Comprehensive Guide to Bobcat S150 Parts Diagram

The intricate machinery used in construction and landscaping relies heavily on a multitude of interconnecting elements. Each component plays a crucial role in ensuring the overall functionality and efficiency of the machine. A thorough understanding of these parts can significantly enhance maintenance practices and prolong the lifespan of the equipment.

By examining a visual representation of the various sections, operators and technicians can gain valuable insights into the layout and interrelationships between the elements. This knowledge is essential for troubleshooting, repairs, and upgrades, allowing for more informed decisions when it comes to service and part replacement.

Moreover, familiarizing oneself with the specific arrangement of components empowers users to identify potential issues before they escalate. This proactive approach not only saves time but also minimizes costs associated with unexpected breakdowns. Ultimately, a comprehensive grasp of the machinery’s structure leads to improved operational efficiency and safety in the field.

Understanding Bobcat S150 Overview

This section provides an essential insight into a compact and versatile machinery model, widely recognized for its efficiency and reliability in various tasks. Understanding its components and functionalities is crucial for operators and maintenance personnel alike, ensuring optimal performance in diverse applications.

Key Features

- Powerful engine performance

- Compact design for maneuverability

- Variety of attachment compatibility

- User-friendly controls

Common Applications

- Landscaping and grading

- Construction site preparation

- Snow removal and winter maintenance

- Excavation and material handling

Familiarity with this machine’s structure and operation is essential for maximizing its potential and ensuring smooth, effective use in various settings.

Key Features of Bobcat S150

This section highlights the essential characteristics of a compact machine designed for various tasks in construction and landscaping. Its versatile capabilities and robust build make it a preferred choice for professionals seeking efficiency and reliability in tight spaces.

Performance and Efficiency

- Powerful engine that ensures optimal performance in challenging conditions.

- Exceptional lifting capacity for handling heavy materials effortlessly.

- Advanced hydraulic system that enhances maneuverability and speed.

Design and Comfort

- Compact dimensions allow for easy navigation in restricted areas.

- Ergonomically designed operator’s cabin for improved comfort during long working hours.

- Enhanced visibility from the operator’s seat for better awareness of surroundings.

Overall, this machine combines power, efficiency, and user-friendly design, making it an invaluable asset for various applications.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repair. Visual representations serve as invaluable tools, allowing users to quickly identify individual elements and their interconnections. This clarity can significantly reduce the time spent troubleshooting issues.

Clarity and Precision: Having a visual reference aids technicians in locating specific pieces with ease. This reduces the risk of errors during repairs, ensuring that each component is addressed appropriately.

Efficiency in Repairs: When mechanics can swiftly access detailed visuals, they can work more effectively. This translates to shorter downtime for equipment and improved overall productivity.

Enhanced Communication: Visual aids facilitate better communication among team members. Everyone can reference the same image, leading to a shared understanding of the machinery and its components.

Training and Education: For those new to machinery maintenance, visual guides serve as excellent educational resources. They provide a clear foundation upon which learners can build their knowledge and skills.

In summary, detailed visuals are crucial in the world of machinery maintenance. They foster accuracy, efficiency, and effective communication, ultimately contributing to better performance and reliability of equipment.

Common Issues with S150 Components

In the realm of compact machinery, certain components may frequently exhibit problems that affect overall performance and reliability. Understanding these common challenges can help operators anticipate maintenance needs and avoid potential downtime. Addressing these issues promptly is crucial to ensure the longevity and efficiency of the equipment.

