Comprehensive Guide to Fox 2.0 Shock Parts Diagram

The intricate world of vehicle suspension systems plays a crucial role in performance and comfort. By delving into the various elements that make up these systems, enthusiasts can gain valuable insights into their functionality and maintenance. This exploration highlights the significance of each component and its contribution to overall handling.

As technology evolves, the design of these mechanisms becomes increasingly sophisticated. Familiarity with the arrangement and interaction of different parts is essential for anyone seeking to enhance their understanding or tackle upgrades. Grasping these concepts allows for informed decisions when it comes to repairs or enhancements.

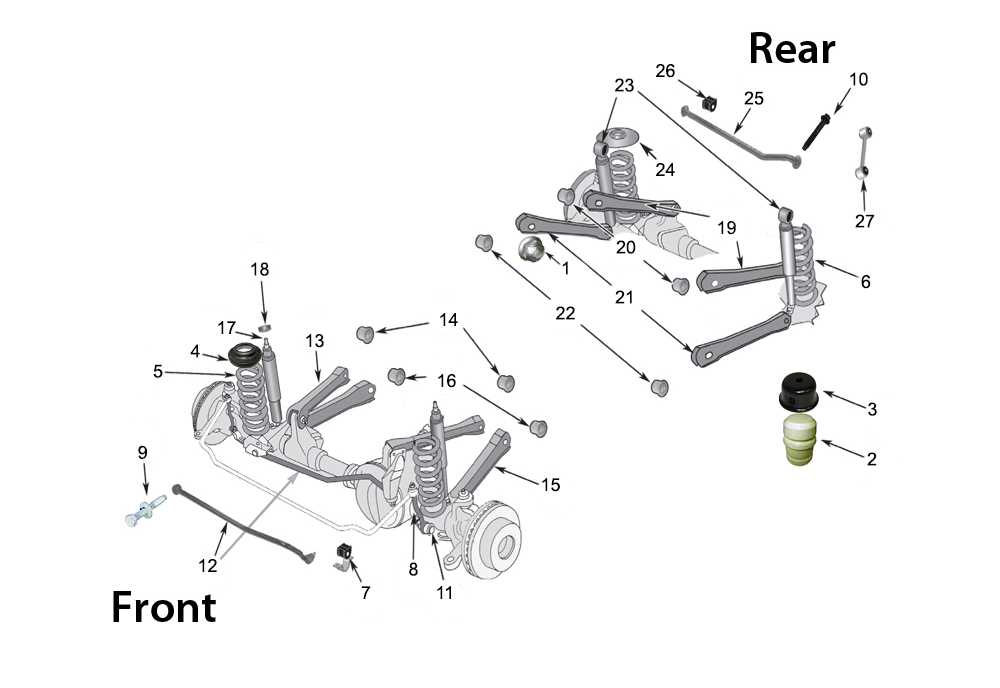

Whether you’re a seasoned expert or a newcomer, visual representations of these systems can clarify the relationships between components. By examining detailed illustrations, one can appreciate the engineering that underpins modern automotive performance. Such resources are indispensable for anyone looking to optimize their ride’s capabilities.

