Comprehensive Guide to Mercury Alpha One Parts Diagram

Exploring the intricate assembly of a watercraft’s propulsion system reveals a fascinating world of mechanical synergy. Each element plays a vital role in ensuring optimal performance and reliability on the water. By examining these essential components, enthusiasts and technicians alike can deepen their understanding of how these systems operate and interact.

In this section, we will delve into the various segments that constitute the drive mechanism, highlighting their functions and interrelationships. From the core engine unit to auxiliary components, each part contributes to the overall efficiency and effectiveness of the vessel’s movement. Whether you’re a seasoned professional or a curious novice, grasping these details can enhance your appreciation of marine engineering.

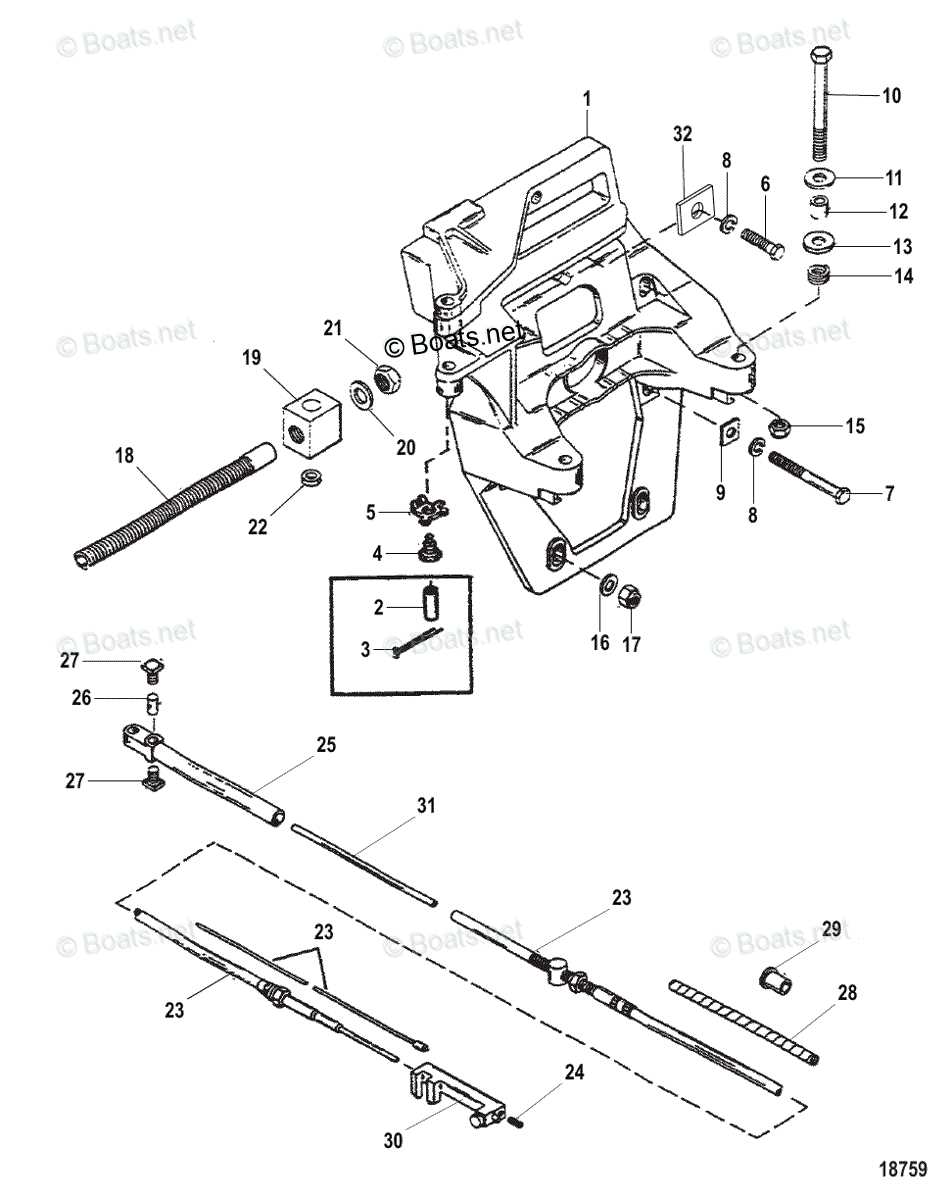

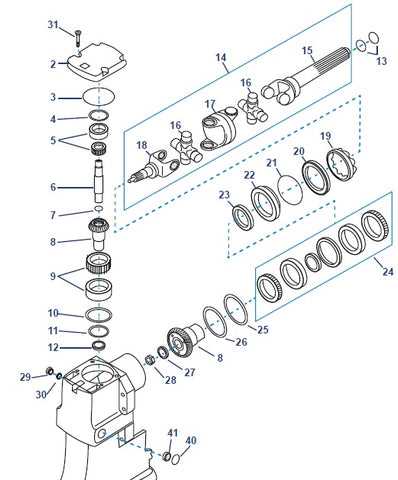

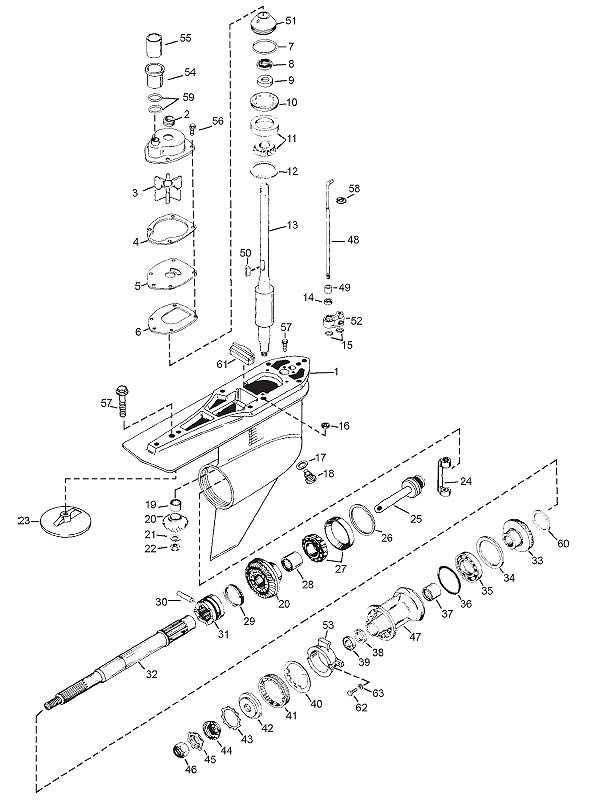

Furthermore, visual aids can significantly aid in the comprehension of these assemblies. Detailed illustrations provide clarity on how each piece fits into the larger picture, facilitating a better grasp of both assembly and maintenance processes. Understanding these relationships is essential for anyone involved in the upkeep or enhancement of watercraft systems.

Understanding Mercury Alpha One Components

Grasping the intricacies of marine propulsion systems involves familiarizing oneself with various essential elements that ensure optimal performance and reliability. Each component plays a vital role in the overall functionality, contributing to the efficiency of watercraft operation. A comprehensive understanding of these parts aids in proper maintenance and enhances the longevity of the system.

Key Elements of the System

Among the critical components, the drive unit stands out, functioning as the primary interface between the engine and the propeller. Additionally, the gear mechanism is crucial, allowing for smooth transitions in power delivery. Each of these parts interacts harmoniously to deliver seamless performance.

