Comprehensive Guide to Detroit Locker Parts Diagram

In the realm of automotive engineering, the inner workings of drive systems play a crucial role in vehicle performance and handling. This section delves into the intricacies of specific mechanisms that facilitate power distribution, enhancing traction and stability during various driving conditions. A comprehensive understanding of these elements is essential for enthusiasts and professionals alike, allowing for informed decisions during repairs or upgrades.

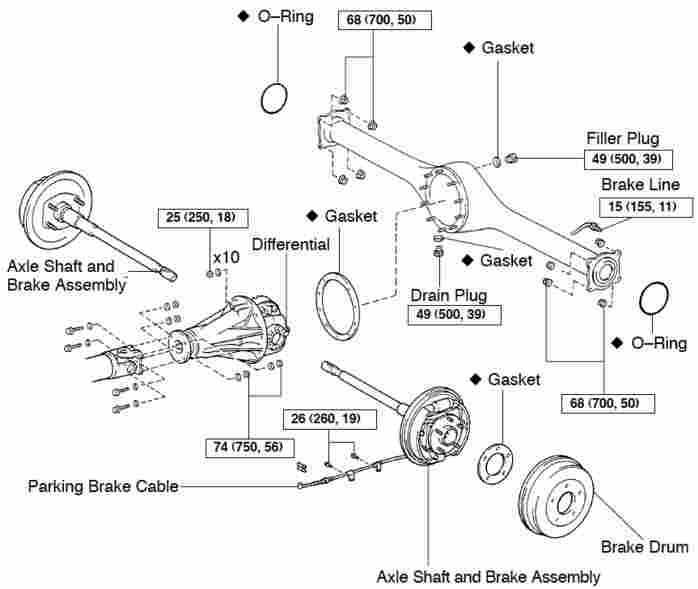

Visual aids serve as invaluable tools in grasping the complex relationships between various elements involved in power transfer. By examining the layout and function of each component, one can appreciate the meticulous design that contributes to the overall efficiency of a vehicle’s drivetrain. Whether for maintenance purposes or simply to satisfy a curiosity about automotive mechanics, detailed illustrations can greatly enhance one’s comprehension.

Furthermore, a thorough exploration of these components can illuminate potential issues that may arise over time. Recognizing the signs of wear and tear or malfunction can lead to timely interventions, preventing more significant problems down the road. This proactive approach not only ensures safety but also optimizes the performance of the vehicle.

Understanding Detroit Locker Functionality

The unique mechanism in certain automotive differentials plays a crucial role in enhancing vehicle traction. This system allows for an even distribution of power to the wheels, particularly during challenging driving conditions, ensuring that the vehicle maintains stability and performance. By grasping the fundamental operations of this device, one can appreciate how it optimizes traction and control.

The mechanism operates by automatically engaging and disengaging based on wheel speed and traction conditions. When one wheel experiences a loss of grip, the system locks to provide power to both wheels, improving performance in off-road scenarios or slippery environments.

| Feature | Description |

|---|---|

| Automatic Engagement | Locks when a wheel slips, ensuring power is distributed to both wheels. |

| Independent Functioning | Allows wheels to turn at different speeds during cornering, reducing tire wear. |

| Durability | Constructed to withstand high torque and demanding driving conditions. |

| Maintenance | Requires periodic checks to ensure optimal performance and longevity. |

Understanding this system’s functionality not only aids in vehicle operation but also informs maintenance and upgrade decisions for enthusiasts and professionals alike.

Key Components of Detroit Locker

Understanding the essential elements of a specific type of locking differential is crucial for optimizing vehicle performance, particularly in demanding off-road conditions. These components work in unison to enhance traction and stability, ensuring that power is effectively distributed to the wheels when needed most.

Main Elements

- Case: The outer shell that houses all internal components, providing structural integrity and support.

- Spiders: Gear-like elements that allow for wheel speed differences while maintaining power transfer under load.

- Clutches: Mechanisms that engage or disengage based on driving conditions, facilitating smooth operation.

