Sickle Bar Mower Parts Diagram Explained

The intricate design of a cutting apparatus plays a crucial role in its efficiency and effectiveness. Each element contributes to the overall functionality, ensuring smooth operation and optimal performance. By exploring the various components, one can gain insights into how these machines tackle the tasks they are built for.

In this section, we will delve into the essential elements that make up this cutting device. Recognizing the significance of each section can enhance your understanding and maintenance skills. From the driving force to the cutting edge, every part has its ultimate function in the machinery.

Whether you are a seasoned operator or a newcomer, familiarizing yourself with these components can lead to improved handling and better results in the field. Join us as we dissect these critical aspects and uncover the mechanics behind successful cutting operations.

Components Overview

This section aims to provide a detailed look at the various elements that make up a specific cutting apparatus used in agricultural settings. Understanding these components is essential for effective maintenance and operation, ensuring optimal performance and longevity of the equipment.

Key Elements

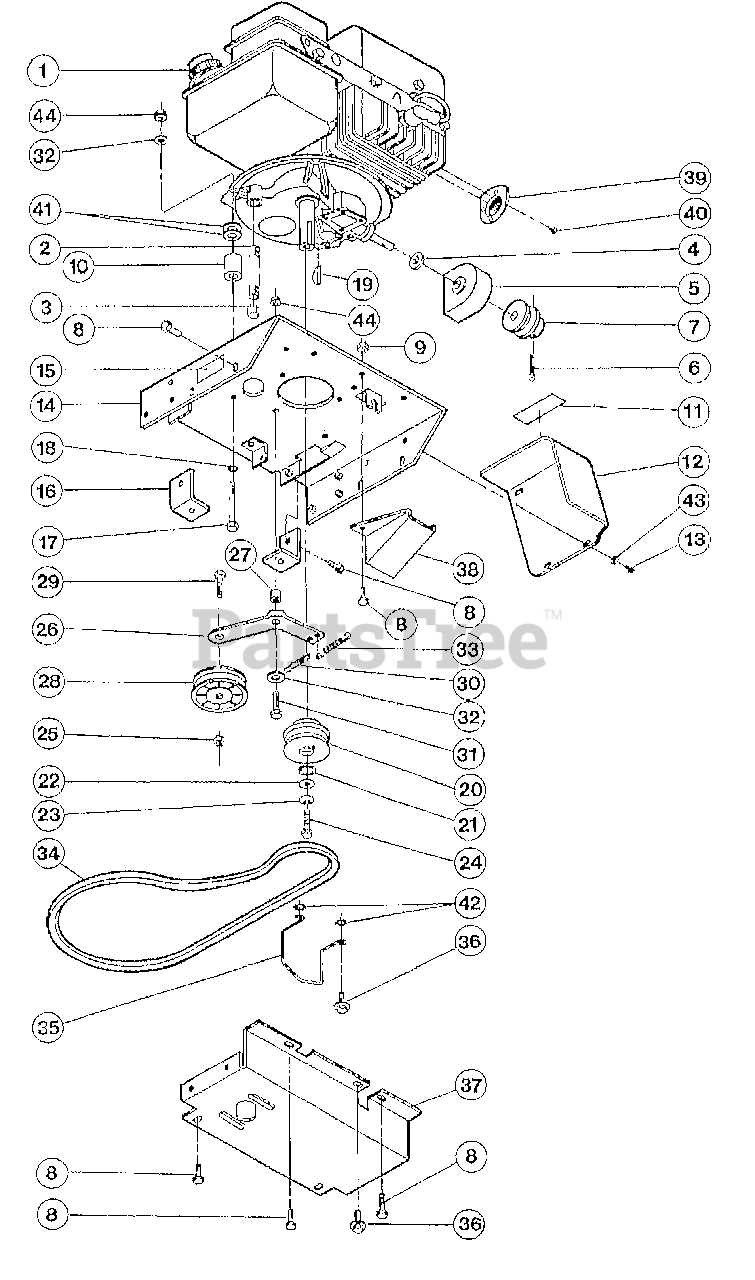

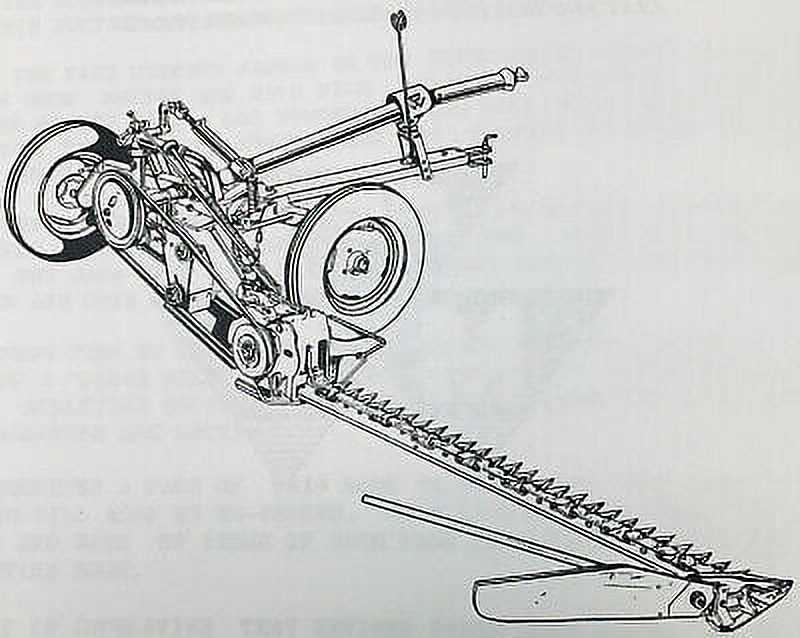

The main components of this cutting tool include the frame, cutting mechanism, and drive system. Each element plays a crucial role in the overall functionality. The frame serves as the backbone, providing stability and support, while the cutting mechanism is responsible for executing precise cuts through vegetation. The drive system, on the other hand, powers the entire setup, allowing for efficient operation.

Maintenance and Care

Regular upkeep of these components is vital for sustaining performance. Inspection of the cutting edges and lubrication of moving parts can prevent wear and tear. Additionally, ensuring that all connections are secure and free from rust will contribute to the reliability and effectiveness of the equipment.

Understanding the Mower’s Functionality

The mechanics of cutting equipment revolve around the intricate interplay of various components designed to achieve precise results. By exploring how these elements collaborate, one can appreciate the efficiency and effectiveness of this agricultural tool.

Key Components and Their Roles

Each section of the device serves a specific purpose, contributing to its overall performance. The cutting mechanism is typically driven by a power source that enables swift action, while guiding elements ensure stability and accuracy during operation.

