Belle Minimix 150 Parts Diagram Overview

In the realm of construction and masonry, the significance of efficient mixing equipment cannot be overstated. These machines play a crucial role in ensuring that concrete is blended uniformly, enhancing both durability and performance. A comprehensive understanding of their components is essential for both novice and experienced users, enabling them to operate the machinery safely and effectively.

The intricate design of such mixers comprises various essential elements, each contributing to the overall functionality. By examining the configuration of these components, users can gain insights into how each part interacts to facilitate the mixing process. This knowledge not only aids in optimal operation but also assists in troubleshooting and maintenance, ensuring longevity and reliability.

In this section, we will delve into a detailed exploration of the assembly layout, highlighting key elements and their roles. Armed with this information, operators can enhance their expertise and ensure that their equipment remains in peak condition, ready to tackle any project with confidence.

Belle Minimix 150 Overview

This section provides a comprehensive look at a compact and efficient mixing device designed for construction and masonry tasks. Ideal for both professionals and DIY enthusiasts, this equipment facilitates the quick blending of various materials, ensuring consistent results.

The machine is characterized by its lightweight design, making it easily transportable while still maintaining a robust performance. With a powerful motor, it efficiently handles various mixtures, from cement to mortar, ensuring that projects are completed on time and to the highest standards.

Key features include a user-friendly interface, allowing operators to adjust settings with ease. Additionally, the durable construction ensures longevity, even when used in demanding environments. The innovative design not only enhances functionality but also simplifies the maintenance process, making it an excellent choice for those seeking reliability.

In summary, this compact mixer stands out as a vital tool in any construction toolkit, offering versatility and performance that meet the diverse needs of its users.

Key Features of the Minimix 150

The compact mixer is designed to provide exceptional performance and reliability, making it a popular choice for various construction and renovation projects. Its robust design and innovative features ensure efficient operation and user-friendly experience, catering to both professionals and DIY enthusiasts.

