Understanding the Berkel Slicer Parts Diagram

The intricate world of food preparation equipment involves a variety of specialized tools designed for efficiency and precision. Among these tools, certain machines stand out due to their exceptional ability to handle delicate tasks with ease. This section aims to explore the various elements that contribute to the functionality of such a device, offering insights into their arrangement and significance.

By examining the configuration of these components, one can gain a deeper understanding of how they work in harmony to produce consistent results. Each part plays a crucial role, from the mechanisms that control slicing thickness to the elements ensuring safety and durability. The synergy between these features ultimately enhances the user experience and the quality of the output.

As we delve into the specifics, it becomes evident that knowledge of these elements not only aids in proper maintenance but also informs users about the machine’s full potential. Understanding how these components interact can lead to improved operational techniques, maximizing efficiency and effectiveness.

Understanding Berkel Slicers

In the realm of culinary tools, certain devices stand out due to their precision and craftsmanship. These instruments are designed to effortlessly transform various ingredients into uniform slices, enhancing both presentation and flavor. Mastering the intricacies of these machines can elevate food preparation, making it both efficient and enjoyable.

Key Components

The functionality of these tools relies on several essential elements. Each part plays a crucial role in ensuring smooth operation, from the sharp blade to the sturdy base. Understanding how these components interact can help users maintain their equipment and achieve the ultimate results.

Maintenance Tips

Regular upkeep is vital for optimal performance. Cleaning, sharpening the blade, and checking alignment are important steps to prevent wear and tear. By delving into these maintenance practices, users can extend the lifespan of their equipment and consistently produce exceptional slices.

Components of a Berkel Slicer

This section explores the essential elements that make up a traditional meat-cutting device, highlighting their functions and importance in the overall operation.

- Base: Provides stability and support, ensuring safe usage.

- Blade: The sharp component responsible for slicing; its design influences the thickness and quality of cuts.

- Carriage: Holds the item being cut and moves it towards the blade for even slicing.

- Feed Mechanism: Facilitates smooth movement of the carriage, allowing for consistent pressure and precision.

- Adjustment Knob: Used to set the desired thickness of the slices, crucial for customization.

Understanding these components is essential for anyone looking to delve deeper into the mechanics of this device.

