Kuhn Mower Parts Diagram Guide

In the realm of farming machinery, a comprehensive grasp of the various elements that contribute to efficient operation is essential. Each component plays a pivotal role in ensuring that the equipment functions smoothly and effectively. This section aims to shed light on the intricate arrangements and relationships among these vital elements.

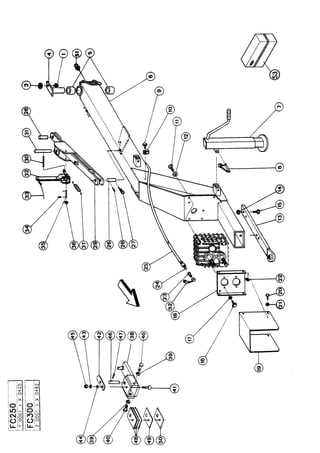

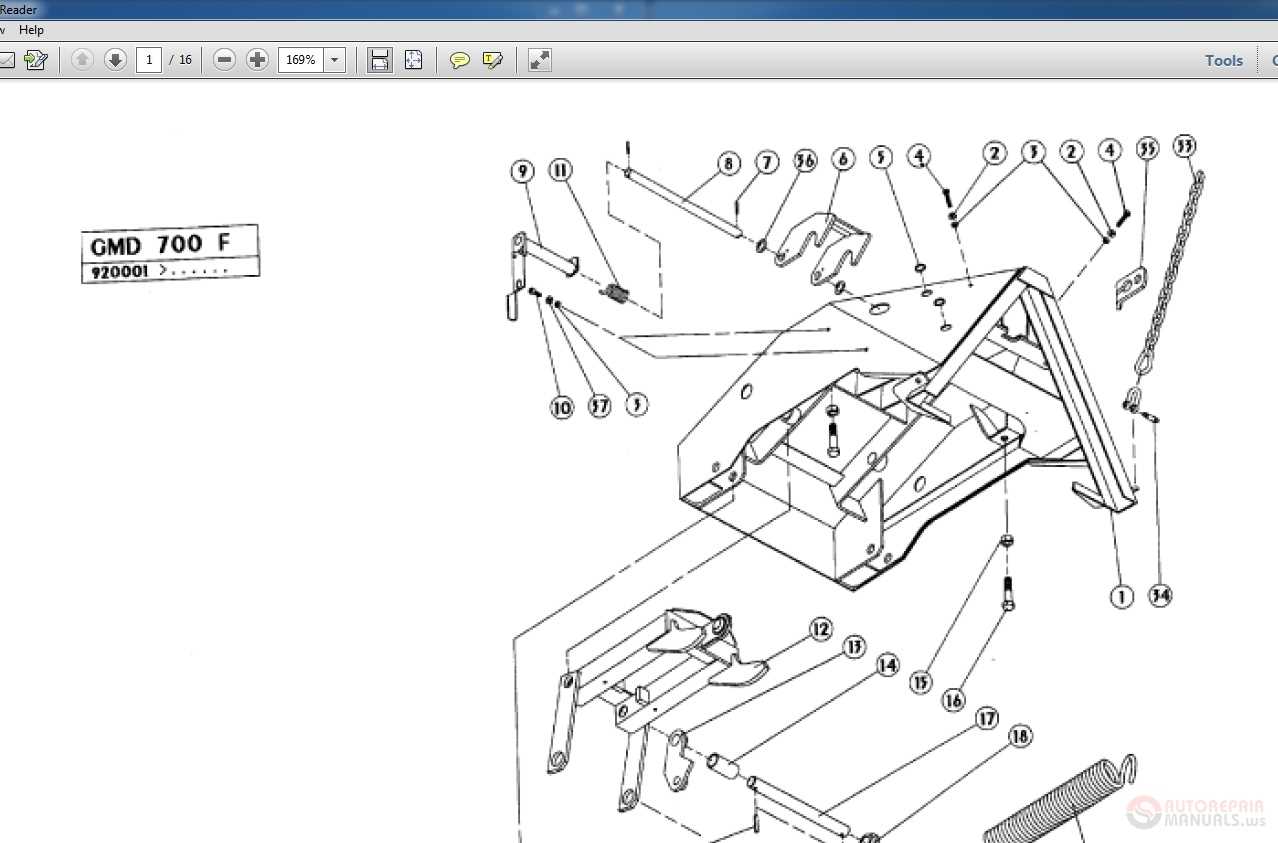

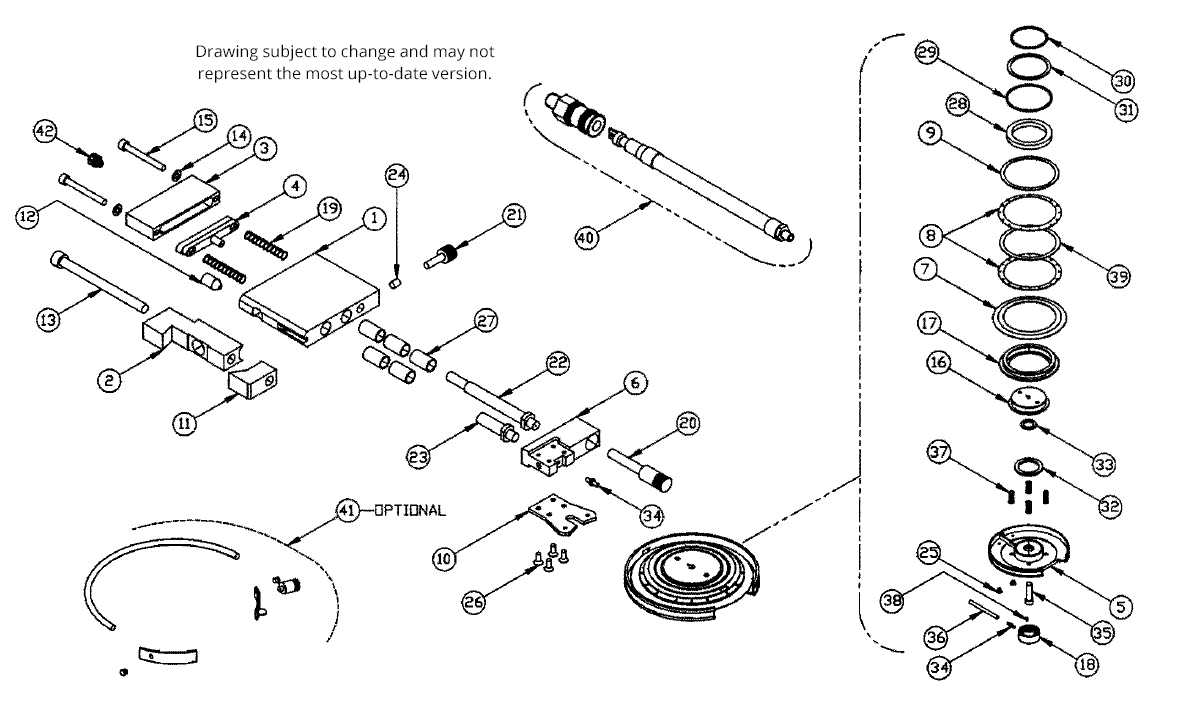

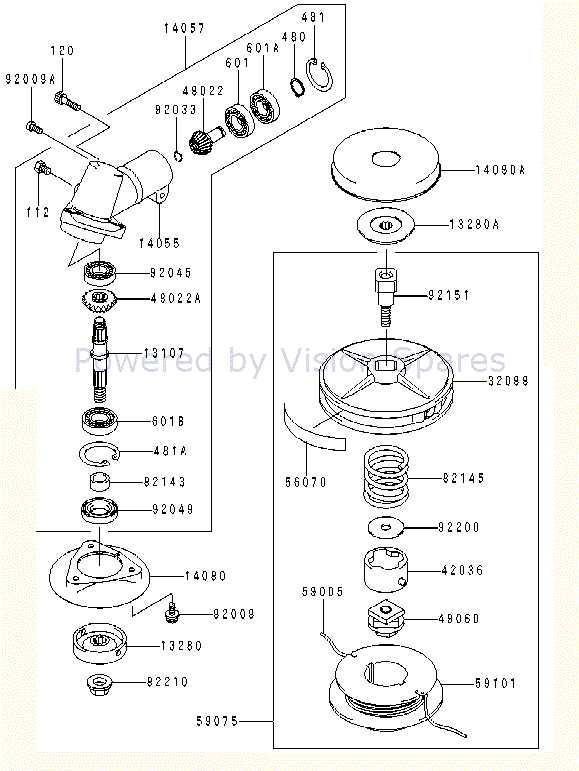

Visual representations can significantly enhance one’s understanding of how different sections interact and contribute to overall performance. By examining these schematics, users can identify specific areas that may require attention or maintenance, ultimately leading to improved functionality.

Moreover, familiarizing oneself with the layout and roles of each segment not only aids in troubleshooting but also fosters a deeper appreciation for the technology involved. This knowledge empowers operators to make informed decisions regarding repairs and enhancements, ensuring that their machinery remains in optimal condition.

Kuhn Mower Parts Overview

This section provides a comprehensive insight into the essential components of agricultural cutting equipment. Understanding these elements is crucial for maintenance, repair, and optimal performance. Each component plays a significant role in the overall functionality, ensuring efficient operation in various conditions.

| Component | Description | Function |

|---|---|---|

| Blades | Sharp cutting instruments that slice through vegetation. | Ensure a clean cut for healthy growth. |

| Gearbox | Mechanical assembly that transfers power from the engine. | Regulates speed and torque for efficient cutting. |