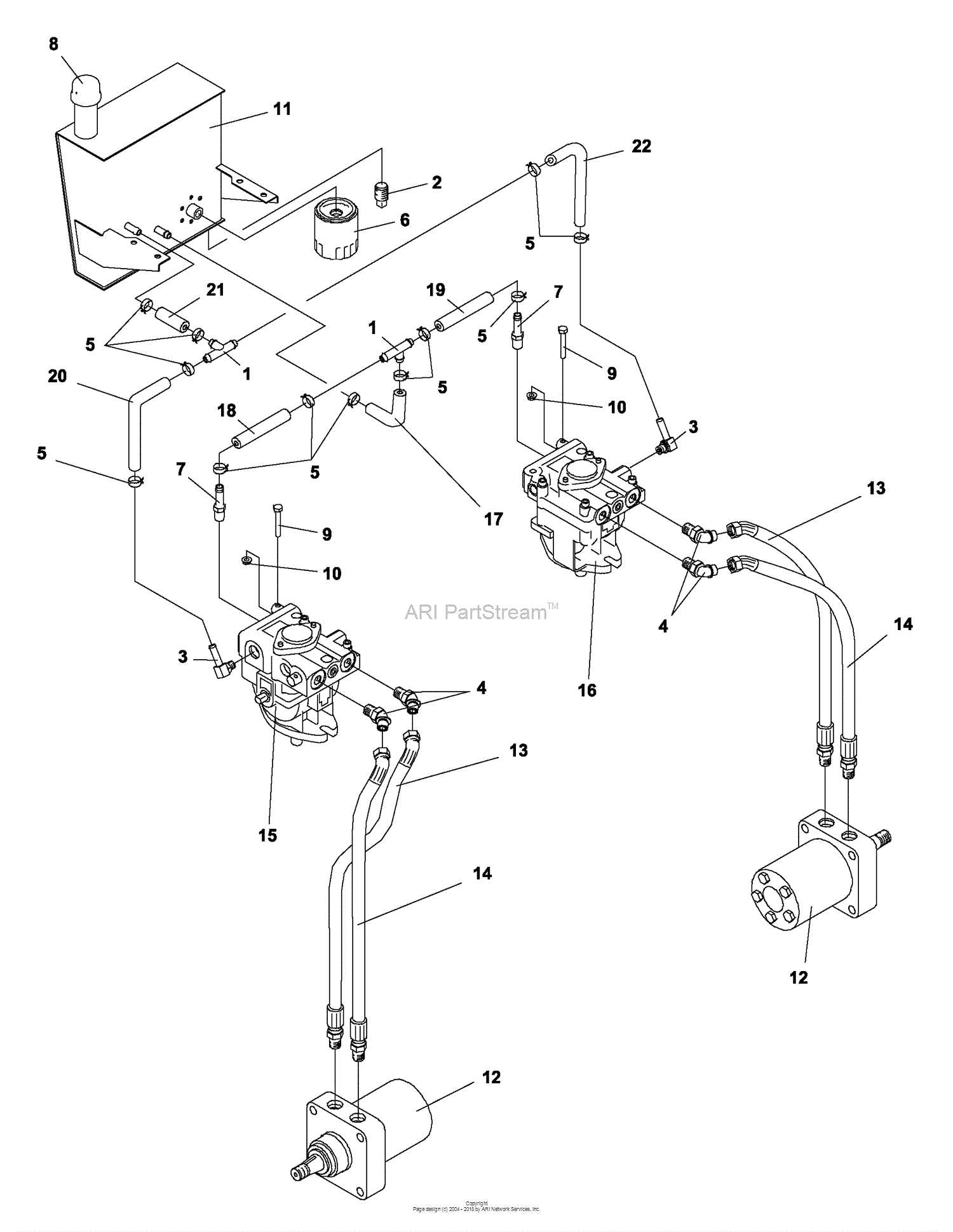

Hydraulic System Failures

One prevalent issue encountered is related to the hydraulic system. Leaks can develop in hoses or fittings, leading to a decrease in pressure and inefficient operation. Regular inspections are essential to identify any signs of wear or damage early, preventing more significant failures that could halt operations.

