Comprehensive Guide to FS 55 Parts Diagram

The intricate assembly of the Fs 55 reveals the synergy of various elements working together to deliver optimal performance. Understanding this configuration is essential for anyone looking to enhance their knowledge or maintenance practices. Each segment plays a crucial role, ensuring seamless operation and durability.

By examining the arrangement and functionality of these individual pieces, users can identify areas for improvement or replacement. This exploration not only aids in troubleshooting but also empowers operators to make informed decisions about care and upgrades. Ultimately, a comprehensive grasp of these components fosters a deeper appreciation for the machinery’s design and capabilities.

As we delve into this topic, we will uncover insights that will enhance your understanding and guide you through the nuances of the Fs 55. With this knowledge, you can confidently navigate maintenance tasks and optimize your equipment’s longevity.

Understanding Fs 55 Parts Diagram

Grasping the components and their arrangement within the Fs 55 model is crucial for effective maintenance and troubleshooting. This overview aims to illuminate the structure and function of each element, enabling users to optimize their experience with the equipment.

The schematic representation provides a comprehensive view of how individual elements interact, ensuring a seamless operation. Familiarity with these components allows for quicker identification of issues and facilitates efficient repairs, ultimately enhancing the longevity of the device.

By breaking down the various sections and detailing their roles, users can develop a deeper appreciation for the intricate design of the Fs 55. This understanding not only aids in routine checks but also empowers operators to make informed decisions regarding upgrades and replacements.

In conclusion, a solid grasp of the configuration of the Fs 55’s internal mechanisms is invaluable for anyone looking to maintain optimal functionality. Engaging with this information paves the way for improved performance and reliability, crucial for any operation relying on this equipment.

Overview of Fs 55 Components

The Fs 55 is a finely engineered machine, showcasing a variety of essential elements that contribute to its efficient operation. Understanding these components is crucial for both maintenance and optimal performance, as each plays a significant role in the overall functionality of the device.

Key Elements

Among the primary constituents are the engine, which provides the necessary power, and the cutting mechanism, designed for precision. Additionally, various control systems allow for user-friendly operation, ensuring that even complex tasks can be executed with ease.

Maintenance Considerations

Regular upkeep of these critical components is vital to prolonging the lifespan of the Fs 55. Identifying signs of wear and addressing them promptly can prevent more significant issues, thereby maintaining the ultimate efficiency of the machine.

Common Issues with Fs 55 Parts

Many users encounter a range of challenges when dealing with components of the Fs 55 model. Understanding these frequent problems can greatly enhance the overall performance and longevity of the equipment.

Wear and Tear: Over time, certain elements may degrade due to regular usage, leading to reduced efficiency. It’s crucial to monitor these items closely.

Improper Installation: Incorrect assembly can result in malfunctions. Always ensure that all pieces are fitted according to the manufacturer’s specifications to avoid complications.

Compatibility Concerns: Using non-original or mismatched components can lead to significant issues. It’s advisable to select parts that are specifically designed for the Fs 55.

Maintenance Neglect: Regular upkeep is essential. Failing to clean and service the machine can exacerbate existing problems and lead to more serious breakdowns.

Fuel Quality: The type of fuel used can impact performance. Always opt for high-quality fuel to prevent engine-related issues.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide valuable insights into the various elements of a system, helping users to identify and locate specific items quickly.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Different illustrations use unique symbols to represent various components. Spend some time understanding what each symbol stands for.

- Check the Key or Legend: Most visuals include a key that explains the symbols and color codes used. Refer to this key to enhance your understanding.

- Follow the Layout: Typically, components are arranged logically. Look for patterns or sequences that may indicate how elements connect or function together.

- Identify Groupings: Components may be grouped by function or location. Recognizing these clusters can simplify your navigation through the illustration.

- Take Notes: As you analyze the visual, jot down important information or references that might help you during actual repairs or assembly.

By mastering these strategies, you can effectively decipher the intricate relationships between different elements and ensure accurate troubleshooting and assembly in any project.

