Understanding the Fj180v Parts Diagram for Efficient Maintenance

In the realm of machinery, a thorough comprehension of each element is essential for optimal performance and maintenance. Knowing how various sections fit together not only enhances functionality but also extends the lifespan of the entire system. This guide delves into the intricate makeup of an engine, providing insights that are crucial for both enthusiasts and professionals alike.

Every machine comprises numerous individual units, each playing a vital role in the overall operation. By familiarizing oneself with these components, operators can identify potential issues early and ensure that the equipment runs smoothly. This exploration will cover essential elements, their interactions, and how to effectively troubleshoot common problems.

In addition to improving operational knowledge, recognizing the arrangement of these parts allows for better planning when it comes to repairs and upgrades. This resource aims to empower users with the information necessary to navigate through the complexities of mechanical systems with confidence and ease.

Understanding the Fj180v Engine Components

Exploring the intricate elements of a small engine reveals the essential roles that each component plays in ensuring optimal performance. A thorough comprehension of these parts not only enhances maintenance practices but also contributes to troubleshooting and efficient operation.

Key Components and Their Functions

Each segment of the engine works in harmony to convert fuel into motion. Below are some of the critical elements:

- Cylinder: The core area where fuel combustion occurs, generating power.

- Piston: A movable element within the cylinder that transmits energy to the crankshaft.

- Crankshaft: Converts the linear motion of the piston into rotational movement.

- Valves: Control the intake of air-fuel mixture and the expulsion of exhaust gases.

- Spark Plug: Initiates the combustion process by igniting the fuel-air mixture.

Maintenance Tips for Optimal Performance

Proper upkeep of each component is vital for longevity and efficiency. Consider the following practices:

- Regularly check and replace the spark plug to ensure efficient ignition.

- Keep the cylinder and piston free from debris to maintain compression.

- Monitor the condition of the crankshaft bearings for signs of wear.

- Inspect and clean the valves to prevent blockages.

- Ensure proper lubrication throughout to reduce friction and wear.

By understanding and maintaining these components, users can significantly enhance the performance and reliability of their engines.

Importance of a Parts Diagram

Understanding the structure of any mechanical system is crucial for effective maintenance and repair. A visual representation that outlines individual components serves as a vital tool for technicians and enthusiasts alike, enhancing clarity and efficiency in handling machinery.

Such a visual guide provides several key benefits:

- Enhanced Clarity: It simplifies the identification of various elements, making it easier to comprehend the assembly and disassembly processes.

- Streamlined Repairs: When issues arise, having a clear reference allows for quicker diagnosis and targeted solutions, reducing downtime.

- Informed Ordering: Knowing the exact components needed helps in procuring the right replacements, saving time and effort.

- Improved Safety: Understanding how parts interact minimizes the risk of accidents during repairs or modifications.

- Educational Resource: For newcomers, it serves as a valuable learning tool, helping to familiarize them with the equipment.

In conclusion, a well-organized visual reference is indispensable for anyone working with machinery. It not only enhances efficiency but also promotes safety and knowledge, making it an essential element in the realm of mechanical systems.

Common Issues with Fj180v Parts

When dealing with small engines, several common challenges can arise that affect their performance and reliability. Understanding these issues is essential for effective maintenance and troubleshooting. Below are some prevalent problems associated with components found in these engines.

| Issue | Description | Possible Solution |

|---|---|---|

| Overheating | Excessive heat can cause components to fail prematurely. | Ensure proper cooling system function and check for blockages. |

| Starting Problems | Difficulty in starting may indicate issues with ignition or fuel delivery. | Inspect spark plugs and fuel lines for clogs or wear. |

| Loss of Power | Reduced output can stem from worn or damaged internal components. | Examine and replace worn parts as needed. |

| Vibration | Unusual vibrations may signal misalignment or imbalance in moving parts. | Check alignment and tighten any loose components. |