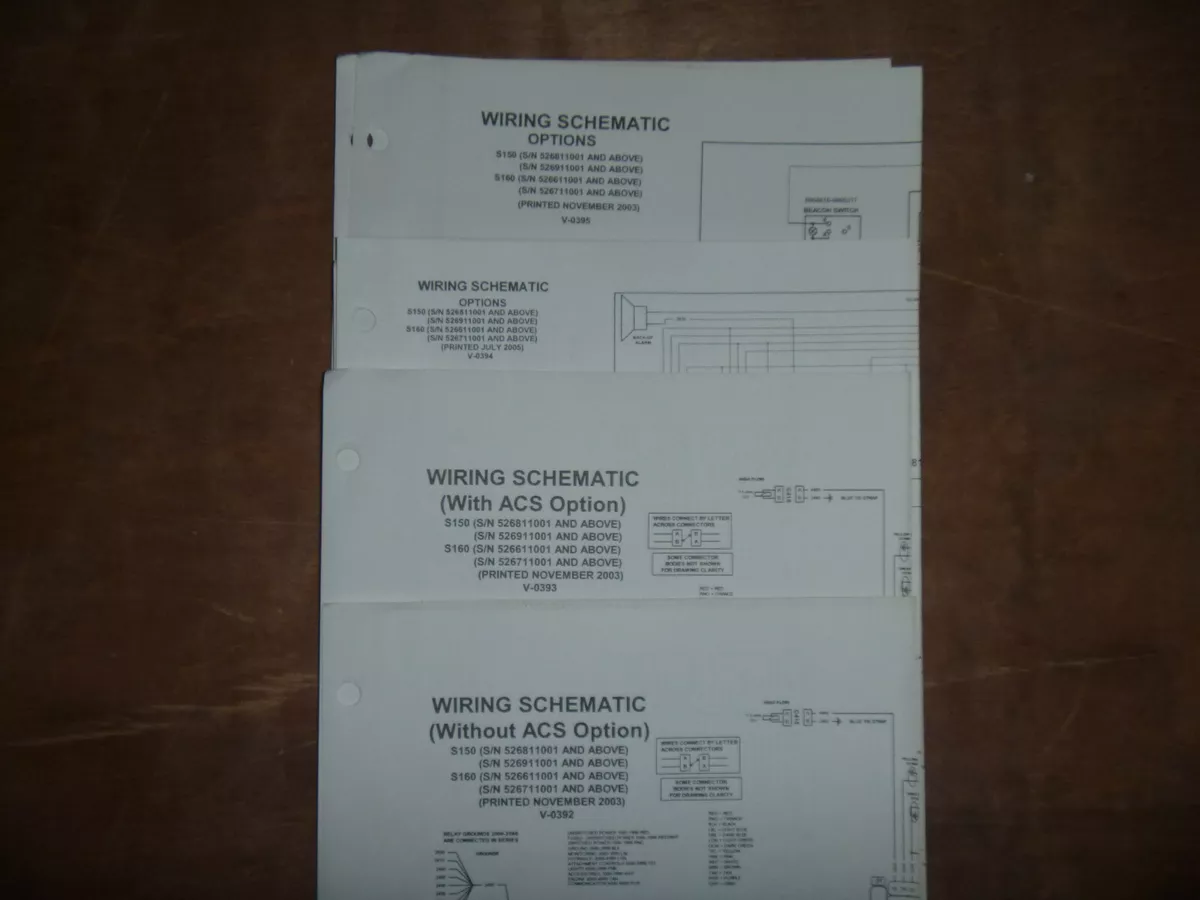

Electrical Component Malfunctions

Electrical systems can also pose challenges, with common malfunctions including faulty sensors and connection issues. These problems may result in erratic performance or complete shutdowns. Ensuring all connections are secure and that components are free from corrosion can mitigate these risks and promote smoother functionality.

Essential Maintenance Tips

Proper upkeep of machinery is crucial for ensuring optimal performance and longevity. Regular attention to key components not only enhances efficiency but also prevents unexpected breakdowns, which can lead to costly repairs and downtime. This section outlines vital practices to maintain your equipment in top condition.

1. Regular Inspections: Schedule routine examinations to identify wear and tear before it escalates. Check for leaks, cracks, and signs of corrosion. Early detection can save time and resources.

