Comprehensive Guide to 460 Rancher Parts Diagram

Maintaining and repairing outdoor machinery can often seem daunting, but with the right resources, it becomes a manageable task. A thorough visual representation of components can be invaluable, helping enthusiasts and professionals alike to navigate the intricacies of their tools. By familiarizing oneself with these layouts, users can enhance their operational knowledge and ensure optimal performance.

Each element plays a crucial role in the overall functionality, and recognizing how they interconnect is essential for effective upkeep. Detailed illustrations not only aid in identifying parts but also empower users to make informed decisions during repairs or modifications. This guide serves as a gateway to mastering the inner workings of your equipment.

Arming yourself with this knowledge paves the way for greater efficiency and longevity of your machinery. Whether you are a hobbyist or a dedicated user, understanding the specifics can lead to improved outcomes and fewer complications. Explore the components and their arrangements to unlock the full potential of your outdoor gear.

Understanding the 460 Rancher Parts Diagram

Grasping the intricacies of machinery components is essential for effective maintenance and repair. A clear illustration showcasing the various elements involved serves as a valuable resource for enthusiasts and professionals alike. Familiarity with these visual guides enhances one’s ability to troubleshoot issues and ensures optimal performance.

Key Components Overview

Every machine comprises critical elements that contribute to its functionality. These include the engine assembly, fuel system, and cutting mechanisms. By examining each segment closely, users can identify potential areas for improvement or failure, ultimately prolonging the lifespan of the equipment.

Importance of Accurate Identification

Accurate recognition of specific features is vital for successful repairs and replacements. Utilizing well-organized schematics allows individuals to pinpoint necessary components quickly. This knowledge fosters confidence when undertaking maintenance tasks, reducing downtime and enhancing productivity.

Essential Components of the 460 Rancher

Understanding the vital elements of this robust tool is crucial for effective operation and maintenance. Each component plays a specific role, contributing to the overall efficiency and functionality of the machine. Below, we explore the key features that define its performance.

Main Features

- Engine: The powerhouse that drives the entire system, providing necessary energy for operation.

- Chain System: Essential for movement, this mechanism ensures smooth and reliable cutting action.

- Fuel Tank: Holds the necessary liquid for operation, designed for easy refueling and maximum capacity.

- Bar and Chain: Integral to the cutting process, these elements work in tandem to deliver precision and effectiveness.

Additional Components

- Air Filter: Critical for maintaining engine performance by keeping contaminants out of the system.

- Clutch Assembly: Ensures proper engagement and disengagement of the chain during operation.

- Handlebar: Provides control and stability, allowing for precise maneuvering.

- Safety Features: Include protective mechanisms designed to prevent accidents and ensure user safety.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for efficient maintenance and repair. These illustrations serve as guides, highlighting the relationship between different elements, their arrangement, and how they interact within a larger system. Familiarity with such visuals can streamline the identification of necessary items and facilitate troubleshooting processes.

To effectively interpret these illustrations, consider the following key points:

| Step | Description |

|---|---|

| 1 | Begin by locating the title or reference number, which often indicates the specific model or assembly group. |

| 2 | Examine the layout, paying attention to how components are arranged. This will help you understand their positioning and connections. |

| 3 | Look for labels or numbers that correspond to a parts list, which provides details about each item, including specifications and quantities. |

| 4 | Identify any legend or key that explains symbols or markings, enhancing your comprehension of the illustration. |

| 5 | Cross-reference the visual with any accompanying manuals to clarify assembly or disassembly instructions. |

By following these guidelines, you can navigate the complexities of component representations with greater ease, ensuring that you are well-prepared for any task at hand.

Common Issues with 460 Rancher Parts

When dealing with outdoor power equipment, users often encounter various challenges related to components. These can stem from wear and tear, improper maintenance, or manufacturing defects. Understanding these issues can help in troubleshooting and extending the lifespan of the machinery.

One frequent concern involves fuel system problems, which can lead to starting difficulties or performance drops. Clogs in the fuel lines or a malfunctioning filter can hinder fuel flow, causing frustration during operation.

Another common issue is with ignition systems. Faulty spark plugs or ignition coils can result in misfires or the engine not starting at all. Regular inspections of these elements are crucial for ensuring reliable functionality.

Additionally, users might face challenges with the cutting mechanism. Dull blades or improper tension can affect cutting efficiency, leading to subpar results and increased effort during use. Addressing these issues promptly can improve performance significantly.

Finally, wear on housing or casings can compromise the equipment’s integrity. Cracks or damages can lead to further complications, making it essential to routinely check and maintain the outer structure for durability.

