Understanding the Exmark Quest Parts Diagram for Efficient Maintenance

Maintaining a well-functioning lawn machine requires a solid grasp of its internal mechanisms. Knowing how various elements interact is crucial for efficient upkeep and optimal performance. In this section, we will explore the intricate web of components that make up your mower, ensuring you are well-equipped to address any issues that may arise.

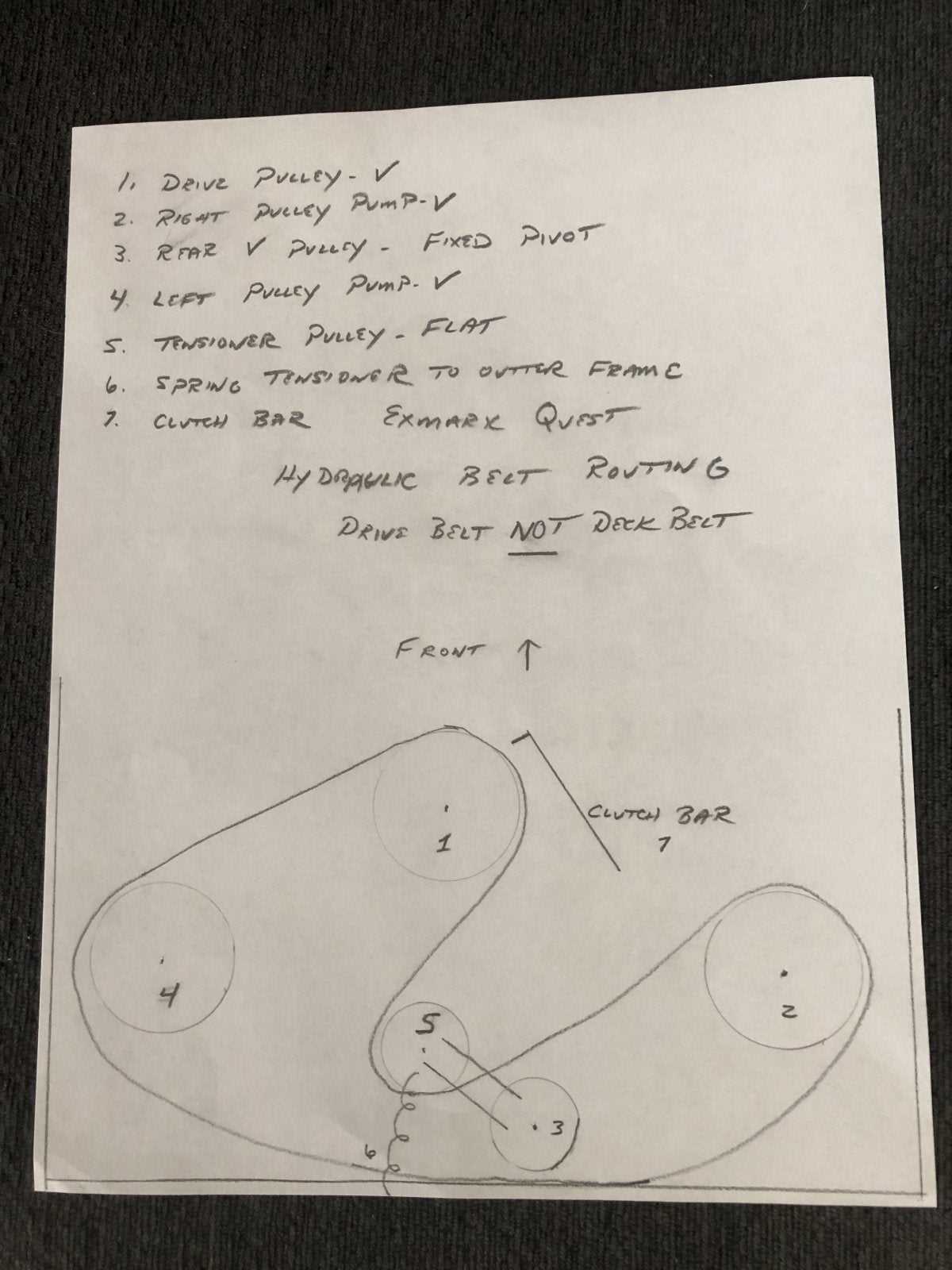

For enthusiasts and professionals alike, visual aids play a pivotal role in understanding the configuration and functionality of these machines. Detailed illustrations not only enhance comprehension but also empower users to diagnose and rectify potential problems swiftly. By breaking down each segment, we aim to provide clarity and confidence in handling your equipment.