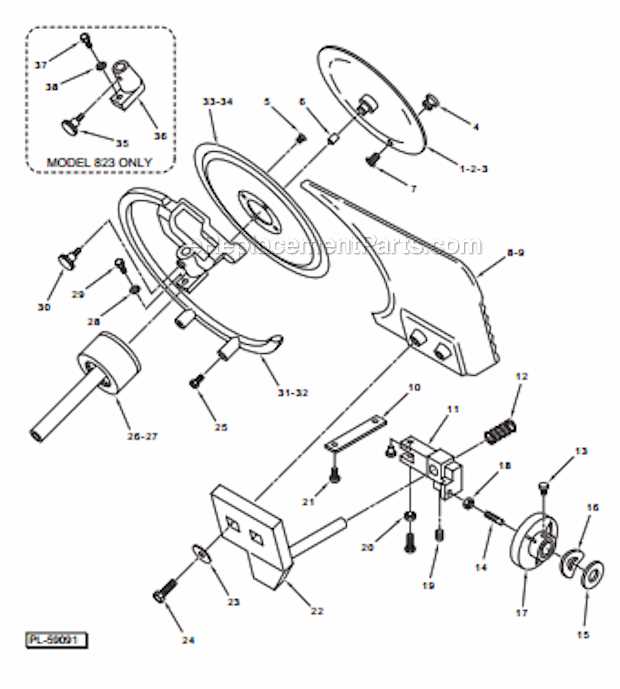

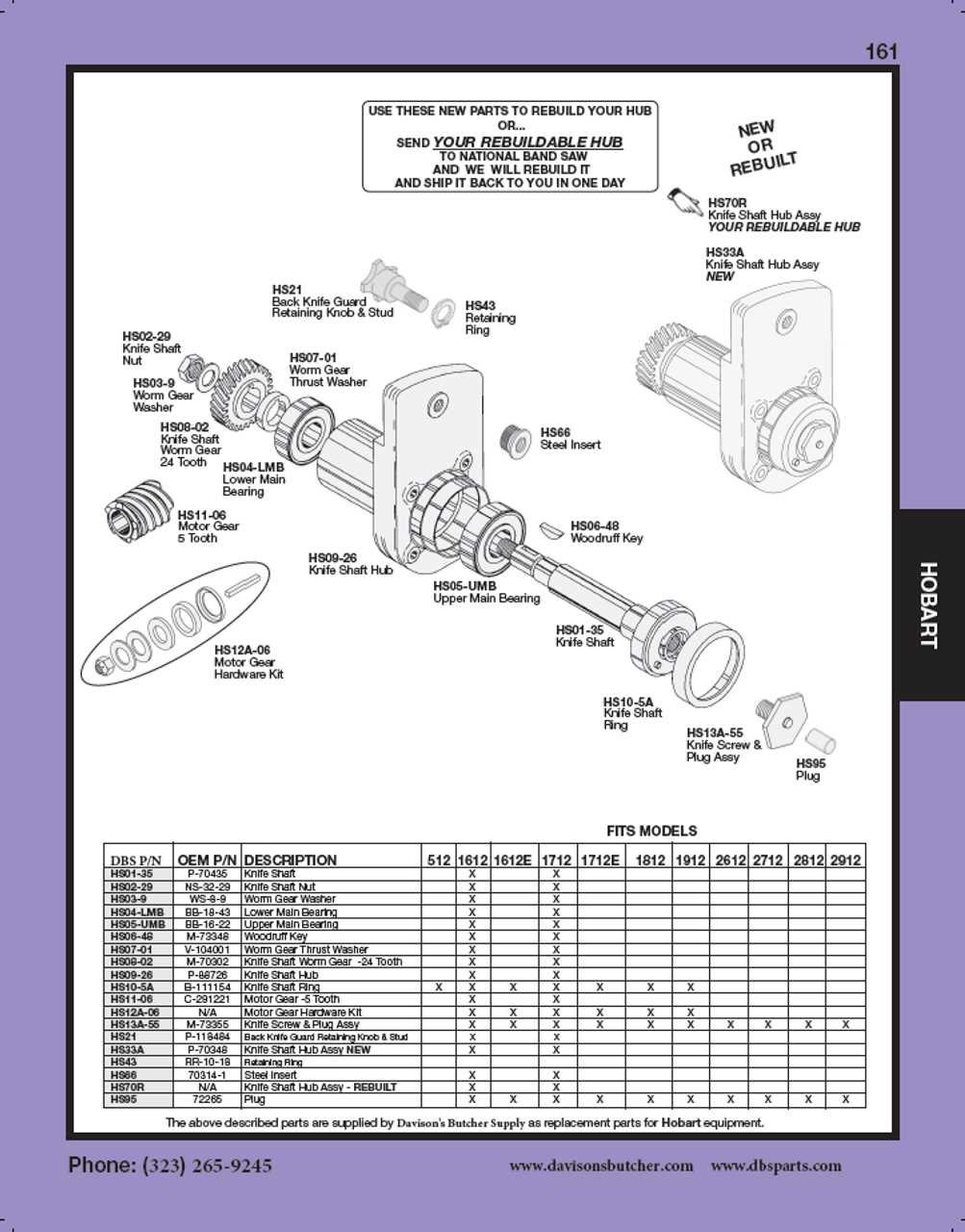

How to Read the Parts Diagram

Understanding a technical illustration can greatly enhance your ability to maintain and repair your equipment. These visual representations provide crucial information about various components, their arrangement, and how they interact with each other. Familiarizing yourself with the layout and terminology used in these schematics is essential for effective troubleshooting and replacement of elements.

First, identify the key sections of the illustration. Typically, you will find a legend that explains symbols and numbers associated with each component. This legend serves as a guide to understanding what each part is and how it contributes to the overall function of the machine.

Next, focus on the labels. Components are often numbered or named, allowing you to cross-reference them with the parts list or manual. By matching these identifiers, you can easily locate the specific pieces needed for repairs or maintenance.

