Understanding the Mercury Outboard Motor Parts Diagram

Exploring the intricate world of marine propulsion systems reveals a complex assembly of components that work harmoniously to ensure optimal performance on the water. A comprehensive overview of these elements not only enhances one’s knowledge but also aids in effective maintenance and repair. Familiarity with the individual parts and their functions can significantly contribute to the longevity and efficiency of the vessel.

Each element plays a crucial role, from the fundamental structure to the more specialized features designed for enhanced functionality. A detailed visual representation allows enthusiasts and professionals alike to navigate through the various components with ease. Understanding how these pieces interact is vital for troubleshooting and optimizing the overall operation.

In the following sections, we will delve deeper into these essential elements, highlighting their specific roles and relationships. Whether you are a seasoned mariner or a newcomer to the aquatic world, grasping these concepts will empower you to make informed decisions regarding maintenance and upgrades, ensuring a smoother sailing experience.

Understanding Mercury Outboard Motors

Grasping the essentials of marine propulsion systems is crucial for enthusiasts and professionals alike. These devices serve as vital components for aquatic vessels, enabling smooth navigation and efficient performance on the water. A comprehensive understanding of their functionality and construction can greatly enhance maintenance practices and operational efficiency.

Key Features of Marine Propulsion Systems

- Design and Engineering: The structural elements are optimized for durability and performance.

- Power Output: Varieties exist to cater to different vessel sizes and intended uses.

- Fuel Efficiency: Innovations in technology aim to reduce fuel consumption while maximizing output.

- Ease of Maintenance: User-friendly designs facilitate straightforward servicing and repairs.

Common Components and Their Functions

- Cooling System: Ensures the unit operates at safe temperatures, preventing overheating.

- Fuel Delivery Mechanism: Manages the supply of fuel to the engine for optimal combustion.

- Ignition System: Initiates the combustion process, critical for starting and running effectively.

- Exhaust System: Directs gases away from the engine, minimizing noise and environmental impact.

By familiarizing oneself with these aspects, operators can better appreciate the complexity and reliability of their marine propulsion systems, leading to improved care and prolonged service life.

Key Components of Outboard Motors

Understanding the essential elements of these watercraft engines is crucial for maintaining optimal performance and longevity. Each component plays a significant role in ensuring efficient operation, from propulsion to power generation. Familiarity with these critical pieces allows for better troubleshooting and repair, enhancing the overall boating experience.

Power Source

The engine serves as the heart of the system, converting fuel into mechanical energy. Its design influences both the speed and efficiency of the vessel. Regular maintenance of the power unit is vital to prevent issues that could hinder performance.

Propulsion System

This segment is responsible for translating the engine’s power into forward motion. It includes elements such as the shaft and propeller, which work together to create thrust. Ensuring these components are in top condition is essential for achieving desired speed and maneuverability.

In summary, a thorough grasp of these fundamental components not only aids in maintenance but also enhances the understanding of how each element contributes to the overall function of the vessel.

