Understanding the Mercury Optimax 225 Parts Diagram

In the world of marine propulsion, comprehending the intricacies of engine configurations is essential for both maintenance and performance optimization. Having a clear visualization of the various elements that comprise a power unit can greatly aid in troubleshooting and servicing. By breaking down the individual components and their interrelations, one can ensure smoother operation and prolonged durability.

For enthusiasts and professionals alike, familiarizing oneself with these intricate layouts can demystify the often complex machinery. Each segment plays a vital role in the overall functionality, and understanding how they work together is crucial. This knowledge not only enhances efficiency but also empowers users to make informed decisions regarding repairs and upgrades.

Furthermore, engaging with schematics fosters a deeper appreciation for engineering precision. The design and arrangement of each piece reflect the thoughtful consideration that goes into creating reliable propulsion systems. By studying these illustrations, one gains insights into the craftsmanship and technology that drive modern marine engines.

Understanding Mercury Optimax 225

The high-performance outboard engines have revolutionized the boating experience by combining efficiency and power. These advanced propulsion systems are designed for both recreational and commercial use, delivering exceptional reliability and performance on the water. Familiarity with their components is essential for optimal maintenance and operation.

Efficiency is a key feature of these engines, allowing users to enjoy longer journeys without frequent refueling. This is achieved through innovative technology that enhances fuel combustion and minimizes emissions, making them environmentally friendly. Understanding how these systems function can lead to better fuel management and operational strategies.

Moreover, regular maintenance is critical for longevity. Being aware of each component’s role helps in identifying potential issues before they escalate. Inspection of essential parts ensures that the engine runs smoothly and efficiently, contributing to a safer and more enjoyable boating experience.

In summary, grasping the intricacies of these outboard engines not only enhances user knowledge but also promotes effective usage and care, ensuring that they remain a reliable choice for water enthusiasts.

Key Components of the Engine

Understanding the fundamental elements of a marine power unit is crucial for maintenance and optimization. Each component plays a vital role in the overall functionality, contributing to performance, efficiency, and longevity. From the fuel system to the ignition apparatus, every part works in harmony to ensure reliable operation in various conditions.

