Brother 1634D Serger Parts Diagram Guide

Maintaining the efficiency of your sewing equipment is essential for achieving high-quality results. Knowing the various elements and how they interact can enhance your sewing experience and prolong the lifespan of your device.

Familiarizing yourself with the internal workings not only aids in troubleshooting but also empowers you to perform necessary adjustments. Each component plays a unique role, contributing to the ultimate functionality of the machine.

In this section, we will explore the intricate layout of your equipment’s structure, offering insights into each segment’s purpose. With a clear understanding, you can navigate repairs and maintenance with confidence.

Understanding the Brother 1634D Serger

This section explores the features and functionalities of a specific sewing machine model designed for advanced stitching techniques. It emphasizes the importance of comprehending the various components that contribute to its performance, ensuring optimal usage for both beginners and seasoned enthusiasts.

Key Features

Among its most notable characteristics are the ability to create professional-grade finishes and the versatility in handling different fabrics. Users can appreciate how the machine allows for a wide range of stitches, enhancing creativity in various projects.

Maintenance Tips

To achieve the ultimate longevity and efficiency, regular upkeep is crucial. This includes routine cleaning and timely replacement of essential elements, which can significantly impact overall functionality.

Overview of Serger Machines

These advanced stitching devices are designed to elevate the quality and efficiency of sewing projects. They offer unique features that distinguish them from traditional sewing machines, making them essential for various textile tasks.

Key characteristics include:

- Multiple threads for intricate stitching.

- Ability to finish edges neatly and prevent fraying.

- Speed and precision in fabric manipulation.

Common applications of these machines are:

- Creating professional-looking hems.

- Assembling knit fabrics.

- Adding decorative elements to garments.

Understanding the components and functions of these devices can greatly enhance sewing skills and project outcomes.

Key Features of Brother 1634D

This versatile machine stands out for its remarkable capabilities, making it an essential tool for enthusiasts and professionals alike. It combines innovative technology with user-friendly design, enabling efficient fabric handling and intricate stitching options. With its robust construction and reliable performance, this device is tailored to meet diverse sewing needs.

Advanced Stitching Options

One of the prominent attributes of this model is its wide array of stitching choices. Users can easily switch between various stitch types, from overlock to rolled hem, allowing for creative exploration. This flexibility empowers crafters to achieve professional-grade finishes on different fabrics, enhancing the quality of their projects.