Key Features of Fs 55 Model

The Fs 55 model stands out in its category due to a combination of innovative design and practical functionality. This model is engineered to meet the diverse needs of users, ensuring both efficiency and ease of use in various applications.

Performance and Efficiency

One of the standout characteristics of the Fs 55 is its remarkable performance. This model integrates advanced technology to provide optimal power while maintaining fuel efficiency. Users can expect a reliable experience that maximizes productivity without compromising environmental considerations.

User-Friendly Design

The ergonomic design of the Fs 55 enhances user comfort and control. With features tailored for ease of handling, operators can navigate tasks more effectively, reducing fatigue during extended use. This attention to user experience makes it a preferred choice among professionals and hobbyists alike.

| Feature | Description |

|---|---|

| Power Output | High-performance engine that balances power and efficiency. |

| Weight | Lightweight construction for enhanced maneuverability. |

| Ergonomics | Comfortable grip and adjustable components for user comfort. |

| Durability | Robust materials designed for long-lasting performance. |

Maintenance Tips for Fs 55

Proper upkeep of your equipment ensures longevity and optimal performance. Regular maintenance not only prevents breakdowns but also enhances efficiency. Here are some essential tips to keep your device in top shape.

- Regularly clean the exterior to remove dirt and debris.

- Check and replace the air filter as needed to ensure airflow.

- Inspect the spark plug for wear and replace it if necessary.

- Lubricate moving parts to reduce friction and wear.

- Examine fuel lines for cracks or leaks and replace them if damaged.

Following these guidelines will help maintain your equipment and extend its lifespan. Always consult the user manual for specific instructions related to your model.

Finding Replacement Parts Efficiently

Locating suitable components for your equipment can often be a daunting task. Understanding how to streamline this process can save time and ensure you find the right elements for maintenance or upgrades. Whether you’re tackling a repair or enhancing functionality, knowing where and how to search effectively is key.

Utilizing Online Resources

The internet is a treasure trove of information when it comes to sourcing essential components. Numerous platforms specialize in providing detailed listings, often featuring specifications, compatibility information, and user reviews. Make use of search engines and specific websites dedicated to your equipment’s brand.

Consulting Manufacturer’s Documentation

Your equipment’s documentation is an invaluable resource. Manuals often include not only the necessary specifications but also recommendations for authorized suppliers. This can help you avoid counterfeit or substandard items, ensuring you receive quality replacements.

| Resource Type | Description | Benefits |

|---|---|---|

| Online Marketplaces | Websites that sell various components | Wide selection, user reviews |

| Manufacturer’s Website | Official site for brand-specific items | Authenticity, warranty support |

| Forums and Communities | Discussion platforms for enthusiasts | Shared experiences, tips |

| Local Retailers | Brick-and-mortar stores | Immediate availability, personal assistance |

Comparing Fs 55 to Similar Models

When evaluating the Fs 55 alongside comparable models, it’s essential to consider various aspects that contribute to their performance and usability. This analysis aims to highlight key differences and similarities that potential users might find significant in their decision-making process.

Performance Metrics

- Power Output: The Fs 55 typically offers a robust engine performance, making it suitable for demanding tasks.

- Weight: In terms of portability, the weight of the Fs 55 can be a determining factor when compared to lighter alternatives.

- Fuel Efficiency: Comparing fuel consumption can reveal advantages in long-term operational costs.

Features and Usability

- Ease of Use: User-friendly controls are a critical consideration that can enhance the overall experience.

- Durability: Material quality and build can significantly influence longevity and reliability.

- Maintenance: Assessing maintenance requirements helps in understanding the long-term commitment involved.

