Comprehensive Guide to 4L80E Parts Diagram

When delving into the intricate workings of automotive gear systems, a clear visual representation of each element is invaluable. This exploration focuses on the essential components that contribute to the efficiency and performance of a specific transmission model, shedding light on their interconnections and functions.

Recognizing the individual elements within a transmission system is crucial for both enthusiasts and professionals alike. By examining how each piece interacts, one gains insight into the overall functionality and potential areas for improvement or repair.

Whether you’re planning a rebuild or simply seeking to enhance your understanding, a comprehensive overview of these mechanical parts will prove beneficial. The details provided will serve as a guide, aiding in the identification and appreciation of the complex engineering behind modern transmissions.

Understanding the 4L80E Transmission

The 4L80E is a robust automatic gearbox widely used in various heavy-duty vehicles. Its design and engineering provide exceptional durability and efficiency, making it a favored choice among performance enthusiasts and professionals alike. This section delves into the fundamental aspects of this transmission, including its functionality, key components, and advantages.

Key Features

This transmission is known for its strong construction, enabling it to handle high torque loads effectively. It features a sophisticated electronic control system that optimizes shifting patterns based on driving conditions, enhancing both performance and fuel efficiency. The ability to adapt to different engine outputs allows for a smoother driving experience, making it suitable for both street and off-road applications.