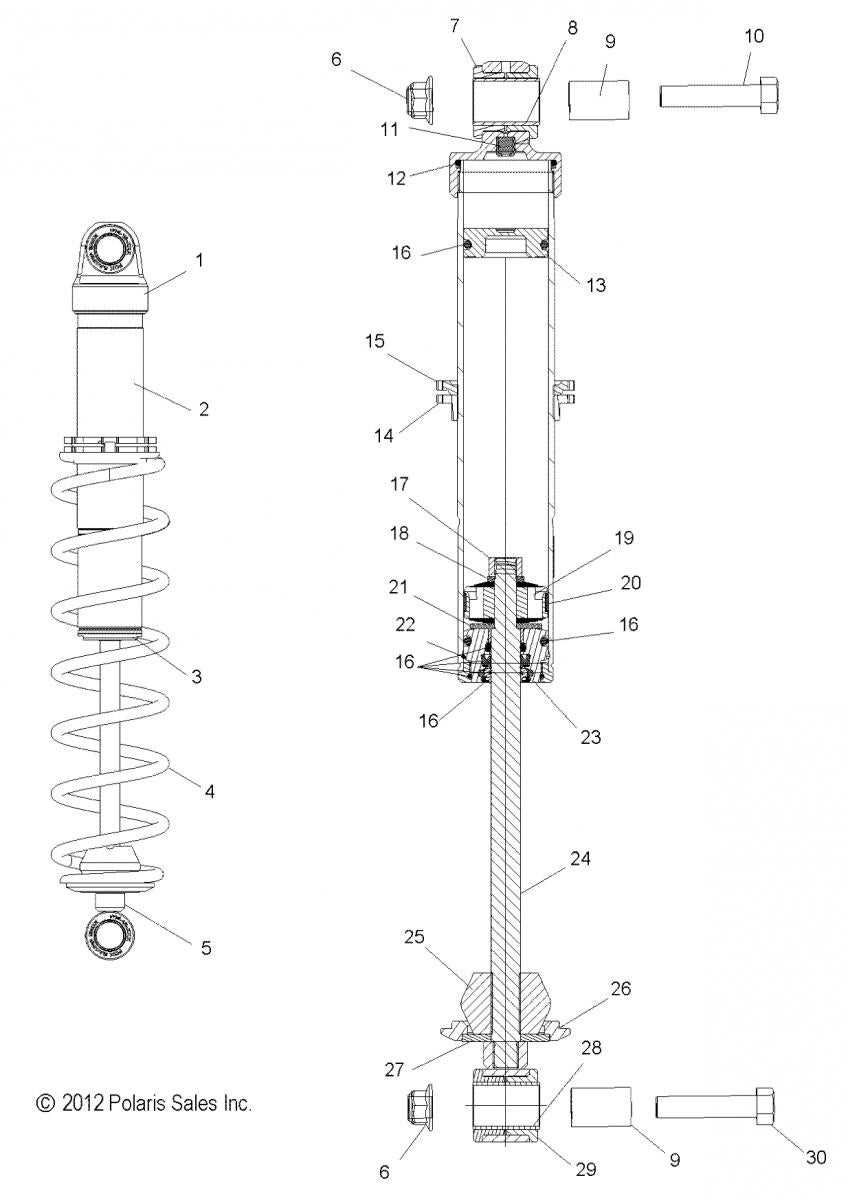

Understanding Fox 2.0 Shock Components

Exploring the intricate elements of suspension systems reveals a complex interplay of components that work in harmony to enhance performance. Each piece plays a crucial role in managing energy transfer, ensuring optimal handling and comfort on varied terrains. A comprehensive grasp of these elements is essential for enthusiasts looking to optimize their ride quality and durability.

The core assembly typically includes features designed to absorb impacts, adjust damping, and maintain stability. Each component is engineered for specific functions, such as regulating fluid flow and providing support under different conditions. Knowledge of these mechanisms can lead to improved maintenance practices and customized tuning, enhancing overall functionality.

Furthermore, understanding the nuances of each element can significantly impact performance. From the main cylinder to the various seals and adjusters, familiarity with their roles allows for informed decisions during upgrades or repairs. Ultimately, mastering these concepts fosters a deeper appreciation for the technology behind advanced suspension systems.

Overview of Shock Absorber Functions

This section explores the essential roles that damping systems play in enhancing vehicle performance and rider comfort. By managing energy absorption and maintaining stability, these components contribute significantly to overall handling and safety.

Key Functions

- Energy Dissipation: Converts kinetic energy into thermal energy, reducing vibrations.

- Stability Maintenance: Helps keep the tires in contact with the ground, improving traction.

- Ride Quality Improvement: Minimizes jolts and bumps, providing a smoother experience.

Importance in Performance

Effective damping systems are crucial for optimal vehicle dynamics. They ensure that responses to road conditions are managed, allowing for precision control and enhanced safety during various driving scenarios.

