Understanding the Dr Brush Mower Parts Diagram for Efficient Maintenance

Maintaining your outdoor machinery requires a thorough understanding of its inner workings. By exploring the intricate connections between each element, you can ensure optimal performance and longevity. This section aims to provide insights into how each segment contributes to the overall functionality.

Gaining clarity on the various mechanisms involved can significantly enhance your maintenance skills. Familiarity with the essential components allows users to identify issues promptly and address them effectively. Ultimately, this knowledge fosters a more reliable operation of your equipment.

As you delve deeper into the specifics, you will uncover the ultimate benefits of being well-versed in these crucial elements. Understanding each function not only aids in repairs but also enhances your ability to utilize the machinery to its full potential.

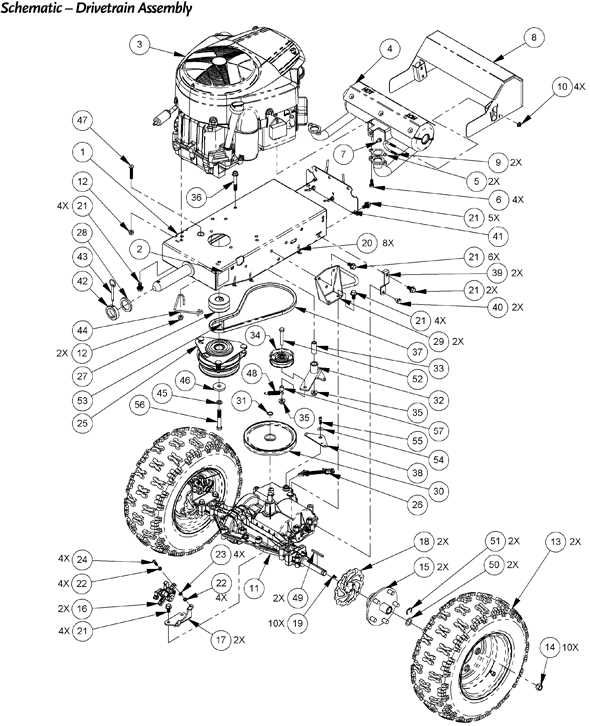

Understanding Dr Brush Mower Components

When operating a specialized machine designed for tackling dense vegetation, it’s essential to comprehend the various elements that contribute to its efficiency and functionality. Each component plays a crucial role in ensuring smooth operation, durability, and optimal performance in challenging terrains.

Key sections include the propulsion system, which powers the unit forward, and the cutting mechanism that tackles tough growth. The chassis provides structural integrity, while the controls offer user-friendly interaction. Additionally, maintenance elements ensure longevity and reliability, making understanding these features vital for effective usage.

By delving into the individual components, operators can enhance their knowledge, leading to better care and improved operational effectiveness. This understanding ultimately results in a more productive experience when managing overgrown areas.

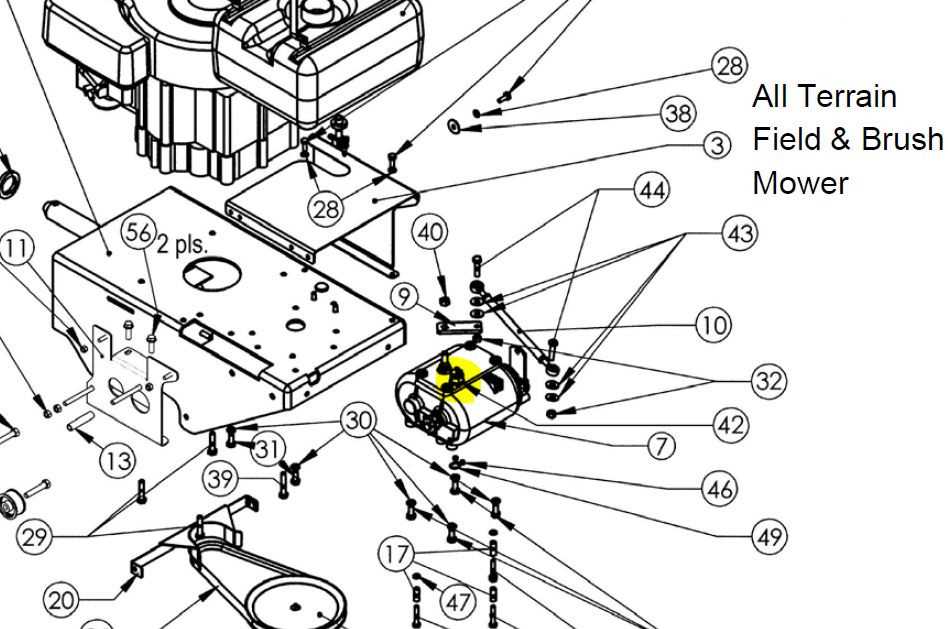

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Clear visual representations enable users to identify specific elements, facilitating quicker troubleshooting and assembly. This knowledge ultimately enhances the longevity and efficiency of the equipment.