Common Components Overview

| Component | Description |

|---|---|

| Drive Unit | The assembly that connects the engine to the propulsion system, responsible for translating engine power into movement. |

| Gear Assembly | Facilitates power transfer from the engine, enabling adjustments in speed and torque. |

| Propeller | Transforms rotational energy into thrust, propelling the vessel forward. |

| Steering Mechanism | Allows for directional control, ensuring maneuverability in various water conditions. |

Overview of Mercury Alpha One System

The system in question serves as a critical component for aquatic propulsion, delivering an efficient means of power transfer and maneuverability. Designed with reliability and performance in mind, it integrates various mechanical and hydraulic elements to ensure optimal functioning in marine environments.

This assembly features a unique configuration that facilitates seamless operation while enhancing the overall user experience. Its robust design not only withstands harsh conditions but also promotes ease of maintenance, making it a preferred choice among boating enthusiasts.

Understanding the intricacies of this system is essential for both owners and technicians, as it allows for informed decision-making regarding repairs and upgrades. Comprehensive knowledge of its structure and function can lead to improved performance and longevity of the vessel.

Key Parts of the Outdrive

The outdrive system plays a crucial role in the overall functionality of a marine vessel, enabling efficient propulsion and steering. Understanding its essential components is vital for maintaining optimal performance and ensuring safety on the water.

Drive Unit

The drive unit serves as the heart of the propulsion system. It houses the gearing mechanism that converts engine power into rotational motion, ultimately driving the propeller. A well-functioning drive unit is essential for smooth acceleration and effective handling.

