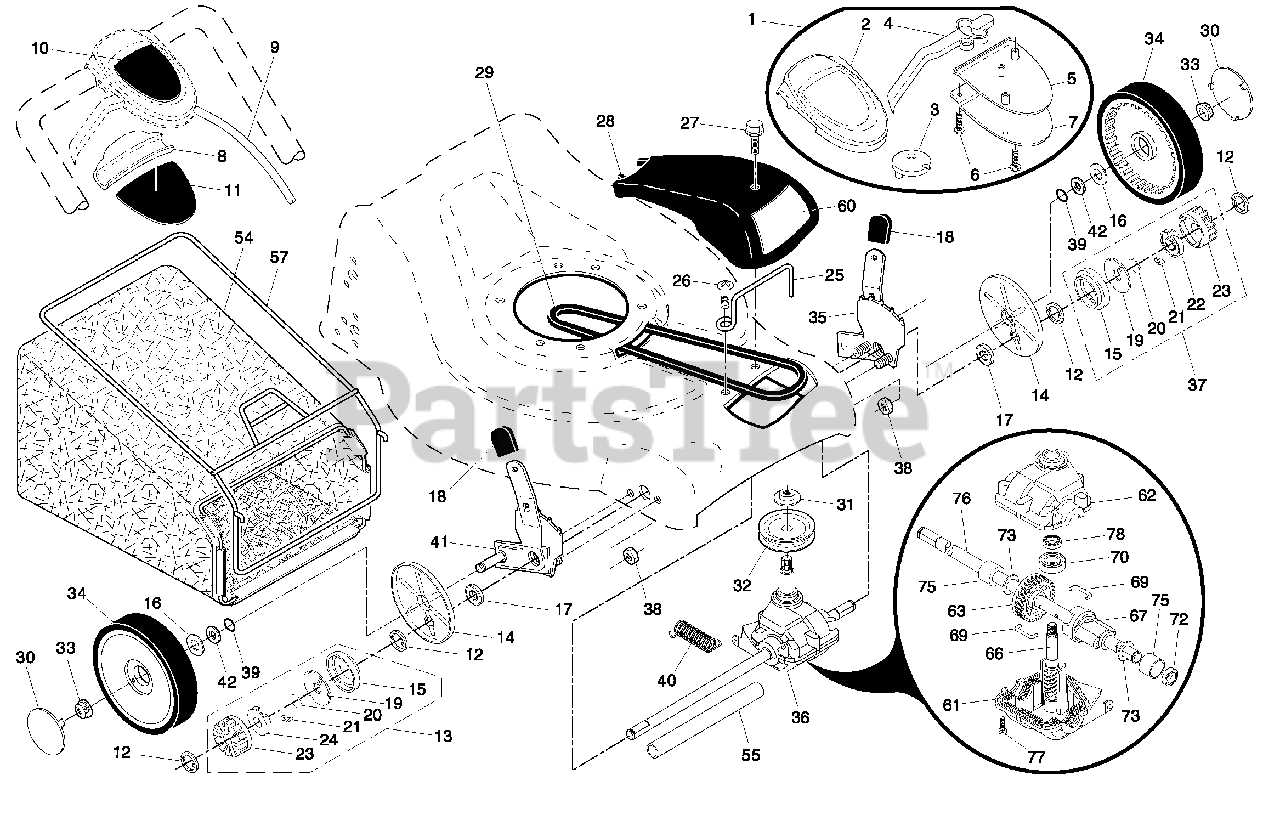

Poulan Mower Parts Breakdown and Diagram Guide

Understanding the layout and structure of your outdoor equipment is essential for proper maintenance and repairs. This guide provides a detailed look at the various components that make up your machine, offering insights into their arrangement and functionality. Familiarizing yourself with these elements will help ensure smooth operation and prolong the lifespan of your device.

By knowing the exact positioning and purpose of each element, you can troubleshoot issues more effectively, whether it’s replacing worn-out elements or performing routine upkeep. This knowledge allows you to maintain peak performance, minimizing the risk of unexpected breakdowns and maximizing efficiency.