Enhanced Troubleshooting

Visual aids streamline the diagnostic process by allowing users to quickly pinpoint issues. When each element is clearly labeled, identifying malfunctions becomes a straightforward task, reducing downtime and improving productivity.

Efficient Assembly and Disassembly

Accurate representations guide users through the assembly and disassembly processes. This clarity minimizes errors and ensures that each component is correctly positioned, promoting optimal performance and safety.

Common Issues with Brush Mower Parts

When it comes to maintenance and operation of outdoor machinery, certain challenges frequently arise that can hinder performance and efficiency. Understanding these common obstacles is crucial for any operator aiming to ensure longevity and reliability of their equipment.

Wear and Tear: Over time, components may experience significant wear, leading to reduced functionality. Regular inspection can help identify signs of deterioration before they escalate.

Clogging: Accumulation of debris can obstruct essential mechanisms, affecting operation. Clearing out these blockages is vital for optimal performance.

Alignment Issues: Misalignment of crucial elements can result in uneven operation and potential damage. Ensuring correct alignment is necessary to maintain smooth functionality.

Fluid Leaks: Any leakage from vital systems can lead to inadequate lubrication or cooling, risking further damage. Regular checks for leaks are essential for preventing more serious issues.

Being proactive in addressing these common challenges can greatly enhance the performance and lifespan of outdoor equipment.

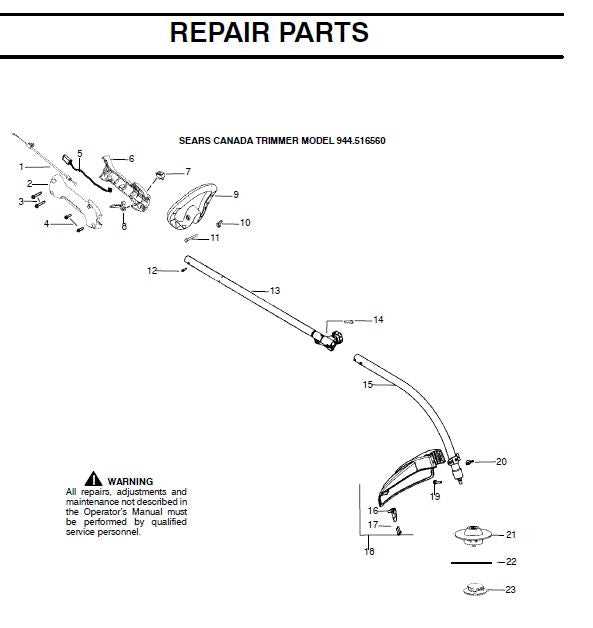

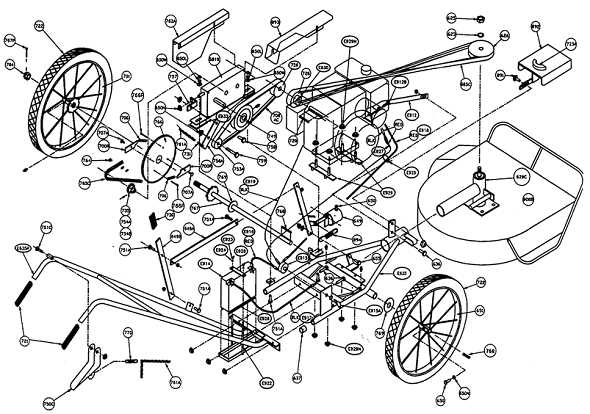

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repairs. These illustrations serve as a roadmap, guiding users through the various components of machinery. By interpreting these visuals, one can easily identify parts, comprehend their functions, and facilitate accurate assembly or disassembly.

When examining a schematic, start by familiarizing yourself with the layout. Often, components are organized logically, either by function or location. Pay attention to labels and numbers, as they correspond to descriptions in accompanying documentation. This connection is crucial for ensuring you grasp the relationship between the parts.

Next, note any symbols or conventions used within the illustration. These may represent specific types of connections or operational elements. Understanding these notations can enhance your overall comprehension of how each piece interacts within the whole system.

Additionally, consider the scale and proportions presented in the visual. Some schematics may not reflect true size, but they provide a relative perspective on how components fit together. This awareness can be invaluable when sourcing replacements or making modifications.

Finally, practice is key. The more you engage with such visuals, the more intuitive reading them will become. With time, you will develop a quicker understanding, making your repair processes smoother and more efficient.

Key Components of Dr Brush Mowers

Understanding the essential elements of these outdoor machines is crucial for effective operation and maintenance. Each component plays a significant role in ensuring efficiency, durability, and overall performance in various terrains.

Engine and Power System

The engine serves as the heart of the equipment, providing the necessary power to navigate through tough vegetation. A reliable power system enhances performance and ensures that the machinery can handle demanding tasks without faltering.

Cutter Mechanism

This element is vital for achieving precise cutting. Designed for efficiency, it can tackle thick growth and ensure a clean finish, making it essential for maintaining landscapes and clearing overgrowth.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor equipment requires regular upkeep and attention. By following a few essential practices, you can extend the lifespan of your machine and maintain its peak performance. Here are some key strategies to consider.

