Bissell Cleanview Parts Breakdown

Understanding how different elements of a device work together is essential for keeping it in optimal condition. Having a clear visualization of the internal components allows for easier maintenance, troubleshooting, and part replacement when needed. A well-organized breakdown can greatly assist in identifying key areas that require attention.

Visualizing the assembly of a product helps to see how each element plays a role in its functionality. Whether you need to perform routine maintenance or replace certain elements, having access to detailed information makes the process straightforward and efficient.

In this guide, you will find a comprehensive breakdown of the main internal and external components, enabling you to easily navigate the structure of the machine. This knowledge is crucial for anyone looking to maintain or enhance the performance of their equipment.

Key Components Overview

The vacuum cleaner is made up of various essential parts that work together to ensure efficient cleaning performance. Understanding these components is important for maintenance and optimal use. Below is an overview of the critical elements that contribute to its overall functionality.

Motor Unit: This is the powerhouse, responsible for generating the suction needed to pick up dirt and debris from floors. A well-maintained motor ensures consistent performance.

Filtration System: The filter plays a crucial role in trapping dust and allergens, keeping the air clean while the vacuum operates. Regular cleaning or replacement of the filter helps maintain air quality.

Brush Roll: Positioned at the base, the brush roll agitates the carpet fibers, loosening dirt and ensuring a thorough clean

Main Structure and Design Features

The overall layout of this cleaning device incorporates a well-organized framework that balances practicality with user-friendly elements. Its design prioritizes efficiency, ensuring ease of use while maximizing functionality during operation.

- Durable frame: Built to withstand regular use, ensuring long-lasting performance.

- Ergonomic handle: Designed for comfortable handling and improved maneuverability.

- Transparent container: Allows for easy monitoring of collected debris and quick disposal.

- Advanced filtration: Equipped with a multi-level system to capture dust and allergens efficiently.

- Flexible attachments: Versatile tools that enhance performance on various surfaces.

Exploring the Dustbin Mechanism

The dust collection system is a crucial part of any vacuum, ensuring that debris is efficiently captured and stored. This section will delve into how the dustbin mechanism operates, focusing on its structure and functionality. Understanding this will help improve maintenance and usage, ensuring optimal cleaning performance.

- The container is designed to hold various types of dirt and particles, including larger debris like crumbs and smaller dust particles.

- Its transparent body allows users to easily monitor when it needs to be emptied, ensuring continuous operation without blockages.

- The latch system secures the dustbin in place, preventing accidental spills during use.

- Many models feature a quick-release button, simplifying the process of removing and emptying the container.

- Filters are often integrated into the system to trap fine particles, ensuring cleaner air is expelled back into the environment.

By understanding the key components and functions of the dustbin system, users can better manage the vacuum’s upkeep, leading to more effective cleaning results.

Brush Roll and its Maintenance

The brush roll is a critical component in ensuring effective cleaning by agitating dirt and debris from various surfaces. Proper upkeep of this feature is essential to maintaining optimal performance and longevity. Regular care will prevent blockages and wear, helping to extend the overall life of your device.

To maintain the brush roll, it is recommended to check for tangled hair, threads, or other debris that might obstruct its movement. A thorough inspection should be done frequently, especially after cleaning high-traffic areas. Removing blockages promptly will prevent excessive strain on the motor and ensure efficient operation.

If you notice a decrease in cleaning efficiency, it may be time to remove the brush roll for a more detailed cleaning. Detach it carefully and clear out any accumulated dirt or fibers. After cleaning, ensure the roll is properly aligned before reattaching it, as improper positioning could impact performance.

Filtration System: Parts and Functions

The filtration system is crucial for maintaining the efficiency and cleanliness of any vacuum cleaner. It ensures that dust and debris are properly separated, preventing particles from being released back into the air. Understanding the components of this system helps to keep the device running smoothly while promoting a cleaner indoor environment.

Primary Filter: This component captures larger debris, ensuring that they don’t clog other parts of the system. Regular cleaning of this filter is essential for optimal performance.

Secondary Filter: Positioned behind the main one, this filter works to trap smaller particles that may have passed through the first layer. It plays a key role in preventing fine dust from reaching the motor.

HEPA Filter: The HEPA filter is designed to capture even the finest allergens and dust particles, offering superior air

Hose Assembly: How It Works

The hose assembly is a vital component of a vacuum cleaner, facilitating the efficient transfer of dirt and debris from the floor to the collection tank. This flexible tube allows for easy maneuverability and access to various surfaces, ensuring thorough cleaning. Understanding its operation can enhance your cleaning experience and maintain optimal performance.