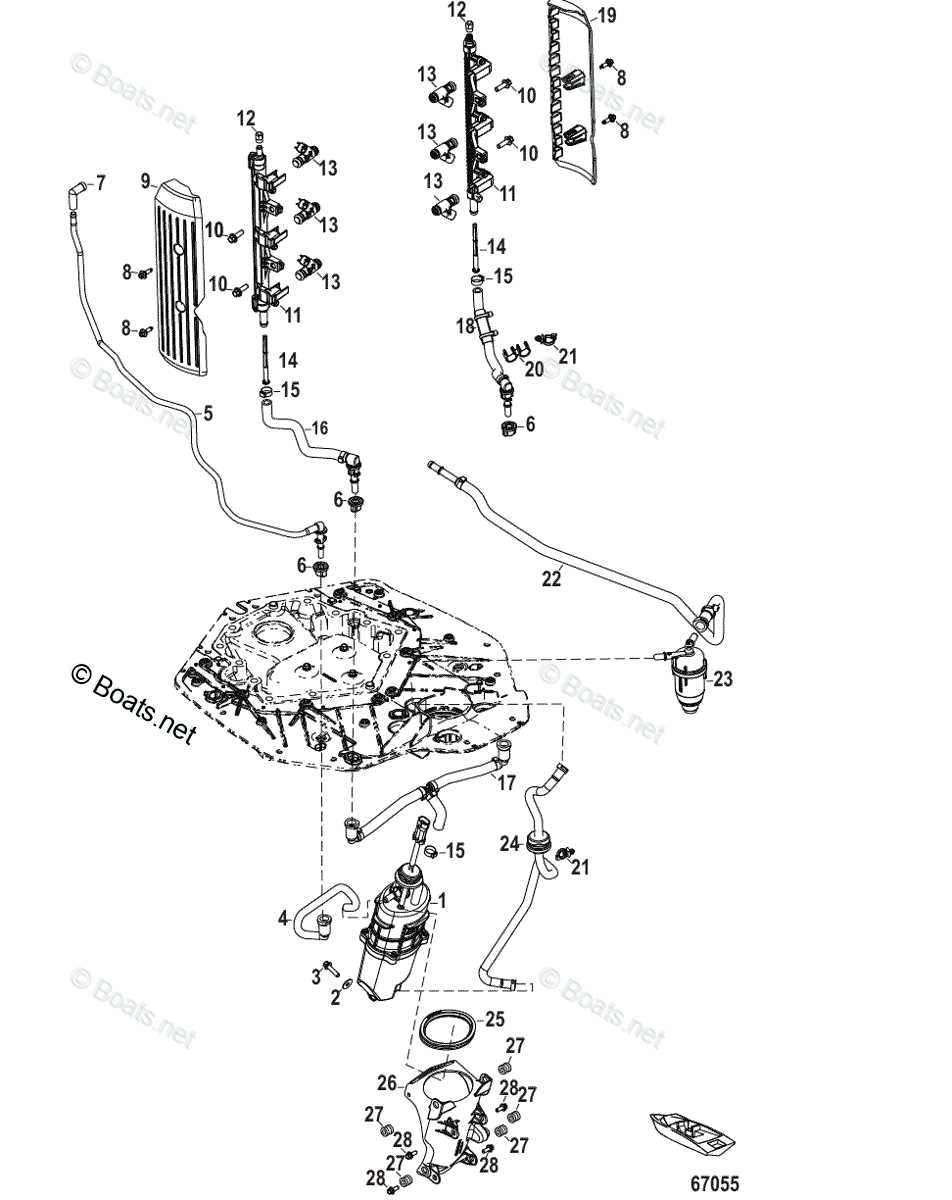

Fuel System

The fuel delivery mechanism is responsible for providing the necessary energy to the engine. This system includes various components that filter, pump, and inject fuel into the combustion chamber. Proper functioning of this system is essential for optimal performance and efficiency.

Ignition System

The ignition apparatus initiates the combustion process by generating a spark at the right moment. It consists of several parts that ensure reliable starts and consistent operation. Maintaining this system is critical for avoiding misfires and ensuring smooth acceleration.

| Component | Function |

|---|---|

| Fuel Pump | Delivers fuel from the tank to the engine |

| Fuel Injector | Sprays fuel into the combustion chamber |

| Ignition Coil | Transforms battery voltage to create a spark |

| Spark Plug | Ignites the fuel-air mixture |

Importance of Parts Diagrams

Understanding the layout and components of a complex machinery system is crucial for effective maintenance and repairs. Visual representations serve as essential tools for technicians and enthusiasts alike, enabling them to grasp the intricate relationships between various elements. These illustrations facilitate a more comprehensive understanding of how each component contributes to the overall functionality.

- Enhanced Communication: Clear visuals improve discussions between team members, ensuring everyone is on the same page regarding assembly and repair tasks.

- Time Efficiency: Technicians can quickly locate specific elements, reducing the time spent searching for parts or understanding configurations.

- Error Reduction: Accurate representations help minimize mistakes during reassembly, as they provide a reliable reference point.

- Training Aid: New technicians can benefit from visual guides that illustrate complex systems, aiding in their learning and development.

In summary, utilizing these visual aids is vital for anyone involved in maintenance or repair work. They not only streamline processes but also contribute to safer and more effective operations.

Common Issues with Mercury Optimax

Understanding frequent problems with high-performance marine engines is crucial for effective maintenance and longevity. These issues can stem from various factors, including design characteristics, operational practices, and environmental conditions. Identifying and addressing these common challenges can enhance engine reliability and performance.