- Regular Cleaning: Keep the exterior free from debris and buildup to prevent rust and corrosion.

- Check Fluid Levels: Regularly inspect and refill oil, fuel, and coolant to ensure optimal operation.

- Inspect Blades: Sharpen or replace cutting elements as needed to maintain cutting efficiency and prevent strain on the engine.

- Air Filter Maintenance: Clean or replace the air filter periodically to promote proper airflow and enhance performance.

Additionally, consider the following practices:

- Routine Inspections: Schedule frequent checks for wear and tear on components, ensuring that any issues are addressed promptly.

- Proper Storage: Store your equipment in a dry, sheltered location to protect it from harsh weather conditions.

- Follow Manufacturer Guidelines: Adhere to the recommended service intervals and maintenance procedures outlined in the user manual.

By implementing these practices, you can maximize the functionality and lifespan of your outdoor machinery, ensuring it serves you well for years to come.

Replacing Worn-Out Parts Effectively

Maintaining optimal performance of any machinery involves timely substitutions of deteriorating components. This process ensures longevity and efficiency, allowing the equipment to function at its best. Recognizing when to replace elements is crucial for preventing further damage and minimizing operational downtime.

Identifying Signs of Wear

Regular inspections are essential for spotting deterioration. Look for signs such as unusual noises, decreased performance, or visible damage. Monitoring these indicators can help determine the right moment for a replacement, ensuring that the device continues to operate smoothly.

Choosing the Right Components

When it’s time to replace items, selecting the correct ones is vital. Always refer to the manufacturer’s specifications to find compatible replacements. Using high-quality alternatives can also enhance performance and extend the lifespan of the equipment, making it a worthwhile investment in the long run.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions should be taken to create a secure working environment, allowing for effective repairs without unnecessary risks.

Personal Protective Equipment

Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear. These items help shield against sharp objects and flying debris, minimizing potential harm.

Work Environment Safety

Keep your workspace organized and free from clutter. Ensure that tools are in good condition and stored properly. Additionally, make sure to disconnect power sources before beginning any work to prevent accidental activation.

Where to Find Replacement Parts

When it comes to maintaining and repairing your equipment, locating the right components is essential for optimal performance. Whether you’re looking for specific elements or general accessories, there are several reliable avenues to explore that can help you acquire what you need efficiently.

Online Retailers

Many online platforms specialize in offering a wide range of components. These websites often provide detailed descriptions and customer reviews, making it easier to find the appropriate items. Some popular options include:

| Website | Description |

|---|---|

| Amazon | A vast selection with competitive pricing and user reviews. |

| eBay | A marketplace for both new and used components, often at lower prices. |

| Manufacturer’s Website | Direct source for genuine items and often includes warranty information. |

Local Dealers and Repair Shops

Visiting local distributors can be advantageous as well. These establishments often have knowledgeable staff who can assist in identifying the right components. Additionally, they may offer the benefit of immediate availability, reducing wait times associated with online orders.

DIY vs. Professional Repairs

When it comes to fixing outdoor machinery, individuals often face the choice between tackling repairs themselves or hiring an expert. Each approach has its advantages and drawbacks, which can significantly impact both the outcome and overall experience.

| Aspect | DIY Repairs | Professional Repairs |

|---|---|---|

| Cost | Typically lower, depending on the extent of the repair. | Higher due to labor and expertise. |

| Time | Can take longer if you lack experience. | Usually quicker with seasoned professionals. |

| Skill Level | Requires a certain level of knowledge and tools. | Expertise ensures reliable results. |

| Control | You have complete oversight of the process. | Less control, as it relies on the technician’s judgment. |

Cost Factors for Replacement Parts

When it comes to maintaining equipment, understanding the financial elements associated with new components is crucial. Various factors influence the overall expenses, impacting both the budget and the decision-making process for users. By evaluating these elements, one can make informed choices that ensure optimal performance without overspending.

Quality and Material

The caliber of materials used in manufacturing new elements plays a significant role in pricing. Higher-quality components often come at a premium, but they can offer enhanced durability and performance, ultimately leading to cost savings in the long run. It’s essential to weigh the benefits of investing in superior materials against the immediate cost implications.

Supplier and Availability

Where one sources replacements can greatly affect costs. Suppliers with a strong reputation may charge more for their offerings, but they often provide better customer service and support. Additionally, the availability of specific components can drive prices up; items that are rare or in high demand may carry a higher price tag due to their scarcity.

Enhancements for Improved Performance

Optimizing machinery can significantly elevate its efficiency and longevity. By focusing on specific upgrades, users can experience enhanced functionality and reduced maintenance costs.

- Regularly inspect and replace worn components to maintain optimal operation.

- Upgrade the power system for better energy efficiency and output.

- Implement advanced cutting technology for cleaner and quicker results.

- Incorporate ergonomic designs to improve user comfort and reduce fatigue.

These enhancements not only boost performance but also contribute to a more satisfying user experience overall.