Ao Smith Pool Pump Motor Parts Diagram Explained

In the realm of aquatic systems, comprehending the intricate elements that contribute to optimal functionality is crucial. A detailed examination of these components not only enhances performance but also prolongs the lifespan of the entire apparatus.

By exploring various schematics, one can uncover the specific roles each element plays within the assembly. This knowledge serves as the ultimate guide for maintenance and troubleshooting, ensuring a seamless operation.

For enthusiasts and professionals alike, having access to accurate visual representations fosters a deeper understanding of how these mechanisms interconnect. This exploration enables users to delve into the intricacies of their systems with confidence and expertise.

Understanding A.O. Smith Pool Pumps

A.O. Smith products are renowned for their reliability and efficiency in maintaining aquatic environments. These devices play a crucial role in ensuring cleanliness and optimal water circulation. Understanding the components and functioning of these machines can enhance their performance and longevity.

Each unit comprises several essential elements that work in harmony to achieve desired results. The design and engineering behind these systems reflect a commitment to innovation and quality, allowing users to enjoy a seamless experience.

Regular maintenance is vital for preserving the integrity of these units. Knowledge of the various components can assist owners in identifying potential issues before they escalate. Familiarity with the workings of the equipment ensures effective troubleshooting and repair.

Investing time in understanding these mechanisms can lead to better decision-making when it comes to upgrades and replacements. Moreover, having a grasp of how each part interacts will aid in maximizing the efficiency of the entire system.

In summary, appreciating the intricacies of A.O. Smith offerings not only enhances user experience but also contributes to a well-maintained aquatic environment.