| Frame | Sturdy structure that supports all components. | Provides stability and durability during operation. |

| Wheels | Circular devices that enable mobility. | Facilitate movement across various terrains. |

| Hitch | Connector for attaching to towing vehicles. | Allows for easy transport and maneuverability. |

Familiarity with these vital components enhances the understanding of how equipment functions and assists in identifying potential issues that may arise during use. Regular inspection and maintenance can lead to increased efficiency and longevity of the machine.

Understanding Mower Components

Comprehending the various elements of a cutting machine is essential for efficient operation and maintenance. Each component plays a crucial role in the overall functionality and performance, influencing not only how well the equipment operates but also its longevity.

Engine serves as the heart of the machine, providing the necessary power for operation. It is essential to understand its specifications and maintenance requirements to ensure optimal performance.

Cutting Deck is the part responsible for the actual trimming process. Its design and size can significantly affect the quality of the cut and the ease of maneuverability. Regular inspection of this element is vital for maintaining cutting efficiency.

Blades are critical for achieving a clean and precise cut. Various types are available, each designed for specific tasks. Understanding their characteristics and when to sharpen or replace them is key to effective maintenance.

Wheels and Tires impact the mobility and stability of the machine. Proper tire pressure and tread condition are important for safe and efficient operation, especially on uneven terrain.