- Fuel Delivery Problems:

- Clogged filters

- Inadequate fuel pressure

- Injector malfunctions

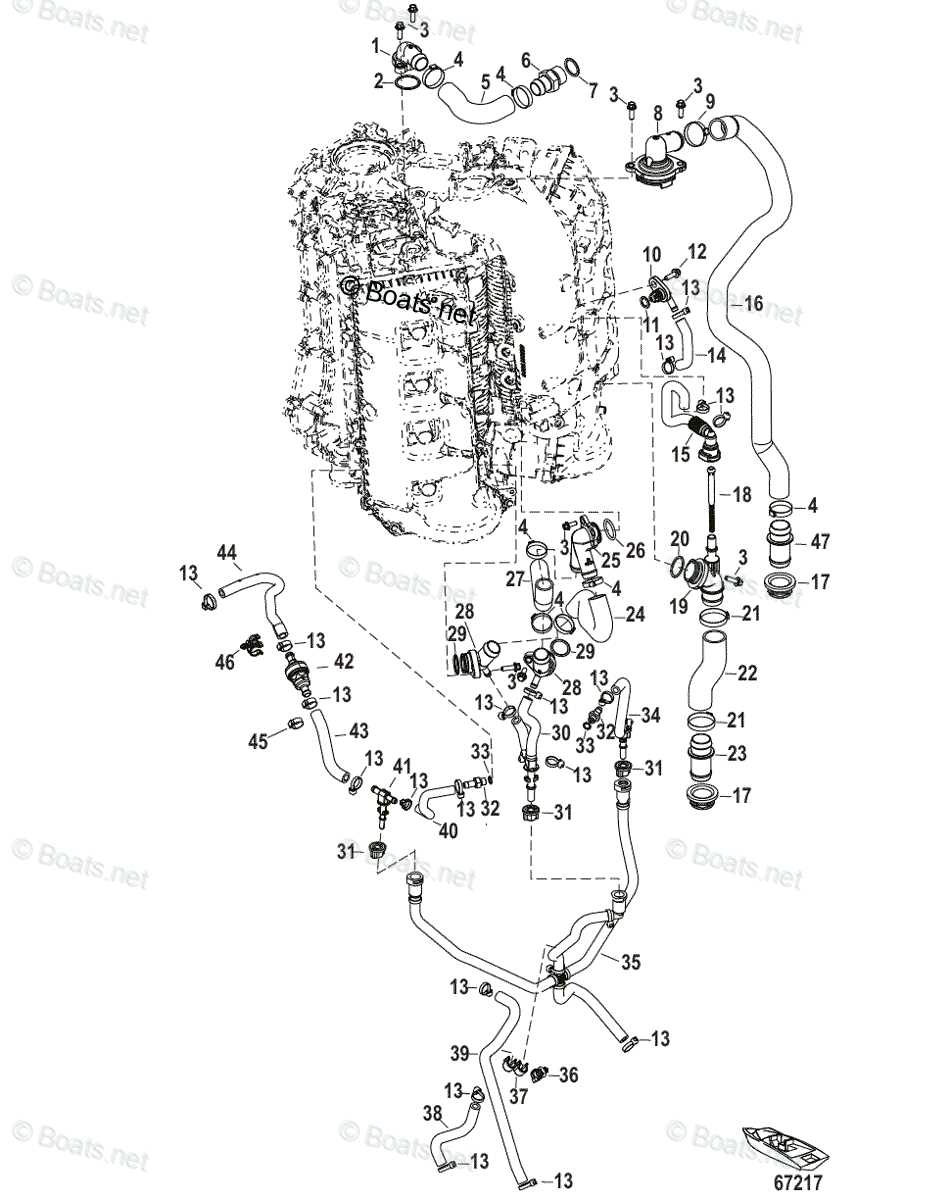

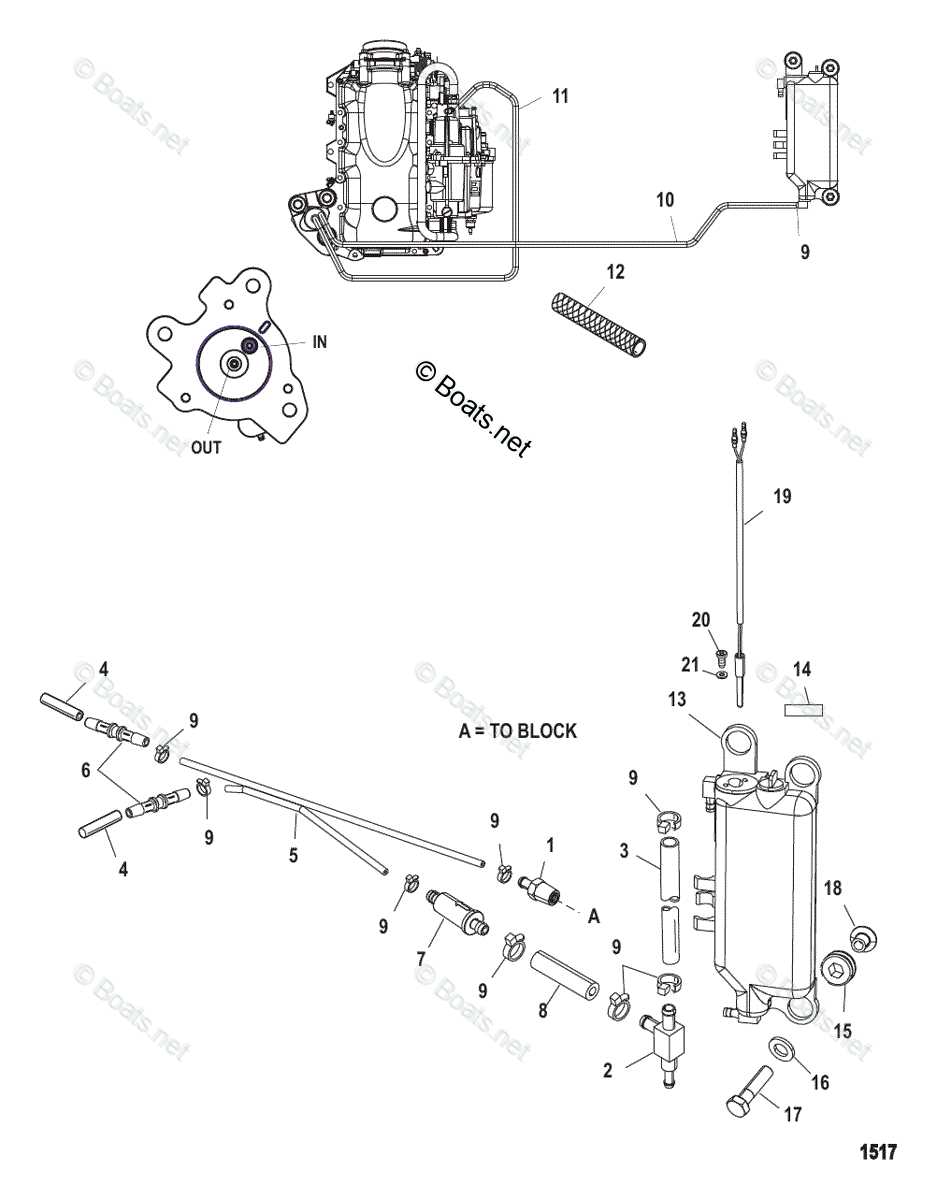

- Cooling System Failures:

- Overheating due to blocked passages

- Faulty thermostats

- Insufficient water flow

- Electrical Issues:

- Dead batteries

- Corroded connections

- Faulty wiring harnesses

- Powerhead Concerns:

- Compression loss

- Oil leaks

- Seized pistons

Regular inspections and preventative measures can significantly mitigate these issues, ensuring optimal performance and extending the lifespan of the engine.