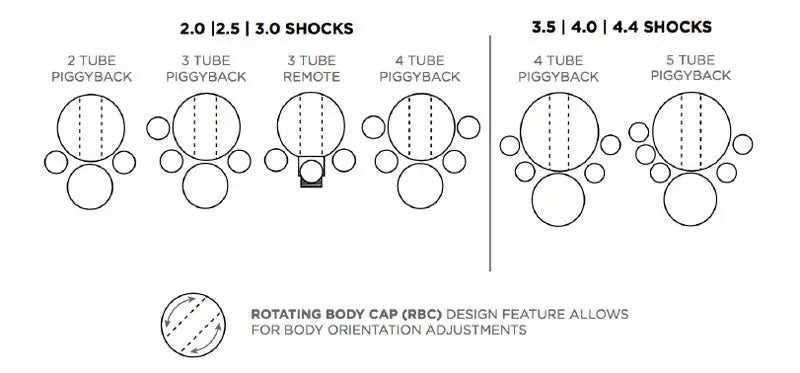

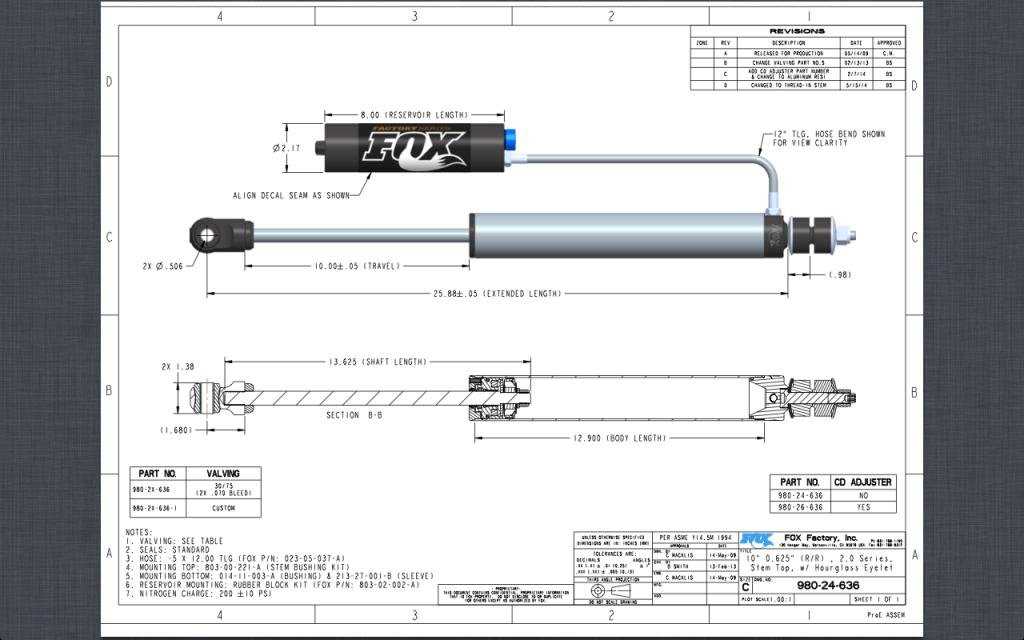

Key Parts in Fox 2.0 Design

This section explores the essential components that contribute to the overall functionality and performance of a specific suspension system. Understanding these elements is crucial for optimizing ride quality and handling characteristics.

- Spring Assembly: The element responsible for absorbing impacts and providing support during motion.

- Damper Unit: A crucial component that controls the oscillation of the spring, ensuring stability and comfort.

- Adjuster Knobs: Allow users to fine-tune the performance according to various terrains and personal preferences.

- Mounting Brackets: Essential for securing the entire system to the frame, providing structural integrity.

- Fluid Reservoir: A compartment that holds hydraulic fluid, aiding in the damping process and heat management.

Each of these components plays a vital role in delivering a smooth and controlled experience, enhancing both performance and reliability.

How to Read a Shock Diagram

Understanding a visual representation of suspension components can greatly enhance your ability to maintain and modify your equipment effectively. These illustrations provide critical insights into the various elements and their interactions, enabling you to troubleshoot issues or perform upgrades with confidence.