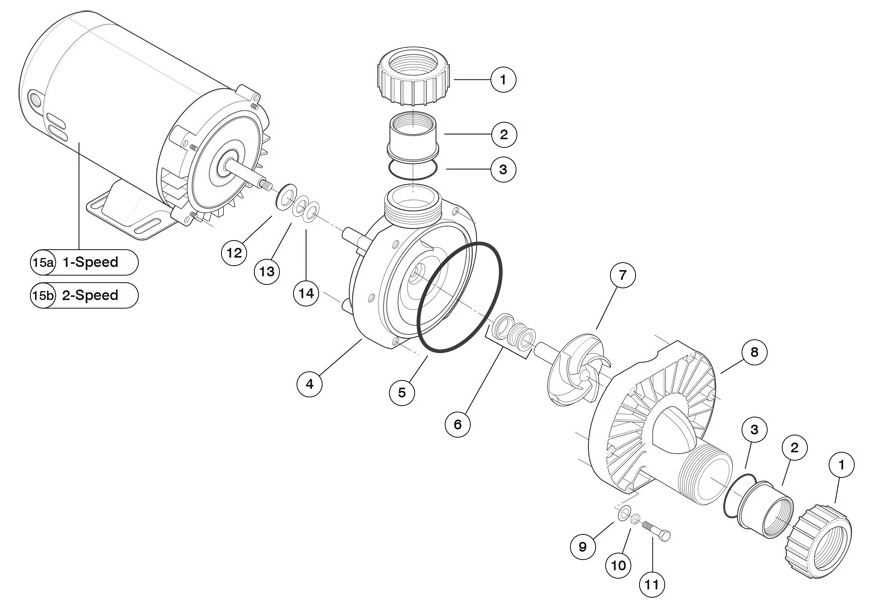

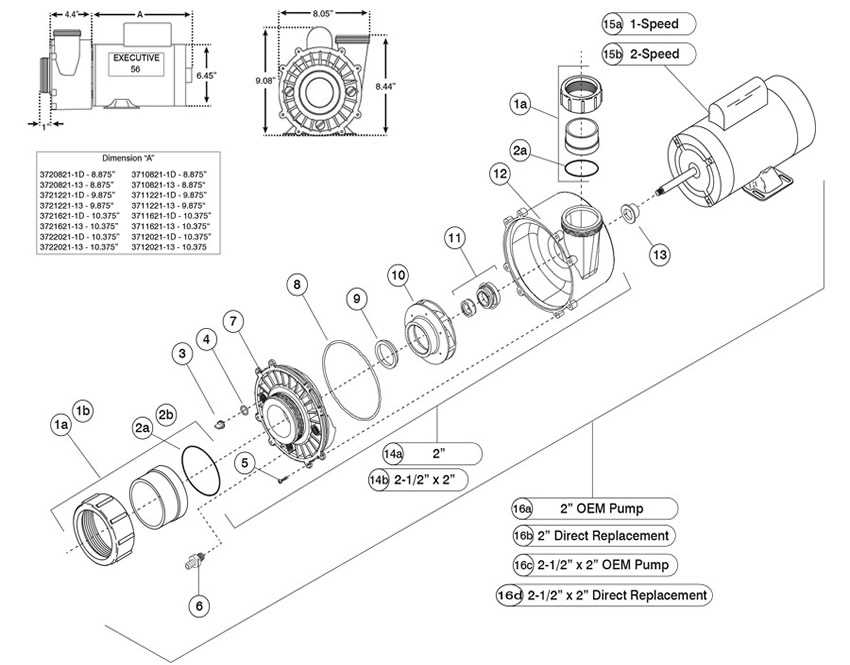

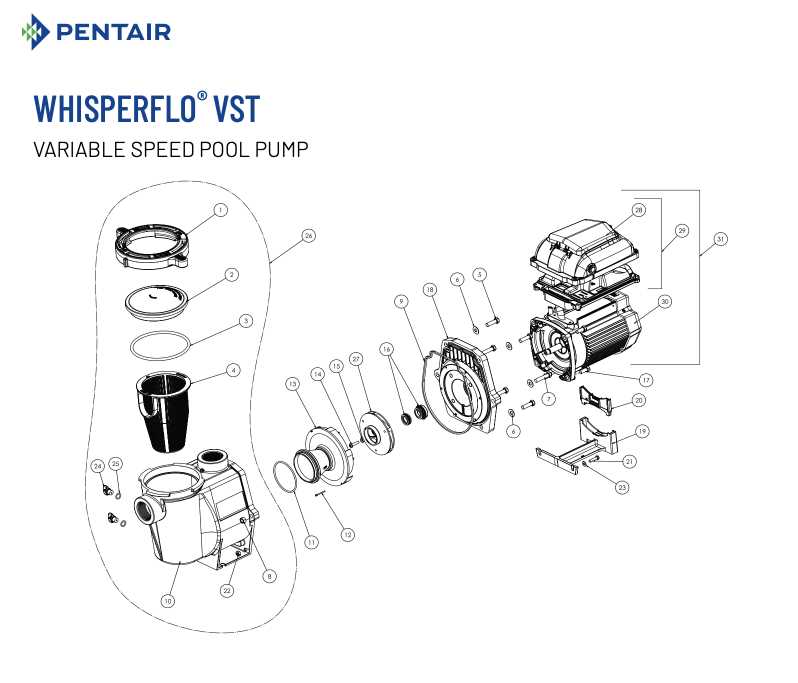

Components of Pool Pump Motors

The efficiency and functionality of a water circulation system hinge on various essential elements. Understanding these components aids in maintenance and troubleshooting, ensuring longevity and optimal performance.

Key Elements

- Housing: Provides structural integrity and protection for internal components.

- Impeller: Drives water movement, crucial for flow generation.

- Diffuser: Directs the flow from the impeller, enhancing efficiency.

- Seal: Prevents leaks, ensuring a secure and efficient operation.

Support Structures

- Base: Stabilizes the entire assembly, minimizing vibrations.

- Mounting Brackets: Facilitates secure attachment to surrounding structures.

- Cooling Fan: Helps maintain optimal operating temperatures during use.

Common Issues with A.O. Smith Motors

A.O. Smith units are renowned for their durability and efficiency, yet they are not immune to certain challenges. Understanding these common difficulties can aid users in maintaining optimal performance and extending the lifespan of their equipment.

One prevalent concern involves overheating, which can stem from insufficient ventilation or overloading. Users should ensure that the environment around the unit is well-ventilated and that the device is not working beyond its capacity.

Another issue often reported is unusual noise during operation. This may indicate a problem with bearings or alignment. Regular inspections and maintenance can help identify such issues early on, preventing more significant damage.

Electrical failures, including issues with wiring or connections, can disrupt functionality. Users should regularly check for frayed wires or loose connections to ensure reliable operation.

Lastly, performance inconsistency can arise from wear and tear on internal components. Routine maintenance, including lubrication and parts replacement, can mitigate these effects and ensure consistent performance.

Maintenance Tips for Pool Equipment

Proper upkeep of aquatic machinery is essential for ensuring longevity and optimal performance. Regular attention to various components can prevent issues and enhance efficiency, allowing for a more enjoyable experience. Here are some essential strategies to maintain your equipment effectively.

Regular Cleaning

Frequent cleaning of all apparatus is crucial. Debris and dirt can accumulate, leading to inefficiencies or even malfunctions. Ensure to clear out any obstructions, and use suitable cleaning solutions to maintain surfaces and mechanical parts. This not only enhances performance but also prolongs the lifespan of the equipment.

Routine Inspections

Conducting regular inspections allows you to catch potential problems early. Check for signs of wear or damage, such as leaks or unusual noises. Pay special attention to seals, connections, and electrical components. Keeping a log of these inspections can help track changes over time and identify patterns that may indicate a need for service.