Transmission facilitates power transfer from the engine to the wheels, affecting speed and control. Familiarity with its function can help troubleshoot performance issues and ensure a smooth operation.

By gaining insight into these fundamental components, users can enhance their proficiency in handling the equipment, leading to improved results and extended lifespan.

Importance of Maintenance Guidelines

Regular upkeep is crucial for the longevity and optimal performance of any mechanical equipment. Establishing a systematic approach to maintenance ensures that all components function efficiently, reducing the likelihood of unexpected failures and costly repairs. Adhering to these protocols not only enhances reliability but also contributes to safety and user satisfaction.

Key Benefits of Following Maintenance Protocols

- Extended Lifespan: Routine care helps prevent wear and tear, ultimately prolonging the operational life of the machinery.

- Improved Efficiency: Well-maintained equipment operates more smoothly, enhancing overall productivity.

- Cost Savings: Preventive measures reduce the need for extensive repairs, saving money in the long run.

- Safety Assurance: Regular inspections help identify potential hazards, ensuring a safer working environment.

Essential Maintenance Practices

- Conduct regular inspections to identify signs of wear or damage.

- Keep all moving parts lubricated to minimize friction and overheating.

- Replace worn-out components promptly to maintain performance levels.

- Follow the manufacturer’s guidelines for optimal maintenance schedules.

By implementing these practices, users can ensure their equipment remains in peak condition, ultimately fostering a more productive and safe operational experience.

