Understanding the Fimco Sprayer Parts Diagram for Efficient Maintenance

In the realm of agricultural machinery, the intricate network of components plays a vital role in ensuring optimal functionality. Understanding how these elements interact can significantly enhance efficiency and performance in various applications. A comprehensive overview of these components allows users to appreciate their importance and facilitate better maintenance practices.

By exploring the connections and configurations of these essential items, one can gain valuable insights into the mechanics that drive effective operation. This knowledge empowers users to troubleshoot issues effectively and make informed decisions when it comes to repairs or upgrades. Such an understanding is ultimately crucial for maximizing productivity and extending the lifespan of the equipment.

Whether you are a seasoned professional or a novice, delving into the specifics of these elements can unveil the intricacies of their design and functionality. Recognizing the relationships between different components not only simplifies repairs but also enhances the overall user experience, leading to a more seamless interaction with the machinery.

Understanding Fimco Sprayer Components

Gaining insight into the various elements of a liquid application system is essential for optimal functionality and maintenance. Each component plays a crucial role in ensuring effective performance, making familiarity with their functions and interactions invaluable for users.

| Component | Function |

|---|---|

| Tank | Holds the solution to be distributed. |

| Pump | Generates the pressure needed to move the liquid. |

| Hoses | Transport the mixture from the tank to the application site. |

| Nozzle | Disperses the solution in a controlled manner. |

| Filter | Prevents clogs by removing debris from the solution. |

Key Parts of Fimco Sprayers

This section explores the essential components that contribute to the functionality and efficiency of these agricultural tools. Understanding each element is crucial for maintenance and optimal performance.

Main Components

The following are some of the primary elements that make up these devices:

| Component | Description |

|---|---|

| Tank | Holds the liquid for application. |

| Pump | Facilitates the movement of fluid from the tank to the nozzle. |

| Nozzle | Disperses the liquid in a controlled manner. |

| Hoses | Transport the liquid between components. |

Additional Features

Beyond the basics, other elements enhance usability and efficiency:

| Feature | Function |

|---|---|

| Pressure Gauge | Monitors the system pressure for optimal operation. |

| Filter | Prevents debris from clogging the system. |

| Control Valves | Regulate the flow and distribution of the liquid. |

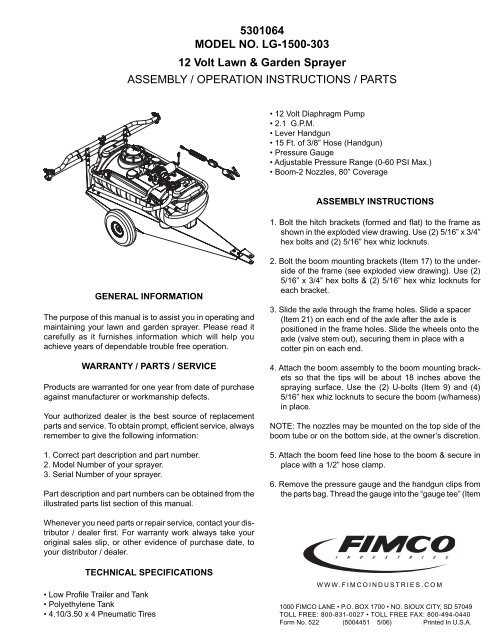

Importance of Sprayer Diagrams

Understanding the layout and components of equipment is crucial for effective maintenance and operation. Visual representations serve as valuable tools, allowing users to quickly identify and troubleshoot issues. By grasping the arrangement of various elements, operators can enhance performance and ensure longevity.

Clear visual aids provide a roadmap for assembling and disassembling machinery, making the process more efficient. Moreover, these illustrations facilitate training for new users, ensuring they comprehend how different sections interact. With detailed visuals, users can minimize errors and streamline workflows, ultimately leading to improved productivity.

Additionally, having access to accurate representations aids in sourcing the correct replacements, preventing delays and ensuring that maintenance tasks are executed seamlessly. In summary, comprehensive illustrations are not just supplementary; they are essential for optimal functionality and care of equipment.

Common Issues with Sprayer Parts

Understanding the frequent challenges faced by users of spraying equipment is crucial for maintaining optimal performance. These difficulties can arise from various components and their interactions, leading to inefficiencies and reduced effectiveness in application tasks. Recognizing and addressing these common problems can enhance the longevity and reliability of the machinery.