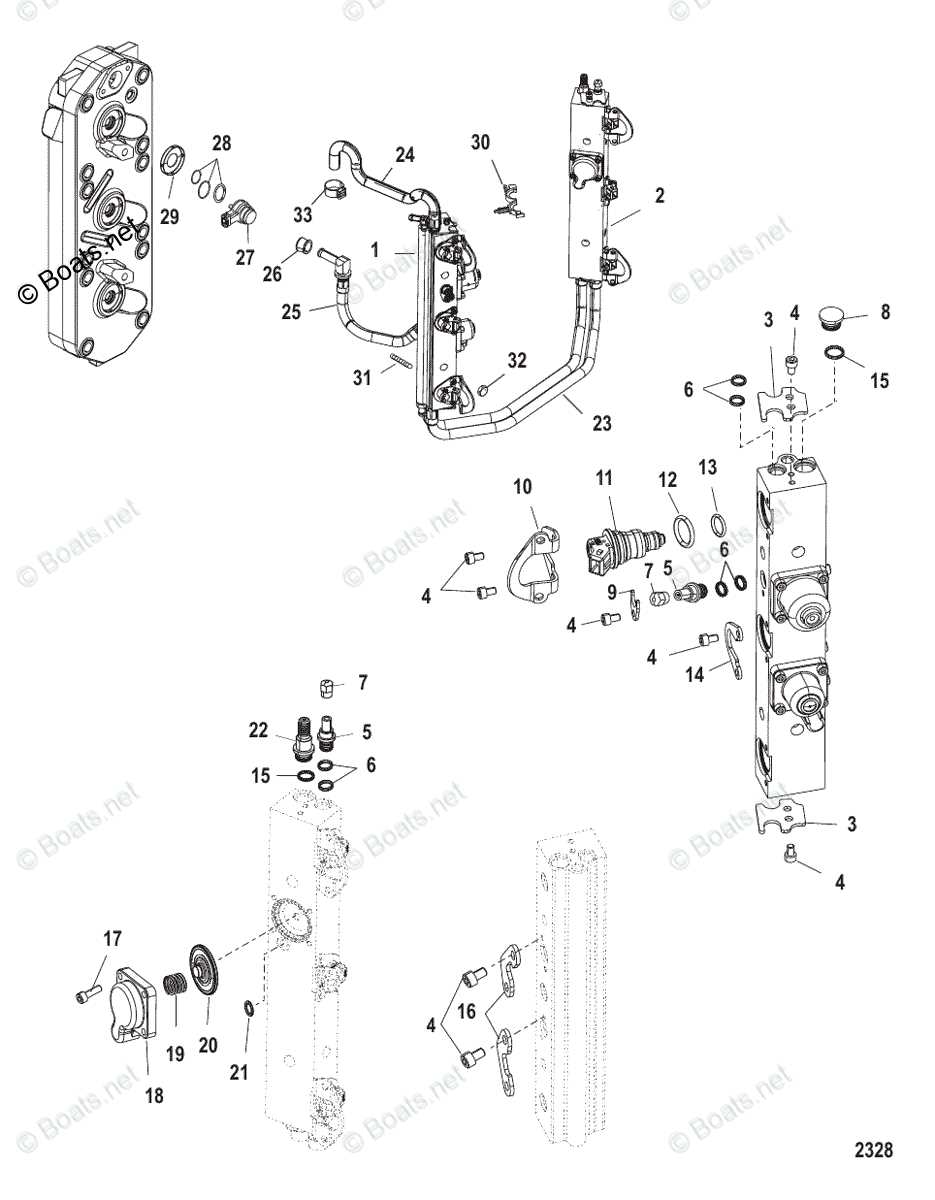

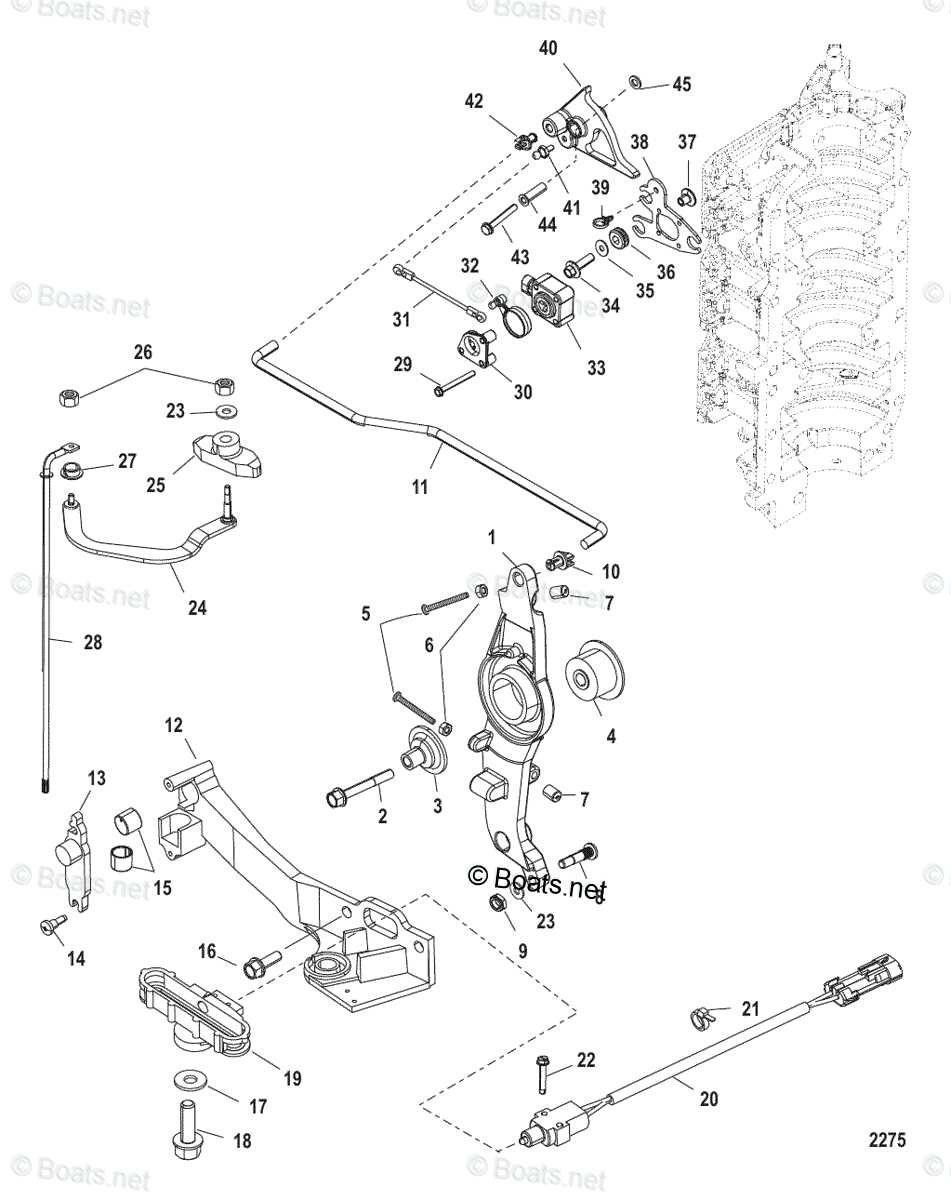

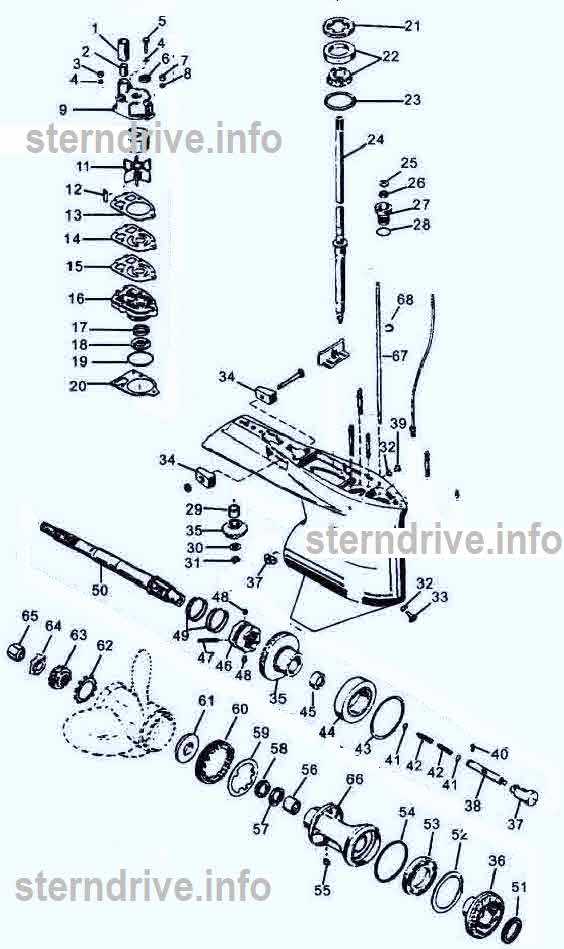

How to Read the Diagram

Understanding technical illustrations can greatly enhance your ability to perform maintenance and repairs. This guide provides essential tips for interpreting these visual representations effectively, ensuring you can locate and identify components with ease.

Here are some key steps to help you navigate the illustration:

- Familiarize Yourself with Symbols:

- Study the legend or key, as it provides meanings for various symbols.

- Recognize common icons that represent different components.

- Identify the Layout:

- Note the orientation of the image, which may depict the assembly from different angles.

- Understand the flow of connections and how parts interact with one another.

- Follow Numbering or Labeling:

- Check for numbers or letters that correspond to specific elements.

- Use these references to locate parts in any accompanying documentation.

- Pay Attention to Detail:

- Look for annotations that may indicate assembly order or specific adjustments.