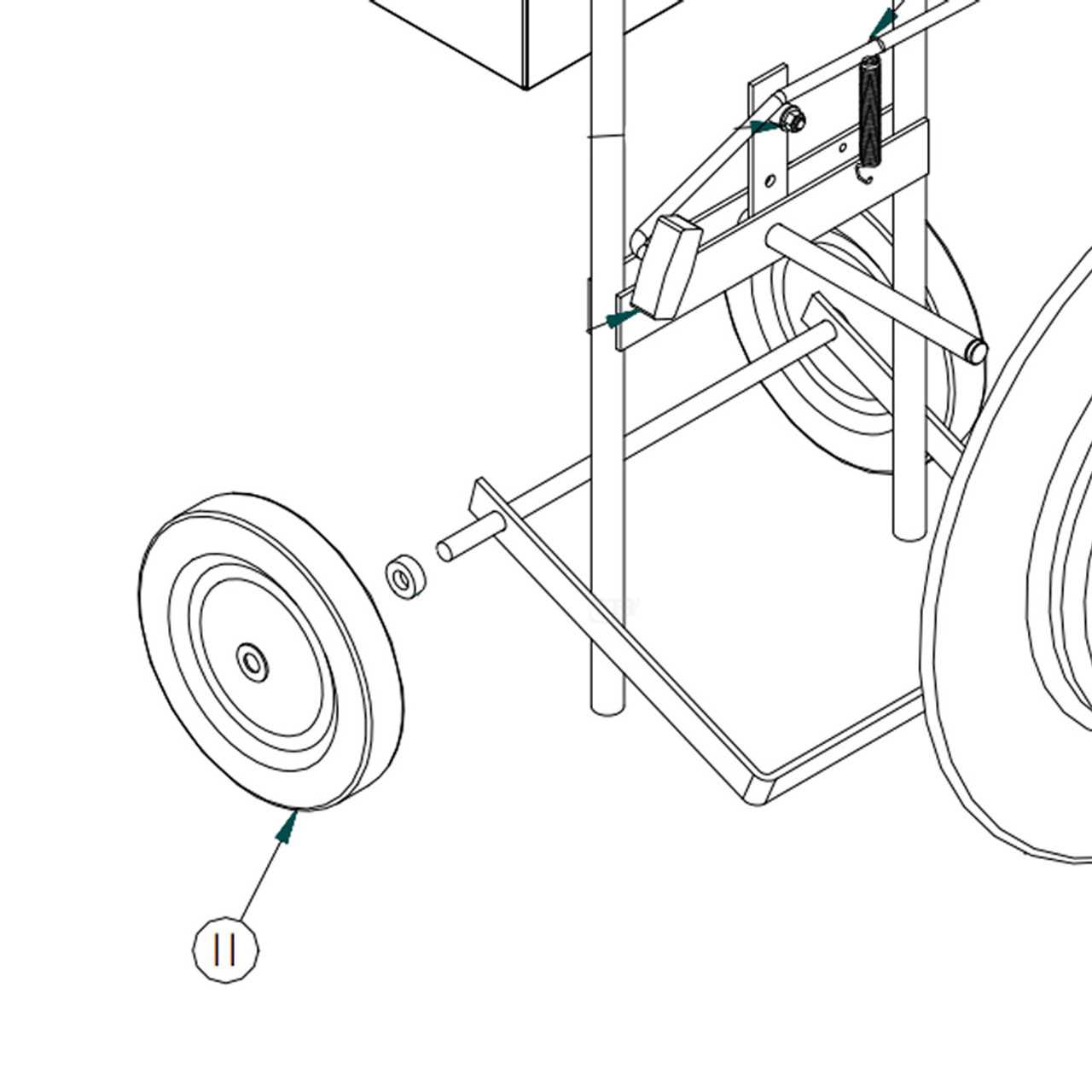

Portability: This model is lightweight and easy to maneuver, allowing for convenient transportation across job sites. Its compact size ensures that it can fit into tight spaces without compromising functionality.

Durability: Built with high-quality materials, the equipment is engineered to withstand the rigors of daily use. Its sturdy construction ensures a long lifespan, making it a worthwhile investment for any project.

Efficient Mixing: The powerful motor guarantees a consistent and thorough blend of materials, which is crucial for achieving optimal results. Users can expect a smooth mixture every time, enhancing overall work quality.

Ease of Use: Designed with user-friendly controls, this machine can be operated with minimal training. Its intuitive layout allows for quick adjustments, streamlining the mixing process.

Versatility: Capable of handling various materials, from concrete to mortar, this equipment is suitable for a wide range of applications. Whether for small repairs or larger construction tasks, it adapts to different needs effortlessly.

