Understanding the Motorguide X3 Parts Diagram for Better Maintenance

When navigating the waters, having a reliable propulsion system is essential for a seamless experience. Knowing the intricacies of your motor’s assembly can significantly enhance its performance and longevity. By familiarizing yourself with each element, you can ensure that your equipment remains in optimal condition, ready for any adventure.

In this section, we will explore the various elements that contribute to the functionality of your trolling device. Each component plays a crucial role, and understanding their arrangement will empower you to troubleshoot issues effectively. Whether you’re a seasoned boater or a newcomer, a solid grasp of these mechanical aspects is invaluable.

Moreover, having access to a comprehensive overview of these elements allows you to make informed decisions regarding maintenance and upgrades. This knowledge can lead to the ultimate enhancement of your on-water experience, ensuring that you get the most out of your equipment every time you set sail.

Understanding the Motorguide X3 System

The system in question is designed to enhance aquatic navigation and maneuverability, providing users with a reliable solution for their boating needs. Its innovative features facilitate seamless control, ensuring optimal performance in various water conditions. This technology represents a culmination of engineering prowess aimed at delivering the ultimate experience for enthusiasts and professionals alike.

Core components play a vital role in the functionality of this setup. Each element works in harmony to ensure precise responsiveness, allowing for effortless steering and propulsion. Understanding these components is essential for anyone looking to maximize their operational efficiency.

Moreover, maintenance of this system is crucial for longevity and reliability. Regular inspections and timely replacements of worn parts can prevent malfunctions, ensuring that the equipment remains in top condition. By delving into the specifics of upkeep, users can achieve sustained performance throughout their journeys.

Key Components of Motorguide X3

This section explores the essential elements that contribute to the overall functionality and efficiency of the trolling motor. Understanding these components is crucial for maintenance and performance enhancement.

- Propeller: The primary element responsible for thrust, influencing speed and maneuverability.

- Motor Housing: Protects internal components and houses the electrical mechanisms.

- Control System: Allows for easy operation and adjustments while on the water.

- Shaft: Connects the propeller to the motor and determines the depth at which it operates.

- Mounting Bracket: Secures the unit to the boat, providing stability during use.

Each of these components plays a vital role in the overall performance and durability of the system, ensuring an enjoyable boating experience.

Benefits of Proper Maintenance

Regular upkeep of equipment is essential for ensuring optimal performance and longevity. A well-maintained system not only functions more efficiently but also minimizes the risk of unexpected breakdowns. By investing time in routine care, users can enjoy a range of advantages that contribute to overall satisfaction and reliability.

Enhanced Performance

Proper care leads to improved functionality and responsiveness. Key benefits include:

- Increased efficiency in operation

- Reduced energy consumption

- Consistent output quality

Cost Savings

Investing in regular maintenance can lead to significant financial benefits over time:

- Lower repair costs by preventing major issues

- Extended lifespan of equipment

- Improved resale value

Overall, prioritizing maintenance is a smart strategy for maximizing both performance and savings.

Common Issues and Solutions

When operating a marine propulsion system, users often encounter various challenges that can affect performance and reliability. Understanding these common problems and their corresponding solutions is essential for maintaining optimal functionality.

Frequent Problems

- Poor Performance

- Unusual Noises

- Electrical Failures

- Overheating

- Steering Issues

Possible Solutions

- Poor Performance: Check the battery charge and ensure proper connections. Inspect the propeller for damage or debris.

- Unusual Noises: Examine for loose components and ensure everything is securely fastened. Lubricate moving parts as necessary.

- Electrical Failures: Test the circuit connections and replace any faulty fuses. Confirm that the control system is functioning correctly.

- Overheating: Inspect the cooling system for blockages and ensure that water intake is unobstructed. Replace any worn-out components.

- Steering Issues: Verify the alignment of the steering system and check for any obstructions. Adjust or replace worn cables as needed.

Finding Replacement Parts Easily

Locating the necessary components for your equipment can be a straightforward process if approached systematically. By utilizing the right resources and strategies, you can ensure that you have access to quality replacements without unnecessary hassle.

- Online Retailers: Explore dedicated websites that specialize in marine gear. They often provide detailed catalogs for easy navigation.

- Manufacturer Resources: Check the official site for your equipment. They usually offer detailed guides and a list of authorized distributors.

- Community Forums: Engage with fellow enthusiasts in online communities. They can offer insights and recommendations based on personal experiences.

- Local Shops: Visit nearby marine supply stores. Local experts can often assist you in identifying what you need.

By leveraging these resources, you can delve into the specifics of your requirements and find the ultimate solutions for your equipment restoration needs.