- Ramps: Inclined surfaces that assist in the locking process, enabling seamless engagement when required.

- Springs: Essential for maintaining pressure on clutches, ensuring reliable locking behavior during operation.

Functionality Overview

Each component plays a vital role in the overall functionality of the system. The case protects the internals, while spiders and clutches work together to balance traction and wheel speed. Ramps and springs ensure that the engagement process is responsive, allowing for efficient power distribution when facing challenging terrain. Understanding these elements helps in both maintenance and performance tuning.

Common Issues with Detroit Locker

In the realm of high-performance differentials, various challenges can arise that impact functionality and longevity. Understanding these potential problems is essential for any enthusiast looking to maintain optimal performance in their vehicle.

1. Noise and Vibration

One of the most frequently reported issues is excessive noise during operation. This can be attributed to several factors:

- Improper installation

- Worn components

- Lack of lubrication

Vibration can also accompany noise, which may signal misalignment or imbalance within the assembly.

2. Engagement Problems

Another common concern involves the engagement of the mechanism. Users might experience:

- Delayed engagement when turning

- Inconsistent locking behavior

- Failure to lock entirely

These issues can lead to decreased traction and compromised safety, making it crucial to address them promptly.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of mechanical components in any vehicle. Regular attention to detail can prevent premature wear and ensure optimal performance. Here are some effective strategies to consider:

- Conduct routine inspections to identify signs of wear or damage early.

- Ensure all moving elements are adequately lubricated to reduce friction.

- Maintain correct torque specifications during installation and repairs to avoid stress on components.

- Keep the surrounding area clean and free from debris to prevent contamination.

- Store your vehicle in a sheltered environment to protect against environmental factors.

By following these guidelines, you can significantly improve the reliability and durability of your vehicle’s critical mechanisms.

How to Identify Parts in Diagrams

Understanding visual representations of mechanical components can be crucial for effective assembly and maintenance. Recognizing the various elements illustrated in these schematics requires a systematic approach and attention to detail. Each symbol or line conveys specific information that can aid in the identification and functionality of individual items.

Familiarization with Symbols: The first step in deciphering any illustration is to familiarize yourself with common symbols used within the industry. Many diagrams adhere to standardized notations, allowing for quicker recognition of components. Invest time in learning these symbols to streamline the identification process.

Color Coding: Often, color is employed strategically to differentiate between various parts. By paying attention to color schemes, you can easily categorize components and understand their relationships within the assembly. Take note of any legends or keys provided, as they can offer valuable insights.

Contextual Clues: Context is essential when analyzing a visual schematic. Look for additional details, such as arrows indicating movement or connections that reveal how components interact. These cues can provide a broader understanding of the assembly’s functionality and help pinpoint specific items more effectively.

Consulting Resources: If you’re struggling to identify certain elements, don’t hesitate to consult manuals or online resources. Many manufacturers provide comprehensive guides that include detailed explanations of their illustrations. Leveraging these resources can enhance your comprehension and facilitate accurate identification.

By employing these strategies, you can enhance your ability to navigate and interpret visual guides, leading to improved efficiency in working with complex assemblies.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective understanding and communication in technical fields. Accurate illustrations serve as essential tools that guide users through complex assemblies, ensuring clarity and preventing errors during installation or maintenance. Without well-crafted visuals, even experienced individuals may struggle to interpret the components correctly.

Detailed illustrations not only enhance comprehension but also streamline the troubleshooting process. When individuals encounter issues, having a reliable reference allows them to quickly identify the source of a problem. This can significantly reduce downtime and improve overall efficiency in operations.

Furthermore, accurate representations are vital for training and education purposes. Newcomers benefit from clear visuals that help them grasp intricate concepts more rapidly. This foundational knowledge builds confidence and competence, empowering them to tackle more challenging tasks in the future.

In summary, precise visual guides are indispensable assets in any technical environment. They foster understanding, enhance problem-solving capabilities, and support the learning process, ultimately contributing to smoother workflows and greater success in achieving objectives.