Common Issues with Kuhn Mowers

When operating high-performance agricultural machinery, various challenges can arise that affect efficiency and productivity. Understanding these common problems is essential for maintaining optimal functionality and ensuring longevity of the equipment.

- Engine Troubles: Difficulties with starting or stalling can lead to operational delays. Regular maintenance and inspections can help identify underlying issues.

- Hydraulic Failures: Leaks or inadequate pressure in the hydraulic system can hinder performance. Checking for fluid levels and inspecting hoses is crucial.

- Cutting Mechanism Issues: Dull blades or misalignments can result in uneven cutting. Regular sharpening and proper adjustments are necessary.

- Tire Problems: Flat or worn tires can impact mobility. Regular checks for air pressure and tread condition can prevent these issues.

- Electrical Malfunctions: Problems with wiring or battery failure can lead to operational interruptions. Routine inspections of electrical components are recommended.

By proactively addressing these common challenges, operators can enhance the performance and lifespan of their agricultural tools, ensuring efficient operation and reduced downtime.

How to Access the Parts Diagram

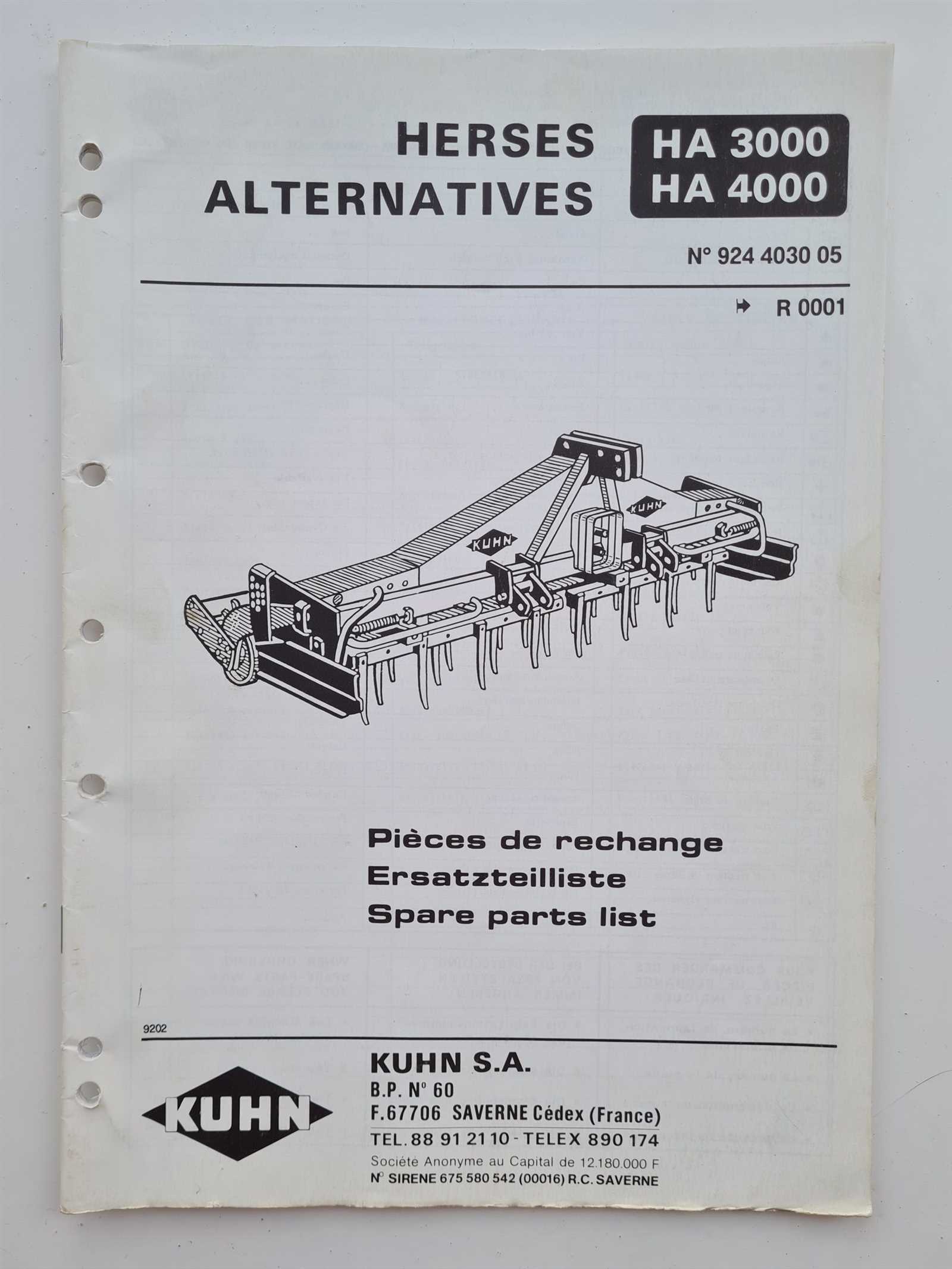

Understanding the components of your equipment is crucial for effective maintenance and repair. Accessing the visual representation of these elements can streamline the process, allowing for better identification and ordering of necessary items. This guide will walk you through the steps to locate and utilize this valuable resource.

Finding the Right Resource

Begin by checking the manufacturer’s official website. Most companies provide an online library of resources, including visual guides for their equipment. Look for sections dedicated to support or product information. Often, these areas include downloadable files or interactive tools that can enhance your understanding.

Utilizing User Manuals

If online resources are unavailable, consider referring to the user manual that accompanied your device. Manuals typically include detailed illustrations and lists of all components. If you cannot locate your manual, many manufacturers offer digital versions that can be accessed for free. This can be particularly helpful in identifying specific items needed for maintenance or replacement.

Tip: Make sure to have the model number on hand, as this will assist in narrowing down your search effectively.

By following these steps, you can easily access the necessary visual guides to ensure your equipment remains in optimal condition.

Identifying Key Components Easily

Understanding the essential elements of any machinery can significantly enhance maintenance and troubleshooting processes. By familiarizing oneself with the core components, users can quickly recognize issues, perform repairs, and ensure optimal functionality. This section aims to provide insight into how to identify these critical elements with ease and confidence.