Maintenance Tips for 460 Rancher

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular attention to specific areas not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Following a structured maintenance routine can help you enjoy a hassle-free experience with your machine.

Regular Cleaning

Keeping your equipment clean is vital. After each use, take the time to remove any debris or dirt that may have accumulated. Pay special attention to the air filter, as a clogged filter can lead to poor performance. Cleaning should be performed regularly, especially in dusty or dirty environments, to maintain airflow and engine efficiency.

Fluid Checks and Changes

Periodic checks of oil and fuel levels are crucial for maintaining engine health. Ensure that the oil is at the recommended level and change it according to the manufacturer’s guidelines. Replacing fuel filters at regular intervals helps prevent contamination and keeps the engine running smoothly. Additionally, inspect hydraulic fluids to ensure optimal operation.

Following these maintenance tips will not only prolong the lifespan of your equipment but also enhance its performance, allowing you to tackle tasks efficiently.

Where to Find Replacement Parts

Locating components for maintenance or repair tasks can be a straightforward process if you know where to look. Various resources offer a range of options for sourcing these essential items, ensuring that your equipment remains in optimal condition.

Online Resources

- Manufacturer’s Website: Always check the official site of the brand for genuine items and specifications.

- E-commerce Platforms: Websites like Amazon, eBay, and specialized retailers often carry a wide selection of components.

- Parts Suppliers: Dedicated online stores specialize in replacement components, providing detailed catalogs for easy navigation.

Local Options

- Hardware Stores: Local shops may stock common items or can order them for you.

- Repair Shops: Service centers often have connections for sourcing specific components.

- Trade Shows: Attending industry events can provide opportunities to connect with suppliers and discover new items.