Upgrading Detroit Locker Parts

Enhancing the components of a specific gear system can significantly improve performance and reliability. Whether for off-road adventures or high-speed driving, upgrading certain elements can provide better traction, durability, and overall efficiency. It is crucial to understand the various options available to ensure optimal functionality.

Key Benefits of Component Upgrades

Upgrading essential elements can lead to various advantages, including improved handling, reduced wear, and increased power transfer. By choosing high-quality alternatives, users can experience enhanced responsiveness and stability in challenging conditions.

Considerations for Selecting Upgrades

When selecting components for enhancement, consider the following factors: compatibility with existing systems, material quality, and intended use. Each choice can impact the overall performance, so thorough research is essential before making a decision.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Gear Ratio | Higher Ratio Gears | Improved acceleration and torque |

| Internal Mechanism | Heavy-Duty Springs | Increased durability and responsiveness |

| Seals | High-Performance Seals | Better protection against contaminants |

Comparing Detroit Locker to Alternatives

When evaluating different types of gear engagement systems for off-road vehicles, it’s essential to understand the advantages and drawbacks of each option. This analysis aims to highlight how one specific system stacks up against its competitors, focusing on performance, durability, and user experience.

Performance Comparison

Performance is a crucial factor when selecting a system for enhanced traction. Each option offers unique features that cater to various driving conditions. Below is a comparison of performance attributes.

| Feature | System A | System B | System C |

|---|---|---|---|

| Traction Control | High | Moderate | High |

| Response Time | Instant | Delayed | Instant |

| Noise Level | Low | High | Moderate |

Durability and Maintenance

Longevity and ease of maintenance are critical considerations for any gear engagement system. Each alternative has its strengths and weaknesses regarding wear resistance and upkeep requirements. The table below summarizes these aspects.

| Attribute | System A | System B | System C |

|---|---|---|---|

| Material Quality | High | Moderate | High |

| Maintenance Frequency | Low | High | Moderate |

| Failure Rate | Very Low | Moderate | Low |

Installation Process for Detroit Locker

The installation of this differential mechanism is a crucial step in enhancing vehicle performance and handling. Proper execution ensures optimal functionality and durability, making it essential for off-road enthusiasts and racing aficionados alike.

Preparation: Begin by gathering all necessary tools and components. Ensure the vehicle is securely lifted and supported, allowing easy access to the rear axle assembly. It’s advisable to work in a clean environment to prevent contamination.

Disassembly: Remove the wheel and brake components to expose the differential cover. Drain the lubricant and detach the cover, followed by the removal of existing components within the housing. Take care to note the arrangement of each part for reassembly.

Installation: Place the new mechanism into the housing, ensuring it aligns correctly with the existing gear structure. Follow the manufacturer’s instructions for torque specifications on bolts and fasteners. Once everything is secure, reattach the differential cover and refill with the appropriate lubricant.

Final Checks: After installation, conduct a thorough inspection to ensure everything is correctly positioned. Test drive the vehicle to confirm smooth operation and listen for any unusual noises, which may indicate further adjustments are necessary.

Following these steps will lead to a successful installation, enhancing traction and stability in various driving conditions.

Safety Precautions During Installation

Ensuring safety during the installation process is crucial to prevent accidents and ensure proper functionality. Following specific guidelines can help mitigate risks associated with handling equipment and components.

- Wear appropriate personal protective equipment, including gloves, goggles, and steel-toed boots.

- Ensure the workspace is clean and free of clutter to avoid trip hazards.

- Disconnect all power sources before starting the installation.

- Use tools that are in good condition and suitable for the job.

- Follow the manufacturer’s instructions carefully to avoid mistakes.

- Have a fire extinguisher nearby in case of emergencies.

- Keep first aid supplies accessible in case of injury.

- Work with a partner when handling heavy components to reduce the risk of injury.

- Be aware of your surroundings and any potential hazards in the work area.

- Communicate clearly with your team to ensure everyone is aware of their tasks and any hazards present.