Maintenance and Upgrades

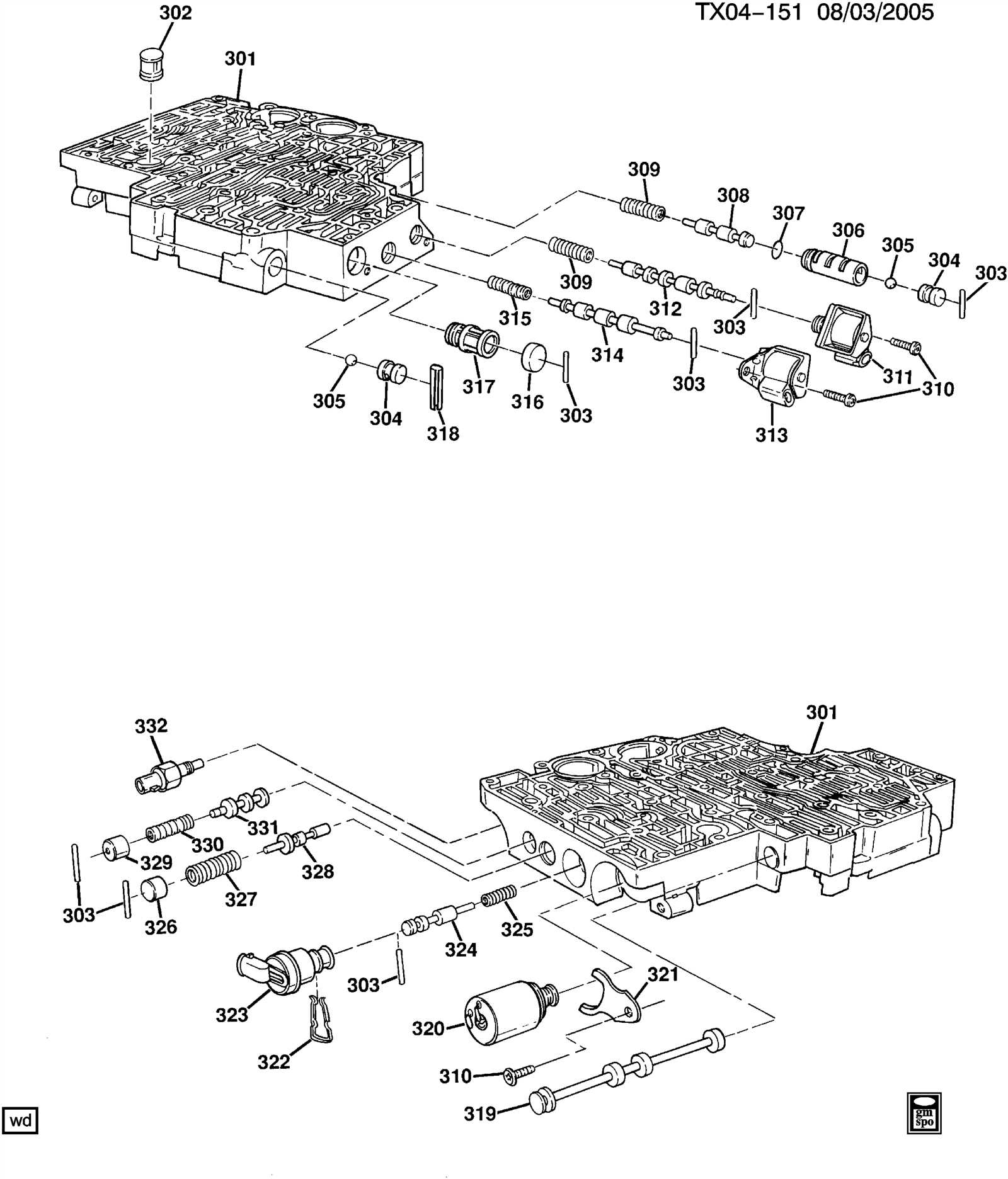

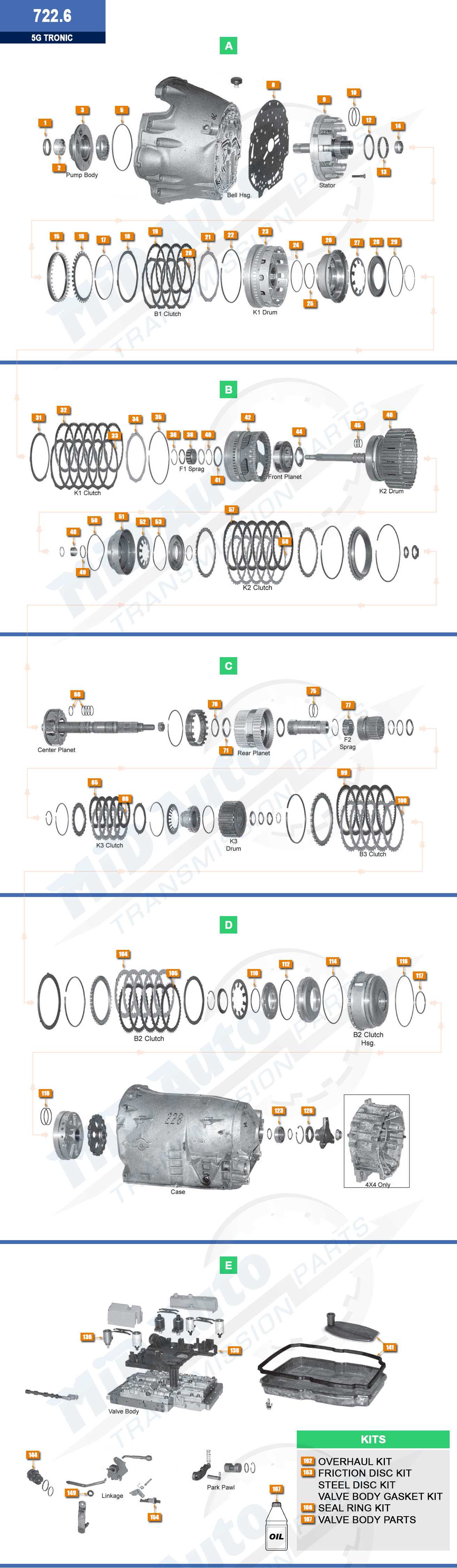

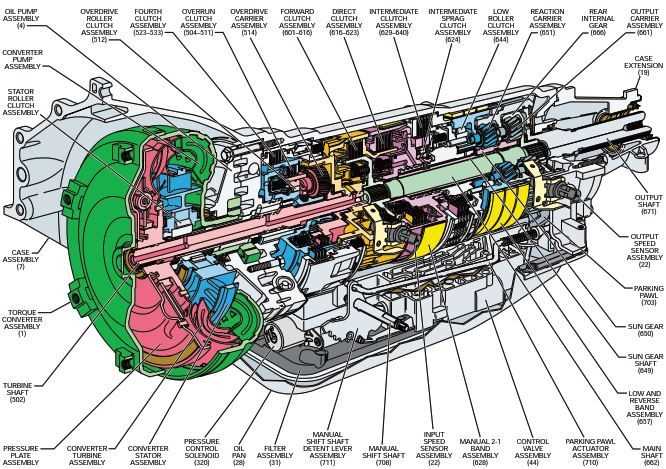

Key Components of 4L80E

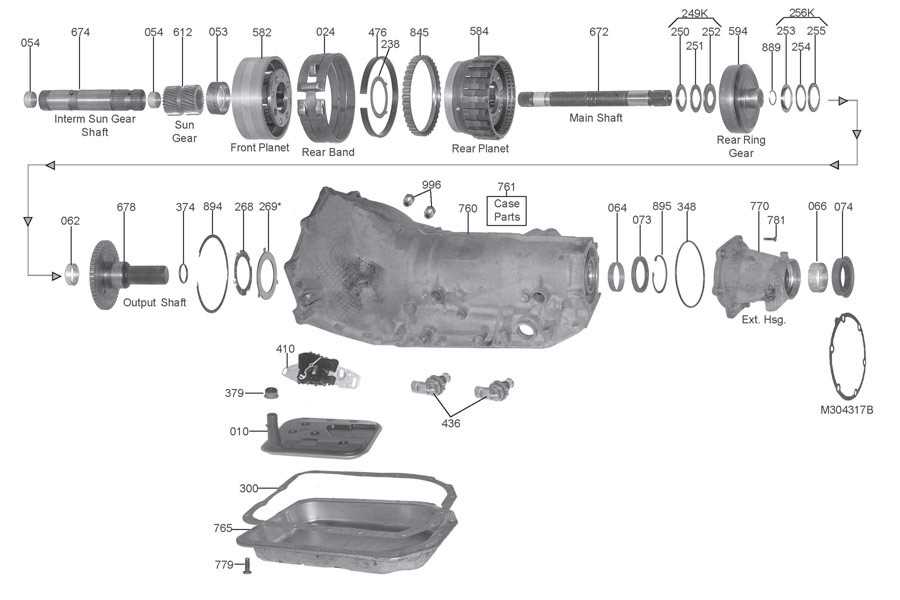

The transmission system consists of various essential elements that work in harmony to ensure optimal performance and reliability. Understanding these components is crucial for effective maintenance and repairs.