Ease of Use

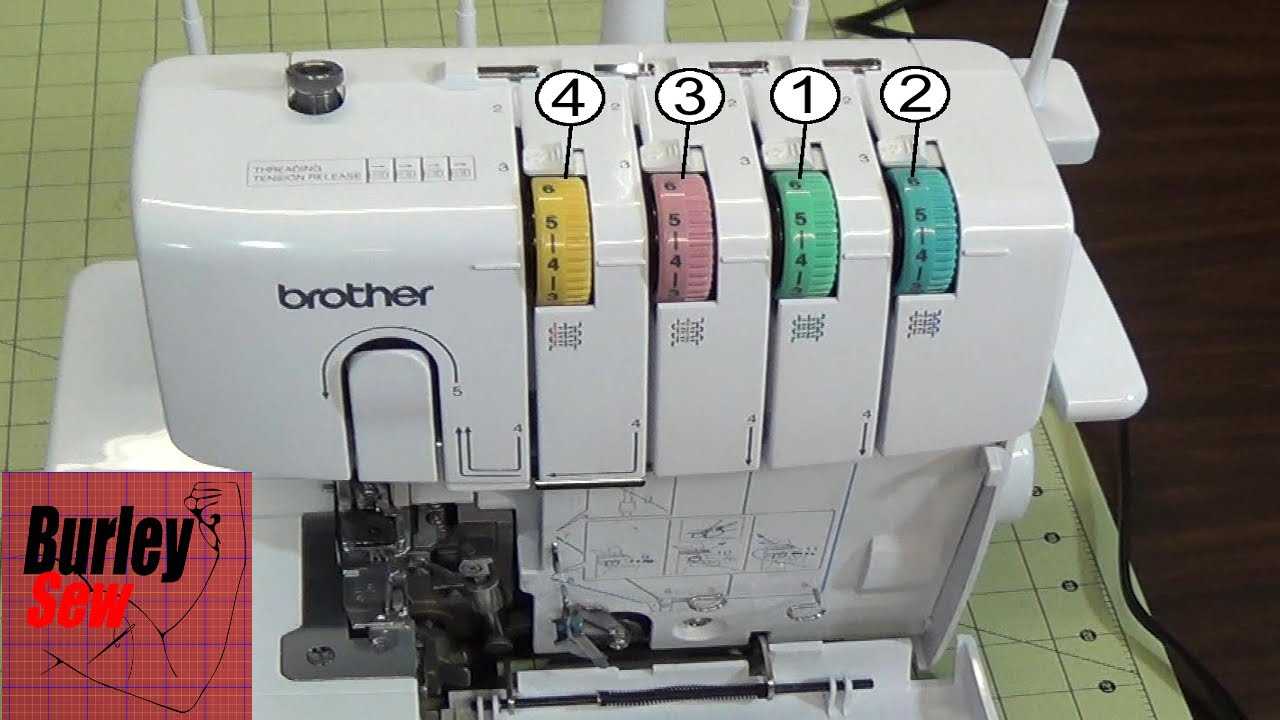

The intuitive interface and well-organized layout simplify the setup process. Comprehensive guides and color-coded threading systems ensure that both beginners and seasoned users can operate the machine with confidence. Additionally, its compact design makes it convenient for storage and transport, perfect for those who attend workshops or classes.

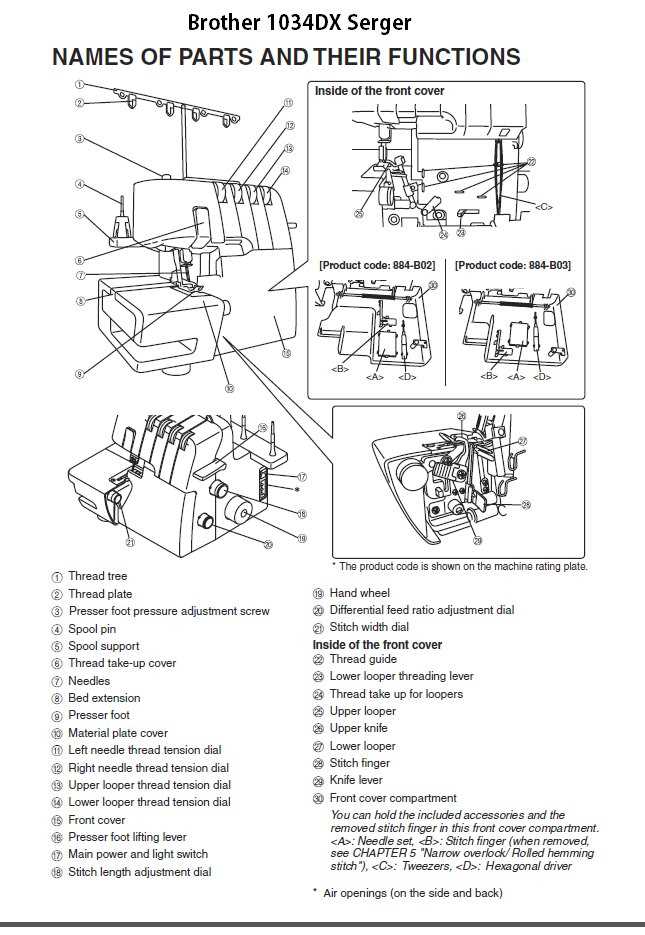

Common Parts and Their Functions

In any advanced stitching machine, various components work together to create seamless and professional results. Understanding the primary elements and their roles can enhance both the efficiency of the device and the quality of the finished work. Each section contributes uniquely, ensuring that the fabric is fed, stitched, and finished to perfection.