At its core, the hose assembly consists of a durable tube designed to withstand wear and tear while providing a reliable connection between the main body of the cleaner and various attachments. When activated, the suction generated by the vacuum pulls air and particles through the hose, effectively removing dirt from carpets, upholstery, and hard floors.

The assembly typically includes connectors that securely attach to both the vacuum body and the cleaning tools. These connectors ensure a tight seal, preventing loss of suction and enhancing overall efficiency. Regular inspection and maintenance of the hose assembly are essential to avoid clogs and ensure uninterrupted cleaning performance.

To further optimize functionality, many hose assemblies feature additional components such as filters and brushes that work in tandem with the suction mechanism. These elements help to capture fine dust particles and improve the cleanliness of the air expelled from the machine.

In summary, the hose assembly plays a crucial role in the cleaning process, contributing to the overall effectiveness of the vacuum cleaner. Proper understanding and care of this component can significantly impact the cleaning results and extend the life of the appliance.

Understanding the Belt System

The belt system in a vacuum cleaner plays a crucial role in its overall functionality. It connects the motor to the brush roller, enabling the device to effectively pick up dirt and debris from various surfaces. Understanding how this system operates is essential for proper maintenance and troubleshooting.

There are several key components involved in the belt mechanism:

- Belt: This flexible band transfers power from the motor to the brush, allowing for effective cleaning.

- Brush Roller: The rotating brush that agitates carpet fibers and lifts dirt for better suction.

- Motor: The engine that powers the entire unit, driving the belt and brush roller.

- Idler Pulley: This component helps maintain tension on the belt, ensuring it operates smoothly.

Regular inspection of the belt system is recommended to prevent performance issues. Signs of wear, such as cracks or fraying, may indicate the need for replacement. Maintaining the integrity of this system will help prolong the lifespan of the vacuum cleaner and enhance its cleaning efficiency.

In summary, understanding the belt system is vital for effective cleaning and upkeep. By knowing its components and functions, users can ensure their vacuum cleaner operates at its best.

Power Switch and Control Elements

The power switch and control components of a cleaning device play a crucial role in its operation. These elements allow users to easily manage the functionality of the appliance, ensuring efficient performance during use. Understanding how these controls work can enhance the overall cleaning experience.

Power Switch: The primary control mechanism enables the user to turn the device on or off. This essential feature is designed for convenience, often located within easy reach for quick access during operation.

Control Buttons: Various buttons or dials may be present to adjust settings such as suction power and mode selection. These controls are intuitive, allowing users to customize their cleaning experience based on specific needs.

Indicator Lights: Some devices are equipped with indicator lights that provide visual feedback about the status of the appliance, such as power activation or maintenance reminders. This feature helps users stay informed about the operational state of their equipment.

Base Plate and Protective Covers

The base plate and protective covers are essential components that provide stability and safeguarding for the internal mechanisms of a vacuum cleaner. Their design is critical for ensuring optimal performance and longevity, as they help to shield sensitive parts from damage while enhancing the overall user experience.

Importance of the Base Plate

The base plate serves as the foundation of the appliance, offering support and balance during operation. It plays a significant role in maintaining proper airflow, which is crucial for effective dirt and debris suction. Additionally, a sturdy base plate helps to minimize vibrations, ensuring smoother operation and reducing wear on internal parts.

Protective Covers Functionality

Protective covers are designed to shield various components from dust, dirt, and potential impact. They not only extend the life of the machine but also contribute to user safety by preventing accidental contact with moving parts. Regular inspection and maintenance of these covers are advisable to ensure they are intact and functioning correctly.

| Component | Function | Maintenance Tips |

|---|---|---|

| Base Plate | Provides stability and supports airflow | Check for cracks and ensure secure attachment |

| Protective Covers | Shield internal parts from dirt and damage | Inspect for wear and clean regularly |

Attachments and Accessory Parts

Understanding the various accessories and attachments that enhance the functionality of your cleaning equipment is essential for optimal performance. These components play a crucial role in ensuring that the device operates efficiently, catering to different cleaning needs and surfaces. Each accessory is designed to provide specific advantages, making it easier to tackle various tasks around the home or workspace.

Types of Accessories

Various attachments are available, including specialized nozzles, brushes, and extension hoses. Each type serves a unique purpose, such as reaching tight spaces, deep cleaning carpets, or effectively removing pet hair. Selecting the right accessory can significantly improve cleaning results, ensuring that every area is addressed appropriately.