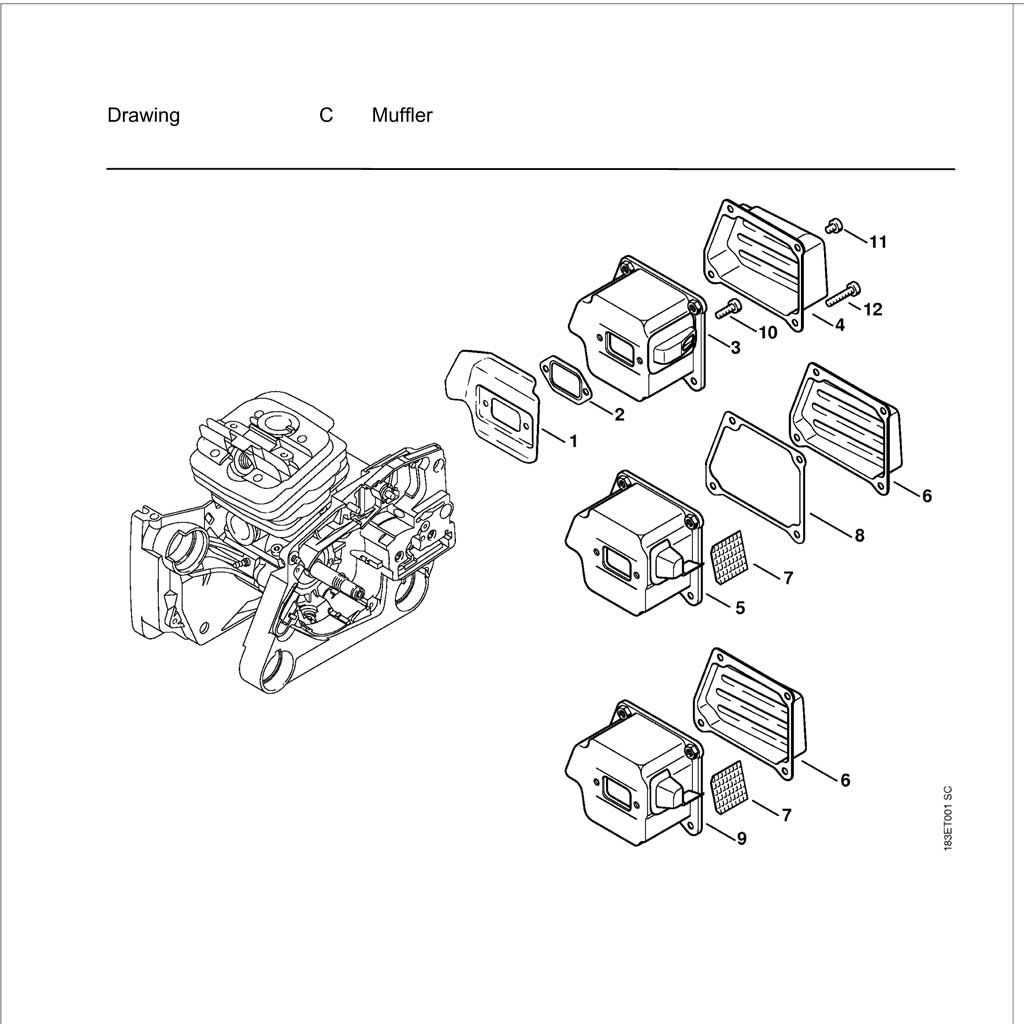

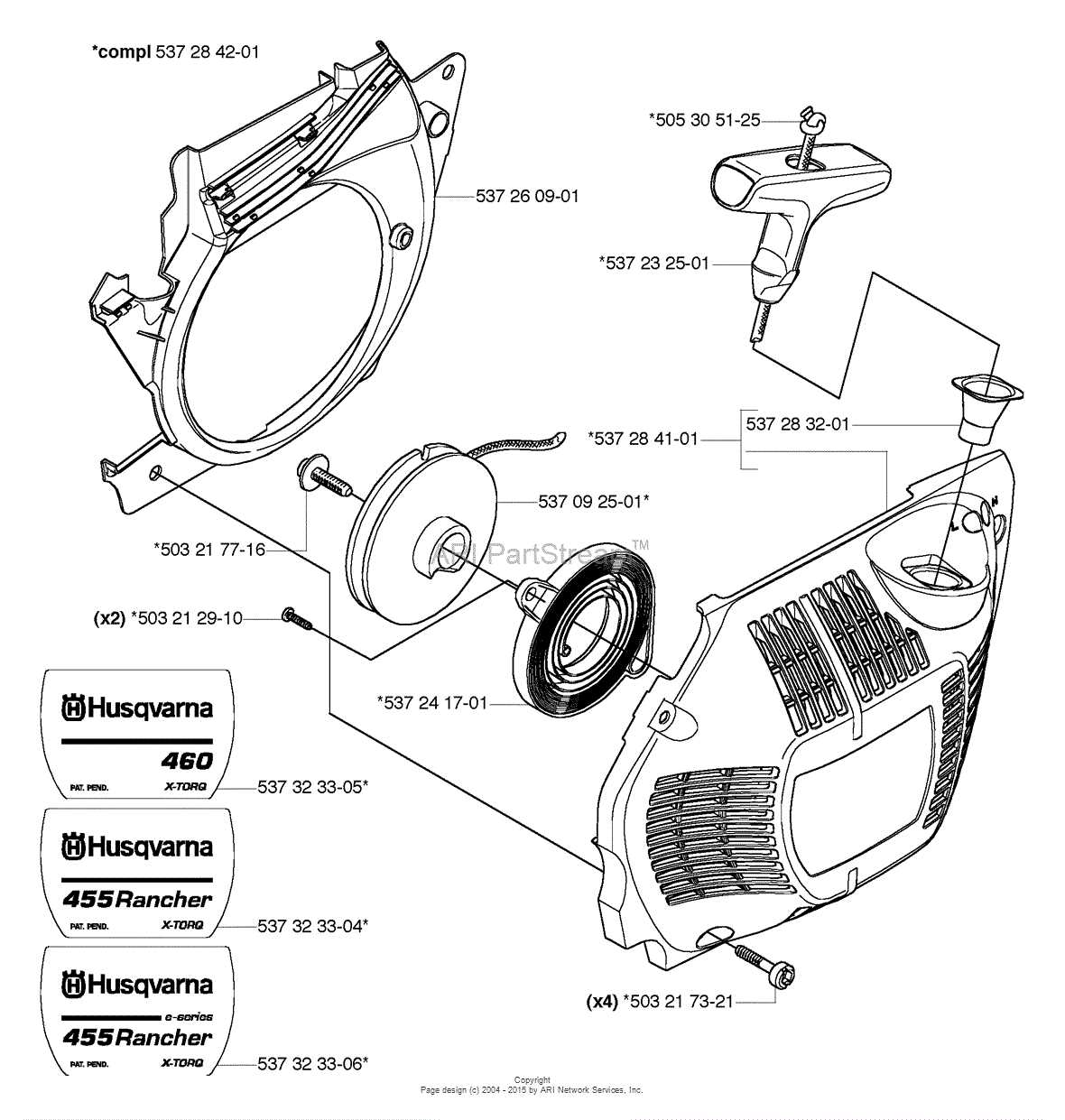

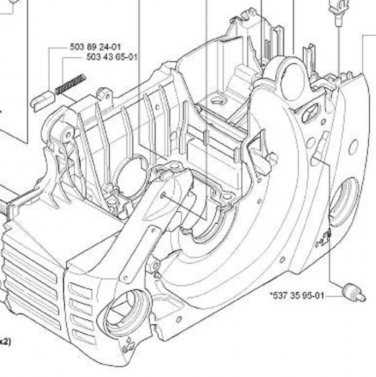

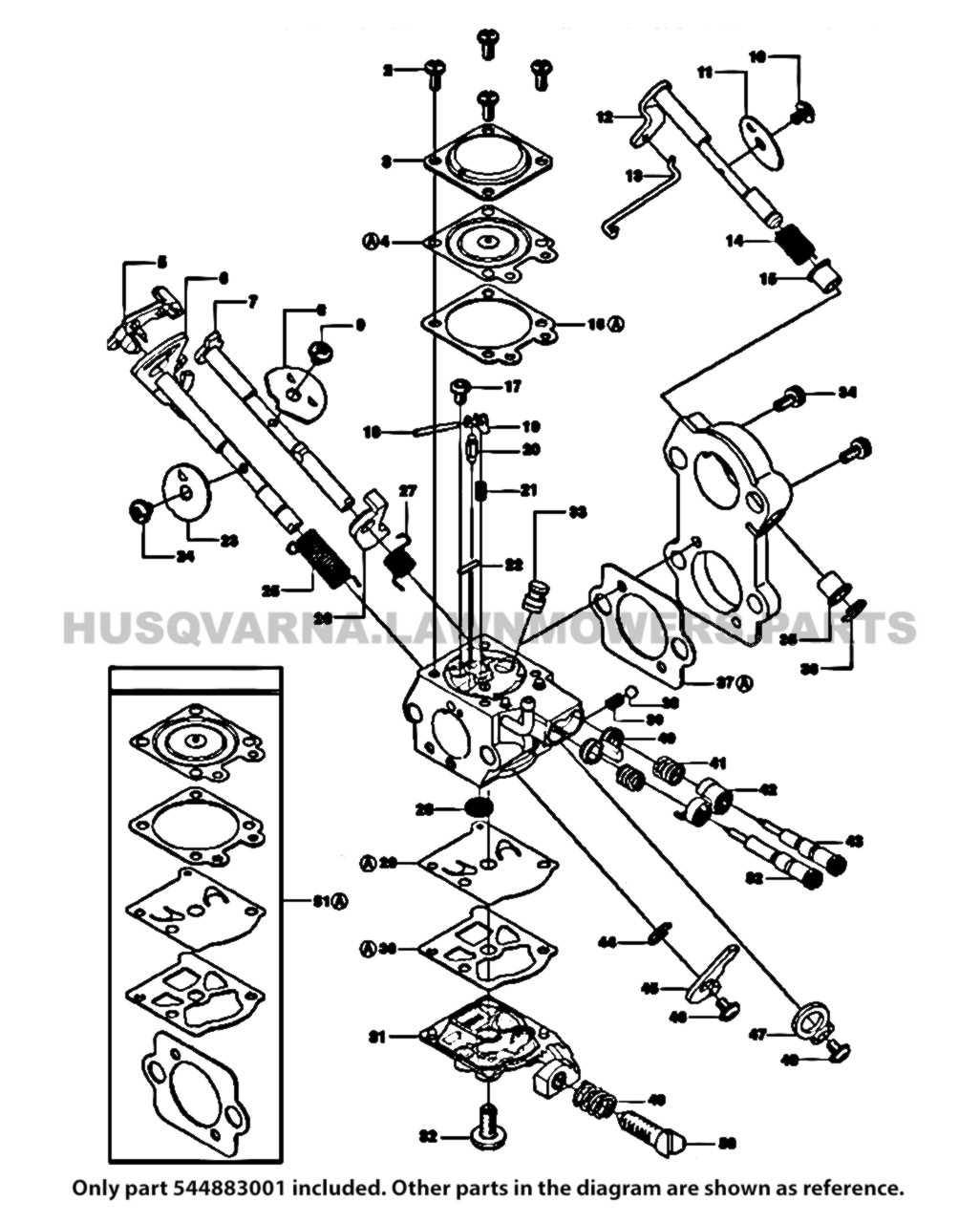

Visual Identification of Key Parts

Understanding the various components of machinery is essential for effective maintenance and operation. This section aims to enhance your ability to recognize crucial elements, facilitating troubleshooting and repairs. By becoming familiar with these parts, you can ensure better performance and longevity of your equipment.