Main Elements

- Torque Converter

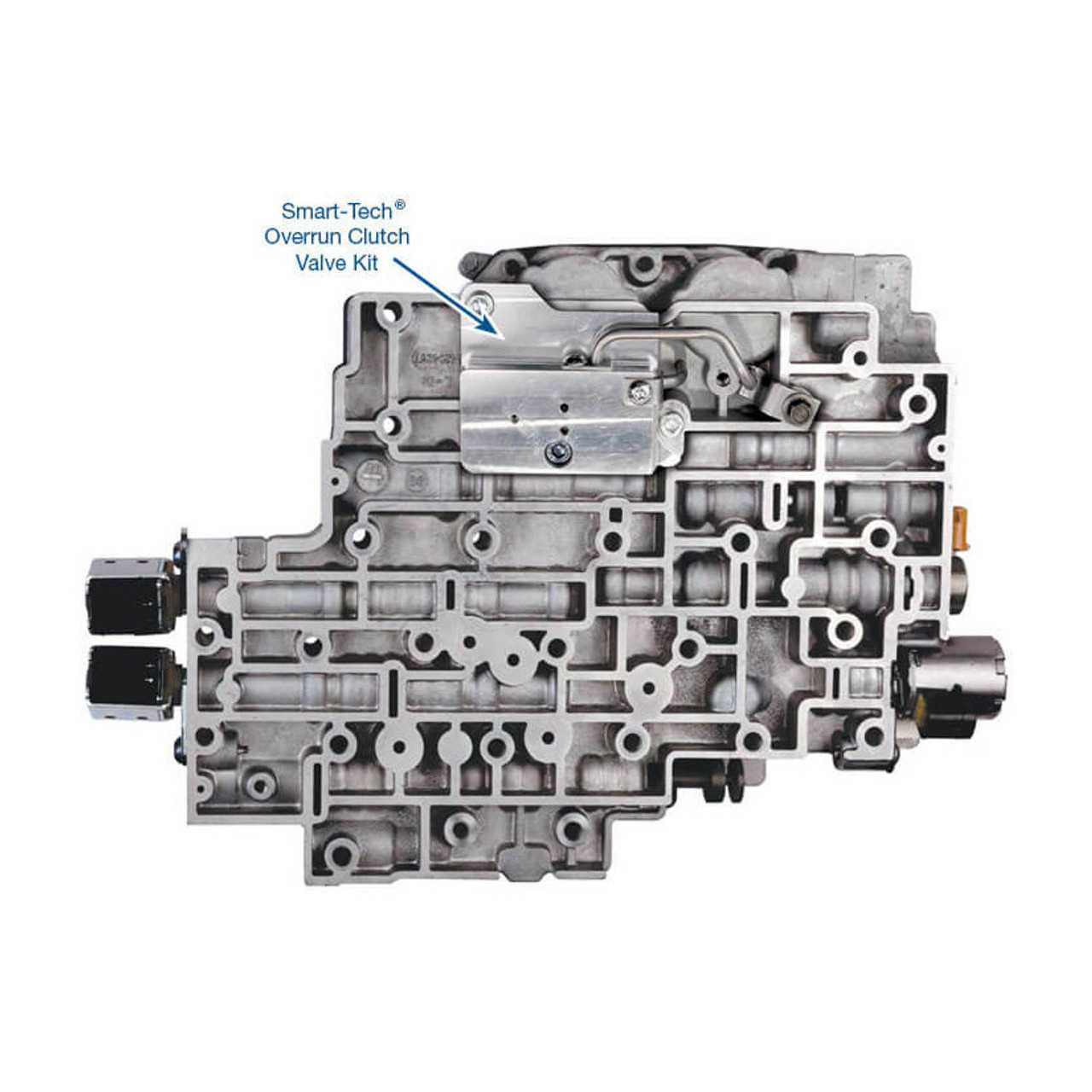

- Transmission Valve Body

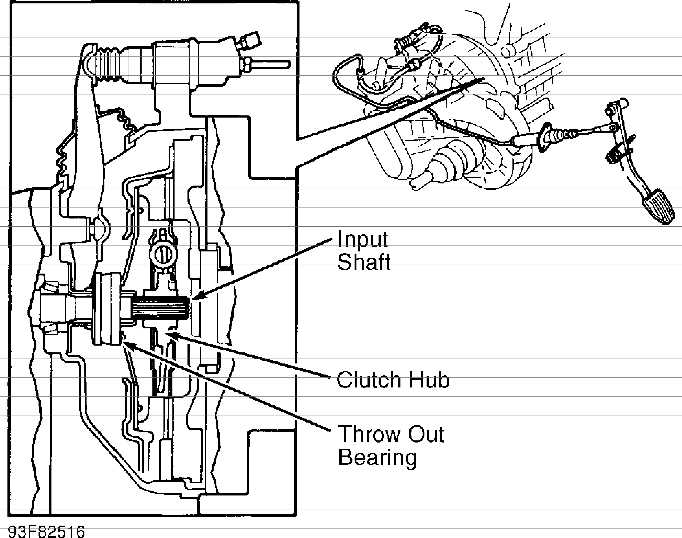

- Clutch Packs

- Planetary Gear Set

- Output Shaft

Supporting Components

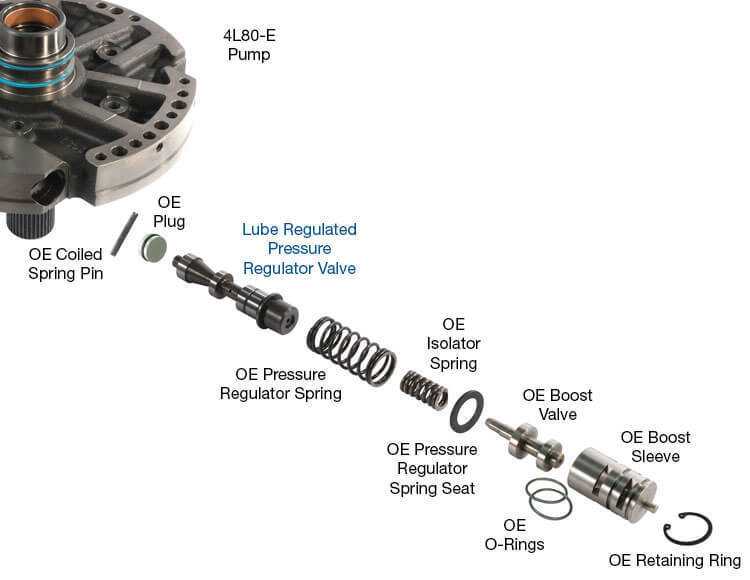

- Oil Pump

- Filter

- Accumulator

- Sensors and Actuators

Each of these components plays a significant role in the overall function of the system, contributing to power delivery and driving experience.