1. Clogging and Blockages

One of the most prevalent issues involves clogs within the system. Over time, residues and particulates can accumulate in hoses and nozzles, disrupting the flow of liquid. Regular maintenance and cleaning are essential to prevent these obstructions. Using filters and ensuring proper mixing of solutions can also mitigate this problem.

2. Leaks and Drips

Leakage is another significant concern that can affect performance. Connections and seals may wear out, resulting in unintended fluid loss. Inspecting seals and fittings regularly helps identify potential issues before they escalate. Additionally, using compatible replacement components can significantly reduce the risk of future leaks.

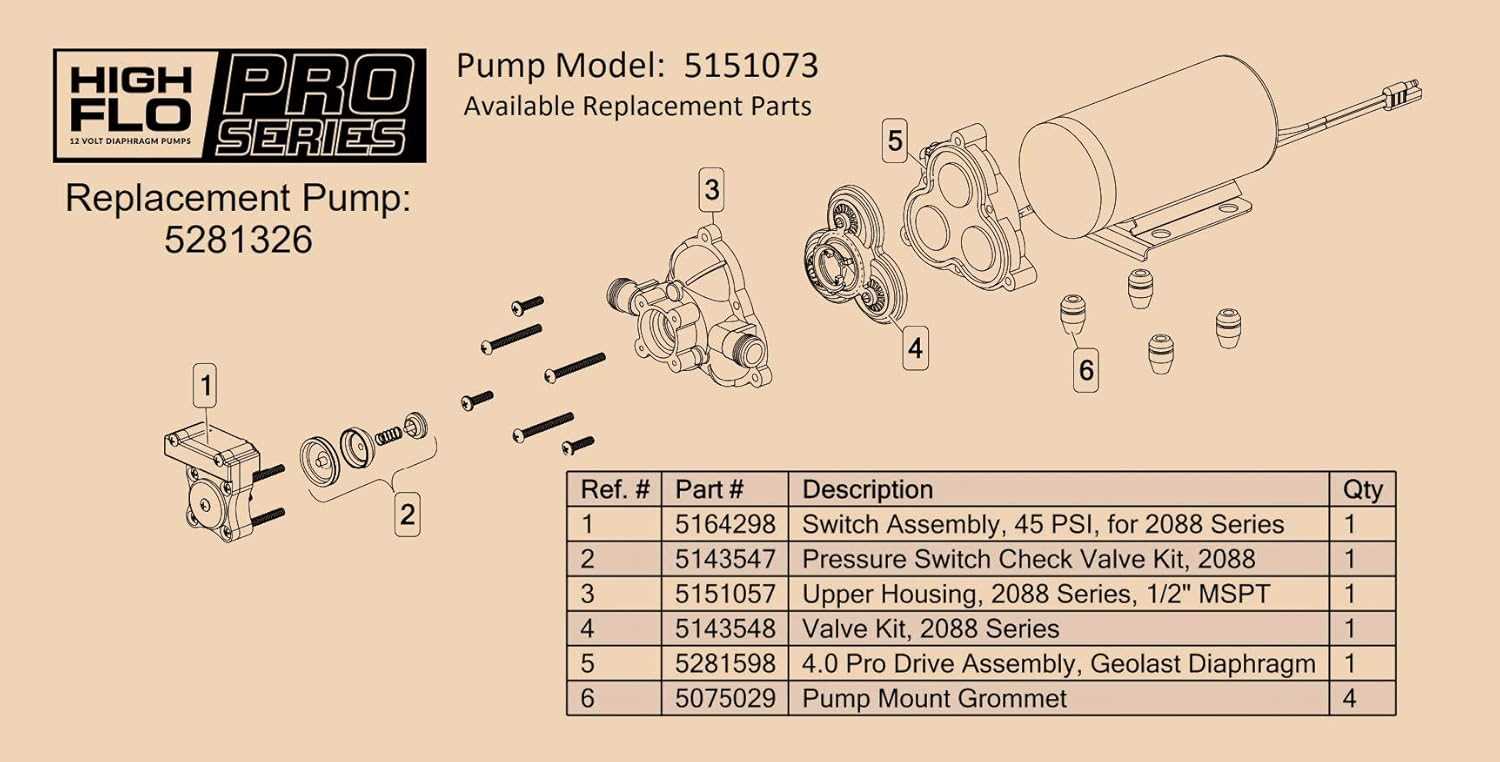

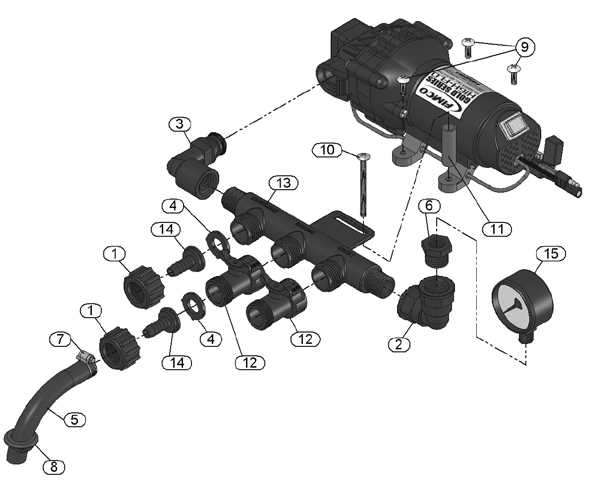

How to Read Fimco Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of various equipment. These visual guides provide crucial information about components and their connections, enabling users to identify parts and comprehend assembly processes efficiently. Mastering the interpretation of these resources can greatly enhance your ability to troubleshoot and service your machinery.

To start, familiarize yourself with the symbols and notations commonly used in these illustrations. Each symbol typically represents a specific element, such as valves, pumps, or hoses. Often, a legend is included, detailing the meaning of each symbol, making it easier to decode the information presented.

Next, pay attention to the layout of the illustration. Components are usually arranged in a logical sequence, reflecting how they interact within the system. By tracing the connections and following the flow from one element to another, you can gain insights into the operational mechanics of the equipment.

Additionally, note any annotations or notes included alongside the visuals. These can offer valuable instructions, maintenance tips, or troubleshooting advice that can aid you in understanding the assembly or diagnosing issues effectively.

Lastly, practice makes perfect. Regularly reviewing and interpreting these illustrations will enhance your skills over time, allowing you to become more proficient in managing and repairing the equipment. With patience and attention to detail, you will find these resources to be invaluable tools in your technical endeavors.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often be a straightforward task if approached with the right strategy. Understanding where to look and how to identify the necessary elements can save both time and effort. This section aims to provide guidance on streamlining the search for replacements to ensure your machinery operates efficiently.