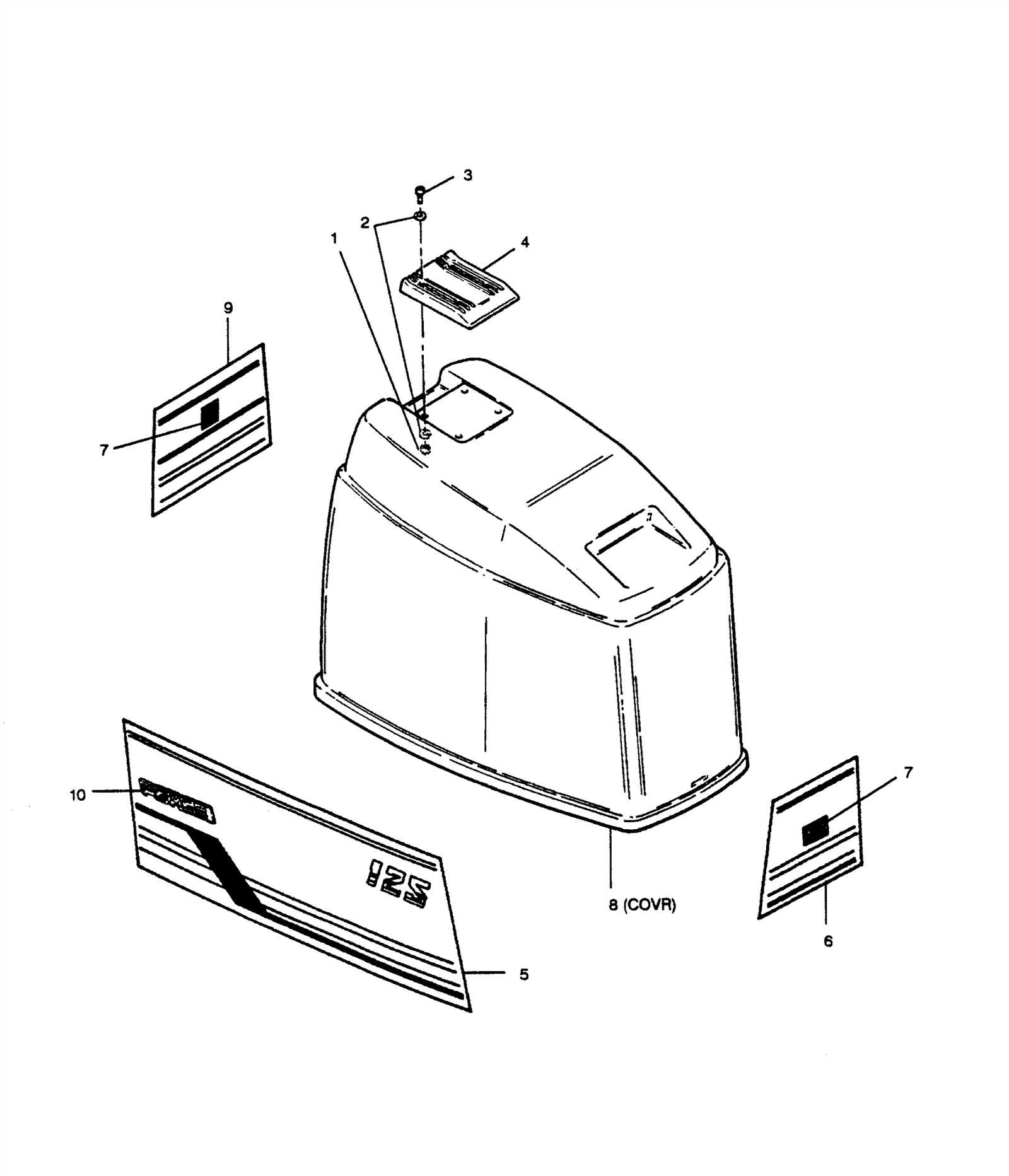

Importance of a Parts Diagram

A comprehensive visual representation of components is crucial for effective maintenance and repair. Such illustrations offer a clear overview, allowing users to identify and understand the various elements involved in a system. This clarity can significantly enhance the efficiency of troubleshooting and assembly processes.

Here are some key benefits of having a detailed schematic:

- Improved Understanding: Visual aids help users grasp the relationships between different elements, facilitating better comprehension of how the entire assembly functions.

- Enhanced Maintenance: Knowing the exact locations and roles of components allows for more efficient servicing and replacements, reducing downtime.

- Accurate Troubleshooting: With a clear outline of each part, diagnosing issues becomes simpler, enabling quicker resolutions.

- Informed Upgrades: Users can identify which components can be upgraded or replaced for enhanced performance, based on the schematic layout.

In summary, having a clear visual guide is not just a convenience; it is an essential tool for anyone looking to ensure optimal functionality and longevity of their equipment.

How to Read Motor Diagrams

Understanding technical illustrations is crucial for anyone working with machinery. These visuals serve as a roadmap, providing insights into the various components and their interconnections. By grasping how to interpret these illustrations, you can diagnose issues, perform maintenance, and ensure optimal performance.

Familiarize Yourself with Symbols: Every schematic uses a specific set of symbols to represent different elements. Spend time learning these icons, as they form the foundation of comprehension. Each symbol conveys unique information about the part it represents, such as its function or how it interacts with other components.

Follow the Flow: Most visuals are designed to depict the flow of energy or fluids through the system. Pay attention to the direction indicated by arrows or lines. This flow is essential for understanding how the entire assembly operates, allowing you to trace the path from one element to another.

Identify Key Components: Take note of critical parts highlighted in the illustration. Recognizing these elements helps you focus on areas that may require attention or maintenance. Understanding their roles will also aid in troubleshooting any issues that arise.

Refer to the Legend: Many visuals include a legend or key that explains the symbols used. This reference is invaluable, especially for complex systems. Use it as a guide to clarify any uncertainties and enhance your overall understanding.

Practice Makes Perfect: The more you engage with these illustrations, the better you will become at interpreting them. Regularly review different schematics, even if they are not directly related to your current work. This practice will improve your skills and boost your confidence in reading technical documentation.

Common Parts of Mercury Outboards

Understanding the fundamental components of marine propulsion systems is essential for effective maintenance and performance. Each unit consists of various elements that work together to ensure reliability and efficiency on the water. Here, we explore the key components typically found in these engines.

