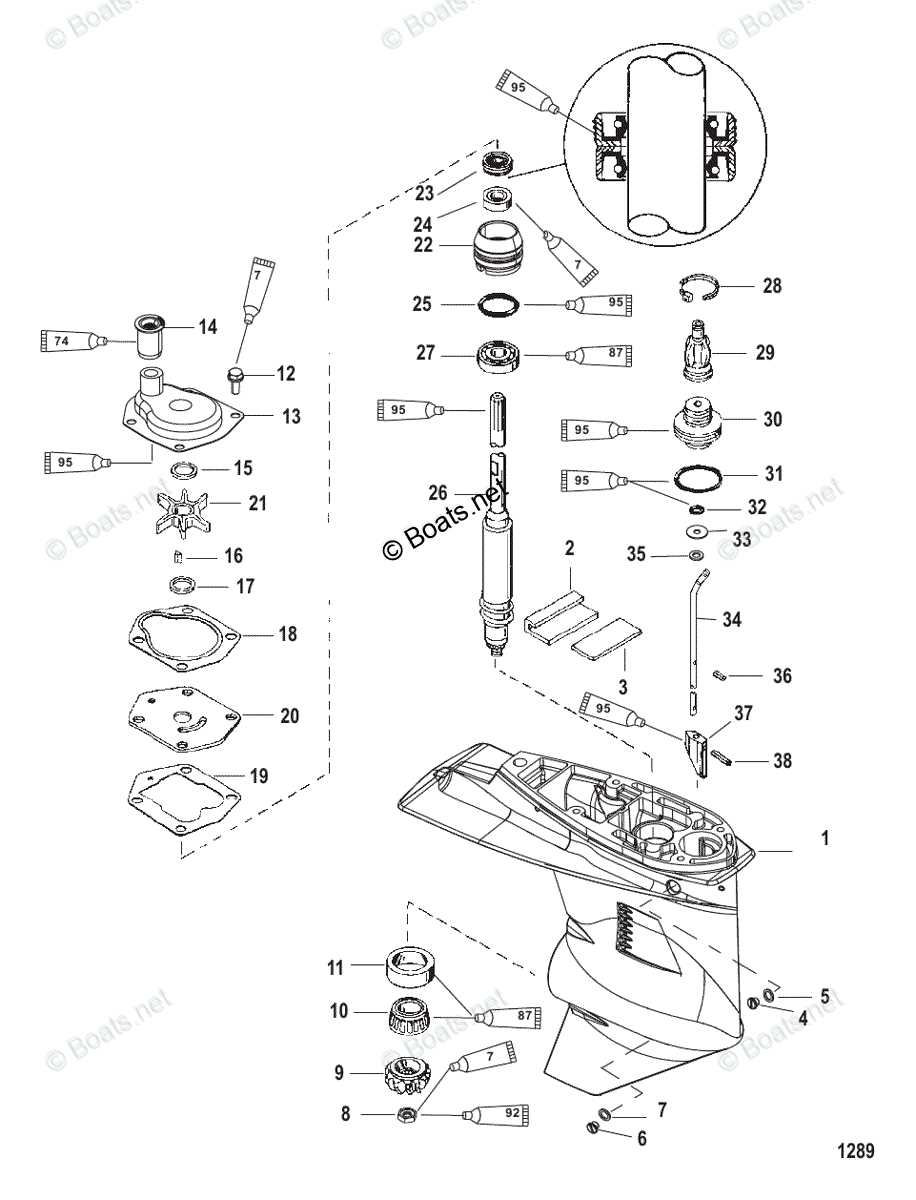

Understanding a visual representation of components can significantly enhance your ability to identify and work with mechanical systems. These illustrations serve as essential guides, providing a clear layout of individual elements and their interconnections. By familiarizing yourself with the symbols and numbering used, you can streamline the process of maintenance and repair.

Familiarize Yourself with the Key

Most illustrations include a legend or key that explains the various symbols used throughout the image. This section is crucial for comprehending what each representation signifies. Pay close attention to any annotations that clarify the function or location of each element, as this information is vital for effective troubleshooting.

Follow the Numbering System

Many visual aids utilize a sequential numbering system to correlate each part with a corresponding list, typically found in the accompanying documentation. This numerical relationship allows you to quickly locate a specific component and understand its role within the larger assembly. Take notes on any parts that seem unfamiliar or require further research, ensuring you grasp their significance.

In summary, by mastering these basic elements, you can enhance your technical proficiency and approach repairs with greater confidence and clarity.