Propeller

The propeller is a critical element responsible for generating thrust. Its design and pitch directly influence the vessel’s speed and maneuverability. Selecting the appropriate propeller can significantly enhance performance and fuel efficiency, making it an integral consideration for boat owners.

Regular maintenance of these components is crucial for ensuring longevity and reliability. Regular checks can prevent potential issues and enhance the overall experience on the water.

Importance of a Parts Diagram

Understanding the intricacies of any mechanical system is crucial for effective maintenance and repair. A visual representation of components serves as an invaluable tool for both professionals and enthusiasts. This resource not only aids in identification but also facilitates troubleshooting and assembly processes.

Here are several key reasons why such visual guides are essential:

- Clarity: They provide a clear and organized view of the various elements, making it easier to comprehend complex arrangements.

- Efficiency: With a reference at hand, individuals can quickly locate and address issues without unnecessary delays.

- Accuracy: Accurate identification of each part ensures that the correct replacements are used, minimizing the risk of errors.

- Guidance: These visuals serve as a roadmap for disassembly and reassembly, reducing the likelihood of missing steps.

- Training Tool: They are invaluable for training new technicians, allowing them to familiarize themselves with components before hands-on experience.

In summary, a well-crafted visual representation is not just a reference; it is a critical asset for anyone involved in the upkeep and repair of mechanical systems. Its role in enhancing understanding, promoting efficiency, and ensuring accuracy cannot be overstated.

Common Issues with Mercury Alpha One

When it comes to watercraft propulsion systems, various challenges can arise that affect performance and reliability. Understanding these typical problems is essential for maintenance and troubleshooting, ensuring smooth operation and longevity of the equipment.

Overheating Problems

One of the most frequent issues encountered is overheating. This can be caused by blockages in the cooling system, which prevent water from circulating effectively. Regularly checking for debris in the intakes and ensuring that the water pump is functioning properly can help mitigate this risk.

Gear Shift Difficulties

Another common concern involves the gear shifting mechanism. Users may experience sluggish or unresponsive shifts, often attributed to low fluid levels or contamination. Ensuring that the appropriate type and level of lubricant is maintained is crucial for optimal performance.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of components, saving time and money in the long run. By adopting a proactive approach, you can identify potential issues before they escalate, allowing for timely interventions.

Routine Inspections

Conducting regular inspections is crucial for spotting wear and tear early. Check all essential parts for signs of damage or corrosion. Pay close attention to seals and gaskets, as they often bear the brunt of wear. Keeping a detailed log of these checks can help track performance over time and inform future maintenance decisions.

Proper Cleaning and Lubrication

Regular cleaning is essential to prevent the buildup of dirt and grime, which can impede functionality. Use appropriate cleaning agents that won’t damage surfaces. Additionally, ensure all moving parts are adequately lubricated to reduce friction and enhance operation. Follow manufacturer guidelines for the best results.

Identifying Worn Components

Recognizing signs of deterioration in mechanical elements is crucial for maintaining optimal performance. Over time, various components can exhibit wear that may lead to decreased efficiency or failure. Regular inspection and understanding of common wear indicators can help in early detection and replacement, ensuring longevity and reliability of the equipment.

Key aspects to consider when evaluating the condition of these elements include visual inspections, measurements, and functional tests. Identifying specific symptoms of wear can streamline maintenance efforts and improve safety.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Seals | Cracks, hardening, or leaks | Replace immediately to prevent fluid loss |

| Bearings | Noise, rough movement, or overheating | Inspect and replace if necessary |

| Gaskets | Compression, brittleness, or fluid seepage | Replace to maintain a secure seal |

| Belts | Fraying, cracking, or stretching | Change to avoid slippage or breakage |

| Hoses | Softness, bulges, or leaks | Inspect regularly and replace as needed |

By being vigilant and proactive in identifying these signs, operators can mitigate risks and enhance the performance of their machinery.

How to Read the Diagram

Understanding technical illustrations can be daunting, yet it is essential for effective maintenance and assembly. These visual representations offer a wealth of information about components and their interactions. By familiarizing yourself with key elements, you can navigate these illustrations with confidence.

Here are some tips to help you decode these visuals:

- Identify the Legend: Most illustrations include a legend that explains symbols and color codes. Refer to this section first to grasp the meanings of various markings.

- Focus on Layout: Notice how components are arranged. Often, they follow a logical sequence, making it easier to understand their relationships.

- Trace Connections: Pay attention to lines and arrows. These often indicate how parts connect or interact, highlighting the flow of operation.