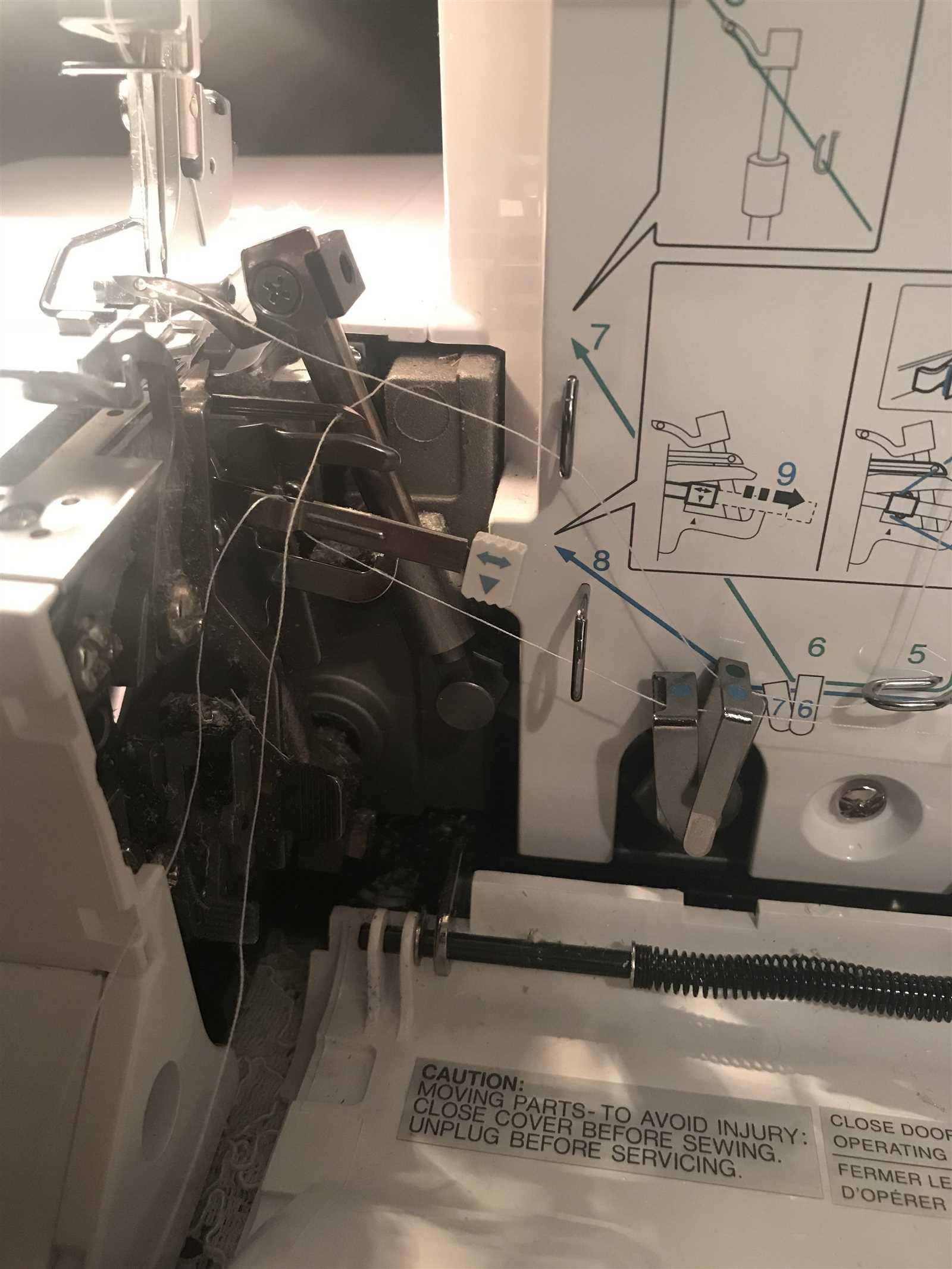

The cutting mechanism is essential for trimming excess fabric as it stitches, allowing for a clean edge and preventing fraying. The needle holder plays a crucial role in securing the needle in place, ensuring consistent stitching patterns. Tension discs regulate the tightness of the threads, which is vital for achieving the desired stitch quality.