- Examine all lines and arrows that demonstrate movement or connection paths.

By mastering these techniques, you can enhance your comprehension of technical illustrations, leading to more efficient and effective maintenance practices.

Identifying Replacement Parts

When maintaining high-performance marine engines, recognizing the necessary components for replacement is crucial for ensuring optimal functionality. Understanding the specific elements that may need to be substituted can enhance the longevity and reliability of your vessel’s power system.

Common Components for Replacement

Engines often require the replacement of various elements over time. Typical candidates include filters, fuel injectors, and spark plugs. Regular inspection of these items can prevent performance issues and contribute to smoother operation. Keeping a close eye on wear and tear helps in identifying parts that may soon need to be addressed.

Consulting Reference Materials

Utilizing detailed reference guides can significantly aid in pinpointing the required components. These resources often include visual aids and descriptions that facilitate quick identification. Accessing manufacturer documentation or specialized manuals allows for a more informed selection process, ensuring that you obtain the correct items for your engine’s maintenance needs.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your marine engine requires diligent care and attention. By adhering to a systematic maintenance routine, you can prevent potential issues and enhance overall performance. Here are some essential practices that can contribute to the durability and efficiency of your equipment.

Regular Inspection

Conducting routine checks is vital for identifying wear and tear before they escalate into significant problems. Focus on examining the cooling system, fuel lines, and electrical connections. Pay special attention to signs of corrosion and leaks, as early detection can save both time and money in repairs.

Fluid Management

Maintaining optimal fluid levels is crucial for smooth operation. Regularly check and replace engine oil, coolant, and fuel filters according to the manufacturer’s recommendations. Clean fluids not only ensure efficient functioning but also prevent internal damage that could result from contamination.