Ultimately, a thorough understanding of your machinery will lead to better maintenance practices, prolonging its lifespan and improving its efficiency. As we delve deeper into the various sections of your mower, you’ll gain invaluable insights that will enhance your overall experience.

Understanding Exmark Quest Components

Gaining insight into the various elements that make up a lawn care machine is essential for effective maintenance and operation. Each component plays a vital role in ensuring the equipment functions smoothly and efficiently. Familiarity with these parts not only enhances performance but also extends the lifespan of the machinery.

Key Elements of Lawn Care Machinery

Every unit consists of several crucial segments, including the engine, cutting deck, transmission, and control systems. The engine provides the necessary power, while the cutting deck determines the quality of the cut. Transmission allows for movement and speed control, and the control systems enable the operator to manage the functions seamlessly. Understanding how these components interact can help users troubleshoot issues more effectively.

Importance of Regular Maintenance

To ensure optimal operation, regular upkeep of each individual part is paramount. This includes checking for wear and tear, replacing worn-out components, and keeping the machine clean. By paying attention to these details, operators can prevent larger issues from arising, thus maintaining the equipment in peak condition for years to come.

Key Features of Exmark Quest

This section highlights the essential characteristics that set this lawn maintenance machine apart from its competitors. Each feature has been meticulously designed to enhance performance, efficiency, and user experience, making it a top choice for both homeowners and professionals.

Robust Construction: Built with durable materials, the machine ensures longevity and resistance to wear and tear, making it suitable for rigorous use.

Efficient Engine: The powerful motor delivers optimal performance, allowing for smooth operation across various terrains while conserving fuel.

Advanced Cutting Technology: Equipped with precision blades, the system provides a clean cut, promoting healthier grass growth and enhancing the overall appearance of your lawn.

User-Friendly Controls: Intuitive controls make operation effortless, ensuring that even novice users can handle it with confidence and ease.

Exceptional Maneuverability: Designed for agility, the model allows users to navigate tight spaces and complex landscapes without hassle.

Comfortable Seating: Ergonomically designed seats provide ample support during extended use, minimizing fatigue and enhancing overall comfort.

Versatile Attachments: Compatibility with a range of accessories allows for multifunctional use, adapting to different lawn care needs throughout the year.

Importance of Parts Diagrams

Understanding the assembly and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as invaluable resources, guiding users through intricate structures and facilitating the identification of individual elements.

- Enhances clarity by illustrating component relationships.

- Simplifies the troubleshooting process, reducing downtime.

- Aids in ordering the correct replacements, minimizing errors.

Incorporating these visual tools into routine practices ultimately leads to more effective and informed operations.

Common Issues with Exmark Quest

Every machinery model comes with its own set of challenges that users may encounter over time. Understanding these common difficulties can help in timely maintenance and enhance overall performance.

One frequent concern is the engine performance, where operators might notice fluctuations in power output. This can often be traced back to fuel quality or air filter blockages, which require regular checks to ensure optimal functioning.

Another issue is blade wear and tear, affecting cutting efficiency. Regular inspections and timely replacements can prevent this from impacting the quality of work significantly.