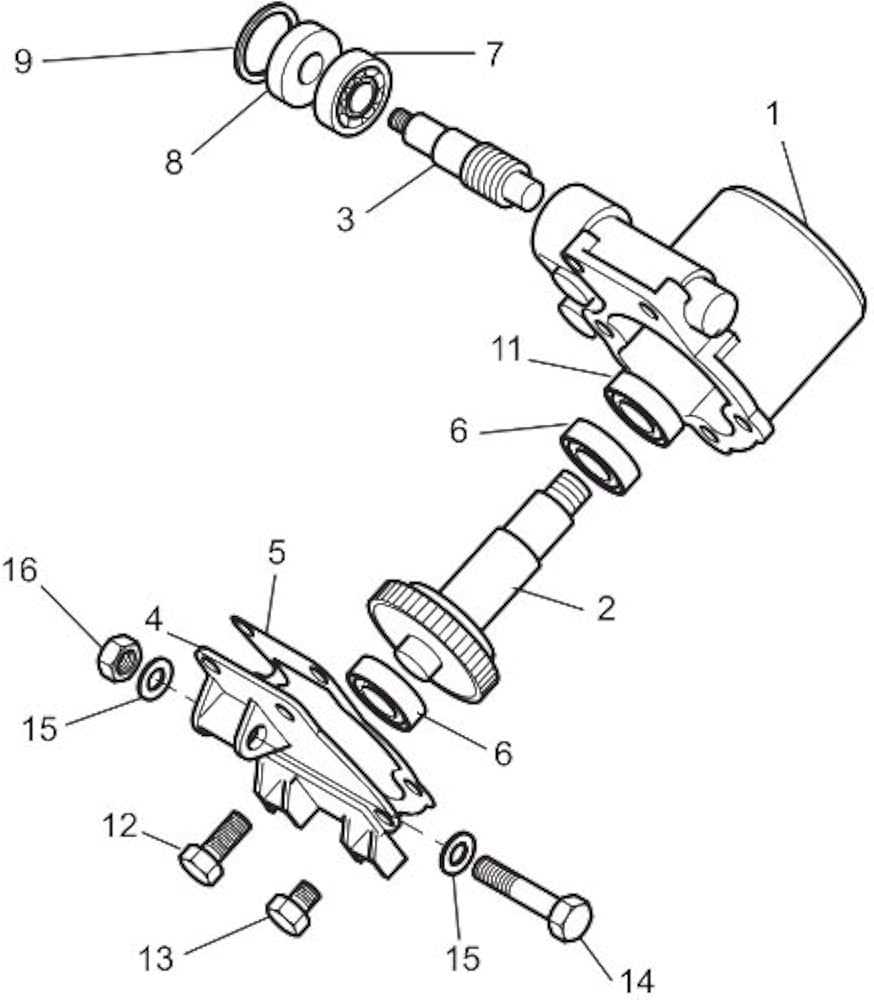

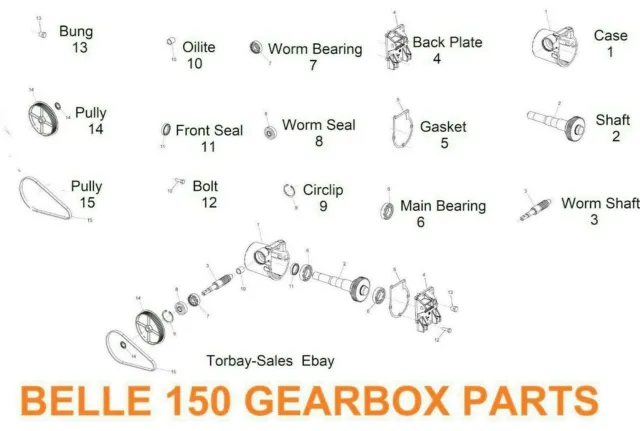

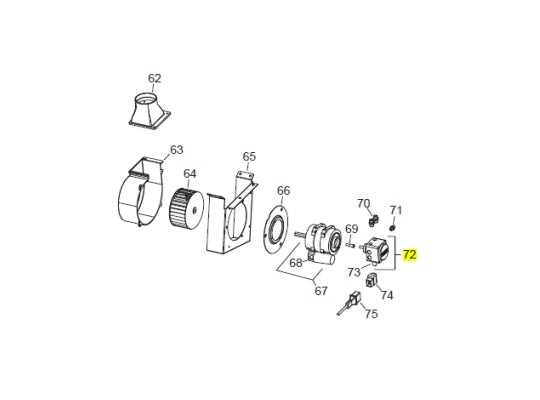

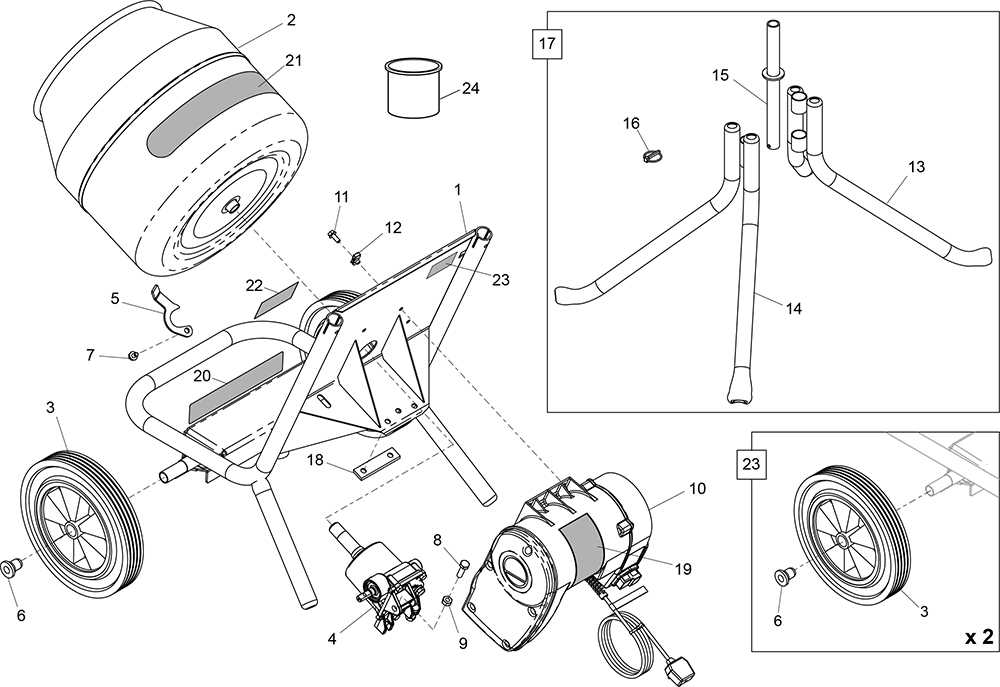

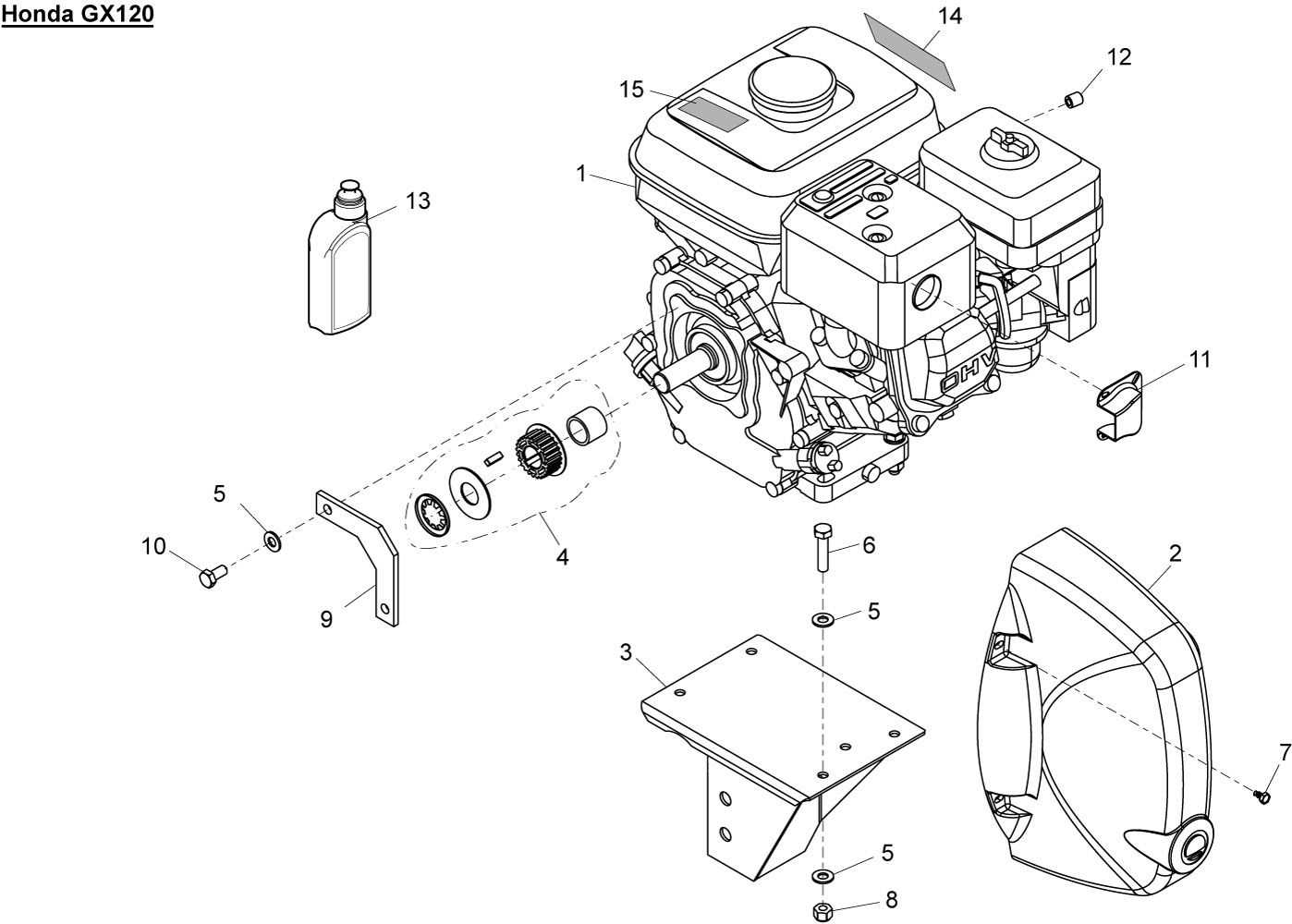

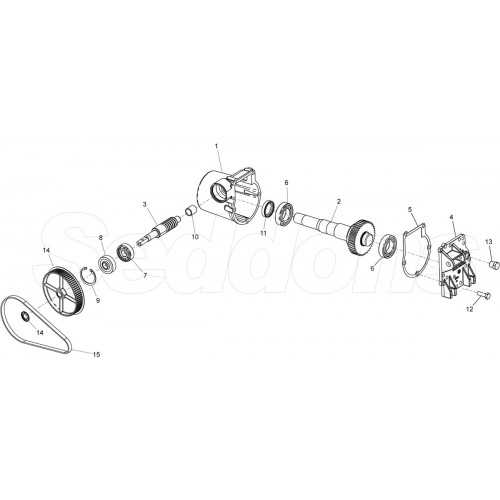

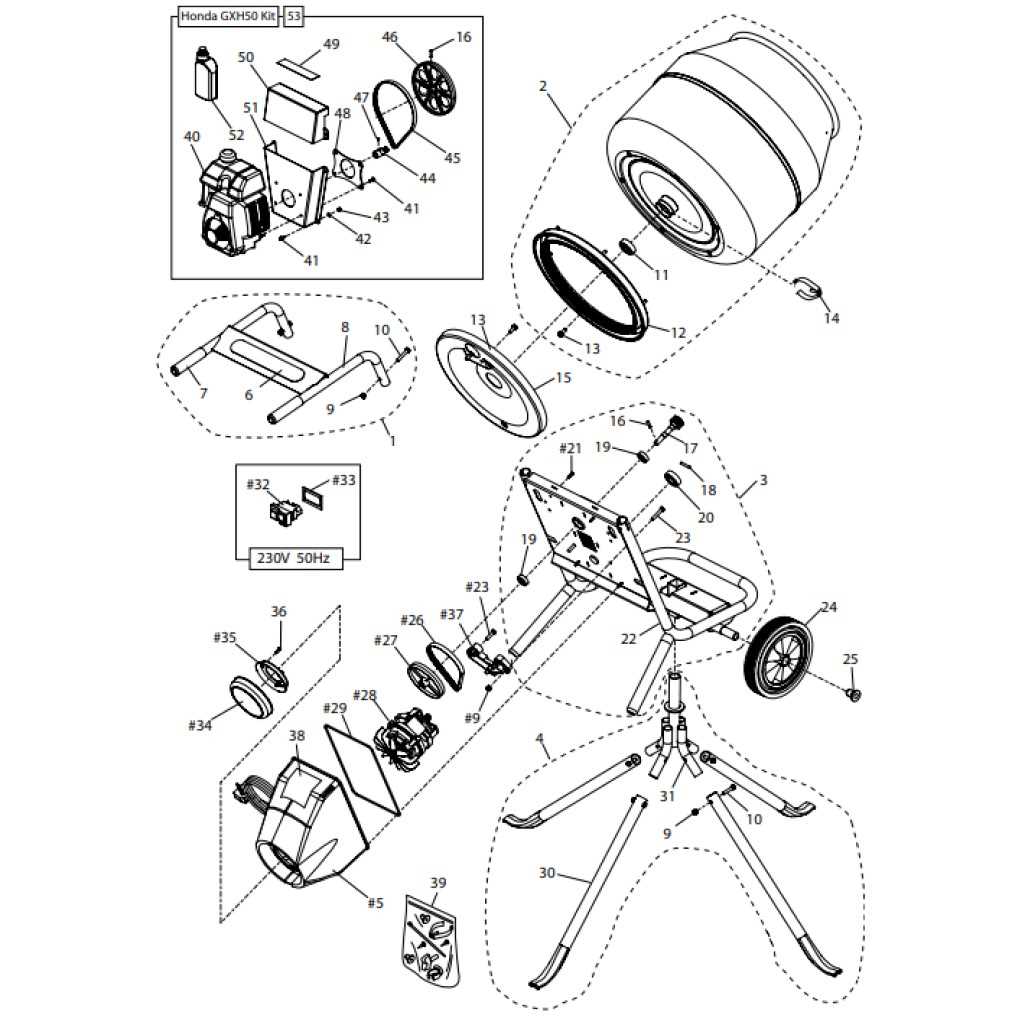

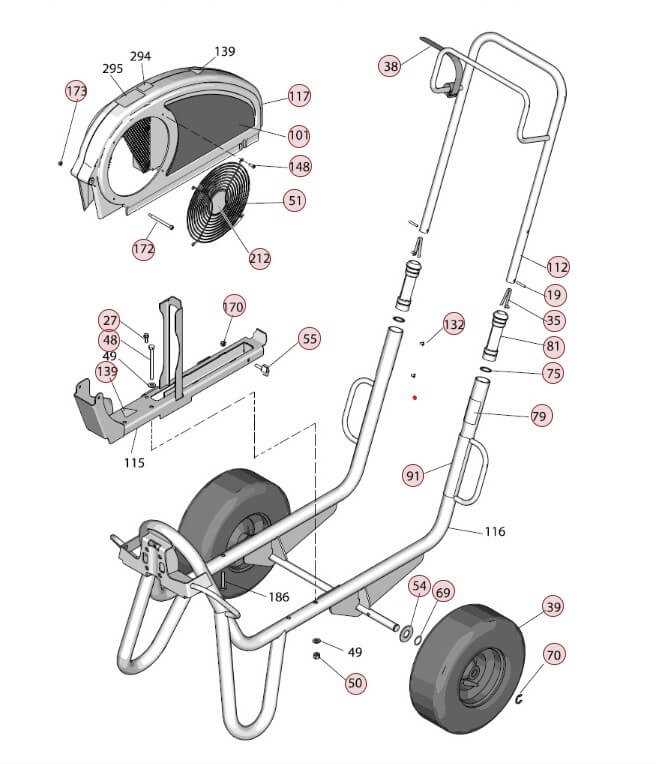

Understanding the Parts Diagram

This section aims to provide insight into the visual representation of components found in a particular machinery model. Grasping this illustration is essential for effective maintenance and troubleshooting, as it serves as a roadmap for identifying individual elements and their functions.

Importance of Component Identification

Recognizing each element’s role is crucial for several reasons:

- Facilitates efficient repairs and replacements.