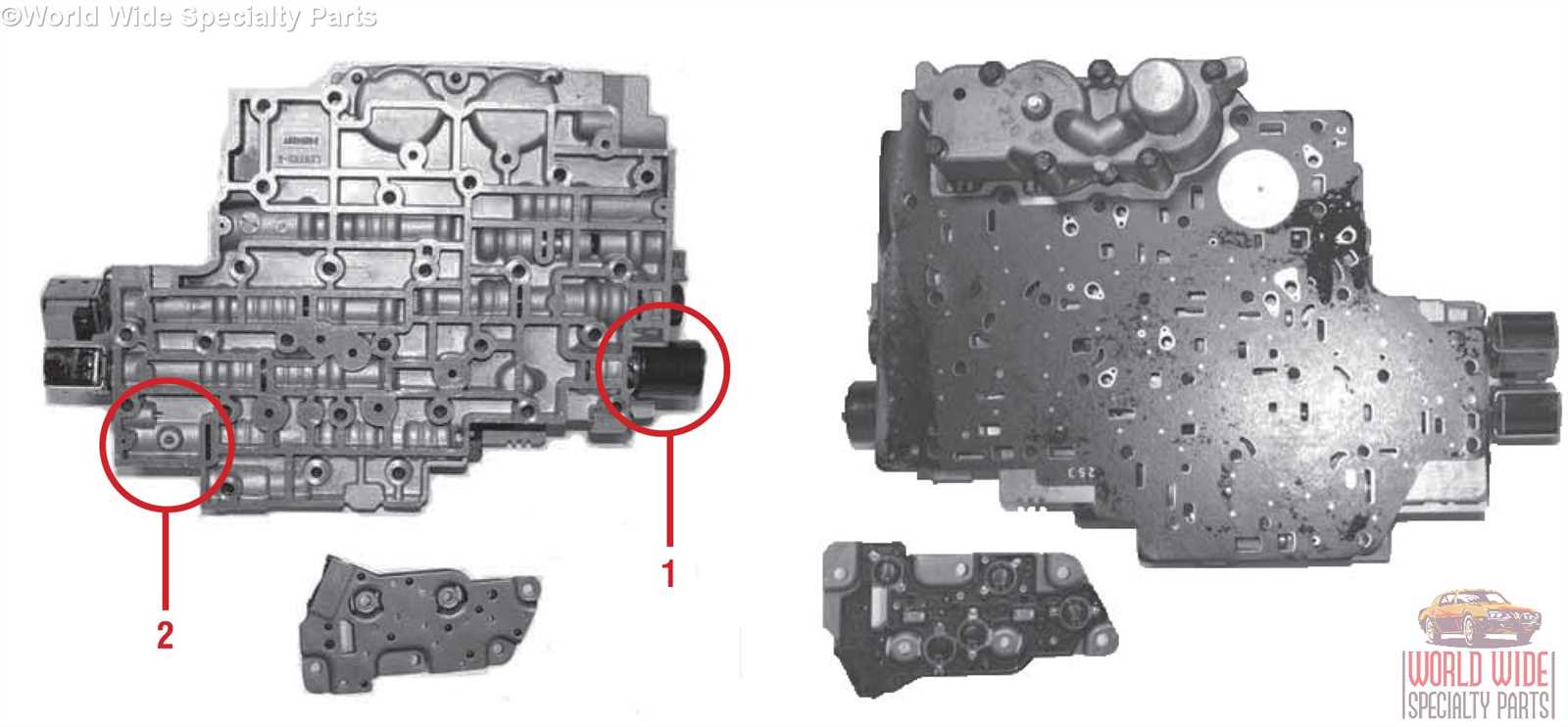

Importance of Parts Diagram

A detailed representation of components is essential for understanding the functionality and assembly of complex systems. It serves as a vital resource for both professionals and enthusiasts, enabling them to visualize the relationships between various elements and ensuring that everything fits together seamlessly.