In the following sections, you’ll discover a clear and detailed breakdown of all the critical elements within your equipment, making it easier to understand how everything fits together. Whether you’re new to handling such machinery or experienced, this guide will provide valuable assistance in keeping your tool in top condition.

Equipment Components Overview

Understanding the structure of outdoor machinery is essential for maintaining its longevity and ensuring efficient operation. This section provides an outline of the key mechanical elements that work together to deliver precise cutting performance, smooth movement, and overall functionality.

Main Mechanical Elements

At the heart of the equipment are various essential mechanical elements that facilitate smooth movement and operational efficiency. These include the central cutting mechanism, powered by the engine, and the structural frame that supports the entire unit. Proper care of these elements

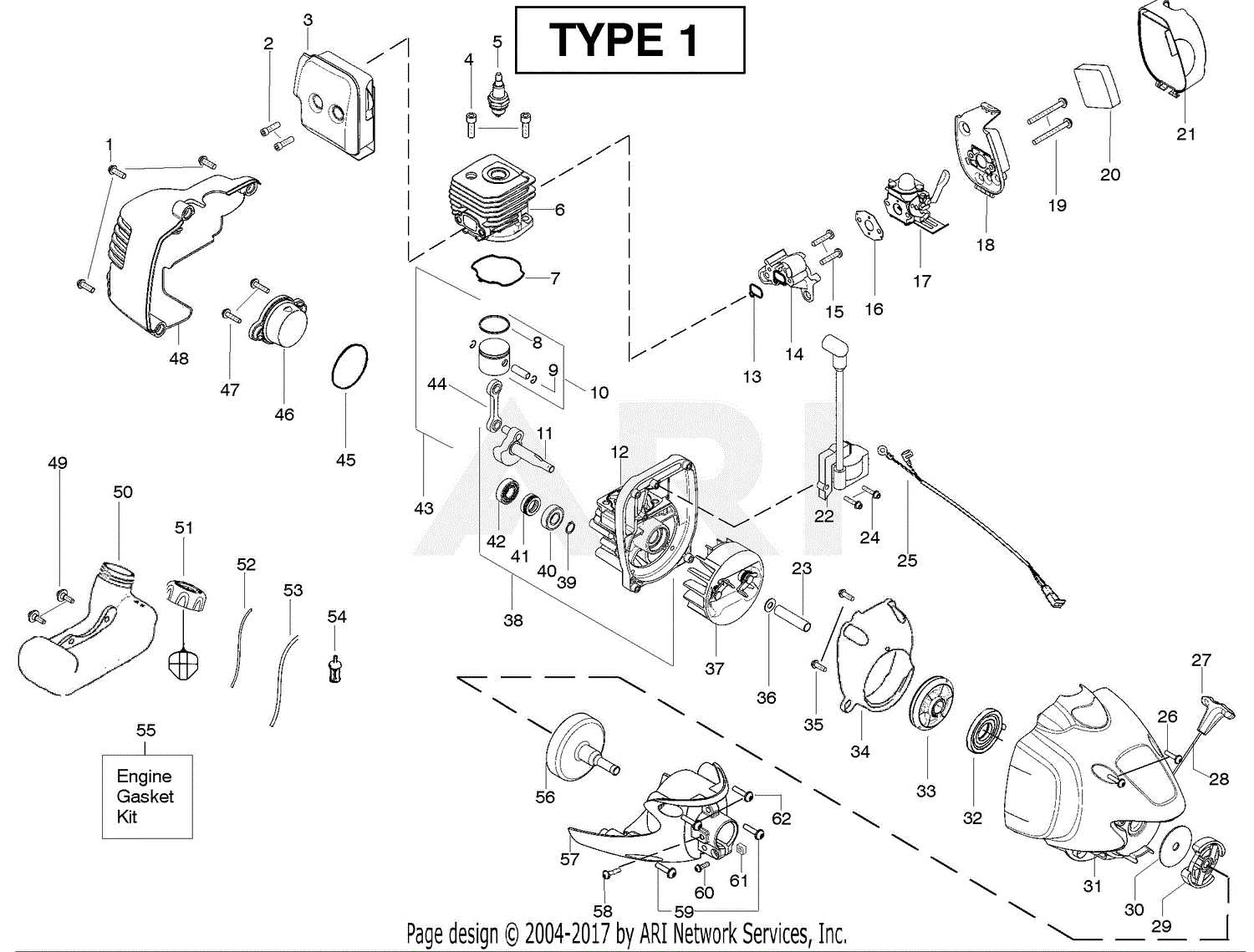

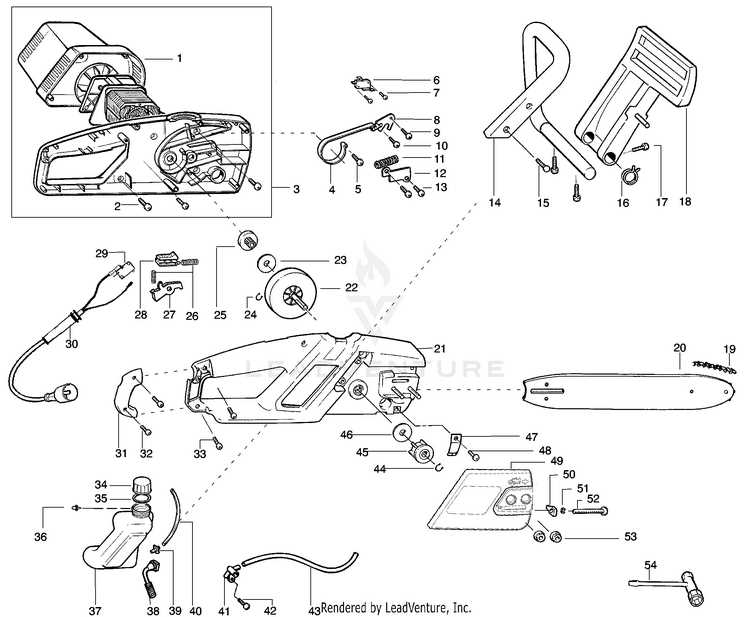

Main Engine Parts of Poulan Mowers

The core components of any lawn maintenance machine’s engine are critical for its performance and longevity. These elements work together to ensure efficient operation, allowing the device to cut through grass smoothly and handle tough conditions. Understanding the key sections of the engine can help in maintaining and troubleshooting when necessary.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel combustion occurs, producing the power needed to run the machine. |

| Crankshaft | Transforms the linear motion from the piston into rotational motion, driving the blades. |