Upgrades for Performance Improvement

Enhancing the capabilities of your vessel can significantly elevate your overall experience on the water. By focusing on specific modifications, you can achieve better speed, efficiency, and responsiveness, making every outing more enjoyable. Below are some popular upgrades to consider for boosting performance.

Engine Modifications

- ECU Tuning: Optimizing the engine control unit can improve fuel efficiency and increase horsepower.

- Exhaust System Upgrade: A performance exhaust system can enhance engine breathing, resulting in better power output.

- High-Performance Air Filters: Replacing stock air filters with high-flow options can improve airflow and overall engine performance.

Propeller and Hull Enhancements

- Propeller Replacement: Choosing a propeller that matches your setup can maximize speed and fuel efficiency.

- Hull Modifications: Consider altering the hull design or applying coatings to reduce drag and increase speed.

- Weight Distribution: Adjusting weight placement can enhance stability and maneuverability on the water.

By investing in these upgrades, you can unlock the full potential of your vessel, ensuring a more thrilling and efficient experience every time you head out to sea.

Where to Buy Authentic Parts

When it comes to maintaining your marine equipment, sourcing genuine components is crucial for optimal performance and longevity. Authentic items not only ensure compatibility but also enhance the reliability of your vessel. Here are some trusted avenues to explore when searching for high-quality replacements.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers are sanctioned by manufacturers and offer a wide range of genuine products, often with warranties and support. |

| Online Marketplaces | Reputable e-commerce platforms may have sections dedicated to authentic items, featuring seller ratings to help you choose wisely. |

| Manufacturer’s Website | The official website often provides direct sales or lists authorized sellers, ensuring you get legitimate components. |

| Marine Supply Stores | Local shops that specialize in marine equipment typically stock a variety of authentic items and can offer personalized assistance. |

By utilizing these resources, you can confidently acquire the components you need to keep your watercraft in peak condition.

Expert Recommendations for Repairs

When tackling engine maintenance, it’s crucial to approach repairs with a well-informed strategy. Understanding the various components and their interrelations can significantly enhance efficiency and longevity. This section provides valuable insights and guidance to ensure effective troubleshooting and restoration.

Assessing Common Issues

Start by identifying the prevalent challenges that may arise with your engine. Common problems include irregular performance, unusual noises, or overheating. Conducting a thorough examination will help pinpoint the underlying causes. Utilizing diagnostic tools can facilitate this process, providing detailed information that aids in accurate assessments.

Choosing Quality Components

When replacement is necessary, prioritize high-quality components. Opt for reputable manufacturers to ensure compatibility and reliability. Additionally, always refer to the official documentation for specifications and recommendations. This approach not only guarantees optimal performance but also minimizes the risk of future complications. Investing in quality is investing in longevity.

FAQs About Optimax 225 Parts

This section addresses common inquiries regarding components of a specific marine engine. Understanding the intricacies of these elements is crucial for maintenance and repair, ensuring optimal performance on the water.

What are the most frequently replaced components?

Typically, items such as fuel injectors, spark plugs, and gaskets see the most wear and may require regular replacement to maintain engine efficiency.

How can I identify the correct component for my engine?

Consulting the manufacturer’s manual or using a reliable online resource can help you identify the appropriate specifications and models for your engine’s requirements.

Are aftermarket components reliable?

While many aftermarket options can be cost-effective, it’s essential to choose reputable brands to ensure compatibility and reliability, as lower-quality alternatives may affect performance.

What maintenance should I perform regularly?

Regular checks on oil levels, coolant systems, and thorough cleaning of filters are vital to prolonging the lifespan of the engine and its components.

Where can I find detailed schematics for replacement?

Many online platforms and specialist retailers offer detailed guides and schematics, which can help you understand the layout and function of each component within your engine.