Operational Efficiency

Maintaining optimal functionality requires regular inspection and adjustments. Understanding the nuances of how each part interacts can lead to improved longevity and reliability, ensuring that the task at hand is executed with precision and ease.

Key Parts of Sickle Bar Mowers

This section delves into the essential components of a particular type of agricultural equipment, highlighting their roles and significance. Understanding these elements is crucial for effective maintenance and operation, ensuring optimal performance in cutting and harvesting tasks.

Major Components

- Cutter Head: The main mechanism responsible for the cutting action, equipped with multiple blades.

- Frame: The structural foundation that supports the entire system and connects it to the towing vehicle.

- Drive System: Powers the blades and facilitates their movement, often utilizing gears or belts.

- Guard: Protects the blades and ensures safe operation, preventing debris from causing damage.

- Lift Cylinder: Enables the adjustment of the cutting height, allowing flexibility based on field conditions.

Additional Elements

- Blades: Sharp edges that perform the actual cutting, designed for efficiency and durability.

- Knives: Often attached to the cutting head, these help to enhance the cutting action.

- Driveshaft: Transfers power from the drive system to the cutting components, ensuring smooth operation.

- Swather: A mechanism that helps in gathering and organizing the cut material for easier handling.

Familiarity with these fundamental elements contributes to a deeper appreciation of the machinery’s functionality, ultimately leading to better agricultural practices.

Importance of Maintenance and Care

Proper upkeep and attention to agricultural equipment are essential for ensuring longevity and efficiency. Regular maintenance not only enhances performance but also minimizes the risk of unexpected failures during operation.

Routine inspections play a crucial role in identifying potential issues before they escalate. By checking for wear and tear, operators can address minor problems, which ultimately saves time and resources.

Additionally, cleaning and lubricating components helps maintain optimal function, reducing friction and preventing damage. Implementing a scheduled maintenance routine fosters reliability, making it the ultimate strategy for successful operation.

Investing time in care also contributes to safety, ensuring that machinery operates smoothly and reducing the likelihood of accidents. Thus, prioritizing maintenance is vital for any operator aiming for efficiency and safety in their tasks.