Key Components

- Engine Block: The central structure housing the cylinders and supporting the entire mechanism.

- Powerhead: Contains the combustion system, responsible for generating thrust.

- Lower Unit: The section that houses the drive shaft and propeller, critical for propulsion.

- Fuel System: Includes the tank, lines, and injectors, ensuring a steady supply of fuel.

- Cooling System: Maintains optimal operating temperatures, preventing overheating.

- Electrical System: Comprises the battery, wiring, and ignition, enabling efficient starting and operation.

Additional Elements

- Propeller: The rotating blade that translates engine power into forward motion.

- Steering System: Allows for directional control, ensuring maneuverability.

- Trim System: Adjusts the angle of the unit, optimizing performance and fuel efficiency.

- Shift Mechanism: Engages and disengages gears for forward or reverse operation.

- Fuel Filter: Protects the engine from contaminants, ensuring longevity and efficiency.

By familiarizing yourself with these essential components, you can better understand the maintenance needs and operational characteristics of your marine engine, leading to improved performance and reliability.

Maintenance Tips for Outboard Engines

Proper upkeep of marine propulsion systems is essential for longevity and optimal performance. Regular attention can prevent minor issues from escalating into significant problems, ensuring a smoother experience on the water.

Regular Checks

- Inspect the fuel system for leaks and contamination.

- Examine electrical connections and battery health.

- Check the cooling system for any obstructions.

- Look for signs of corrosion or wear on components.

Seasonal Maintenance

- Change the oil and filters before the start of the season.

- Replace worn spark plugs to ensure efficient ignition.

- Clean or replace the propeller if damaged or clogged.

- Flush the system with fresh water after each use to prevent salt buildup.

Following these guidelines can enhance performance and prolong the life of your propulsion system, making every outing more enjoyable.

Identifying Components by Model

Understanding the specific elements of an engine is essential for maintenance and repairs. Each model has its unique features and specifications, making it crucial to know how to identify these components accurately. This knowledge not only aids in troubleshooting but also ensures that replacements and upgrades are appropriate for the unit in question.

Recognizing Key Features

To begin identifying the essential elements, focus on the model number typically found on the unit. This number provides vital information about the production year, size, and other significant characteristics. Visual cues such as the shape, size, and configuration of the components can also guide your identification process. Familiarizing yourself with these details enhances your understanding and helps in sourcing the right items.

Utilizing Resources for Clarity

Many manufacturers offer detailed resources, including manuals and catalogs, which can be invaluable. Online forums and communities dedicated to enthusiasts often share insights and troubleshooting tips that can assist you in identifying components. Leveraging these resources can significantly simplify the task, ensuring that you are well-equipped to maintain and optimize performance effectively.

Where to Find Replacement Parts

Locating suitable components for your aquatic engine can be a straightforward process when you know where to look. Whether you’re aiming to restore performance or simply ensure longevity, various sources can provide the necessary items to get your vessel back in top shape.

Here are some effective avenues to explore:

- Authorized Dealers: Visiting a certified dealership can ensure you find genuine components that fit perfectly and meet manufacturer standards.

- Online Retailers: Numerous e-commerce platforms specialize in marine equipment. A quick search can yield a variety of options, often with user reviews to guide your choice.

- Local Marine Supply Stores: These shops often stock a range of components and can provide personalized advice. Establishing a relationship with local suppliers can also lead to valuable insights about your equipment.

- Salvage Yards: For budget-conscious repairs, marine salvage yards can offer used components at a fraction of the price. Ensure to check the condition and compatibility before purchasing.

- Online Marketplaces: Websites that allow users to buy and sell items can be treasure troves for hard-to-find components. Be cautious and verify the seller’s credibility.

- Manufacturer Websites: Many manufacturers provide direct sales through their official sites, including detailed catalogs that make finding the right item easier.

By exploring these resources, you can effectively track down the necessary elements to maintain your aquatic equipment efficiently and affordably.

Signs of Wear in Motor Parts

Understanding the indicators of deterioration in engine components is essential for maintaining optimal performance and longevity. Recognizing these signs early can prevent significant damage and costly repairs. Observing certain symptoms can help you determine when intervention is necessary.

| Indicator | Description |

|---|---|

| Unusual Noises | Unexpected sounds such as grinding, knocking, or rattling can signal internal issues. |

| Vibrations | Excessive shaking during operation often indicates misalignment or wear in moving elements. |

| Fluid Leaks | Puddles or spots of fluid underneath the unit may suggest seal or gasket failure. |

| Overheating | An increase in temperature beyond normal operating levels can indicate cooling system problems. |

| Difficulty Starting | Struggles or failures to ignite may point to issues with electrical systems or fuel delivery. |

Monitoring these warning signs can aid in early detection of wear, ensuring that your equipment remains reliable and efficient. Regular inspections and maintenance are crucial in addressing potential issues before they escalate.