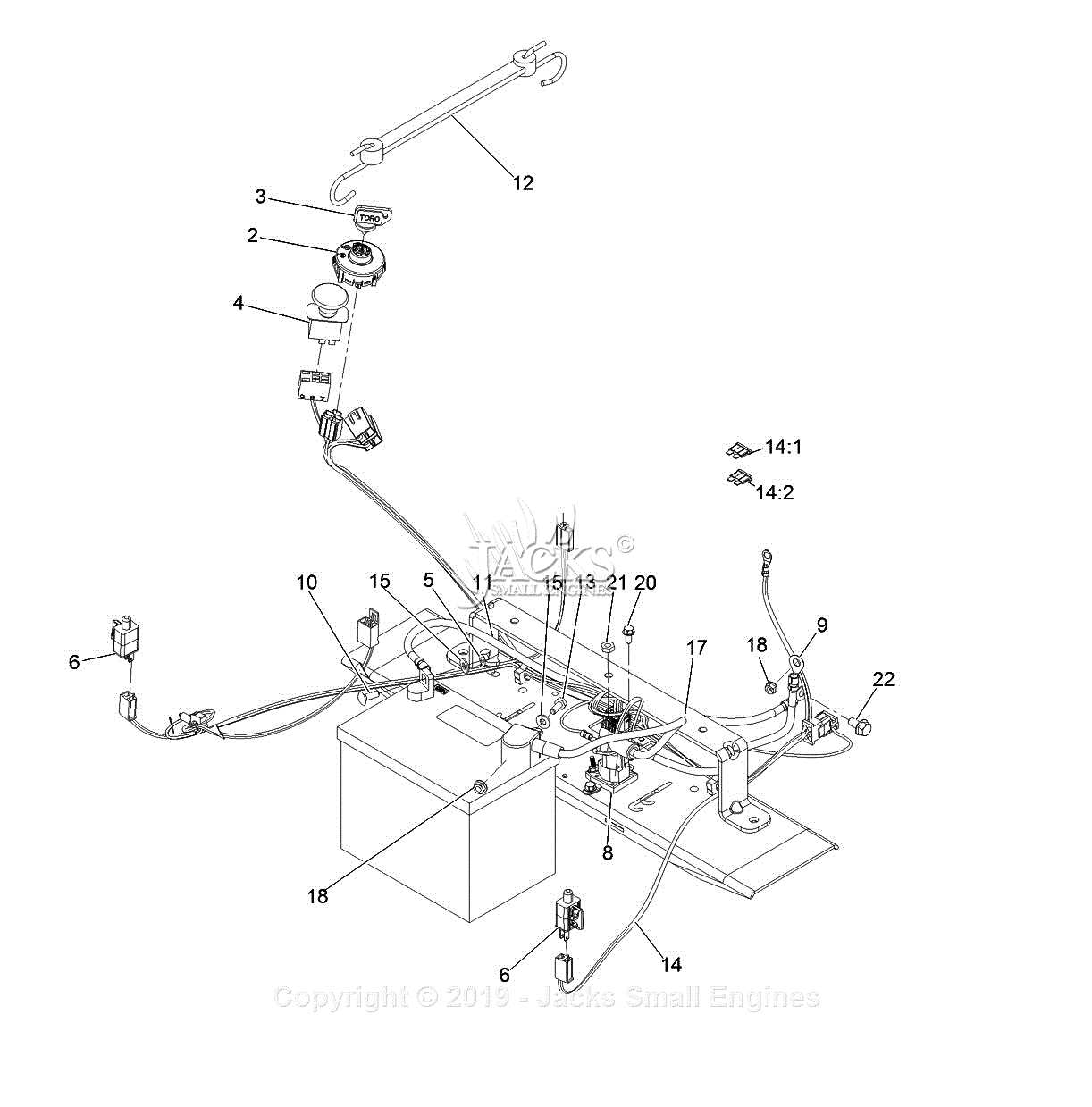

Additionally, users sometimes face electrical problems, such as malfunctioning lights or starter issues. Proper wiring checks and battery maintenance are essential to avoid unexpected breakdowns.

By being aware of these potential problems, operators can proactively address them, ensuring their machinery remains in peak condition.

Identifying Replacement Parts Easily

Finding the right components for your equipment can often feel overwhelming, especially when there are numerous options available. Simplifying this process is crucial for ensuring that your machinery operates efficiently and effectively. By following a few key strategies, you can streamline your search for the necessary items.

Understanding Your Equipment

The first step in locating the correct components is to familiarize yourself with your machinery. This includes knowing the make, model, and specific features. Here are some tips to help you:

- Refer to the owner’s manual for detailed information about your equipment.

- Note down the model number and any serial numbers, as these can help in identifying suitable replacements.

- Look for any identifying marks or labels on the machine that may provide additional information.

Utilizing Online Resources

The internet offers a wealth of resources that can aid in your search. Consider the following approaches:

- Visit manufacturer websites that often provide guides and specifications.