Having access to such illustrations offers numerous advantages:

- Enhanced Understanding: Visual aids clarify how different components interact, making it easier to grasp intricate designs.

- Efficient Repairs: Identifying specific elements quickly streamlines troubleshooting and maintenance processes.

- Accurate Assembly: Clear references help in correctly putting together systems, reducing the risk of errors.

- Informed Upgrades: Knowledge of existing components allows for better decision-making when selecting replacements or enhancements.

In summary, visual representations of components play a crucial role in fostering comprehension, facilitating maintenance, and ensuring the longevity of mechanical systems.

Common Issues with 4L80E Parts

When dealing with automatic transmissions, various complications can arise that affect performance and reliability. Understanding these common challenges is essential for maintenance and repair. From wear and tear to fluid problems, each issue can lead to significant operational difficulties.

Wear and Tear

One of the most prevalent problems stems from the natural deterioration of components over time. Gears, clutches, and seals can experience significant wear, leading to slippage and shifting issues. Regular inspections and timely replacements can help mitigate these effects.

Fluid Contamination

Another critical concern involves the contamination of transmission fluid. Debris, metal shavings, and even moisture can compromise fluid integrity, resulting in poor lubrication and overheating. Keeping the fluid clean and at the correct level is vital for optimal function.

Prevention is key in maintaining a healthy transmission system. Regular maintenance, including fluid changes and inspections, can greatly enhance longevity and performance.

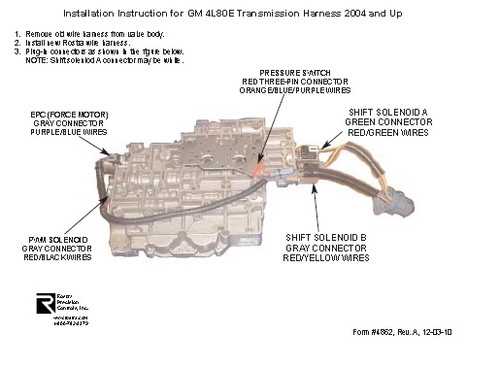

How to Read the Diagram

Understanding a technical illustration can greatly enhance your ability to work with mechanical components. These visual representations serve as blueprints, detailing the relationships and functionalities of various elements within a system. Grasping how to interpret these images is crucial for effective assembly, maintenance, and troubleshooting.

Begin by familiarizing yourself with the layout. Typically, key components are labeled clearly, allowing you to identify their roles quickly. Pay attention to the symbols used; each one represents a specific part or action. For example, arrows may indicate movement or flow, while boxes might denote individual components.

Next, examine the connections between elements. Lines often represent physical links or pathways, and understanding these connections is vital for diagnosing issues or planning repairs. Take note of any color coding or numbering systems, as they often provide additional context and can simplify navigation through complex systems.

Finally, consult the accompanying legend or key, which often explains the symbols and conventions used in the illustration. This resource is invaluable for clarifying any uncertainties and ensuring you fully comprehend the representation at hand. Mastering this skill will empower you to effectively manage and optimize the mechanical system you are working with.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your transmission system requires regular attention and care. Adopting a proactive maintenance routine can significantly extend the lifespan of your equipment and prevent costly repairs. Here are some essential practices to keep in mind.

Regular Fluid Checks

Monitoring and changing the fluid at specified intervals is crucial. Clean, high-quality fluid helps in proper lubrication and temperature regulation, reducing wear on internal components. Always use the manufacturer’s recommended type for best results.

Routine Inspections

Conducting routine inspections allows for the early detection of potential issues. Look for leaks, unusual noises, or performance inconsistencies. Addressing these problems promptly can prevent more severe damage and extend the life of your system.

Replacement Parts Overview

This section provides a comprehensive look at essential components required for the effective functioning of automatic transmission systems. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity.

Key Components

Among the vital elements are clutches, solenoids, and pumps. Each component plays a significant role in the transmission’s operation, contributing to smooth shifting and overall efficiency. Selecting high-quality replacements is essential for reliability.