Engine Assembly: The heart of any mechanical system, the engine assembly comprises numerous interconnected elements. Recognizing the cylinder head, crankshaft, and fuel system components is vital for diagnosing performance issues.

Cutting Mechanism: This includes the blades and drive systems that are fundamental for operation. Identifying the type of cutting tool and its configuration helps in optimizing performance and safety during use.

Fuel System: A well-functioning fuel system is crucial for efficient operation. Key components such as the fuel tank, filter, and pump must be recognized to ensure proper fuel flow and prevent potential issues.

Chassis and Frame: The structural integrity of the machine is provided by the chassis and frame. Understanding how these components support other systems can aid in identifying wear and necessary maintenance.

Familiarity with these critical elements not only aids in the upkeep but also enhances your overall operational proficiency, making your tasks more efficient and effective.

Benefits of Using Official Diagrams

Utilizing authorized schematics offers a range of advantages that enhance both understanding and maintenance processes. These resources serve as essential tools for users, providing clarity and precision in navigating complex systems.

- Accuracy: Official illustrations are crafted by experts, ensuring that all components and their relationships are depicted correctly.

- Consistency: Using standardized visuals helps maintain uniformity across various models, making it easier to compare and contrast different setups.

- Efficiency: Accessing these resources streamlines troubleshooting and repair tasks, saving time and effort.

- Safety: Authorized visuals often include crucial safety information, reducing the risk of accidents during maintenance.

Incorporating these validated representations into your workflow can significantly improve the effectiveness of repair and maintenance activities.

Comparing 460 Rancher to Other Models

When evaluating different models of outdoor power equipment, it’s essential to understand the unique characteristics and capabilities that set each one apart. By examining various options, users can identify the most suitable choice based on performance, weight, and features that cater to specific tasks. This comparison not only highlights strengths and weaknesses but also helps users make informed decisions for their needs.

Performance and Efficiency

One key aspect to consider is the performance and efficiency of each model. Some variants are engineered for higher power output, making them ideal for heavy-duty jobs, while others focus on fuel efficiency, appealing to users who prioritize economy over sheer power. Analyzing the horsepower ratings and torque can provide valuable insights into which model excels in demanding environments.

Design and Usability

Another crucial factor is the design and usability of the equipment. Certain models may feature ergonomic handles and lighter weights, enhancing user comfort during prolonged use. Others might incorporate advanced technology, such as easier starting mechanisms or vibration reduction systems. Comparing these design elements can significantly impact user experience and overall satisfaction.

Upgrades and Modifications for Performance

Enhancing the efficiency and functionality of outdoor equipment can significantly improve their usability and longevity. By implementing strategic upgrades, users can optimize performance, increase power output, and improve handling. This section explores various modifications that can elevate your machine’s capabilities.

Engine Enhancements

One of the most effective ways to boost performance is through engine modifications. Upgrading components such as the air filter and exhaust system can enhance airflow and increase horsepower. Additionally, tuning the carburetor or fuel injection system ensures the engine runs at optimal efficiency, providing better throttle response and overall performance.

Chassis and Suspension Modifications

Improving the chassis and suspension can greatly impact handling and stability. Reinforcing the frame and installing high-performance suspension kits can provide a smoother ride and better control over rough terrain. Adding wider tires can also enhance traction, allowing for improved maneuverability in challenging conditions.

By focusing on these areas, enthusiasts can transform their machines into powerful, reliable tools that meet the demands of any task or adventure.

Customer Reviews on 460 Rancher Parts

When it comes to maintaining outdoor machinery, user feedback plays a crucial role in guiding potential buyers. Reviews often highlight the quality, durability, and performance of various components, helping others make informed decisions. This section delves into what customers are saying about these essential elements for their equipment.

| Feature | Customer Rating | Comments |

|---|---|---|

| Durability | ★★★★☆ | Many users report that these components withstand rigorous use, showing minimal wear over time. |

| Ease of Installation | ★★★★★ | Most customers appreciate how straightforward it is to replace these items without needing specialized tools. |

| Performance | ★★★★☆ | Users have noted improved efficiency and smoother operation after upgrading their machinery with these components. |

| Value for Money | ★★★☆☆ | While some found the price slightly higher than alternatives, the consensus is that the quality justifies the cost. |

Overall, feedback from users indicates a high level of satisfaction with these crucial elements, pointing to their reliability and effectiveness in enhancing machinery performance.