To effectively interpret these visuals, familiarize yourself with the symbols and notations used within the image. Each section typically highlights specific components, often accompanied by labels indicating their respective functions or specifications. This knowledge will assist in pinpointing areas of interest when assessing performance or conducting repairs.

| Element | Description |

|---|---|

| Body | The main structure that houses internal components. |

| Spring | Provides the necessary resistance and support during movement. |

| Valve | Regulates fluid flow to control compression and rebound. |

| Reservoir | Holds extra fluid for improved performance and heat dissipation. |

| Seal | Prevents leakage of fluid and maintains pressure within the assembly. |

When examining the visual guide, pay attention to the arrows and lines that indicate movement or flow. These will often demonstrate how forces interact during operation. By comprehending these dynamics, you can better understand the system’s behavior under various conditions, leading to improved performance and longevity of your gear.

Importance of Proper Assembly Techniques

Effective construction methods are crucial for ensuring the longevity and performance of mechanical systems. When components are meticulously assembled, it enhances their functionality and minimizes the risk of malfunctions. Neglecting these techniques can lead to premature wear, inefficiencies, and safety hazards.

Precision and Care

Applying precision in assembly involves following specific guidelines and using the right tools. Attention to detail ensures that each element fits together seamlessly, which is essential for optimal operation. Careless handling can result in misalignments, which compromise the integrity of the entire assembly.

Maintenance of Performance

Regular checks during the assembly process help maintain consistent performance levels. Ensuring that every component is correctly positioned and secured allows the system to operate at its ultimate efficiency. Ultimately, investing time in proper techniques pays off in reliability and durability.

Common Issues with Fox 2.0 Shocks

Many users encounter various challenges with performance dampers designed for off-road vehicles. Understanding these common complications can significantly enhance both the longevity and efficiency of the suspension system.

| Issue | Description |

|---|---|

| Leaking Fluid | One frequent problem is the leakage of hydraulic fluid, which can compromise damping performance. |

| Noise | Unusual sounds during operation may indicate internal wear or improper installation. |

| Inconsistent Response | A lack of predictability in performance can result from worn components or incorrect settings. |

| Overheating | Excessive heat build-up can lead to fading and reduced effectiveness in rugged conditions. |

| Corrosion | Environmental factors can cause rusting, negatively impacting durability and functionality. |

Tools Needed for Maintenance

Proper upkeep of your suspension system is essential for optimal performance and longevity. Utilizing the right instruments not only simplifies the maintenance process but also ensures precision in adjustments and repairs. This section outlines the essential tools that will aid in the effective servicing of your equipment.

Essential Instruments

Gathering the appropriate tools will prepare you for various tasks, from routine checks to more complex repairs. Here’s a list of indispensable items:

| Tool | Purpose |

|---|---|

| Torque Wrench | To ensure bolts are tightened to the correct specifications. |

| Pump | For adjusting air pressure in the system. |

| Shock Oil | For lubrication and maintenance of internal components. |

| Seal Kit | For replacing worn or damaged seals. |

Additional Equipment

In addition to the primary tools, having a few supplementary items on hand can enhance your maintenance routine. Consider including the following:

| Tool | Purpose |

|---|---|

| Cleaning Brush | To remove dirt and debris from surfaces. |

| Measuring Tape | For accurate measurement of travel and setup. |

| Gloves | To protect hands while handling oil and chemicals. |

Replacing Shock Parts: A Guide

Maintaining the integrity of your suspension system is crucial for optimal performance and comfort. This section offers a comprehensive overview of how to effectively replace components to enhance your ride experience. By understanding the process, you can ensure a smoother journey on varied terrains.

Essential Tools Needed

| Tool | Purpose |

|---|---|

| Wrench Set | To remove and secure fasteners |

| Torque Wrench | For precise tightening to manufacturer specifications |

| Replacement Components | Necessary for upgrades or repairs |

| Safety Gear | To protect during the replacement process |

Step-by-Step Replacement Process

Begin by securely elevating the vehicle to ensure safety. Next, systematically remove the old components, taking care to note the arrangement for reassembly. After cleaning the areas, install the new items carefully, following any provided instructions for proper alignment and fitting. Finally, test the system to confirm functionality and stability.

Adjusting Settings for Optimal Performance

Achieving the best performance from your suspension system requires careful calibration of various settings. Proper adjustments can significantly enhance ride quality, responsiveness, and overall handling. This section will guide you through the essential steps to fine-tune your setup for optimal results.