Where to Find Replacement Parts

Locating suitable components for your outboard motor can be a straightforward process with the right approach. Various resources are available that cater to enthusiasts and professionals alike, ensuring that you can maintain optimal performance. Understanding where to look can save you time and ensure you get the best quality for your needs.

Online Retailers

The internet is a treasure trove for those seeking specific components. Numerous e-commerce platforms specialize in marine equipment, offering an extensive selection of items for different makes and models. It is advisable to compare prices and check customer reviews to ensure reliability before making a purchase.

Local Marine Shops

Your local boating supply stores can be invaluable resources. Many have knowledgeable staff who can assist you in finding the correct components. Additionally, these shops often carry essential items and can order specific pieces if they are not in stock, providing a convenient option for immediate needs.

Maintenance Tips for Mercury 40 HP

Regular upkeep is essential for ensuring optimal performance and longevity of your outboard engine. Following a systematic maintenance routine can help identify potential issues before they escalate, allowing for a smoother and more enjoyable boating experience. By investing time in care, you can enhance reliability and efficiency, ensuring that your watercraft is always ready for the next adventure.

Routine Checks

Start with frequent inspections of the fuel and oil systems. Check for any leaks or signs of wear that may indicate the need for replacement. Additionally, monitor the battery’s condition and connections to prevent starting issues. It’s important to clean or replace the air filter regularly to ensure proper airflow and engine performance.

Seasonal Maintenance

At the beginning and end of the boating season, perform a thorough inspection. Change the oil and replace the oil filter to maintain engine health. Inspect the propeller for damage, as a faulty prop can affect performance. Don’t forget to flush the cooling system with fresh water after each use, especially if you frequently operate in saltwater conditions.

Identifying Original vs. Aftermarket Parts

Understanding the differences between genuine components and their alternatives is crucial for ensuring optimal performance and longevity of your machinery. This section aims to clarify how to distinguish these options, highlighting key factors that can affect quality, reliability, and compatibility.

Key Differences

When evaluating components, consider the following aspects:

| Feature | Original Components | Aftermarket Alternatives |

|---|---|---|

| Quality Control | Manufactured under strict guidelines | Varies widely; not always held to the same standards |

| Warranty | Typically comes with a manufacturer warranty | Warranty conditions can differ; often limited |

| Fit and Compatibility | Designed for precise fit with specific models | May not fit perfectly; compatibility can be uncertain |

| Price | Generally higher cost | Often more affordable; may appeal to budget-conscious users |

Making the Right Choice

When selecting between genuine and alternative components, consider your specific needs and usage conditions. Investing in high-quality originals can save you from potential issues, while reliable alternatives may offer a cost-effective solution if researched thoroughly.

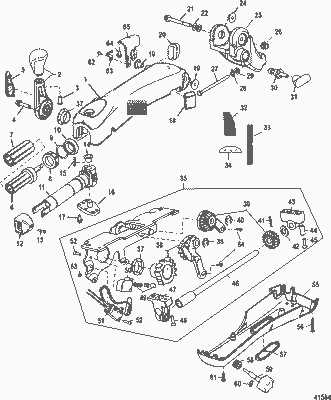

Assembly Process of Mercury 40 HP

The assembly of a 40 HP outboard engine involves several critical steps that ensure optimal performance and reliability. Each component must be carefully handled and correctly installed to guarantee seamless operation and longevity.

-

Preparation:

- Gather all necessary components and tools.

- Clean the work area to prevent contamination.

- Review the assembly manual for specific instructions.

-

Assembly of the Powerhead:

- Begin with the crankcase, ensuring proper sealing.

- Install the pistons, connecting rods, and crankshaft.

- Attach the cylinder heads and torque them to specifications.

-

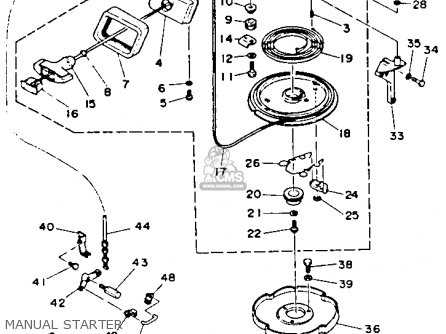

Fuel and Ignition System Setup:

- Install the carburetor, ensuring a secure fit.

- Connect fuel lines and check for leaks.

- Set up the ignition system, including coils and spark plugs.