Maintenance and Care

To prolong the life of your attachments, regular maintenance is necessary. Cleaning brushes and nozzles after each use can prevent clogs and maintain suction power. Additionally, storing accessories in a designated area helps keep them organized and ready for use when needed. Proper care ensures that each component performs at its best, making cleaning tasks more efficient.

Handle and Carrying Mechanism

The handle and carrying mechanism of a vacuum cleaner is essential for user convenience and mobility. This component is designed to provide a comfortable grip and facilitate easy transportation from one area to another, enhancing the overall cleaning experience. A well-engineered handle not only allows for smooth maneuverability but also supports the weight of the device, ensuring stability during use.

Ergonomic Design

An ergonomic design is a crucial aspect of the handle, as it helps reduce strain on the user’s hands and wrists during extended cleaning sessions. Features such as soft grips and adjustable heights cater to various user preferences, promoting a more comfortable and efficient operation.

Durability and Stability

Durability is another vital characteristic of the carrying mechanism. High-quality materials are used to ensure that the handle can withstand the rigors of daily use while maintaining stability. This robustness is essential for preventing accidental breaks or malfunctions, ultimately leading to a more reliable and satisfying cleaning tool.

Replacing the Wheels and Casters

Maintaining the mobility of your cleaning appliance is crucial for optimal performance. Over time, wheels and casters may wear out or become damaged, impacting maneuverability. This section will guide you through the process of replacing these components to ensure your device operates smoothly.

Before starting, gather the necessary tools such as a screwdriver and replacement wheels. Begin by turning the appliance upside down, allowing easy access to the base. Carefully remove the screws securing the wheels and casters in place. Keep these screws, as you will need them for the installation of the new parts.

Next, detach the worn wheels and casters. Align the new components with the designated slots and firmly attach them using the screws you previously removed. Ensure everything is securely fastened to prevent any future issues. Finally, flip the appliance back to its upright position and test the wheels for smooth operation.

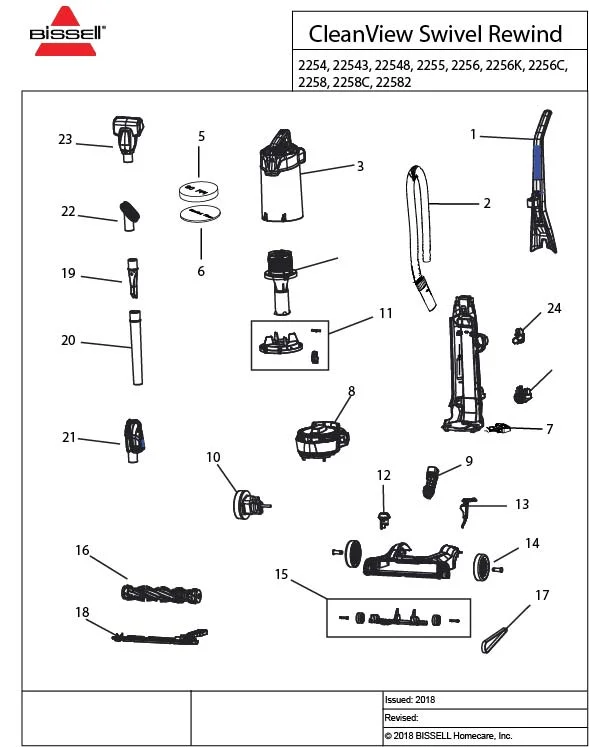

Diagram Legend: Identifying Part Numbers

This section provides a comprehensive overview of how to interpret the symbols and notations found in the illustration of various components. Understanding these references is essential for accurate identification and selection of the necessary elements for maintenance or replacement.

Component Identification: Each item within the visual representation is accompanied by a unique identifier, often a numerical code. These codes enable users to pinpoint specific elements quickly, ensuring efficient repair or assembly processes.

Color Codes: In many cases, color differentiation is utilized to categorize items based on their functionality or compatibility. Recognizing these color cues can aid in distinguishing between similar components, facilitating a smoother selection experience.

Reference Numbers: It’s important to note that some identifiers may appear multiple times, indicating interchangeable options or related items. Pay close attention to the accompanying descriptions to ensure proper compatibility with your device.

Overall, familiarizing oneself with this reference guide will enhance the user’s ability to navigate the component landscape effectively, promoting a better understanding of the machinery’s inner workings.