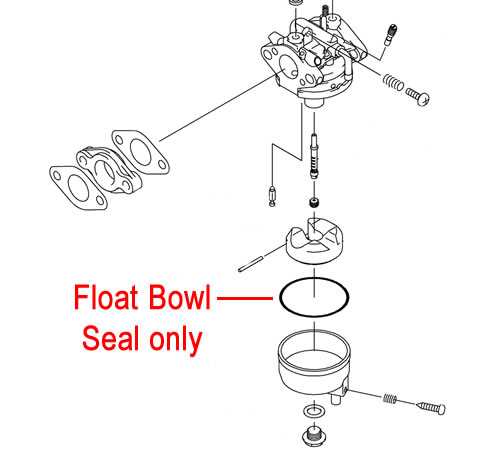

| Fuel Leaks | Leaks can lead to performance issues and safety hazards. | Inspect hoses and gaskets for signs of wear and replace them. |

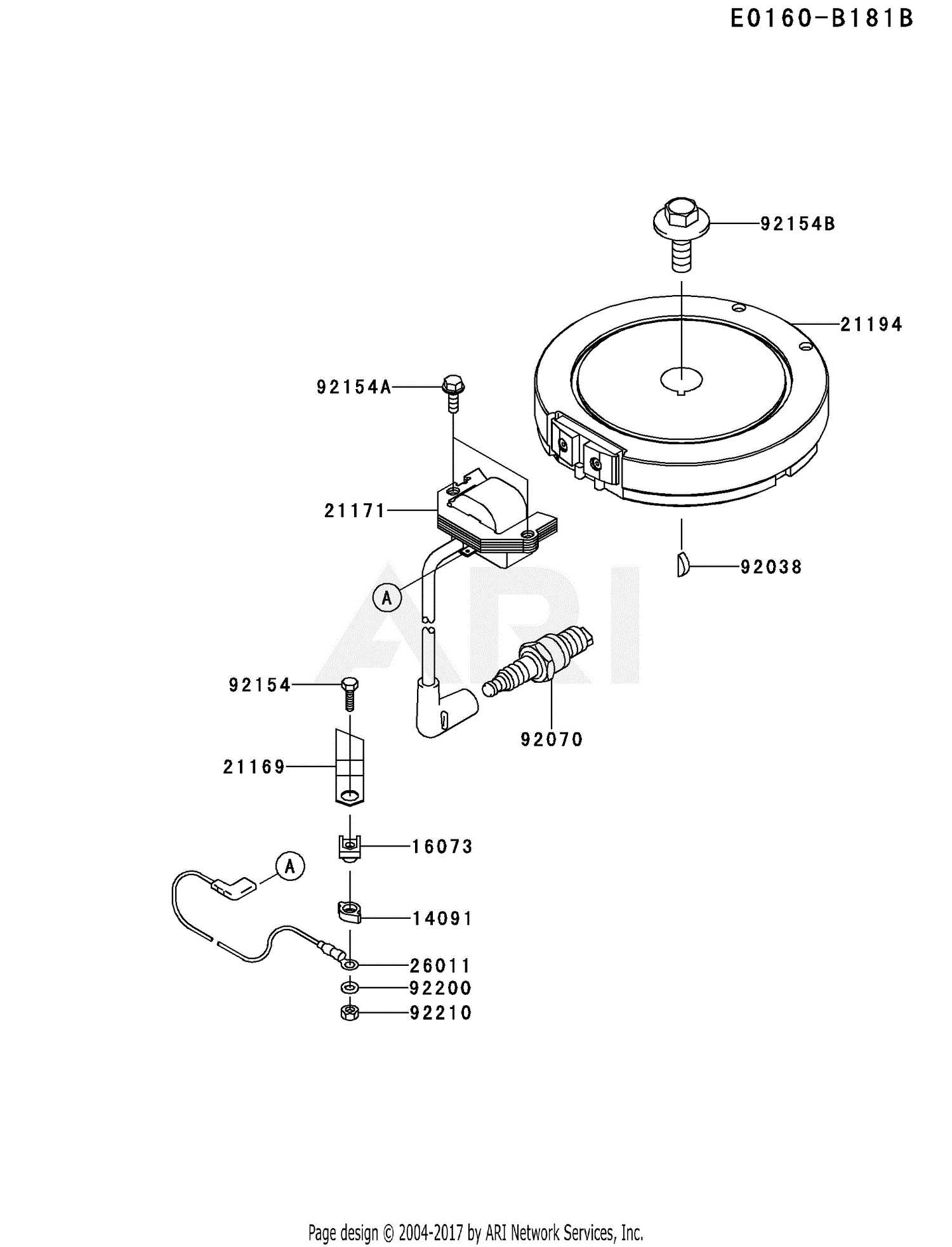

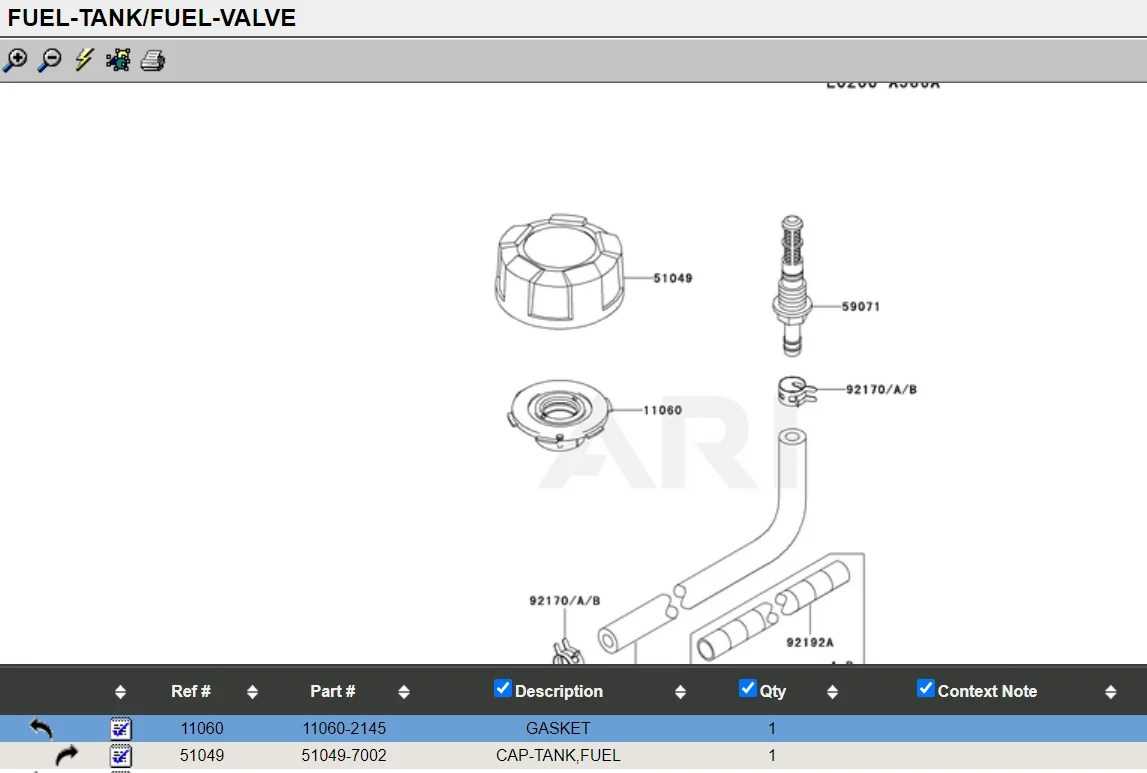

How to Read Engine Diagrams

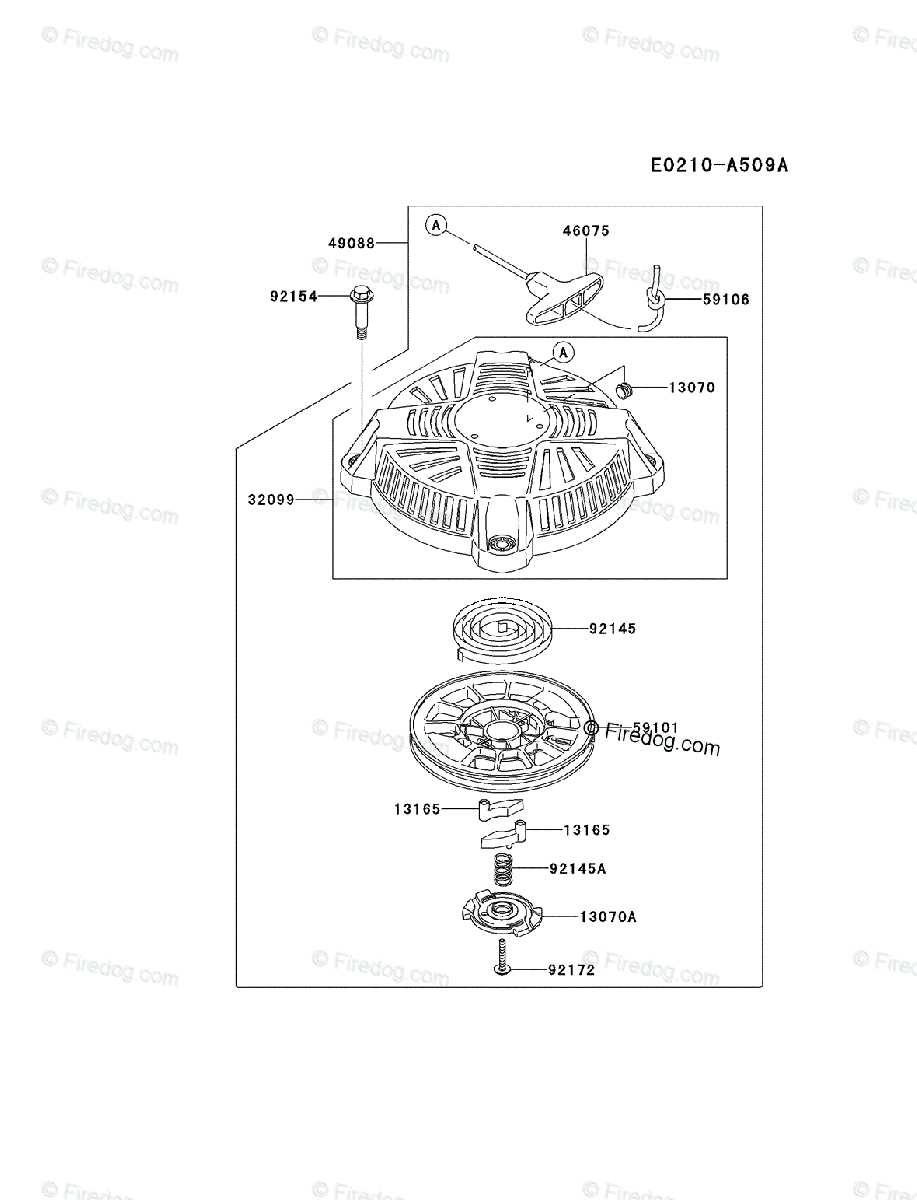

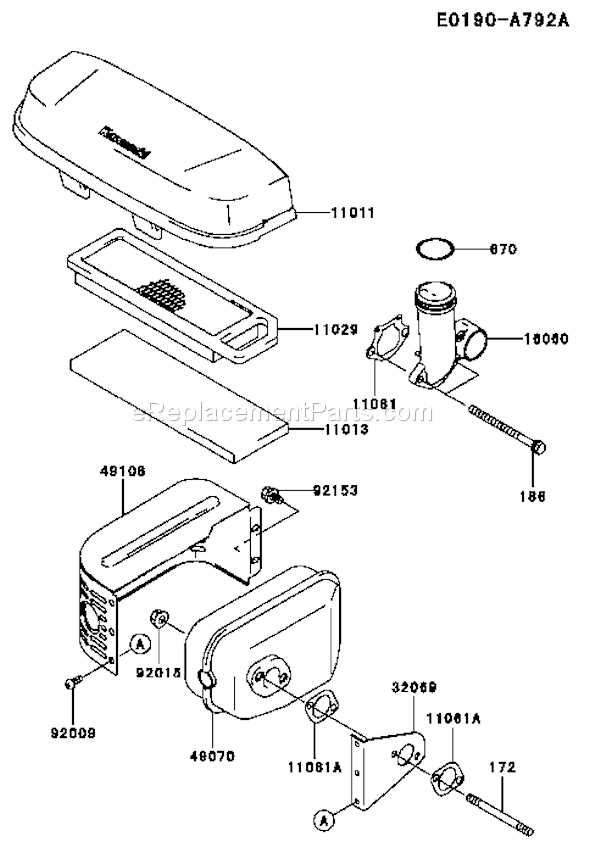

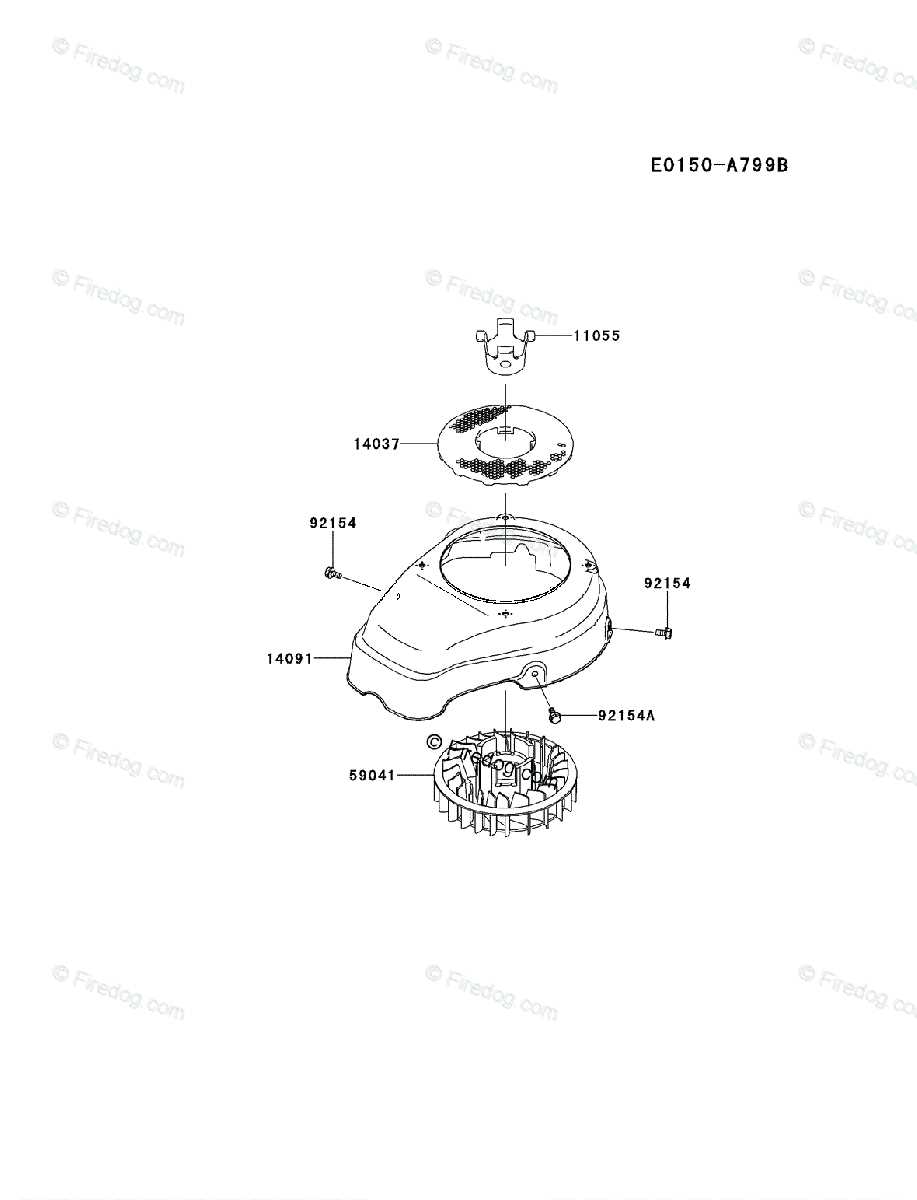

Understanding mechanical illustrations can be crucial for effective maintenance and repair tasks. These visual representations simplify complex components and their interrelationships, allowing individuals to grasp how various elements work together. Mastering this skill can significantly enhance your ability to diagnose issues and perform necessary interventions.

Identifying Components