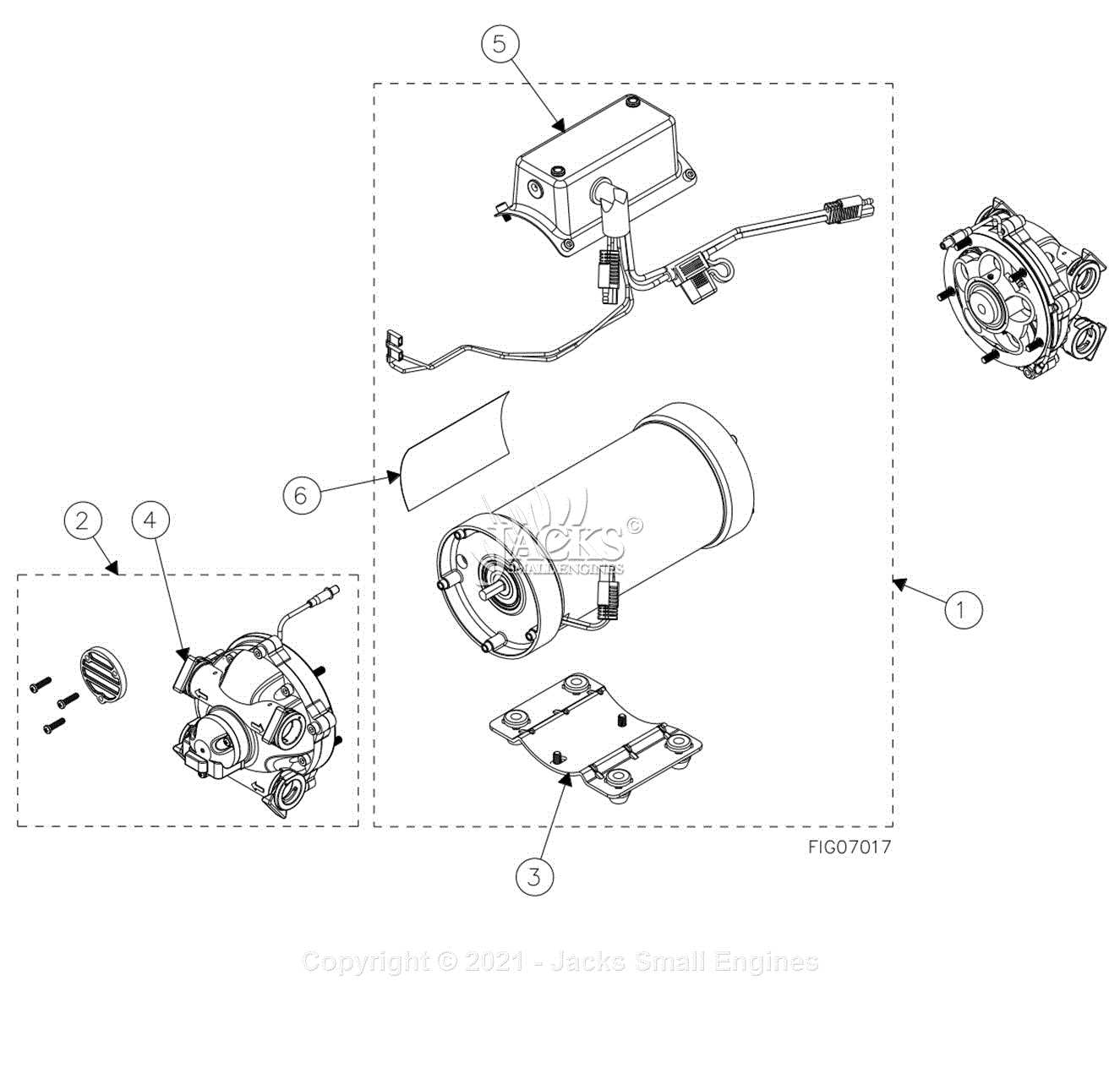

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to troubleshoot and maintain your equipment. Familiarizing yourself with these visual aids allows you to identify each element’s function and relation to the whole system. By grasping the symbols and layout, you can more effectively plan repairs or replacements.

Identifying Symbols and Labels

Every illustration uses specific symbols to represent different components. Pay attention to the key or legend provided, as it explains what each symbol signifies. Often, elements will have numbers or letters corresponding to a list, making it easier to find replacements or to reference in manuals. Take your time to familiarize yourself with these representations, as they are crucial for understanding the entire setup.

Understanding Connections and Flow

Look at how the various elements are interconnected. Arrows often indicate the direction of flow or movement, which is essential for recognizing how the system operates. Following these pathways can help you understand how changes to one component might affect others, ensuring a comprehensive grasp of the assembly’s functionality.