Identifying the Right Components

To facilitate the process, begin by familiarizing yourself with the specifications of your device. This includes model numbers, dimensions, and any unique identifiers that may assist in the search. Online resources, manufacturer websites, and user manuals can be invaluable tools in gathering this information.

Resources for Finding Components

Several avenues can be explored when seeking out replacements:

| Resource Type | Description |

|---|---|

| Manufacturer Website | Often contains detailed catalogs and ordering options for specific items. |

| Online Retailers | Many sites offer a wide variety of components, often with user reviews to aid in decision-making. |

| Local Distributors | Can provide personalized service and immediate availability for urgent needs. |

| Community Forums | Platforms where users share experiences and recommendations can lead to valuable insights. |

By utilizing these resources and having a clear understanding of what you need, you can simplify the process of finding suitable replacements and keep your equipment running smoothly.

Maintenance Tips for Fimco Sprayers

Regular upkeep is essential for ensuring longevity and optimal performance of your equipment. Proper care can prevent issues, enhance efficiency, and ultimately save you time and money.

- Always clean the machine thoroughly after each use to remove any residue.

- Inspect hoses and connections for leaks or wear and replace them as needed.

- Check filters regularly; clean or replace them to maintain proper flow.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Store the unit in a dry, sheltered location to protect it from the elements.

By following these guidelines, you can ensure your equipment remains in peak condition and ready for future tasks.

Identifying Worn Components

Understanding the signs of deterioration in equipment is essential for maintaining optimal performance. Recognizing these indicators can prevent further damage and ensure longevity. Various components may exhibit wear over time, and knowing what to look for is crucial for timely maintenance.