The feed dogs are responsible for moving the fabric through the machine, providing control over the pace and accuracy of the sewing process. Additionally, the loopers create intricate stitch formations by interlocking threads, enhancing the machine’s versatility. Lastly, the presser foot stabilizes the fabric during operation, facilitating smoother movements and preventing distortion.

Reading the Parts Diagram

Understanding the layout of a machine’s components is essential for efficient maintenance and repairs. This visual representation serves as a guide, enabling users to identify each element, ensuring seamless operation and longevity of the equipment.

Identifying Components

Each section in the visual representation corresponds to specific parts, typically labeled for clarity. By familiarizing yourself with these identifiers, you can easily locate necessary elements when troubleshooting or performing upgrades.

Maintenance and Repairs

Utilizing the visual guide simplifies the process of maintenance. Knowing where each component resides allows for quicker access during repairs, ultimately enhancing the machine’s functionality and reducing downtime.

Identifying Replacement Parts

Understanding how to recognize components of your machine is essential for maintenance and repair. When issues arise, knowing the specific elements involved can help streamline the troubleshooting process. This section will guide you through the identification of various elements, ensuring that you can easily find what you need for efficient operation.

Common Components and Their Functions

Each machine consists of numerous vital elements that work together to achieve optimal performance. For instance, the needle plays a crucial role in stitching, while the looper aids in forming the stitch. Familiarizing yourself with these parts and their respective functions can help you quickly assess any problems and determine which elements may require attention or replacement.

Finding the Right Components

Once you’ve identified the necessary elements, sourcing replacements can be straightforward. Check your device’s user manual for part numbers, which can significantly ease the search process. Additionally, reputable suppliers and online marketplaces often have extensive inventories. Look for reviews and recommendations to ensure that you are obtaining quality replacements that will enhance your machine’s longevity.

Tools Needed for Repairs

Maintaining and fixing a sewing machine requires a selection of essential instruments. Having the right tools on hand not only simplifies the repair process but also ensures that tasks are completed efficiently and effectively.

- Screwdrivers: Both flathead and Phillips for accessing internal components.

- Scissors: Sharp fabric scissors for cutting threads and fabric.

- Wrenches: Adjustable wrenches for loosening and tightening bolts.

- Needle nose pliers: Helpful for reaching into tight spaces and handling small parts.

- Oil: Specific lubricants designed for sewing machines to keep moving parts functioning smoothly.

- Brush: A small brush to remove lint and dust from the machine.

With these tools, one can delve into repairs with confidence, addressing any issues that may arise effectively.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues with your sewing machine. By following these detailed instructions, you can enhance your skills and ensure your equipment runs smoothly.

1. Identify the Problem

Before you begin any repair work, it’s essential to determine the issue at hand. Common problems may include:

- Skipped stitches

- Thread breaking

- Uneven tension

- Machine jamming

2. Gather Necessary Tools

Having the right tools at your disposal will facilitate the repair process. Ensure you have the following items:

- Screwdrivers (flathead and Phillips)

- Replacement threads

- Oiling tools

- Cleaning brushes

3. Step-by-Step Repair Process

- Turn Off the Machine: Safety first! Ensure your device is unplugged before starting any work.

- Clean the Area: Remove any dust or lint buildup that may be affecting performance.

- Check the Threading: Re-thread your machine, following the threading path carefully.

- Adjust Tension Settings: Make necessary adjustments to the tension dial according to the fabric type.

- Inspect and Replace Needles: If the needle is bent or dull, replace it with a new one.

- Lubricate Moving Parts: Apply appropriate oil to the moving components to ensure smooth operation.

- Test the Machine: Run a few test stitches on scrap fabric to check if the issue is resolved.