Maintenance Considerations

Regular inspection and timely replacement of worn-out components can prevent extensive damage and costly repairs. Staying informed about available options helps in making the ultimate choice for your vehicle’s needs.

Tools Needed for Repairs

When embarking on any mechanical restoration, having the right instruments at your disposal is crucial for efficiency and precision. The appropriate tools not only facilitate smoother operations but also ensure that tasks are performed correctly, minimizing the risk of damage.

Essential Equipment: A comprehensive toolkit should include a variety of wrenches, sockets, and screwdrivers tailored to fit specific fasteners. Additionally, a torque wrench is vital for achieving the correct tightness on critical components.

Specialized Tools: For more intricate work, items such as a transmission jack and fluid transfer pump are indispensable. These tools help maneuver heavy parts and manage fluids safely, enhancing the overall repair experience.

Lastly, don’t forget to include safety gear, like gloves and goggles, to protect yourself during the repair process. Having these tools on hand will ultimately make your project more manageable and successful.

Identifying Wear and Tear

Recognizing signs of deterioration in mechanical components is crucial for maintaining optimal performance. Over time, parts can experience various forms of degradation, which can lead to inefficiencies or failures. Understanding how to spot these issues early can save both time and resources.

Common Indicators: Look for visual cues such as discoloration, cracks, or excessive wear. These signs often suggest that a component may no longer function effectively. Additionally, unusual noises during operation can point to underlying problems that require attention.

Regular Inspections: Conducting routine checks is essential for identifying potential issues. Focus on high-stress areas that are prone to fatigue. Keeping a close eye on these regions can help you catch wear before it escalates into a more significant concern.

Performance Monitoring: Pay attention to any changes in performance metrics. A noticeable drop in efficiency may indicate that certain components are not working as they should. This can manifest in shifts in responsiveness or increases in operational noise.

Documentation: Keeping detailed records of inspections and maintenance can provide insights into trends of wear and help in predicting future issues. Tracking these patterns is invaluable for proactive management of mechanical systems.

Upgrading Your 4L80E System

Enhancing your transmission system can significantly improve performance, reliability, and driving experience. By focusing on key components and modifications, you can tailor the system to meet your specific needs, whether for daily driving or high-performance applications. This guide will explore essential upgrades that can elevate your transmission’s capabilities.

Key Components to Consider

When upgrading, it’s vital to assess the components that impact overall efficiency. Clutches and bands play a crucial role in power transfer, and upgrading to higher-quality options can provide better grip and longevity. Additionally, servos and valve bodies can be enhanced to improve shifting performance and responsiveness, making the driving experience smoother and more enjoyable.

Performance Enhancements

Incorporating aftermarket solutions such as a performance torque converter can dramatically enhance torque management and acceleration. A well-matched converter not only increases power transfer but also improves fuel efficiency. Furthermore, considering a transmission cooler can help maintain optimal operating temperatures, reducing wear and prolonging lifespan.