2. Fluid Changes: Maintain appropriate fluid levels and replace them according to the manufacturer’s recommendations. Clean oil and hydraulic fluids are essential for smooth operation and preventing damage.

3. Filter Maintenance: Replace air and oil filters periodically to ensure that contaminants do not affect performance. Clogged filters can lead to inefficient operation and increased wear on components.

4. Clean Components: Keep the machine clean from dirt and debris. Regular cleaning helps prevent rust and keeps parts functioning correctly. Pay special attention to areas prone to accumulation, such as undercarriages and engine compartments.

5. Lubrication: Apply lubricant to moving parts as recommended. Proper lubrication reduces friction and wear, extending the life of components and enhancing overall efficiency.

6. Tire Maintenance: Regularly check tire pressure and tread depth. Properly inflated tires improve traction and fuel efficiency, while worn tires can compromise safety and performance.

By implementing these essential maintenance practices, you can ensure your equipment remains reliable and efficient, ultimately leading to improved productivity and reduced operational costs.

Finding Reliable Replacement Parts

When it comes to maintaining heavy machinery, sourcing dependable components is crucial for ensuring optimal performance and longevity. Quality replacements not only enhance functionality but also prevent costly repairs and downtime. Therefore, it’s essential to navigate the market with care to identify trustworthy suppliers.

Factors to Consider

- Manufacturer Reputation: Research brands and their history in the industry to gauge reliability.

- Material Quality: Evaluate the materials used in production; higher quality often leads to better performance.

- Warranty and Support: Look for options that offer warranties or customer support for added peace of mind.

Where to Look

- Authorized Dealers: Start with official representatives who sell original equipment.

- Online Marketplaces: Explore e-commerce platforms, but verify seller ratings and reviews.

- Local Repair Shops: Consult with mechanics who may have insights into reliable sources.

By focusing on these aspects, you can significantly increase your chances of finding trustworthy components that meet your needs and ensure smooth operation.