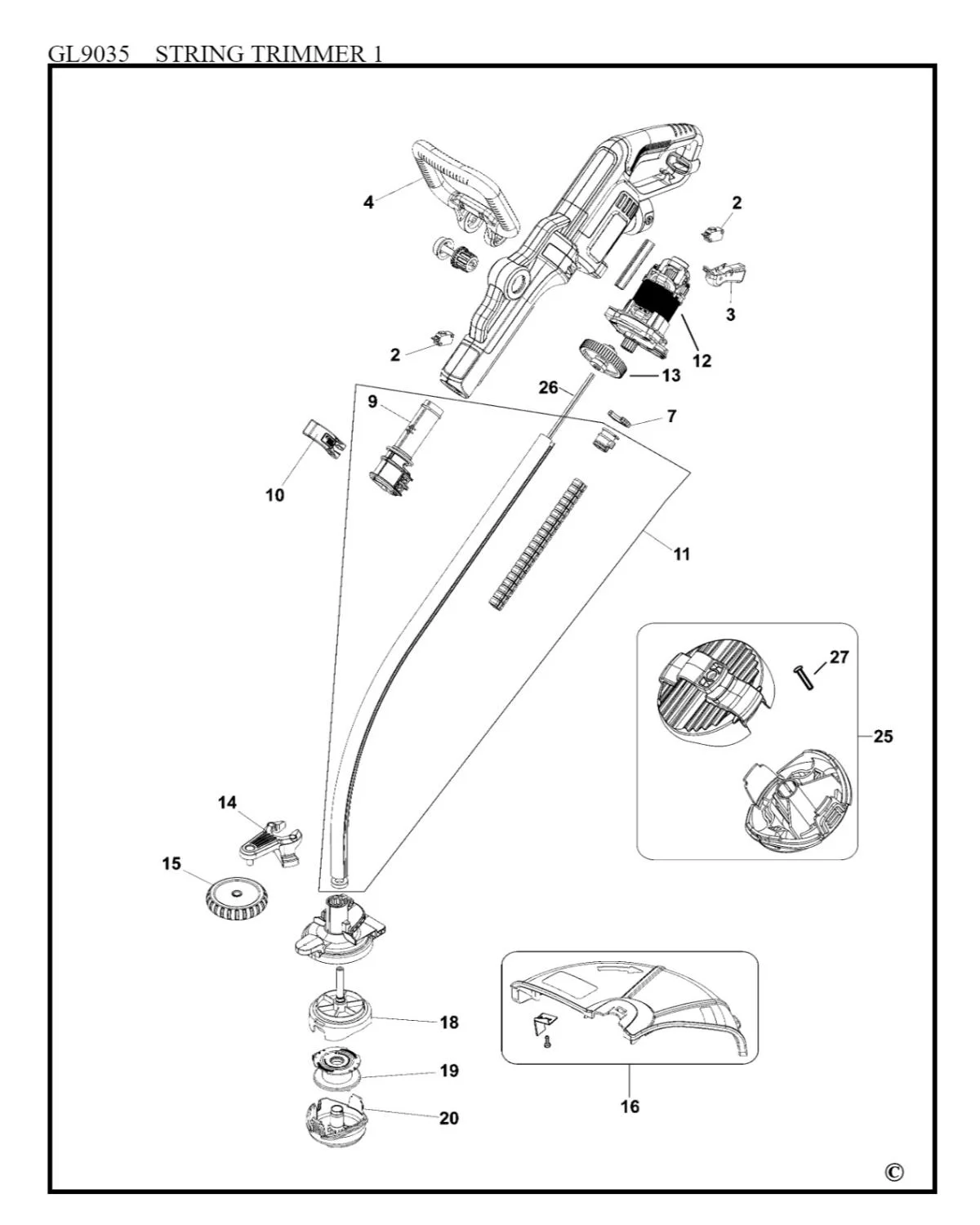

How to Read Parts Diagrams

Understanding schematic representations is crucial for effective maintenance and repair of equipment. These illustrations provide a visual breakdown of components, helping users identify each element and its function within the assembly. Mastering the ability to interpret these visuals can significantly enhance your troubleshooting and assembly skills.

To begin, familiarize yourself with the symbols and notations commonly used in these representations. Each element is usually labeled with a reference number or code, corresponding to a list detailing specifications or part names. This key will guide you in identifying the various sections and components within the visual.

| Symbol | Description |

|---|---|

| A | Motor assembly |

| B | Control unit |

| C | Power source |

| D | Mounting bracket |

Next, analyze the layout to understand how components interact with one another. Look for connecting lines or arrows that indicate the relationship between different parts, which will provide insight into the operational flow and assembly order.

Finally, always cross-reference with the accompanying documentation. This will ensure you have the correct specifications and installation instructions, allowing for a more accurate understanding of the system as a whole.

Tools Needed for Repairs

When it comes to performing maintenance and fixing issues, having the right instruments is crucial for a successful outcome. Proper equipment not only simplifies the process but also ensures that repairs are carried out effectively and safely. Below is a list of essential tools you may need for various repair tasks.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for loosening or tightening screws.

- Wrenches: Adjustable wrenches and socket sets help with nuts and bolts of various sizes.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Multimeter: A vital tool for diagnosing electrical issues, measuring voltage, current, and resistance.

- Cutting Tool: Wire cutters or snips are essential for cutting through cables and other materials.

- Lubricants: Keep moving parts operating smoothly with the appropriate oils or greases.

- Cleaning Supplies: Rags, brushes, and cleaning solutions help maintain a tidy workspace and components.