- Enhances overall understanding of machinery operation.

- Aids in safety precautions during maintenance tasks.

Key Features of the Visual Representation

Familiarizing oneself with the following aspects can greatly improve comprehension:

- Labeling: Each part is marked clearly for easy identification.

- Groupings: Related components are often clustered together, illustrating their interconnections.

- Sequential Layout: The arrangement may follow a logical order, guiding users through the assembly or disassembly process.

Importance of Proper Maintenance

- Enhanced Performance: Regular checks help maintain peak efficiency.

- Cost Savings: Preventive care reduces the likelihood of major repairs.

- Safety: Well-maintained tools minimize risk for users.

- Longevity: Consistent maintenance extends the lifespan of equipment.

In conclusion, investing time and resources into proper maintenance is essential for achieving the ultimate functionality and safety of machinery.

Common Issues and Solutions

In any machinery, certain challenges can arise that affect performance and efficiency. Understanding these common problems, along with their solutions, is crucial for maintaining optimal functionality and extending the equipment’s lifespan.

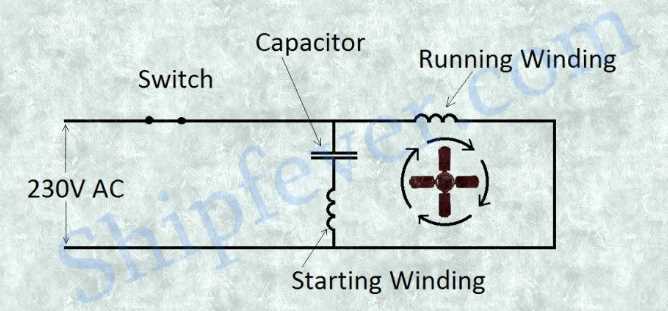

Overheating Problems

One frequent issue is overheating, which can lead to operational failure. This can occur due to insufficient lubrication or blocked air vents. To mitigate this, ensure regular maintenance, including checking oil levels and cleaning ventilation systems.

Starting Difficulties

Another common concern is difficulty in starting the equipment. This may stem from a weak battery or fuel supply issues. To address this, regularly inspect the battery and ensure that the fuel system is free of obstructions and leaks.

Assembly and Disassembly Guide

This section provides essential instructions for putting together and taking apart your equipment effectively. A thorough understanding of the process will enhance both efficiency and safety during operations, ensuring that each component is handled correctly.

Assembly Instructions

Begin by organizing all components, ensuring you have everything needed for the setup. Follow the sequential steps, aligning each part carefully as specified. Use the appropriate tools for secure fittings, and double-check connections to guarantee stability and functionality.