Common Elements to Recognize

Familiarity with typical components such as the engine, cutting system, and drive mechanism is crucial. Each plays a vital role in overall performance. Recognizing these features allows for quicker assessments when problems arise. For instance, knowing where the power source is located can streamline inspections and maintenance tasks.

Tips for Efficient Identification

To enhance the ability to spot important components, consider using a systematic approach. Referencing manuals or reliable online resources can provide visual aids that clarify each part’s location and function. Additionally, taking the time to label components during maintenance can help in recalling their purpose in the future. Hands-on experience is invaluable; regularly interacting with the machinery will bolster recognition skills over time.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is essential for optimal performance and longevity. Fortunately, there are several reliable avenues to explore when looking for suitable replacements. Understanding where to search can save you time and ensure you obtain the right items for your needs.

Here are some effective options for locating the necessary replacements:

| Source | Description |

|---|---|

| Authorized Dealers | These vendors specialize in original components and often provide expert advice and support. |

| Online Marketplaces | Websites like eBay and Amazon offer a wide range of options, often at competitive prices. |

| Local Repair Shops | Independent mechanics can often source parts directly or may have them in stock. |

| Manufacturer’s Website | The official site usually lists available replacements, along with specifications and ordering information. |

| Second-Hand Stores | These can be treasure troves for hard-to-find components, often at lower prices. |

By exploring these options, you can confidently secure the components you need to keep your machinery in excellent working condition.

Tools Needed for Repairs

When it comes to performing maintenance and repairs on your equipment, having the right tools at your disposal is essential for a smooth and effective process. Properly equipped, you can tackle various tasks with confidence and precision, ensuring optimal functionality and longevity of your machine.

Below is a list of essential instruments that will aid you in your repair endeavors:

- Wrenches: Various sizes will help you loosen and tighten bolts effectively.

- Screwdrivers: A set of flathead and Phillips screwdrivers will allow you to address different types of fasteners.

- Socket Set: This is crucial for reaching tight spaces and provides the leverage needed for stubborn bolts.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Cutting Tools: Such as utility knives or scissors for trimming cables and other materials.