Replacing Parts in Pool Motors

Maintaining the efficiency of your aquatic equipment often requires the replacement of various components. Understanding how to identify and substitute these elements can extend the lifespan of the system and improve overall performance. This section delves into the essential steps and considerations involved in this crucial maintenance task.

When embarking on the journey of component replacement, it is vital to first diagnose the issue accurately. Identifying the malfunctioning part is the key to ensuring that the correct replacements are sourced. Familiarity with the system’s assembly and functionality can greatly aid in this process.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Seals | Leakage or corrosion | Ensure proper size and material compatibility |

| Bearings | Unusual noises or vibrations | Use high-quality replacements to prevent future issues |

| Capacitor | Starting difficulties or inconsistent operation | Check voltage ratings before purchasing |

| Impeller | Reduced flow or blockage | Inspect for cracks and ensure proper fit |

Always refer to the manufacturer’s recommendations for specific guidelines on replacement procedures. Following the correct methods not only enhances functionality but also safeguards against potential damage to the system. Emphasizing precision and attention to detail during this process can lead to significant improvements in performance and reliability.

Identifying Motor Types and Models

Understanding the various types and models of machinery is crucial for effective maintenance and repair. Each design comes with distinct features and specifications, which can impact functionality and efficiency. By familiarizing yourself with these variations, you can ensure optimal performance and longevity.

Key Characteristics to Consider

When examining different designs, several characteristics play a pivotal role. These include voltage requirements, horsepower ratings, and construction materials. Analyzing these elements can help distinguish between models.

Common Types of Machinery

| Type | Description |

|---|---|

| Induction | Widely used for reliability and efficiency in various applications. |

| Capacitor Start | Known for high starting torque, ideal for heavy loads. |

| Permanent Split Capacitor | Offers a good balance of efficiency and low maintenance. |

Benefits of Quality Pool Pumps

Investing in high-quality circulation devices brings numerous advantages that enhance the overall experience of aquatic environments. These devices not only improve water clarity but also contribute to energy efficiency and longevity.

Improved Efficiency

- Optimized performance leads to faster water circulation.

- Reduced energy consumption, saving on utility bills.

- Consistent operation minimizes wear and tear.

Enhanced Durability

- Robust construction withstands harsh conditions.

- Longer lifespan reduces the need for frequent replacements.

- Reliable components minimize maintenance costs.

Safety Precautions During Repairs

When undertaking maintenance tasks on equipment, prioritizing safety is essential. Ensuring a secure environment not only protects the individual performing the work but also safeguards the surrounding area from potential hazards. By adhering to specific guidelines, one can minimize risks and enhance the overall efficiency of the repair process.

Before starting any repair, disconnecting the power supply is crucial to prevent accidental activation. Wearing appropriate protective gear, such as gloves and goggles, can shield against injuries. Additionally, keeping tools organized and in good condition helps avoid mishaps. It is advisable to work in a well-ventilated space to mitigate exposure to harmful fumes and ensure comfort during prolonged tasks.

Finally, having a clear understanding of the equipment’s specifications and following the manufacturer’s instructions are vital. This knowledge allows for effective troubleshooting and minimizes the likelihood of errors, contributing to a safer working environment.

Comparing A.O. Smith to Competitors

In the realm of energy-efficient solutions for residential and commercial applications, various manufacturers vie for consumer attention. Among these, one brand stands out for its commitment to quality and innovation. This section explores how this leading name measures up against other industry players, focusing on performance, reliability, and customer satisfaction.

Performance and Efficiency

When evaluating energy efficiency, the brand in question consistently delivers exceptional results. Many competitors offer similar products; however, the unique technology employed ensures superior functionality and lower operational costs. This advantage can significantly influence consumer choice, especially for those prioritizing long-term savings.

Reliability and Support

Reliability is paramount when selecting any device, and this brand has built a solid reputation for durability. Customer feedback highlights fewer maintenance issues compared to alternatives, leading to less downtime. Additionally, robust customer support services enhance the overall user experience, providing assistance and solutions swiftly.

Ultimately, while various manufacturers present compelling options, the combination of performance, reliability, and customer care positions this brand as a formidable contender in the market.

Resources for Pool Pump Maintenance

Proper upkeep of your aquatic circulation system is crucial for longevity and efficiency. Utilizing the right materials and knowledge can make maintenance a straightforward process. This section provides various tools and information sources to enhance your care routine.

Essential Tools

Having the correct instruments at your disposal simplifies maintenance tasks. Below are some fundamental items needed for effective service:

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening or loosening fittings |

| Screwdriver Set | To adjust or replace screws in the system |

| Cleaning Brushes | For removing debris and buildup |

| Vacuum Gauge | To assess suction levels |

Informational Resources

Understanding the components and functioning of your setup is vital. Explore manuals and online tutorials that provide detailed insights and troubleshooting techniques.