Having these tools on hand will prepare you for most repair situations, allowing you to tackle projects with confidence and efficiency. Always ensure that your tools are in good condition for optimal performance.

Assembly Tips for Beginners

Embarking on a new assembly project can be both exciting and daunting, especially for those who are just starting out. Having a clear understanding of the steps involved can greatly enhance the experience and lead to successful completion. This section offers valuable insights and practical advice to ensure a smooth assembly process.

1. Familiarize Yourself with Components: Before diving into the assembly, take the time to examine each component carefully. Understanding their functions and how they interconnect will make the process more intuitive. Use a reference guide to identify each piece and its role in the overall setup.

2. Organize Your Workspace: A clutter-free environment is essential for efficient assembly. Gather all necessary tools and components in one location to minimize distractions. Keeping everything organized not only speeds up the process but also helps prevent misplacing parts.

3. Follow Instructions Carefully: Whether you have a manual or a video guide, adhere closely to the provided instructions. Pay attention to each step, as skipping or misinterpreting information can lead to complications later on. If a particular step is unclear, don’t hesitate to seek additional resources.

4. Take Your Time: Rushing through the assembly can lead to mistakes. Allow yourself ample time to complete each phase, ensuring that everything fits together correctly. Patience is key to achieving a well-constructed final product.

5. Double-Check Your Work: After completing each section, take a moment to review your work. Ensuring that every component is securely attached and aligned can save you from potential issues down the line. This extra step can also provide peace of mind that everything is in order.

6. Ask for Help: If you encounter difficulties or uncertainties, don’t hesitate to reach out for assistance. Whether from friends, family, or online forums, seeking help can provide new perspectives and solutions that you may not have considered.

By following these tips, beginners can approach their assembly projects with confidence and clarity. With practice and attention to detail, the assembly process will become increasingly manageable and enjoyable.

Exploring Wiring Connections

Understanding the intricacies of electrical connections is essential for optimal functionality and safety. This section delves into the various aspects of wiring setups, highlighting the importance of proper installation and maintenance.

Key Components of Wiring Systems

- Connectors: Ensure secure and reliable links.

- Cables: Choose appropriate types for specific applications.

- Switches: Control the flow of electricity efficiently.

Best Practices for Wiring

- Always refer to the manufacturer’s specifications.

- Use quality materials to prevent issues.

- Label connections for easier troubleshooting.

Upgrading Your Motorguide X3

Enhancing the performance of your trolling system can lead to a more enjoyable experience on the water. This process not only improves efficiency but also extends the lifespan of your equipment. Below are some considerations for making your unit more effective.

Key Improvements

- Upgrade the propeller for better thrust and speed.

- Consider installing a more advanced control system for greater responsiveness.

- Replace the battery with a higher capacity option for extended runtime.

Maintenance Tips

- Regularly check and tighten connections to ensure optimal performance.

- Clean the unit thoroughly to prevent buildup and corrosion.

- Inspect the wiring for any signs of wear or damage.

Safety Precautions During Repairs

When undertaking maintenance or repairs on any equipment, prioritizing safety is essential to prevent accidents and ensure a smooth process. Proper precautions not only protect the individual performing the work but also extend the lifespan of the machinery.

Essential Safety Measures

- Always disconnect power sources before starting any repair.

- Use appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Ensure the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Keep a first aid kit nearby in case of emergencies.

Tool and Equipment Handling

- Inspect all tools for damage before use.

- Store tools in a designated area to avoid tripping hazards.

- Follow manufacturer instructions for equipment operation and repair.

Comparing Models: X3 vs Others

When evaluating different models within a specific category, it’s essential to understand the unique features and advantages each brings to the table. The X3 stands out in several key aspects, making it a noteworthy option among its peers. This section explores the distinctions and similarities to help potential users make informed decisions.

Performance and Durability

The X3 offers a robust performance that can rival many competitors. Its design emphasizes durability, making it suitable for various water conditions. In contrast, some alternatives may prioritize lightweight construction, which can impact longevity under challenging circumstances.

Technology and Features

In terms of technology, the X3 integrates advanced functionalities that enhance user experience. Features like precision steering and responsive controls provide a level of ease that some other models lack. However, certain brands may offer specialized tools tailored to specific user needs, emphasizing the importance of individual preferences in the selection process.

Customer Reviews and Experiences

This section highlights the voices of users who have shared their insights and stories about their experiences with their equipment. Feedback from customers provides valuable perspectives that can guide potential buyers and inform them about both the advantages and challenges associated with the product.

Many users appreciate the reliability and performance of their systems, often noting the ease of use and the quality of construction. Conversely, some reviews express concerns regarding specific components and their maintenance requirements, offering a well-rounded view for future users.

| Review Summary | Positive Aspects | Areas for Improvement |

|---|---|---|

| Solid Performance | Reliable in various conditions | Regular maintenance needed |

| User-Friendly | Intuitive controls | Instruction manual could be clearer |

| Durable Design | High-quality materials | Some parts may wear out quickly |

By examining these testimonials, prospective users can gain a clearer understanding of what to expect, enabling them to make informed decisions tailored to their needs.