| Carburetor | Mixes air with fuel before sending it into the engine for combustion. |

| Flywheel | Helps regulate the engine’s speed and maintains momentum for smooth operation. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean air intake. |

Blades and Cutting Mechanism

The blades and cutting system are essential components for ensuring efficient grass trimming. Properly maintained, the cutting edges allow for clean, precise cuts, contributing to the overall performance of the equipment. This section will delve into the function and importance of these elements, highlighting the key aspects of their maintenance and design.

Blade Types

There are various blade designs, each catering to different cutting needs. Some are crafted for fine, even trimming, while others are built to handle tougher tasks, such as dealing with thick, overgrown areas. The selection of the appropriate blade type plays a significant role in achieving desired results.

Maintenance and Sharpening

Regular upkeep is crucial for the cutting mechanism to perform at its best. Blades need to be sharpened periodically to maintain efficiency. Dull edges not only affect the quality of the cut but also increase wear on the engine. It’s recommended to inspect and service the cutting mechanism after prolonged use, ensuring the edges remain sharp and free of damage.

Understanding the Poulan Mower Deck

The deck of a cutting machine plays a crucial role in its overall performance. This section covers the structure and key elements that ensure effective grass trimming. Familiarizing yourself with these components is essential for maintaining smooth operation and addressing common issues that may arise.