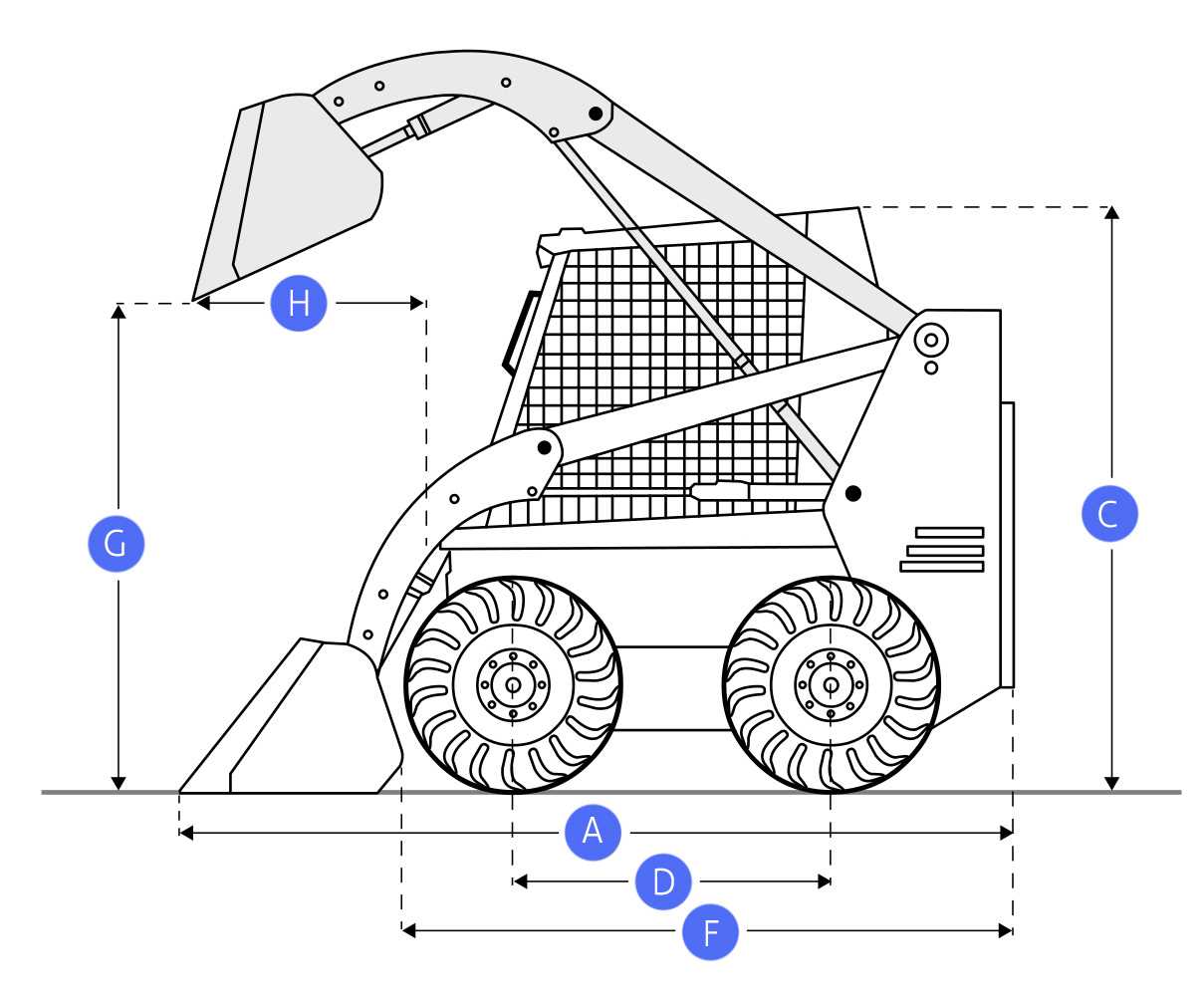

Visual Guide to S150 Parts

This section provides a comprehensive overview of essential components, offering insights into their functions and interrelations. Understanding these elements is crucial for maintenance and operational efficiency, ensuring that the machinery performs optimally in various tasks.

Key Components Overview

- Engine Assembly: The powerhouse that drives all functions.

- Hydraulic System: Facilitates the movement of attachments and enhances lifting capabilities.

- Chassis: The frame that supports all other parts and provides stability.

- Transmission: Responsible for transferring power from the engine to the wheels.

- Electrical System: Powers controls, lights, and monitoring systems.

Importance of Regular Maintenance

- Prevents costly repairs by identifying wear and tear early.

- Ensures safe operation, reducing the risk of accidents.

- Maximizes the lifespan of the equipment, providing better return on investment.

By familiarizing yourself with these components and their maintenance, you can enhance the performance and reliability of your machinery significantly.