Following these steps will help you effectively address and resolve most common issues, prolonging the life of your equipment and enhancing your sewing experience.

Maintaining Your Serger

Regular upkeep of your sewing machine is essential for optimal performance and longevity. A well-maintained device ensures smooth operation and high-quality results, reducing the risk of unexpected issues during your projects.

Cleaning is a fundamental aspect of maintenance. Remove lint and debris from the feed dogs and thread paths regularly. Use a soft brush or a vacuum attachment designed for delicate areas to keep your machine spotless.

Lubrication is equally important. Refer to your manual for specific oiling points and recommended lubricants. Regularly oiling moving parts minimizes friction and wear, ensuring consistent stitching.

Threading correctly is crucial for preventing jams and ensuring even stitches. Always follow the threading path indicated in your manual, and check for any obstructions or tangles before starting a new project.

Timing and tension adjustments may be necessary over time. If you notice uneven stitches, refer to your manual for troubleshooting techniques to reset these parameters effectively.

Finally, consider professional servicing every few years. This thorough inspection can identify potential issues before they become significant problems, ultimately extending the lifespan of your machine.

Finding Quality Replacement Parts

When it comes to maintaining your sewing machine, sourcing high-quality components is essential for ensuring optimal performance. Selecting the right pieces not only extends the life of your equipment but also enhances its efficiency and reliability. This section provides insights into how to identify and acquire the best replacements for your sewing needs.

Where to Look

- Authorized Dealers: These vendors often provide genuine components that meet the manufacturer’s specifications.

- Online Retailers: Websites specializing in sewing supplies usually have a wide selection of items.

- Local Repair Shops: Professional technicians can guide you to quality replacements and may offer installation services.

- Second-Hand Markets: Occasionally, used components in good condition can be found at a fraction of the cost.

Tips for Ensuring Quality

- Check Reviews: Look for feedback from other customers to gauge the reliability of the seller.

- Examine Specifications: Ensure that the replacements meet the exact measurements and requirements of your machine.

- Inquire About Warranties: Reputable sellers often provide guarantees, which can protect your investment.

- Consider Compatibility: Make sure the items you choose are compatible with your specific model for seamless operation.

Tips for Troubleshooting Issues

When dealing with machine problems, a systematic approach can save time and frustration. Understanding the common challenges and their potential solutions can greatly enhance your experience and efficiency.

1. Check Threading: Ensure that the threads are correctly threaded through the tension discs and guides. Incorrect threading is a frequent source of complications.

2. Inspect Tension Settings: Tension settings should be adjusted based on the fabric being used. Test on scrap material to find the optimal settings.

3. Clean Regularly: Accumulated lint and debris can hinder performance. Regular cleaning of the machine can prevent many issues.

4. Use Quality Materials: Low-quality threads or fabrics can cause numerous problems. Invest in good supplies for smoother operation.

5. Refer to the Manual: Always consult the user manual for specific troubleshooting steps related to your device. It can provide valuable insights.

6. Test on Scrap Fabric: Before starting on your main project, test the settings on scrap fabric. This can help identify issues early on.

7. Seek Professional Help: If problems persist, don’t hesitate to contact a technician. Sometimes, expert assistance is the ultimate solution.

Resources for Further Learning

Exploring the intricacies of sewing machines can greatly enhance your skills and creativity. A variety of materials and platforms are available to help you master the art of using these specialized tools. Whether you seek tutorials, manuals, or community forums, numerous resources can guide you on your journey.

Online Tutorials and Video Guides

Numerous websites and platforms offer video tutorials that visually demonstrate techniques and functionalities. Websites like YouTube host channels dedicated to sewing, providing valuable insights and step-by-step instructions. Engaging with these visual resources can deepen your understanding and boost your confidence.

Community Forums and Support Groups

Joining online communities can be immensely beneficial. Platforms such as Reddit and dedicated sewing forums allow enthusiasts to share experiences, ask questions, and exchange tips. Connecting with others who share your passion can provide not only knowledge but also inspiration for your next project.