Main Components of the Deck

The cutting platform consists of several vital parts that work together to ensure precise and efficient grass cutting. Below are some of the primary features:

- Blades: These

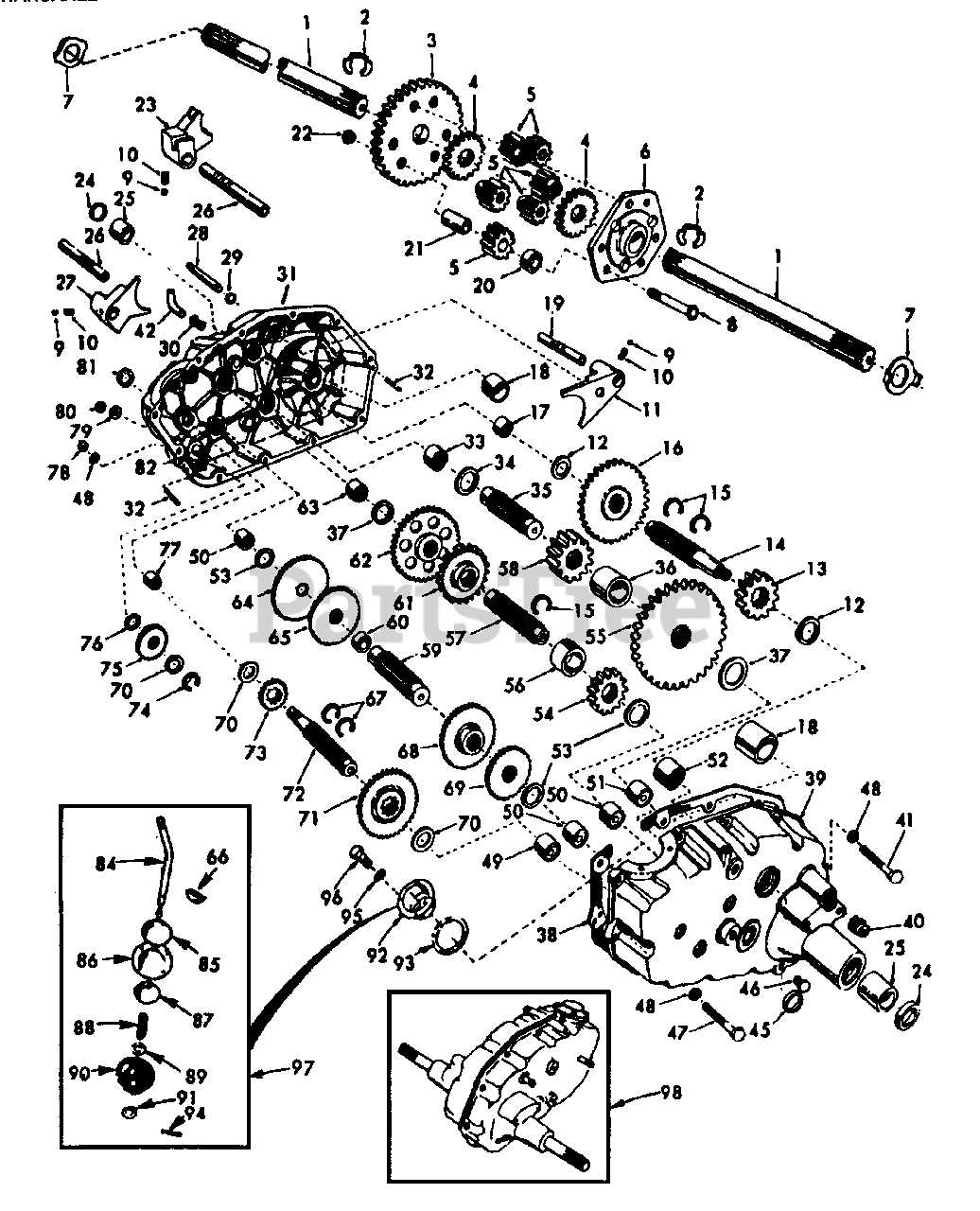

Wheels and Drive System

The functionality and performance of any outdoor equipment rely heavily on the condition and design of the wheels and drive mechanisms. These components are essential for providing mobility and ensuring smooth movement across different terrains. Understanding how the drive system operates helps maintain consistent efficiency and reduces strain on the machine.

Wheel Construction and Durability

The wheels are designed to withstand various surface types, offering stability and control. Their durability depends on the material and tread pattern, which ensure proper traction, minimizing slippage. Properly maintained wheels extend the life of the equipment and enhance maneuverability.