Lastly, take note of the connections between components. Understanding how different parts interact helps in identifying potential issues and their solutions. Pay attention to arrows and lines that indicate movement or flow, as these provide insight into the operation of the machine.

By mastering these elements, you will be better equipped to interpret technical illustrations, making maintenance tasks more straightforward and efficient.

Common Issues with Slicer Parts

When working with precision equipment designed for cutting, users often encounter various challenges that can affect performance and efficiency. Understanding these typical problems can help in maintaining optimal functionality and prolonging the lifespan of the machinery.

- Worn Blades: Dull or damaged cutting edges can lead to uneven slices and increased strain on the motor.

- Alignment Issues: Misalignment of components may cause excessive vibrations and noise, impacting both safety and precision.

- Wear and Tear: Over time, components may degrade due to continuous use, requiring regular inspections and replacements.

- Electrical Failures: Issues with wiring or motor can result in intermittent operation or complete shutdown of the device.

- Cleaning Challenges: Residue buildup can hinder performance and pose hygiene risks, emphasizing the need for routine maintenance.

By being aware of these potential problems, users can take proactive steps to ensure their equipment remains in peak condition.

Maintenance Tips for Longevity

Proper upkeep of your equipment is crucial for ensuring its efficiency and extending its lifespan. Regular attention not only helps maintain optimal performance but also prevents unexpected breakdowns. By following a few essential guidelines, you can keep your machinery running smoothly and reliably for years to come.

Regular Cleaning

One of the simplest yet most effective ways to prolong the life of your apparatus is through routine cleaning. Accumulation of debris and residue can hinder performance and cause wear over time. Utilize appropriate cleaning agents and tools, and pay special attention to hard-to-reach areas.

Scheduled Inspections

Incorporating regular inspections into your maintenance routine allows for early detection of potential issues. Check for wear and tear on components, and ensure that all mechanisms are functioning correctly. Identifying problems early can save time and resources in the long run.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Clean the surface | Daily | Use a damp cloth and mild detergent. |

| Inspect components | Weekly | Look for any signs of damage or wear. |

| Lubricate moving parts | Monthly | Use recommended lubricants to ensure smooth operation. |

| Check electrical connections | Quarterly | Ensure all connections are secure and free of corrosion. |

Identifying Replacement Parts Easily

Finding the right components for kitchen equipment can be a straightforward process if approached systematically. Understanding the essential elements involved and their functions allows for efficient identification, ensuring smooth operation and longevity of the appliance.

Visual aids such as exploded views can significantly enhance your ability to pinpoint necessary replacements. By having a clear reference, users can easily match the required elements with their corresponding positions, reducing confusion and saving time.

Additionally, maintaining a detailed inventory of existing components and their specifications can aid in quick identification when a replacement is needed. This proactive approach minimizes downtime and ensures that your equipment remains in optimal condition.

Utilizing online resources, including forums and manufacturer websites, provides access to valuable insights and community support. Engaging with others who share similar equipment can yield recommendations and tips for identifying and sourcing replacements efficiently.

Importance of Original Berkel Parts

Using authentic components in machinery is crucial for maintaining optimal performance and longevity. These elements are specifically engineered to fit seamlessly with the equipment, ensuring that it operates at peak efficiency and safety. When it comes to premium culinary tools, the significance of choosing original items cannot be overstated.

Quality Assurance

Original components are manufactured under strict quality control standards, which guarantees reliability and durability. Utilizing these genuine elements means that users can trust their equipment to deliver consistent results over time. In contrast, aftermarket alternatives may compromise performance and lead to unforeseen malfunctions.

Enhanced Performance

Incorporating authentic items enhances the overall functionality of the machine. They are designed to work harmoniously with all other components, promoting smoother operation and reducing wear and tear. This not only improves efficiency but also minimizes maintenance costs in the long run.