To start, consider the following key adjustments:

- Compression Settings: Tailor the compression rate to suit your riding style and terrain. A stiffer setting may be beneficial for aggressive riding, while a softer setup can improve comfort on rough trails.

- Rebound Settings: Control the rate at which the suspension returns after compression. Adjusting this can help maintain traction and stability during descents.

- Preload Adjustment: Fine-tune the sag by adjusting the preload. This ensures that the suspension responds correctly to rider weight and riding conditions.

- Volume Spacers: Experiment with volume spacers to modify the mid-stroke and bottom-out characteristics, enhancing the overall feel and performance of your setup.

When making adjustments, it’s essential to test your changes in a controlled environment:

- Start with small adjustments to understand their impact.

- Take notes on your settings and performance after each ride.

- Gradually work towards the optimal configuration by iterating based on your observations.

Remember, each rider has unique preferences, so don’t hesitate to experiment to find what works best for you. With patience and attention to detail, you can unlock the full potential of your suspension system.

Aftermarket Upgrades for Fox 2.0

Enhancing performance through aftermarket modifications is a popular choice for enthusiasts seeking to optimize their suspension systems. These upgrades can significantly improve ride quality, handling, and durability, providing a tailored experience for various terrains and driving styles.

Benefits of Aftermarket Modifications

- Improved dampening capabilities

- Increased adjustability for different driving conditions

- Enhanced durability and lifespan

- Customization options for personal preferences

Popular Upgrade Options

- Performance coilovers

- Upgraded bushings for better stiffness

- External reservoirs for temperature management

- Adjustable end links for fine-tuning

Maintenance Schedule for Longevity

Ensuring the durability and optimal performance of your suspension system requires a well-structured maintenance routine. Regular upkeep not only extends the lifespan of your equipment but also enhances its efficiency during use. Adhering to a scheduled maintenance plan is crucial for avoiding unexpected failures and costly repairs.

Here are key elements to consider for a successful maintenance schedule:

- Regular Inspections:

- Check for any signs of wear and tear.

- Look for leaks or fluid loss.

- Inspect mounting hardware for tightness.

- Fluid Changes:

- Replace fluids according to manufacturer recommendations.

- Monitor fluid condition regularly.

- Cleaning:

- Clean exterior surfaces to prevent dirt accumulation.

- Use appropriate cleaners to avoid damage to seals.

- Lubrication:

- Apply lubrication to all moving parts as needed.

- Use recommended lubricants to ensure compatibility.

In addition to these elements, consider establishing a timeline for routine tasks:

- Daily Checks:

- Inspect for visible damage.

- Ensure all components are securely fastened.

- Monthly Maintenance:

- Check fluid levels and top up as necessary.

- Clean all accessible parts.

- Annual Overhaul:

- Perform a comprehensive inspection.

- Replace any worn or damaged components.

By following this maintenance schedule, you can significantly increase the reliability and lifespan of your suspension system, ensuring a smoother and safer ride for years to come.

Comparing Fox 2.0 with Other Models

This section explores the nuances between various suspension systems, highlighting performance characteristics, build quality, and user preferences. By examining different models, riders can make informed decisions based on their specific needs and riding styles.

Performance and Handling

When assessing performance, it’s essential to consider how each model responds to terrain variations. While some designs excel in providing a smooth ride over rough surfaces, others may offer superior responsiveness and agility in technical sections. The ultimate choice often depends on the balance between comfort and control that the rider seeks.

Durability and Maintenance

Longevity is a critical factor in suspension selection. Many alternatives present robust construction and lower maintenance requirements, which can be appealing for avid enthusiasts. Understanding the maintenance needs and potential longevity of each option can ultimately guide users towards a choice that aligns with their riding habits.

Frequently Asked Questions About Shocks

This section addresses common inquiries regarding suspension systems, focusing on their functionality, maintenance, and troubleshooting. Understanding these aspects can enhance performance and longevity.

General Information

- What are the main functions of a suspension unit?

- How do I know if my system needs servicing?

- What are the signs of wear and tear?

Maintenance Tips

- Regularly inspect for leaks and damage.

- Clean the exterior to prevent corrosion.

- Check the mounting hardware for tightness.