Drive System Mechanism

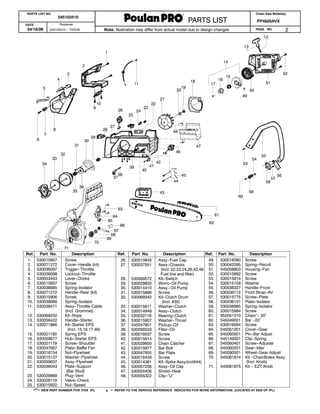

Fuel and Ignition System Components

The fuel and ignition systems play a crucial role in the operation of any engine, ensuring that the necessary energy is produced efficiently. Understanding the various components of these systems is essential for maintenance and troubleshooting. This section delves into the key elements involved in delivering fuel to the engine and igniting it, which are vital for optimal performance.

Fuel Delivery Mechanisms

The fuel delivery mechanisms include several important components that work together to transport fuel from the tank to the combustion chamber. These elements typically consist of a fuel pump, filters, and lines. The fuel pump is responsible for drawing fuel from the tank and pushing it through the system. Filters are crucial for removing impurities, while the fuel lines provide the necessary pathway for the fuel to travel.

Ignition System Components

The ignition system is equally important, as it generates the spark needed to ignite the fuel-air mixture within the engine. Key components of this system include the spark plug, ignition coil, and wiring. The spark plug creates a spark at the appropriate moment, allowing combustion to occur. The ignition coil transforms battery voltage into the high voltage required for the spark plug to function effectively.