-

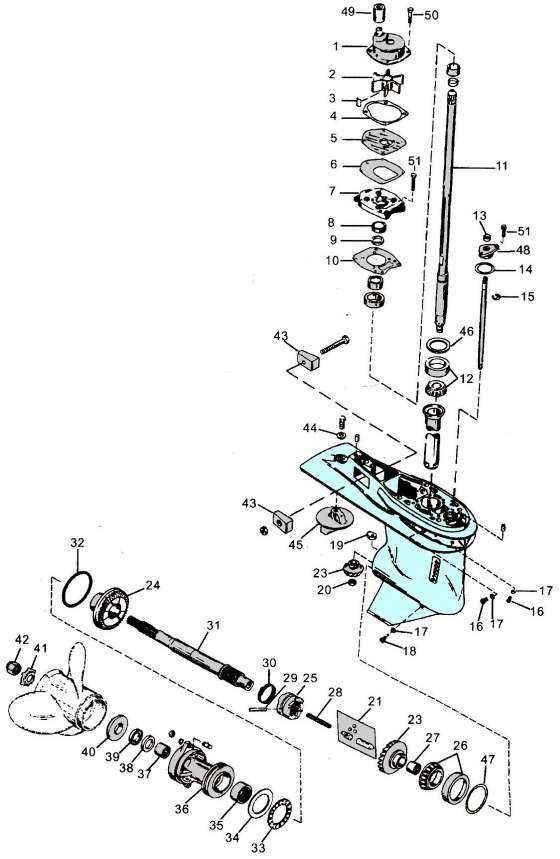

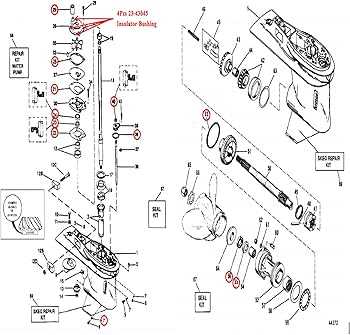

Lower Unit Assembly:

- Attach the drive shaft and gear housing.

- Seal and lubricate moving parts appropriately.

- Install the propeller and check for proper alignment.

-

Final Checks:

- Verify all connections and fasteners are tight.

- Perform a comprehensive inspection of the entire unit.

- Test the engine on a stand or in a controlled environment.

Following these steps carefully will lead to a successful assembly, ensuring the engine operates efficiently and effectively. Proper attention to detail during the process is crucial for achieving optimal performance and reliability.

Tools Needed for Parts Replacement

When undertaking the task of replacing components in a small engine, having the right tools is crucial for a successful outcome. Utilizing the appropriate equipment not only facilitates the process but also ensures that each piece is handled safely and effectively. A well-equipped workspace can significantly reduce the time and effort required, making the job much more manageable.

Essential tools typically include wrenches and sockets for loosening and tightening fasteners, screwdrivers for handling various screws, and pliers for gripping or manipulating small components. Additionally, a torque wrench is vital to ensure that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

Other useful items may include a multimeter for electrical diagnostics, a gasket scraper for removing old seals, and a cleaning solution for maintaining a clean working environment. Having a well-organized toolset will help streamline the replacement process and minimize the risk of misplacing vital components.

Safety Precautions During Repairs

When undertaking maintenance or repairs on any mechanical equipment, it is crucial to prioritize safety. Proper precautions not only protect the individual performing the work but also ensure that the equipment functions correctly once reassembled. Understanding the risks involved and taking the necessary steps to mitigate them is essential for a successful repair process.

Firstly, always wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and sturdy footwear to shield against potential hazards such as sharp edges or chemical exposure. Additionally, consider using hearing protection if working in a noisy environment.

Secondly, ensure the workspace is organized and well-lit. A clutter-free area minimizes the chances of accidents and allows for greater focus on the task at hand. Moreover, keeping tools and materials within reach helps avoid unnecessary movements that could lead to mishaps.

Finally, familiarize yourself with the equipment before starting any work. Understanding its components and operation can prevent mistakes that might lead to injury or equipment damage. If uncertain about any aspect of the repair, consulting manuals or seeking professional assistance is advisable.

Resources for Mercury Engine Owners

For enthusiasts and operators of specific outboard motors, having access to comprehensive resources can significantly enhance the ownership experience. Whether you’re in need of maintenance guidance, troubleshooting assistance, or upgrades, knowing where to find the right information is essential.

Online Communities

Engaging with fellow owners can provide invaluable support. Consider exploring:

- Dedicated forums and discussion boards

- Social media groups focused on boating and engine maintenance

- Online marketplaces for second-hand equipment

Technical Documentation

Accessing manuals and service documents is crucial for effective management. Here are some useful sources:

- Manufacturer’s official website for downloadable manuals

- Third-party websites that offer repair guides

- Video tutorials on popular platforms to visualize maintenance tasks

Utilizing these resources can empower owners to maintain their engines efficiently and ensure a smooth boating experience.