In addition to these basic tools, consider having a few specialized instruments on hand for more complex tasks:

- Multimeter: Ideal for checking electrical systems and diagnosing issues.

- Diagnostic Software: For modern machines, this can help identify faults quickly.

- Grease Gun: Essential for maintaining moving parts and ensuring smooth operation.

Being prepared with the right equipment not only enhances your efficiency but also minimizes the risk of damage during repairs. Regularly check your toolkit to ensure that everything is in working order and ready for use when needed.

Safety Precautions for Mower Repair

Ensuring a secure working environment is crucial when engaging in any form of machinery maintenance. By following essential safety measures, individuals can protect themselves from potential hazards and ensure a smooth repair process.

Before commencing any repair tasks, consider the following guidelines:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Disconnect the power source or remove the battery to prevent accidental activation during repairs.

- Work in a well-ventilated area to avoid inhaling harmful fumes from fuel or oils.

During the repair process, keep the following points in mind:

- Maintain a clean workspace to reduce the risk of accidents and injuries.

- Utilize the correct tools for the job to prevent damage to components and ensure safety.

- Stay focused and avoid distractions to ensure thorough attention to the task at hand.

After completing the repairs, remember to:

- Double-check that all components are securely reassembled.

- Properly dispose of any waste materials, such as oil or filters, according to local regulations.

- Test the machinery in a safe environment before returning it to regular use.

By adhering to these precautions, individuals can significantly minimize risks and contribute to a safer repair experience.

Using Diagrams for Efficient Repairs

Visual representations play a crucial role in simplifying the repair process. By providing a clear overview of components and their relationships, these illustrations enable users to identify issues quickly and understand how to address them effectively. Whether for maintenance or troubleshooting, having a reference guide can significantly enhance efficiency and reduce the likelihood of errors.

Benefits of Visual Guides

One of the primary advantages of utilizing visual aids is the ability to grasp complex systems at a glance. This clarity helps in pinpointing malfunctioning elements without the need for extensive verbal explanations. Additionally, diagrams can highlight assembly sequences, making reassembly after repairs much more straightforward.

Improving Problem-Solving Skills

Regularly consulting these visual tools can sharpen one’s analytical skills. Familiarity with how different parts fit together and operate allows users to diagnose problems more intuitively. As a result, reliance on such guides not only streamlines the repair process but also fosters a deeper understanding of the machinery involved.

Cost Considerations for Parts Replacement

When it comes to maintaining outdoor equipment, evaluating the financial implications of component exchange is essential. Understanding the various factors influencing expenses can help in making informed decisions, ensuring optimal performance without breaking the bank.

Several elements contribute to the overall costs associated with substituting elements in machinery. These include the quality of the replacement items, labor fees, and the potential for additional repairs that may arise during the replacement process.

| Factor | Description | Impact on Cost |

|---|---|---|

| Quality of Components | Higher-grade materials may cost more upfront but offer better durability. | Potentially increases initial expense but lowers long-term costs. |

| Labor Charges | Hiring professionals for installation can add to the total expenditure. | Varies based on complexity and regional pricing. |

| Additional Repairs | Unexpected issues during the replacement process may require further investment. | Can significantly elevate overall costs. |

Ultimately, careful consideration of these factors can lead to more strategic planning and budgeting, ensuring that the investment in new elements yields the best possible outcome for equipment longevity and efficiency.

Upgrading vs. Repairing Components

When it comes to maintaining machinery, the choice between enhancement and restoration is crucial. Each approach has its advantages, and understanding the implications can help in making informed decisions.

Enhancing components can provide numerous benefits, such as:

- Improved efficiency and performance

- Increased durability and longevity

- Enhanced features that align with modern standards

On the other hand, restoring existing elements often involves:

- Cost-effectiveness by utilizing existing materials

- Preservation of original design and functionality

- Potentially quicker turnaround times

Ultimately, the decision should consider factors such as:

- Budget constraints

- Intended usage and frequency of operation

- Availability of new technologies

- Personal preference for maintenance practices

By weighing these considerations, one can determine the best course of action for optimal performance and reliability.