Begin by familiarizing yourself with the various elements depicted in the illustration. Each part is usually labeled with a specific identifier, making it easier to locate and reference in manuals or during repairs. Pay attention to the symbols and color codes, as these often convey additional information about functionality or operational status.

Understanding Relationships

The arrangement of parts is equally important. Arrows and lines often indicate movement or flow, such as fuel or air pathways. Analyzing these connections helps in understanding how each piece interacts within the system. A clear grasp of these relationships will assist in troubleshooting and ensuring everything operates harmoniously.

In summary, mastering the art of interpreting these technical illustrations empowers you to navigate mechanical challenges more effectively, ensuring better performance and longevity of the equipment.

Replacement Parts for Fj180v

When it comes to maintaining machinery, having access to the right components is crucial for optimal performance and longevity. This section focuses on essential elements that can ensure your equipment operates smoothly and efficiently. Understanding the various options available can help in making informed decisions for replacements.

- Engine Components

- Fuel System Parts

- Ignition System Elements

- Cooling System Components

- Exhaust System Parts

Each category plays a vital role in the overall functionality of the machinery. Here are some key aspects to consider:

- Engine Components: Pistons, valves, and gaskets are integral for maintaining engine efficiency. Regular checks can prevent major issues.

- Fuel System Parts: Fuel filters and pumps ensure that the engine receives clean and sufficient fuel, improving performance.

- Ignition System Elements: Spark plugs and ignition coils are essential for reliable starting and consistent operation.

- Cooling System Components: Radiators and thermostats help manage engine temperatures, preventing overheating.

- Exhaust System Parts: Mufflers and catalytic converters reduce emissions and improve engine efficiency.

Identifying the right components is key. Whether you are dealing with wear and tear or simply upgrading your machinery, having a reliable source for replacements will keep your equipment running at its best.

Maintenance Tips for Longevity

Ensuring the extended life of your machinery requires consistent care and attention. By implementing effective maintenance practices, you can prevent issues before they arise and enhance performance over time. Here are some key strategies to consider for optimal upkeep.

Regular Inspections

Frequent evaluations are crucial in identifying potential problems early. Establish a routine that includes the following:

- Check for signs of wear and tear on components.

- Inspect fluid levels and look for leaks.

- Assess the condition of filters and belts.

Proper Cleaning

Keeping machinery clean can significantly impact its functionality. Consider these cleaning practices:

- Remove dirt and debris from external surfaces regularly.

- Use appropriate cleaning solutions for internal components.

- Ensure ventilation areas are clear to prevent overheating.