Disassembly Steps

To disassemble, reverse the assembly process. Start by loosening any fasteners and removing components systematically. Pay attention to any fragile parts to avoid damage. Store all pieces securely for future reassembly, keeping them organized for convenience.

Comparison with Other Mixers

When evaluating different mixing devices, it’s essential to consider various factors such as performance, design, and versatility. This comparison sheds light on how a specific model stands out in relation to its competitors, highlighting strengths and potential weaknesses.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 3 HP | 2.5 HP | 3.5 HP |

| Weight | 100 lbs | 85 lbs | 120 lbs |

| Drum Capacity | 3 cu ft | 2 cu ft | 4 cu ft |

| Portability | Moderate | High | Low |

| Price | $500 | $400 | $600 |

Ultimately, the choice of a mixing machine depends on specific needs and applications. The unique attributes of each device contribute to its suitability for various tasks, making careful consideration vital for optimal performance.

Safety Precautions During Use

Ensuring safety while operating equipment is crucial to prevent accidents and injuries. Adhering to specific guidelines can enhance not only personal safety but also the overall efficiency of tasks. Proper preparation and awareness of potential hazards are fundamental steps every user should follow.

Pre-Operation Guidelines

- Inspect the equipment for any signs of wear or damage.

- Ensure all safety guards and features are in place and functional.

- Review the manufacturer’s manual for specific operating instructions.

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and ear protection.

- Ensure a clean work area to prevent slips and falls.

Operational Safety Tips

- Maintain a stable stance and secure grip while operating.

- Keep hands and clothing clear of moving parts to avoid entanglement.

- Be aware of your surroundings and avoid distractions during use.

- Do not overload the machine beyond its recommended capacity.

- Shut down and unplug the equipment when making adjustments or repairs.

By following these precautions, users can significantly reduce risks associated with operation and promote a safer working environment.

Recommended Accessories for Efficiency

Enhancing productivity and ensuring optimal performance in construction tasks often hinges on the right tools and attachments. By incorporating specific accessories, users can streamline their workflow and achieve superior results while minimizing effort and time.

Essential Add-ons

Investing in quality components can significantly impact the efficiency of operations. For instance, using a durable mixing paddle can ensure a uniform blend, while a reliable stand provides stability during use. Additionally, integrating a portable water tank allows for seamless mixing without interruptions.

Safety and Comfort Features

Prioritizing safety and comfort is crucial for effective operation. Accessories such as noise-canceling ear protection and ergonomic grips enhance user experience, reducing fatigue and the risk of accidents. Moreover, using a sturdy transport cart simplifies the movement of equipment, making it easier to handle heavy loads.

In conclusion, selecting appropriate accessories not only boosts efficiency but also contributes to a safer and more enjoyable working environment.

Tips for Optimal Performance

Achieving maximum efficiency in equipment operation requires attention to detail and proactive maintenance practices. By following key strategies, users can ensure reliable performance and extend the lifespan of their machinery. This section highlights essential tips that will help in optimizing functionality and minimizing potential downtime.

Regular Maintenance Checks

Routine inspections are crucial for identifying wear and tear before they lead to significant issues. Schedule periodic maintenance to examine key components and ensure that everything is functioning smoothly. Keeping an eye on critical parts can prevent unexpected failures and costly repairs.

Proper Usage Techniques

Utilizing equipment according to manufacturer guidelines significantly impacts its performance. Always follow recommended procedures for operation, and be mindful of load limits to avoid overworking the machine. Training users on proper techniques will not only enhance safety but also improve overall efficiency.

User Experiences and Testimonials

This section delves into the perspectives and feedback from individuals who have utilized the equipment. Their insights shed light on the practical applications, benefits, and occasional challenges faced during operation. Real-life accounts serve as a valuable resource for potential users, offering a glimpse into the functionality and performance of the machinery.

Customer A shared, “Using this model has transformed my workflow. The efficiency it brings is unmatched, allowing me to complete tasks in a fraction of the time.”

Customer B remarked, “I initially had concerns about the ease of use, but the intuitive design made it simple to get started. It’s become an essential part of my toolkit.”

Customer C noted, “While the performance exceeded my expectations, I encountered minor issues with maintenance. However, the customer service team was incredibly helpful and responsive.”

These testimonials highlight the diverse experiences of users, illustrating how the equipment meets various needs while also emphasizing the importance of support and reliability.