- Note Dimensions: Dimensions provide crucial information regarding size and spacing, which is vital for proper assembly and fitting.

- Refer to Annotations: Additional notes can offer insights into installation tips, maintenance advice, or troubleshooting steps.

By systematically analyzing these elements, you can gain a clearer understanding of the entire assembly and ensure efficient handling of the components involved.

Replacement Parts Availability

Finding suitable components for your equipment is crucial for maintaining optimal performance and longevity. The availability of these essential elements can significantly impact your ability to carry out repairs and enhancements. A well-stocked supply ensures that you can address issues promptly, minimizing downtime and enhancing efficiency.

Sources for Components

Various suppliers offer a range of options for acquiring necessary items. Online marketplaces, specialized retailers, and even local distributors provide diverse selections to meet different needs. It is advisable to compare prices and quality from various sources to ensure you make informed decisions.

Considerations for Purchase

When selecting replacements, factors such as compatibility, durability, and warranty are important. Ensure that any component you choose meets the specifications required for your model. Additionally, consider opting for products that come with guarantees, as this can provide peace of mind regarding the longevity and performance of your purchase.

DIY Repair Guide for Owners

Taking care of your equipment can be a rewarding experience. By understanding the components and how they work together, you can efficiently address common issues, potentially saving time and money. This guide aims to empower you with practical steps and insights for maintaining your machinery effectively.

Tools and Materials You’ll Need

- Screwdrivers (flathead and Phillips)

- Wrenches and pliers

- Replacement components

- Cleaning supplies

- Lubricants and sealants

- Safety gear (gloves, goggles)

Common Repairs and Maintenance Tasks

-

Cleaning:

- Remove dirt and debris from external surfaces.

- Inspect and clean air filters to ensure proper airflow.

-

Lubrication:

- Apply appropriate lubricants to moving parts to reduce friction.

- Check for any signs of wear and tear on seals and bearings.

-

Component Replacement:

- Identify faulty parts by listening for unusual sounds or observing performance issues.

- Follow the manufacturer’s instructions for proper replacement procedures.

By following these guidelines, owners can confidently tackle maintenance tasks, ensuring their equipment remains in top condition for years to come.

Professional Services and Recommendations

When dealing with specialized equipment, seeking expert assistance is crucial for optimal performance and longevity. Professionals in the field can provide invaluable insights, ensuring that all components are functioning harmoniously and effectively. Their experience allows them to diagnose issues that may not be immediately apparent to the untrained eye.

It is advisable to choose service providers who have a solid reputation and extensive knowledge of the specific systems in question. Engaging with certified technicians can help in identifying the best maintenance practices and potential upgrades. Recommendations from peers or industry reviews can also guide you in selecting the right experts.

Furthermore, staying informed about the latest advancements in technology and service techniques can significantly enhance your overall experience. Regular consultations with specialists will not only prevent future complications but also keep your equipment operating at peak efficiency. Prioritizing professional input is a wise investment in the longevity and reliability of your systems.

Comparing Alpha One Models

This section delves into the various iterations of a popular marine propulsion system, highlighting their unique features and advancements. By examining the different models, enthusiasts and boaters can better understand which version suits their specific needs.

Each variant offers distinct characteristics that cater to varying performance requirements and user preferences. Below are some key aspects to consider when evaluating these models:

- Design Evolution:

- Improvements in hull efficiency

- Refinements in gear ratios

- Updates in cooling systems

- Performance Enhancements:

- Increased horsepower ratings

- Better fuel efficiency

- Improved torque delivery

- Maintenance Considerations:

- Accessibility of components

- Availability of replacement parts

- Ease of servicing

Understanding these differences is crucial for making an informed decision, whether for upgrading existing equipment or selecting new installations.

Resources for Further Learning

Expanding your knowledge in this area can be greatly beneficial. Whether you’re seeking technical manuals, community forums, or video tutorials, there are numerous avenues to explore for enhanced understanding and practical skills.

Here are some valuable resources to consider:

- Online Forums: Engaging with enthusiasts and experts can provide insights and solutions to common challenges.

- Technical Manuals: Comprehensive guides are essential for understanding specifications and operational procedures.

- Video Tutorials: Visual aids can simplify complex concepts and demonstrate step-by-step processes.

- Workshops and Webinars: Participating in live sessions allows for interactive learning and direct access to professionals.

- Books and Publications: Numerous authors have published works that delve deeply into this subject, providing a solid theoretical foundation.

Utilizing these resources will not only enhance your comprehension but also equip you with practical skills for real-world applications.