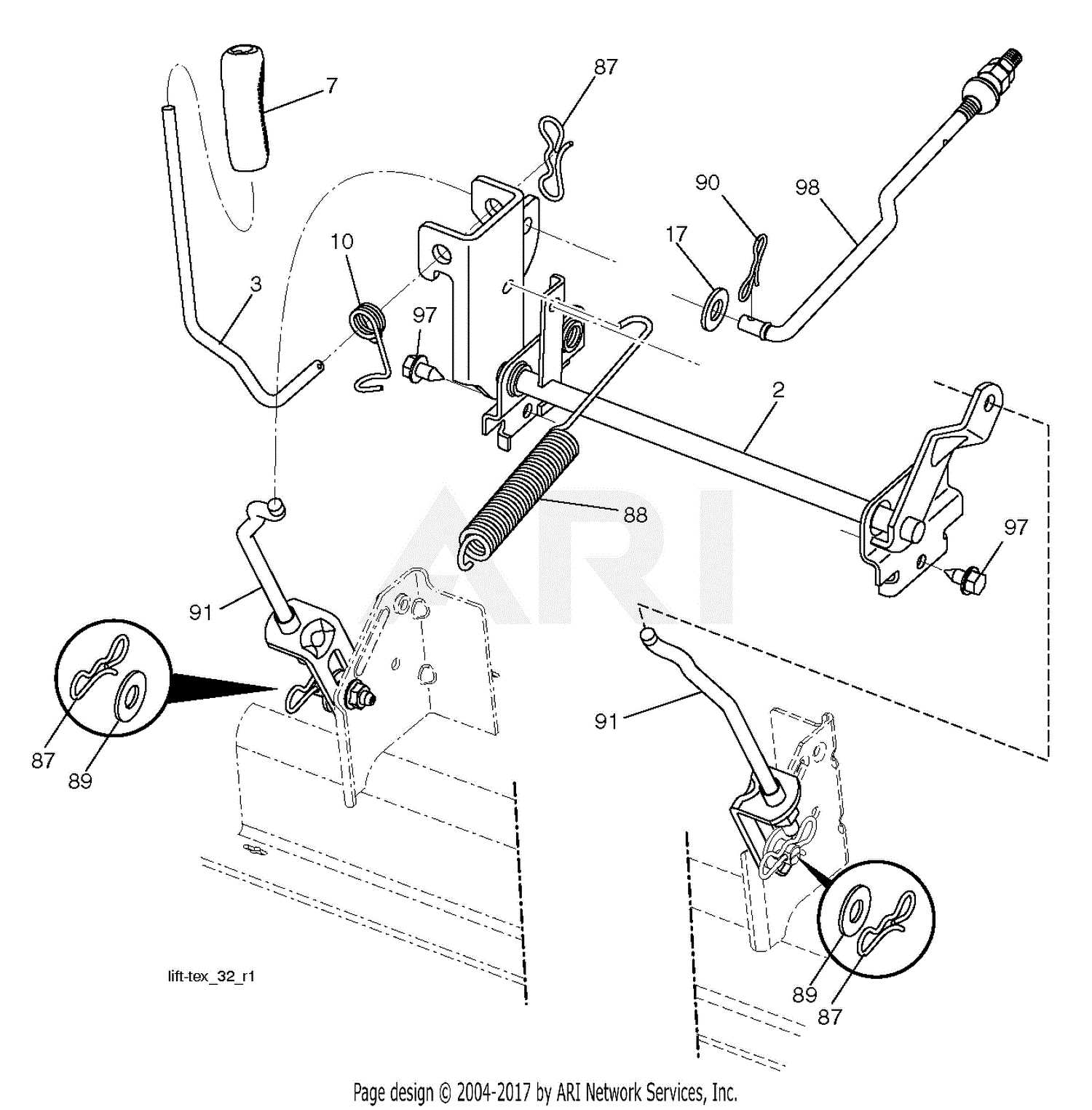

Throttle and Speed Control Mechanism

The throttle and speed control system is essential for regulating the performance of outdoor equipment. This mechanism enables users to adjust the engine’s power output, thus influencing the speed and efficiency of operation. Understanding how this system functions can enhance the user experience and prolong the lifespan of the equipment.

Key components of this system include:

- Throttle Lever: This is the primary control for adjusting engine speed.

- Governor: An automatic device that helps maintain a consistent speed under varying load conditions.

- Linkage: A series of rods and cables that connect the throttle lever to the throttle valve.

- Throttle Valve: A component that regulates the air and fuel mixture entering the engine.

Proper maintenance of the throttle and speed control mechanism is crucial for optimal performance. Regular inspections can prevent issues such as:

- Sticking throttle lever, which can lead to erratic speed control.

- Worn linkage, affecting the responsiveness of the system.

- Dirty throttle valve, which can impede airflow and reduce efficiency.

By keeping these components in good condition, users can ensure smooth operation and extend the durability of their equipment.

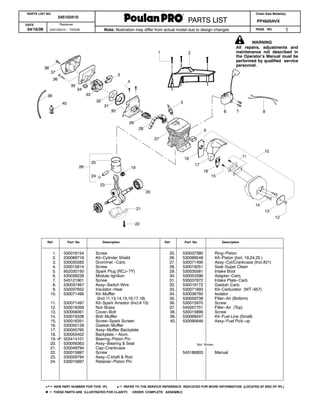

Air Filtration and Cooling System

The air filtration and cooling mechanism is a vital component in the efficient operation of outdoor power equipment. It plays a crucial role in maintaining optimal performance by ensuring clean air enters the engine while preventing overheating. This system not only enhances the longevity of the engine but also contributes to effective fuel combustion, leading to improved overall functionality.

Function of Air Filtration

The primary purpose of the air filtration system is to remove dust, dirt, and debris from the air before it reaches the engine. Clean air is essential for proper combustion, which in turn impacts power output and fuel efficiency. Over time, air filters can become clogged, reducing airflow and potentially causing engine damage if not replaced regularly.

Cooling Mechanism Overview

Cooling systems are designed to manage engine temperature by dissipating heat generated during operation. They typically utilize air or liquid to absorb and transfer heat away from the engine components. An effective cooling system prevents overheating, which can lead to severe mechanical failures and decreased performance.

Component Function Maintenance Tips Air Filter Cleans incoming air for combustion Inspect and replace every season Cooling Fins Dissipate heat from engine surface Keep clean from debris and dirt Fan Circulates air for cooling Check for damage and proper function Handle Assembly and Controls

The handle assembly and its accompanying controls play a crucial role in the overall functionality and usability of outdoor equipment. This section provides an overview of the various components involved in this assembly, as well as the mechanisms that facilitate user interaction. Understanding these elements is essential for effective operation and maintenance.

Components of the Handle Assembly

The handle assembly comprises several key elements that work together to ensure stability and ease of use. These include the main handlebar, grip sections, and any adjustable mechanisms that allow users to tailor the height or angle according to their preference. The design typically incorporates durable materials to withstand outdoor conditions, enhancing longevity and performance.