How to Read a Parts Diagram

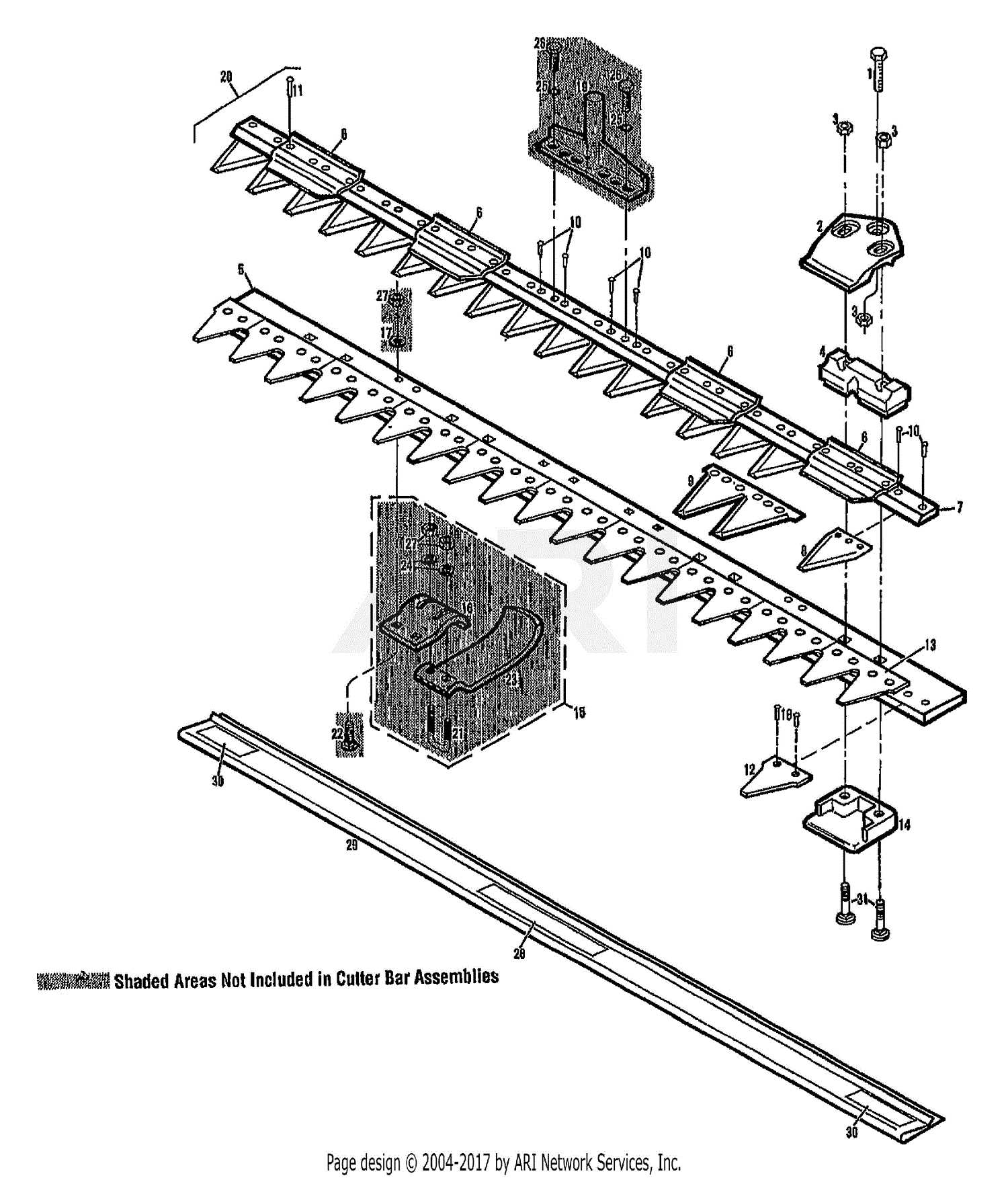

Understanding a visual representation of components can greatly enhance your ability to maintain and repair equipment. These illustrations serve as a valuable guide, offering insight into the arrangement and function of various elements. By grasping the symbols and labels used, you can effectively identify each piece and its role in the overall assembly.

Firstly, familiarize yourself with the legend or key, which often explains the symbols and color codes used in the illustration. This foundational knowledge is crucial for accurate interpretation.

Next, break down the image into sections, focusing on one area at a time. This method allows you to delve deeper into the specifics without becoming overwhelmed.

Lastly, cross-reference the visual with a written description or manual. This ultimate approach not only reinforces your understanding but also aids in pinpointing any potential issues during maintenance.

Common Issues and Troubleshooting Tips

When operating agricultural cutting equipment, various challenges may arise that can hinder performance and efficiency. Understanding these common problems and having effective solutions at hand can greatly enhance operational success.

1. Uneven Cutting: This issue often stems from improper adjustment or dull blades. Regularly inspect the sharpness of the cutting edges and ensure that the height settings are uniform.

2. Excessive Vibration: If the machinery shakes excessively, it could be due to loose components or unbalanced parts. Check for any loose fasteners and ensure that all components are properly aligned.

3. Clogging: Accumulation of material can obstruct the cutting mechanism. To mitigate this, regularly clean the equipment and adjust the feed rate to prevent overload.