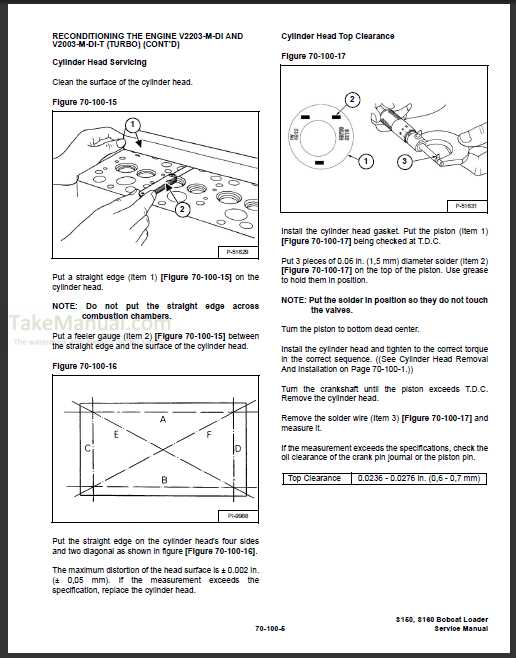

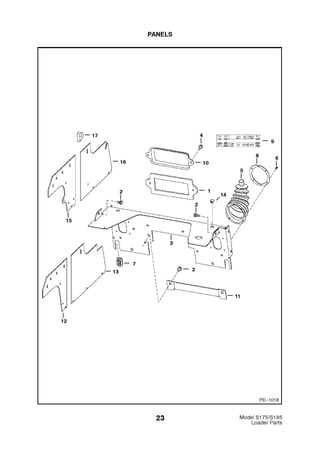

How to Read Parts Diagrams

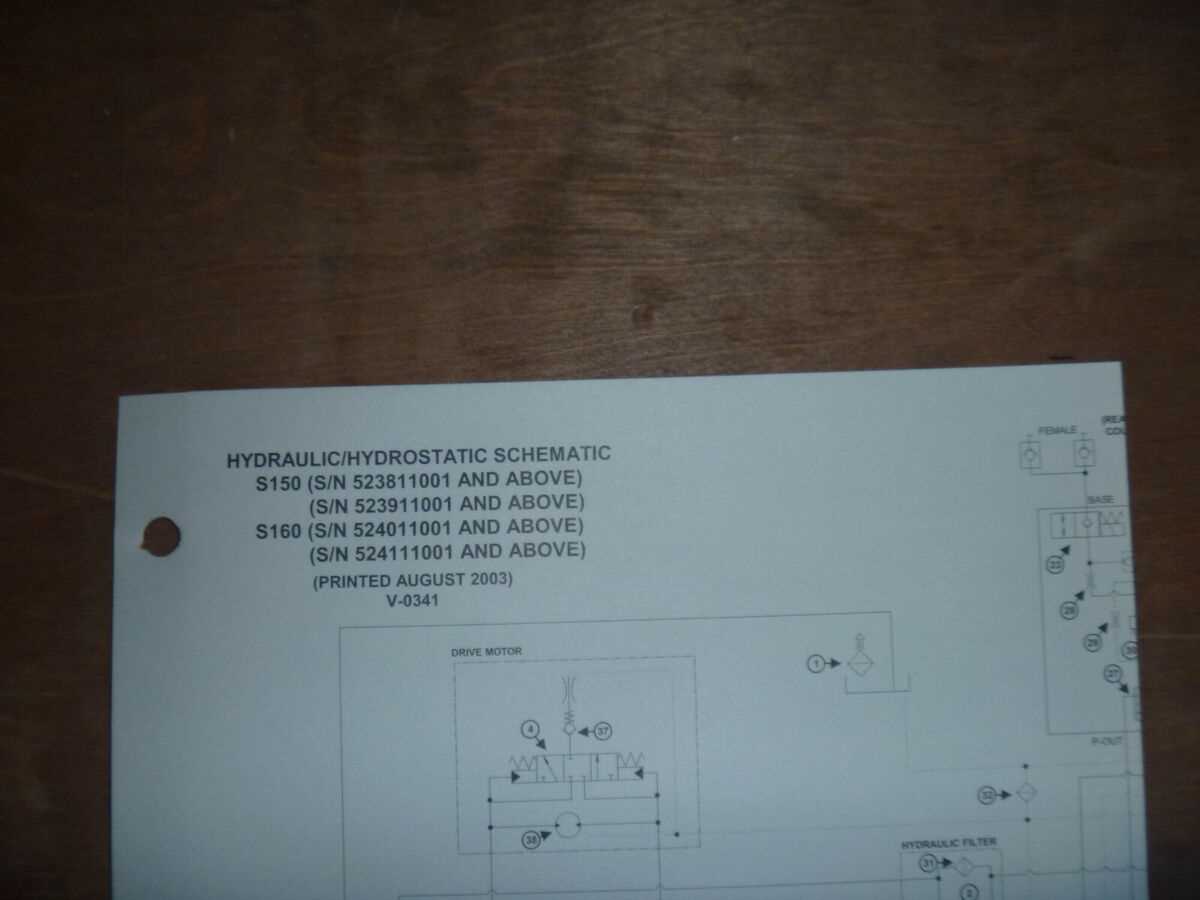

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as valuable tools, offering a clear overview of how different elements fit together and function within a machine. Familiarity with these graphics can significantly enhance your ability to identify specific parts and their relationships to one another.