Control Mechanisms

Control mechanisms integrated into the handle assembly are vital for managing various functions of the equipment. These may include throttle controls, safety switches, and engagement levers. Each control is strategically positioned for accessibility, enabling users to operate the equipment smoothly while maintaining a comfortable grip. Familiarity with these controls is essential for safe and efficient usage.

Battery and Electrical Wiring

Understanding the components of power storage and electrical connections is crucial for maintaining the functionality of your equipment. This section provides an overview of the essential elements related to energy supply and wiring systems that ensure optimal performance and safety.

Battery Specifications

The energy source is a fundamental part of the system, and it is important to choose a battery that meets the required specifications for voltage and capacity. Regularly checking the battery condition can prevent unexpected failures and prolong the lifespan of the entire apparatus.

Wiring Connections

Proper wiring is essential for reliable operation. Each connection must be secure and free from corrosion to ensure efficient power transfer. It is advisable to inspect wiring regularly for any signs of wear or damage, as this can lead to electrical failures or safety hazards.

Transmission and Drive Belts

The mechanism responsible for transferring power from the engine to the wheels is essential for optimal performance in any outdoor equipment. This section explores the components that facilitate this vital function, highlighting their importance and functionality.

Understanding the Functionality

Drive belts play a crucial role in connecting the engine with various operational systems. These components ensure that energy is efficiently transmitted, enabling the equipment to move smoothly. The effectiveness of this system can significantly impact the overall operation, affecting both speed and efficiency.

Types of Drive Belts

Different types of drive belts are utilized, each designed for specific applications. The choice of belt can influence the durability and performance of the machinery. Regular inspection and timely replacement of worn belts are recommended to maintain efficiency and prevent breakdowns.

Type of Belt Description Common Issues V-Belt Used for power transmission; characterized by its V-shape. Wear and slippage can reduce performance. Flat Belt Ideal for applications with lower power needs; runs flat against pulleys. Can become frayed or lose tension over time. Timing Belt Ensures synchronization between components; crucial for precise operation. Failure can lead to significant damage; regular replacement is essential. Grass Bagging and Mulching System

The grass collection and shredding mechanism plays a crucial role in maintaining a tidy outdoor space. This system efficiently gathers clippings during the cutting process, providing a convenient way to manage debris. Moreover, it enhances the overall health of the lawn by returning finely chopped organic material back to the soil, enriching it with nutrients.

Functionality and Benefits

Incorporating a grass collection system allows for a cleaner cutting experience, minimizing the need for additional cleanup. The chopped material can be reused as natural fertilizer, contributing to the sustainability of lawn care. This dual functionality not only simplifies maintenance but also promotes a greener environment.

Maintenance Tips

To ensure optimal performance, regular inspection and cleaning of the collection and mulching components are essential. Checking for blockages and wear can prevent operational issues and extend the lifespan of the equipment. Keeping these parts in good condition guarantees effective grass management and enhances overall efficiency.

Maintenance and Replacement Guidelines

Regular upkeep and timely substitutions are essential for ensuring optimal performance and longevity of your equipment. By adhering to a systematic approach, users can prevent potential issues and maintain the functionality of their machinery.

Below are key recommendations for effective maintenance:

- Routine Inspections: Frequently check for signs of wear or damage. Look for loose components, leaks, or unusual noises.

- Cleaning: Regularly clean the exterior and interior parts to remove dirt and debris that can hinder performance.

- Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer to reduce friction.

- Filter Maintenance: Replace or clean air and fuel filters periodically to ensure efficient operation.

When it comes to component replacement, consider the following steps:

- Identify the Component: Recognize the specific part that requires substitution based on performance issues.

- Select Quality Replacements: Choose high-quality substitutes that meet or exceed original specifications to maintain performance.

- Follow Manufacturer Guidelines: Adhere to instructions provided in the user manual for proper installation procedures.

- Dispose of Old Parts Responsibly: Ensure that replaced components are disposed of in an environmentally friendly manner.

By implementing these practices, users can enhance the efficiency and lifespan of their equipment, ultimately leading to improved performance and reduced operational costs.