By incorporating these maintenance tips into your routine, you can greatly enhance the longevity and reliability of your equipment.

Where to Find Original Parts

Locating authentic components for your equipment is essential for maintaining performance and longevity. Understanding where to source these elements can significantly impact the reliability and efficiency of your machinery. This guide highlights the best avenues to explore when in need of genuine replacements.

Authorized Dealers

The most reliable source for original components is through authorized dealers. These vendors are recognized by manufacturers and often provide guarantees on the authenticity of the items they sell. Visiting their websites or physical locations can yield a wide selection of parts tailored specifically for your needs.

Manufacturer’s Website

Another excellent option is the manufacturer’s official website. Most companies offer an online catalog featuring their complete range of products, including original replacements. This method ensures you are purchasing directly from the source, reducing the risk of counterfeit items and ensuring compatibility with your equipment.

Comparing Aftermarket Options

When considering replacements for specific mechanical components, the market offers a plethora of choices. Evaluating these alternatives is essential to ensure quality, compatibility, and cost-effectiveness. This section delves into the key factors to consider when comparing various aftermarket solutions.

- Quality and Durability: Assess the materials and manufacturing processes used in the alternatives. Higher quality often translates to longer life spans and better performance.

- Compatibility: Ensure that the chosen replacements fit seamlessly with your existing equipment. Look for specifications that match your requirements.

- Price: Compare the cost of different options. While lower prices may be appealing, consider the potential long-term savings of investing in higher-quality products.

- Reviews and Reputation: Research user feedback and brand reputation. Reliable sources can provide insights into the performance and reliability of the alternatives.

- Warranty and Support: Evaluate the warranty offered by manufacturers. Good after-sales support can be crucial in case of issues.

By carefully analyzing these aspects, you can make informed decisions that will enhance the performance and longevity of your equipment.

Diagram Interpretation for DIY Repairs

Understanding technical illustrations is essential for anyone looking to undertake repairs independently. These visual guides serve as blueprints, providing clarity on how components interact within a system. By decoding these visuals, you can enhance your ability to troubleshoot issues and carry out maintenance tasks effectively.

Key Elements to Focus On

When examining these visual aids, pay attention to the labels and annotations that accompany each part. These notations often indicate sizes, specifications, and important installation notes, which can prevent errors during reassembly. Additionally, understanding the flow of connections will help you visualize how each element functions within the larger assembly.

Steps for Effective Interpretation

Start by identifying the main components depicted in the illustration. Familiarize yourself with their shapes and placements. Next, follow any directional arrows or lines that indicate movement or connectivity. Finally, compare these visuals with the actual assembly to ensure a comprehensive understanding of the layout.

By honing your skills in reading these guides, you empower yourself to tackle repairs confidently, minimizing downtime and saving costs on professional services.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. A thorough understanding of the equipment and its components is crucial, as it allows for a more secure and efficient repair process. Proper precautions not only protect the individual performing the work but also safeguard the tools and machinery involved.

Before starting any maintenance activity, ensure that you are wearing appropriate personal protective equipment (PPE), such as gloves, safety goggles, and steel-toed boots. This gear acts as a barrier against potential hazards, reducing the risk of injury. Additionally, it is important to work in a well-ventilated area to avoid inhaling harmful fumes or dust.

Always disconnect the power source before beginning repairs. This step is vital to eliminate the risk of electric shock or unintentional machine activation. It is advisable to use lockout/tagout procedures to ensure that the equipment remains in a safe state during maintenance.

Organizing your workspace can significantly enhance safety. Keep tools and materials neatly arranged to minimize the chances of tripping or dropping items. Familiarize yourself with the machinery’s operational manual and follow the recommended procedures for repairs, as this knowledge is critical for avoiding mishaps.

Lastly, if you are uncertain about any aspect of the repair, do not hesitate to consult with a knowledgeable professional. Seeking assistance can help ensure that the task is completed safely and effectively.