When approaching these visuals, start by examining the labels. Each section is typically numbered or annotated, providing essential information about individual elements. Pay close attention to these identifiers, as they guide you in locating the corresponding components in a physical context.

Next, observe the structure of the image. Components are often arranged to reflect their actual configuration within the equipment. This spatial arrangement allows you to visualize how parts interact and operate together. Understanding this layout can aid in troubleshooting issues and planning repairs more efficiently.

Lastly, refer to the accompanying documentation. Manuals and reference guides usually include a detailed explanation of each item depicted in the illustration. This additional context is invaluable for ensuring accurate identification and selection of the necessary components for your project.

Resources for S150 Owners

Owning a compact loader comes with its own set of responsibilities and needs. To ensure optimal performance and longevity of your machinery, it is crucial to have access to reliable resources. This section provides valuable information and tools that can assist operators in maintaining their equipment efficiently.

1. Official Manuals: Comprehensive guides are essential for understanding the functions and maintenance requirements of your machine. These documents typically cover everything from routine servicing to troubleshooting techniques.

2. Online Forums: Joining community forums allows owners to connect with other users, share experiences, and gain insights into best practices. Engaging in discussions can lead to helpful tips and advice that may not be found in manuals.

3. Spare Parts Suppliers: Reliable vendors offering high-quality replacement components are vital for ensuring that your loader remains in top condition. Look for suppliers with good reputations and reviews to ensure you’re getting the best products.

4. Maintenance Tips: Regular upkeep is key to maximizing the lifespan of your equipment. Seek out resources that provide practical advice on maintenance schedules, common issues, and preventative measures to keep your loader running smoothly.

5. Training Resources: Investing in operator training can greatly enhance safety and efficiency. Look for workshops, online courses, or certification programs that focus on effective machine operation and maintenance.

Upgrades and Modifications Options

Enhancing the performance and functionality of compact machinery can significantly improve efficiency and ease of use. Various upgrades and modifications are available, allowing operators to tailor equipment to their specific needs. This section explores some popular options that can boost capabilities and adapt machines for diverse tasks.

Performance Enhancements

One of the most common ways to improve machinery is by upgrading the engine or hydraulic systems. Higher horsepower engines can provide better power output, enabling the equipment to handle heavier loads and challenging terrains. Additionally, upgraded hydraulic components can enhance lifting capacity and speed, ensuring tasks are completed more swiftly and effectively.

Attachment Options

Incorporating various attachments can significantly expand the functionality of machinery. Options such as buckets, forks, and grapples allow operators to switch between different tasks seamlessly. Implementing a quick coupler system can facilitate fast changes, minimizing downtime and maximizing productivity. Customizing equipment with the right attachments ensures versatility on job sites, making it suitable for a wide range of applications.

Comparing S150 with Other Models

When evaluating the capabilities of a particular compact loader, it is essential to consider how it stands against its peers in the market. Each model brings its unique strengths and specifications, impacting overall performance and suitability for various tasks. By analyzing key features, operators can make informed decisions tailored to their specific needs.

One significant aspect to examine is the engine performance. While some models prioritize horsepower, others may focus on fuel efficiency, which can influence operational costs over time. Additionally, the lifting capacity is a crucial factor; certain alternatives excel in heavier loads, making them ideal for construction sites requiring robust machinery.

Furthermore, maneuverability plays a vital role in determining efficiency, especially in confined spaces. Some loaders are designed with a tighter turning radius, allowing for easier navigation in challenging environments. This aspect can significantly enhance productivity when operating in urban or densely populated areas.

Maintenance considerations should also be factored into the comparison. Models with readily accessible components often lead to reduced downtime and lower maintenance costs, providing a compelling advantage for long-term operations. Understanding these differences can help operators select the most suitable machinery for their projects.