In conclusion, investing in original components is essential for anyone looking to uphold the integrity and performance of their culinary equipment. The benefits of quality assurance and enhanced functionality make it a wise choice for both professional chefs and home cooks alike.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right instruments is crucial for efficiency and safety. Proper tools not only expedite the repair process but also ensure that tasks are completed accurately, reducing the risk of future issues.

Essential equipment includes a set of screwdrivers, which allows for the removal and tightening of various fasteners. A wrench set is also necessary for adjusting bolts and nuts, ensuring secure connections. In addition, a utility knife is handy for cutting through materials and components with precision.

For more intricate repairs, consider a multimeter to check electrical connections and diagnose faults. Safety gear, such as gloves and goggles, is vital to protect yourself from potential hazards during the repair process. Finally, a reliable work surface will provide stability while you work on your equipment.

Step-by-Step Repair Guide

Maintaining your equipment can be a straightforward process when approached methodically. This guide will walk you through the essential steps needed to restore functionality to your machine, ensuring it operates smoothly and efficiently.

Step 1: Begin by gathering all necessary tools and materials. Ensure you have a clean workspace to facilitate the repair process. Familiarize yourself with the components you will be working on.

Step 2: Disconnect the device from any power source to guarantee safety. Carefully remove any covers or shields that protect internal mechanisms, taking note of how they are attached.

Step 3: Inspect each component for wear or damage. Look for signs of rust, breakage, or misalignment. Document any issues that need addressing, as this will guide your repairs.

Step 4: Replace any faulty components. Ensure that replacements are compatible and properly fitted. Use manufacturer recommendations where available to achieve the best results.

Step 5: Reassemble the machine in reverse order of disassembly. Take your time to ensure everything aligns correctly and is secured tightly.

Step 6: Reconnect the power source and test the machine. Monitor its operation to confirm that the repairs were successful. If issues persist, revisit your previous steps to troubleshoot further.

By following this systematic approach, you can effectively address any concerns and extend the life of your equipment.

Comparing Berkel Models and Parts

When evaluating various models and components of a renowned Italian machine maker, it’s essential to understand the differences and similarities that define their functionality and appeal. Each model serves unique culinary needs while maintaining a standard of quality and precision that users expect. This analysis focuses on how different versions cater to diverse requirements, helping users make informed decisions based on their specific applications.

Performance Variability is a critical aspect when comparing these machines. Some versions offer enhanced slicing capabilities, allowing for thicker or thinner cuts depending on the user’s preference. Meanwhile, others emphasize speed and efficiency, making them ideal for commercial environments. Understanding these distinctions helps in selecting a model that aligns with individual or business demands.

Durability is another factor worth considering. While all models are designed to withstand rigorous use, certain versions may incorporate higher-grade materials that extend their lifespan. This resilience can be particularly beneficial in high-volume settings where wear and tear is a significant concern. Knowing which machines feature robust construction can guide users toward a more sustainable investment.

Additionally, accessibility of components plays a vital role in maintenance and repairs. Models vary in the ease with which users can obtain replacements or conduct upkeep. Some may offer readily available parts, while others might require more specialized sources. This factor can impact long-term usability and should be a key consideration during the selection process.

Lastly, design and aesthetics cannot be overlooked. Each version boasts unique visual features, catering to diverse stylistic preferences. Whether for a home kitchen or a professional setting, the look and feel of the machine can significantly influence a user’s choice. Understanding the balance between form and function is crucial in identifying the right model.

Where to Buy Berkel Parts

When it comes to sourcing components for your specialized equipment, finding reliable suppliers is essential. Whether you are looking for original replacements or compatible alternatives, numerous options exist to ensure your machine operates smoothly. Knowing where to look can save you time and effort, as well as ensure the longevity of your investment.

Online marketplaces offer a vast selection, with various retailers specializing in culinary tools and accessories. These platforms often provide user reviews and ratings, allowing you to assess the quality of the items before purchasing. Additionally, many manufacturers have official websites where you can find genuine components, ensuring compatibility and reliability.

Local appliance repair shops can also be valuable resources. Many of these establishments stock essential elements or can order them for you, often providing expert advice on installation and maintenance. Networking with other professionals in your industry may also yield recommendations for trusted suppliers.