Repairing Common Outboard Issues

Maintaining the functionality of marine propulsion systems is crucial for ensuring smooth operation on the water. This section focuses on common problems faced by users, providing insights into diagnosis and solutions to enhance performance and reliability.

Identifying Engine Performance Problems

When experiencing issues with engine performance, several factors may be at play. Symptoms like reduced power or difficulty starting can indicate underlying troubles. Begin by checking the fuel supply; ensure it is clean and free of contaminants. Inspecting the fuel filter for clogs and verifying that the fuel lines are intact can often resolve these issues. Additionally, examining the spark plugs for wear and replacing them if necessary can significantly improve engine responsiveness.

Addressing Cooling System Failures

A properly functioning cooling system is vital to prevent overheating. If you notice unusual temperatures or alarms, it’s essential to check the water intake for blockages. Debris accumulation can restrict water flow, leading to overheating. Regular cleaning and maintenance of the cooling passages and impeller can help avoid these situations. Furthermore, ensuring that the thermostat is operating correctly will aid in maintaining optimal temperatures during operation.

Tools Needed for Outboard Maintenance

Proper upkeep of marine propulsion systems requires a specific set of instruments to ensure efficiency and longevity. Having the right tools at hand not only simplifies the process but also enhances safety during maintenance tasks. A well-equipped toolbox is essential for both routine inspections and more comprehensive repairs.

Wrenches and socket sets are fundamental for loosening and tightening various fasteners, allowing for easy access to internal components. Additionally, pliers and screwdrivers are indispensable for manipulating wires and securing fittings.

To maintain optimal performance, filters and fluids should be regularly checked and replaced. Having a fluid extraction tool can simplify this process, making it easier to remove old oil or fuel. A reliable multimeter is also crucial for diagnosing electrical issues, ensuring that all systems are functioning correctly.

Finally, investing in a quality propeller wrench is vital for safely removing and installing propellers, which is a common task during maintenance. By ensuring you have these essential tools, you’ll be well-prepared to tackle any maintenance challenge effectively.

Upgrading Your Mercury Outboard

Enhancing the performance and efficiency of your aquatic engine can lead to a significantly improved experience on the water. Whether you are seeking better speed, fuel economy, or reliability, there are numerous upgrades available that can transform your vessel’s capabilities. This section will explore various options to consider when looking to elevate your engine’s performance.

Performance Enhancements: Upgrading the intake system, exhaust components, or even the ignition system can yield noticeable gains in horsepower and responsiveness. These modifications not only enhance acceleration but can also provide a smoother ride, making your time on the water more enjoyable.

Fuel Efficiency: Investing in more efficient fuel delivery systems or electronic management units can optimize fuel consumption. This not only saves money but also reduces your environmental footprint while enjoying your aquatic adventures.

Durability Improvements: High-quality materials and advanced technologies can be employed to increase the longevity of your engine. Reinforced components and protective coatings can withstand harsher conditions, ensuring that your engine remains reliable season after season.

Maintenance Ease: Upgrading to parts that are easier to service can save you time and effort. Components designed for quick replacements or that require less frequent servicing can enhance your overall experience, allowing you to focus more on enjoyment and less on upkeep.

In summary, by exploring various enhancements for your aquatic engine, you can achieve significant improvements in performance, efficiency, and reliability. Each upgrade offers unique benefits that can be tailored to fit your specific needs and preferences, ensuring a more enjoyable experience on the water.

Resources for Outboard Motor Owners

For enthusiasts and operators of marine propulsion systems, having access to reliable resources is crucial for maintenance and repair. These tools and references can greatly enhance the experience, ensuring optimal performance and longevity of equipment. Whether you’re looking for technical manuals, instructional videos, or community forums, the right information can make all the difference.

Online Communities and Forums

Engaging with fellow users through online platforms can provide invaluable insights. Many dedicated forums offer a space for sharing experiences, troubleshooting issues, and exchanging tips. Connecting with other enthusiasts not only broadens your knowledge but also fosters a sense of camaraderie among users.

Technical Manuals and Guides

Access to comprehensive manuals is essential for understanding the intricacies of your propulsion system. These guides often include detailed schematics, maintenance schedules, and troubleshooting advice. Many manufacturers and third-party sites offer downloadable resources that can help you tackle repairs confidently and efficiently.