- Utilize forums and communities where other users share their experiences and recommendations.

- Explore online retailers that specialize in equipment supplies; they frequently have search functions to narrow down your options.

By leveraging these techniques, you can enhance your ability to find the right components, ensuring your equipment remains in top working condition.

How to Read Diagrams Effectively

Understanding visual representations can significantly enhance your ability to grasp complex information. By mastering this skill, you can navigate various schematics, making it easier to identify components and their relationships.

Break Down the Elements

Start by examining each section of the visual layout. Identify the symbols, lines, and labels that indicate specific features or functions. Breaking down the elements allows you to create a mental map of the information presented.

Look for Key Annotations

Pay attention to any notes or legends included. These annotations often provide crucial insights about the relationships between different components. Understanding these details is essential for interpreting the overall structure accurately.

Maintenance Tips for Exmark Equipment

Proper upkeep of landscaping machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances the efficiency of the equipment but also prevents unexpected breakdowns, saving both time and money. Here are some essential tips to keep your machines running smoothly.

- Regular Cleaning: After each use, remove grass clippings, dirt, and debris from the machine to prevent rust and corrosion.

- Check Fluids: Regularly inspect oil, fuel, and coolant levels. Change oil according to the manufacturer’s recommendations to ensure engine health.

- Sharpen Blades: Keep cutting blades sharp for cleaner cuts. Dull blades can damage grass and require more power to operate.

- Inspect Belts and Cables: Regularly check for wear and tear. Replace any frayed or damaged belts and cables to maintain safety and performance.

- Battery Maintenance: Clean battery terminals and ensure a secure connection. Test the battery regularly to avoid starting issues.

- Store Properly: During off-seasons, store equipment in a dry, sheltered area to protect it from harsh weather conditions.

By following these maintenance practices, users can extend the life of their machinery and enhance its performance throughout the seasons. Prioritizing care will lead to reliable operation and optimal results in landscaping tasks.

Where to Find Official Parts

Locating authentic components for your equipment can greatly enhance its performance and longevity. Utilizing reliable sources ensures you receive high-quality items that fit seamlessly, preserving functionality and efficiency.

Authorized Dealers

Visiting certified retailers is one of the best ways to acquire genuine components. These dealers maintain a direct relationship with manufacturers, guaranteeing that the items you purchase meet the required specifications.

Online Resources

Many manufacturers provide official websites where you can browse and order components directly. These platforms often feature detailed catalogs, allowing you to find exactly what you need with ease.

Benefits of Using Genuine Parts

Opting for original components in maintenance and repairs offers numerous advantages that contribute to the longevity and efficiency of your equipment. Genuine items are designed to fit perfectly and function seamlessly, ensuring optimal performance.

Quality Assurance

- Manufactured to high standards, ensuring durability.

- Undergo rigorous testing for reliability and safety.

- Consistent performance over time, reducing the need for frequent replacements.

Cost-Effectiveness

- Minimizes the risk of breakdowns and costly repairs.

- Enhances the overall value of the equipment.

- Often includes warranties, providing additional peace of mind.

DIY Repairs for Exmark Quest

Maintaining your lawn equipment can save you both time and money, enabling you to tackle common issues with confidence. This section will guide you through straightforward repair processes that anyone can handle, ensuring your machinery runs smoothly.

Basic Maintenance Tips

Regular upkeep is essential for longevity. Start by checking the oil levels and replacing the air filter. This simple task can improve performance significantly. Always refer to your owner’s manual for specifications.

Troubleshooting Common Issues

If your machine is not starting, inspect the spark plug and battery connections. Cleaning these components can often resolve starting issues. For more complex problems, delve into the wiring system to ensure everything is intact.

Frequently Asked Questions on Parts

This section addresses common inquiries regarding components for various models, providing clarity for users seeking guidance on maintenance and repairs. Here, you will find answers to typical concerns to enhance your understanding of available options.

Common Inquiries

- What are the signs that a component needs replacement?

- Where can I find reliable replacement options?

- How often should maintenance be performed on my equipment?

Maintenance Tips

- Regularly inspect for wear and tear.

- Follow the manufacturer’s recommendations for servicing.

- Keep records of all replacements and maintenance tasks.