4. Overheating: This can occur from prolonged use without adequate breaks or insufficient lubrication. Allow the machine to cool periodically and ensure that all moving parts are well-lubricated.

5. Difficulty in Starting: If the equipment struggles to start, inspect the fuel supply and ignition system. Replace old fuel and check for any electrical issues that may impede operation.

Replacement Parts: What to Consider

When it comes to ensuring the optimal functioning of your equipment, choosing the right components is crucial. Understanding the specifics of what to look for can significantly impact performance and longevity.

Key Factors to Evaluate

- Compatibility with your model

- Quality of materials used

- Manufacturer reputation

- Warranty and support options

Steps to Make an Informed Decision

- Research the specifications needed for your specific equipment.

- Compare prices across different suppliers.

- Read reviews and feedback from other users.

- Consult with professionals if unsure about your choices.

Safety Features in Sickle Bar Mowers

Ensuring user protection is paramount in agricultural machinery design. Various mechanisms and practices are implemented to minimize risks associated with operation. Understanding these features can significantly enhance safe usage.

Key Safety Mechanisms

- Emergency Stop Systems: Quick-access buttons allow for immediate shutdown in case of an emergency.

- Protective Shields: Barriers are installed to prevent accidental contact with moving components.

- Operator Presence Controls: Devices that halt operation when the operator is not in the designated area.

Best Practices for Safety

- Always wear appropriate personal protective equipment (PPE).

- Conduct routine maintenance checks to ensure all safety features are functional.

- Follow the manufacturer’s guidelines for operation and safety protocols.

Assembly and Disassembly Instructions

This section provides essential guidance for both assembling and disassembling the cutting mechanism efficiently. Understanding the proper sequence and techniques is crucial to ensure optimal performance and longevity of the equipment.

Assembly Steps:

Begin by gathering all necessary components and tools. Ensure that the workspace is clean and organized. Start by aligning the main frame with the cutting assembly, making sure all connecting points are properly oriented. Secure each part with the appropriate fasteners, tightening them to the manufacturer’s specifications. Check for any misalignments before proceeding to the next component.

Disassembly Steps:

To safely disassemble, first ensure that the equipment is turned off and disconnected from any power source. Begin by removing any safety guards and protective covers. Loosen the fasteners in the reverse order of assembly, taking care to keep track of each component and its respective hardware. Gently separate the parts to avoid damage, and place them in a designated area for storage or maintenance.

Following these instructions will help maintain the functionality of the mechanism and facilitate easy reassembly when needed.

Comparing Different Sickle Bar Models

When evaluating various cutting implements, it’s essential to understand the unique features and specifications that differentiate them. Each model offers distinct advantages tailored to specific tasks, making it crucial to compare these options effectively.

| Model | Cutting Width | Weight | Best For |

|---|---|---|---|

| Model A | 60 inches | 400 lbs | Medium-sized fields |

| Model B | 72 inches | 450 lbs | Large areas |

| Model C | 54 inches | 350 lbs | Narrow spaces |

Understanding these distinctions will ultimately aid in selecting the most suitable tool for your agricultural needs.

Cost Factors for Replacement Parts

When considering the financial implications of acquiring new components for agricultural machinery, several key elements come into play. These factors can significantly influence the overall expense and should be evaluated to ensure an informed purchasing decision.

Quality and Brand

The manufacturer and quality of the component often dictate the price. Premium brands typically offer enhanced durability and performance, which may justify the higher cost over time.

Availability and Supply Chain

The ease of access to specific items can also affect pricing. Limited availability or high demand may lead to increased costs, while readily available components tend to be more affordable.

| Factor | Impact on Cost |

|---|---|

| Quality | Higher quality usually results in increased expense but better longevity. |

| Brand Reputation | Established brands often charge a premium due to perceived reliability. |

| Market Demand | High demand can inflate prices, especially for rare items. |

| Distribution | Longer supply chains may lead to additional shipping costs. |

Resources for Further Learning

Enhancing your understanding of agricultural machinery can significantly improve maintenance and operational efficiency. Here are several valuable resources to help you deepen your knowledge and skills in this area.

- Online Courses:

- Coursera offers various courses on machinery management.

- Udemy has specific classes focusing on equipment operation and safety.

- Books and Manuals:

- Look for comprehensive guides on agricultural equipment maintenance.

- Manufacturer manuals often provide detailed instructions and troubleshooting tips.

- Video Tutorials:

- YouTube has numerous channels dedicated to machinery operation and repair.

- Webinars hosted by agricultural organizations can offer insights and demonstrations.

- Forums and Online Communities:

- Join platforms like Reddit or specialized forums to engage with fellow enthusiasts.

- Facebook groups can provide a space for sharing experiences and advice.

Utilizing these resources can equip you with the knowledge necessary to ensure optimal performance and longevity of your equipment.