Visual Inspection: Regularly examining the machinery can reveal obvious signs of wear, such as cracks, discoloration, or deformities. Pay attention to any irregularities that deviate from the original design.

Performance Changes: A noticeable decline in efficiency or effectiveness can signal that certain elements are wearing out. If you experience reduced output or inconsistent operation, it may indicate that components need to be assessed or replaced.

Unusual Noises: Listen for any abnormal sounds during operation. Grinding, squeaking, or rattling can suggest that parts are not functioning smoothly and may require immediate attention.

Fluid Leaks: Any leakage of fluids can be a strong indication that seals or gaskets have degraded. Addressing these issues promptly can prevent more extensive damage and costly repairs.

Regular Maintenance: Following a routine maintenance schedule helps identify worn components early. Keeping detailed records of inspections and replacements can assist in recognizing patterns of wear over time.

By staying vigilant and aware of these factors, you can ensure that your equipment remains in peak condition and operates efficiently for years to come.

Upgrading Fimco Sprayer Features

Enhancing the capabilities of your agricultural equipment can lead to improved efficiency and productivity. By integrating advanced components and technology, you can transform your existing setup into a more powerful tool for various tasks.

Consider these potential upgrades:

- Incorporating precision nozzles for better coverage and reduced chemical waste.

- Adding a digital control system for accurate pressure adjustments and flow rates.

- Integrating a GPS system for optimized routing and application mapping.

- Upgrading to a larger tank for increased capacity and reduced downtime.

- Implementing a filtration system to minimize clogging and extend the lifespan of components.

These enhancements can ultimately lead to a more effective and reliable experience in the field.

Compatibility of Various Parts

Understanding the compatibility of components is crucial for optimal performance and longevity of your equipment. Each element must work harmoniously with others to ensure efficiency and reliability. Compatibility can influence not only functionality but also maintenance and ease of use.

Different models may utilize similar features, but slight variations can lead to significant operational differences. It is essential to consult manufacturer guidelines or detailed specifications to verify which items can be interchanged without compromising quality.

Using compatible components can enhance the overall effectiveness of your system, while mismatches may cause malfunctions or damage. Therefore, careful consideration when selecting replacement or upgrade items is vital for achieving the ultimate performance.

Cost-Effective Repair Strategies

Implementing budget-friendly maintenance solutions can significantly extend the lifespan of your equipment while minimizing expenses. By utilizing strategic approaches, you can ensure that repairs are conducted efficiently without compromising quality.

- Regular Maintenance: Establish a routine check-up schedule to identify potential issues early. Preventive care can save you from costly repairs later.

- DIY Repairs: Educate yourself on basic troubleshooting and repair techniques. Online tutorials and manuals can guide you through common fixes, reducing labor costs.

- Quality Replacement Components: Opt for reliable yet affordable alternatives rather than always going for original items. Research reputable aftermarket options that offer warranties.

- Bulk Purchasing: If multiple components are needed, consider buying in bulk. This can lead to significant savings on individual prices.

By employing these strategies, you can effectively manage repair costs while maintaining high operational standards for your equipment.

Where to Buy Fimco Parts

Finding the right components for your equipment can be a straightforward process if you know where to look. There are several options available that cater to various needs and preferences.

- Online Retailers: Numerous websites specialize in offering a wide range of items, often at competitive prices. Look for reputable sources with customer reviews.

- Local Hardware Stores: Many community shops stock essential replacements and can order specific items if not immediately available.

- Manufacturer’s Website: The official site often provides a complete catalog of products, ensuring authenticity and availability.

- Specialty Suppliers: Some retailers focus solely on equipment, providing expert guidance and specialized components.

Consider comparing prices and checking for customer support options to ensure a smooth purchasing experience.

Utilizing Online Resources for Diagrams

In today’s digital age, leveraging web-based tools can significantly enhance one’s understanding of various mechanical systems. Accessing visual representations online not only aids in the assembly or repair processes but also provides a clear overview of complex components and their interconnections.

Numerous platforms offer valuable insights through detailed illustrations, making it easier to grasp the functionality of each element involved. By searching for relevant information, individuals can quickly find the necessary resources to aid in their tasks.

Furthermore, engaging with online communities can lead to discovering additional tips and tricks, as well as personal experiences shared by other users. This collaborative knowledge can be an ultimate advantage when tackling maintenance or upgrades.