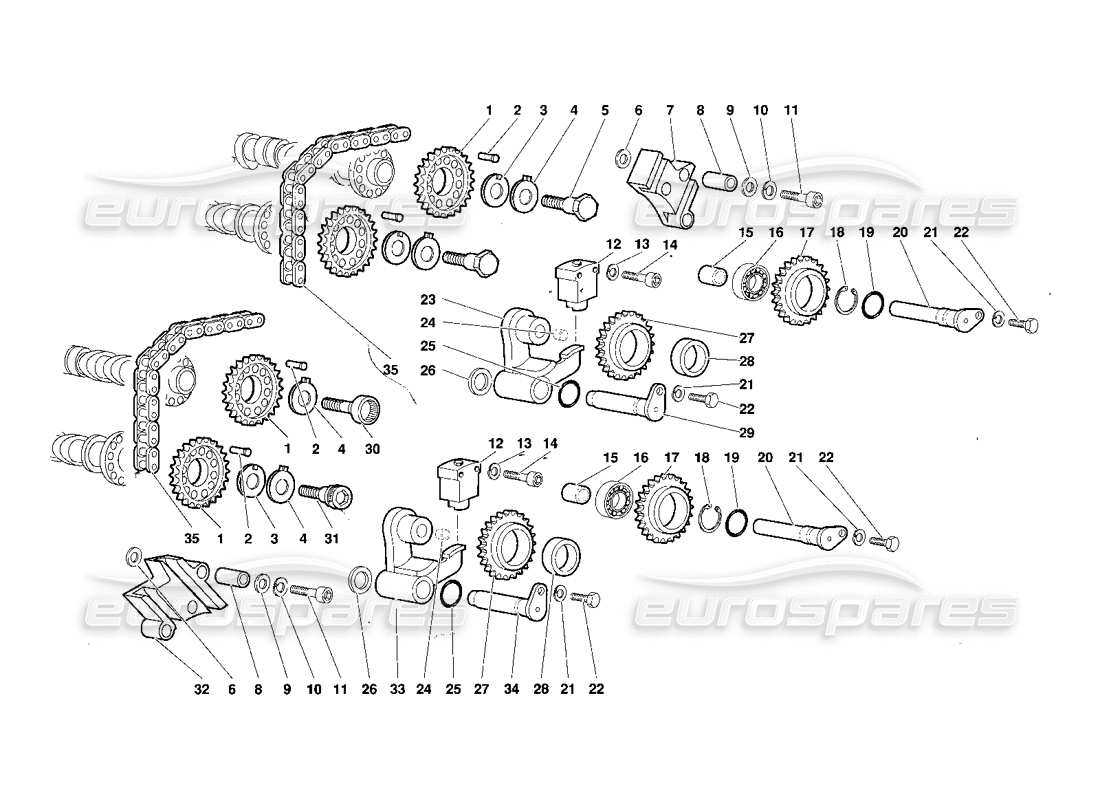

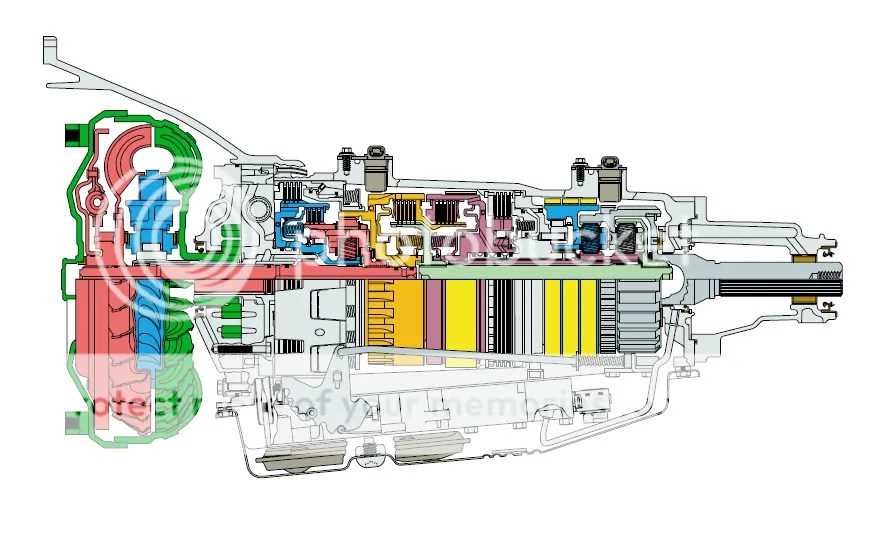

Diagram Variations Across Models

Understanding the differences in schematic representations across various models can greatly enhance one’s ability to troubleshoot and repair. Each variant may feature distinct components and layouts that reflect advancements in design and functionality.

Key Differences to Consider

- Component Placement

- Types of Materials Used

- Inclusion of Updated Features

Common Variants

- Standard Configuration

- Performance-Oriented Version

- Heavy-Duty Edition

Resources for Further Research

For those looking to deepen their understanding of transmission components and their intricate workings, a wealth of information is available. Engaging with various resources can enhance your knowledge and assist in troubleshooting or upgrading systems effectively.

Online Forums and Communities

Participating in automotive forums can provide valuable insights from experienced enthusiasts and professionals. These platforms often feature discussions, troubleshooting tips, and shared experiences that can illuminate complex topics.

Technical Manuals and Guides

Accessing comprehensive manuals can serve as a fundamental resource. These documents typically outline specifications, maintenance procedures, and assembly instructions, enabling users to gain a thorough grasp of the subject matter.