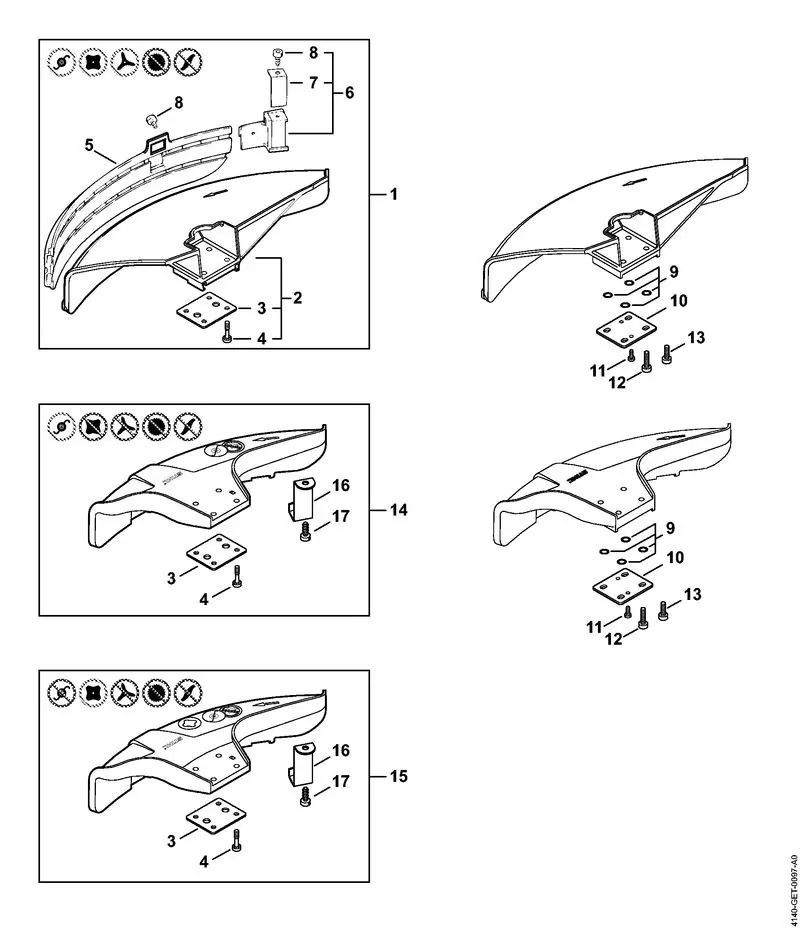

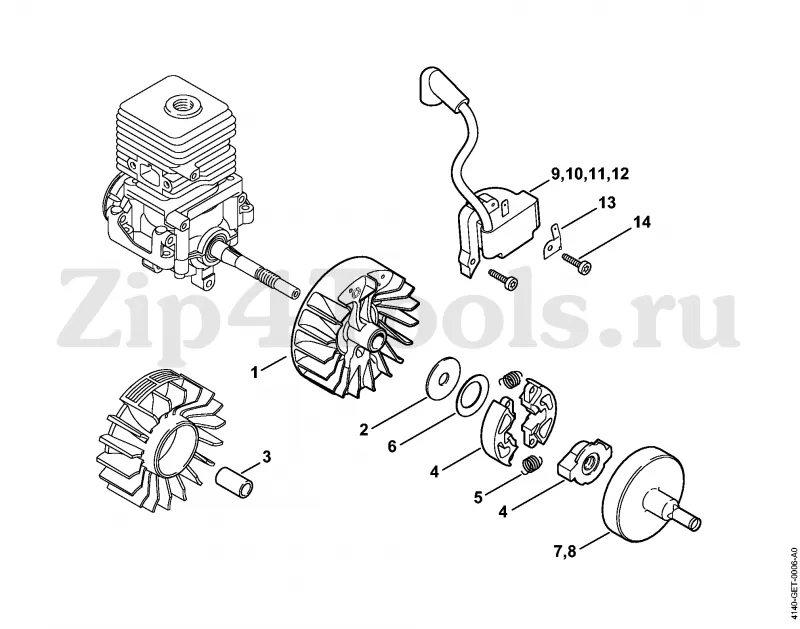

Visual Guide to Assembly Process

This section provides an insightful overview of the assembly procedure, focusing on the essential components involved in the creation of the final product. By breaking down the intricate steps, we aim to enhance understanding and facilitate a smoother construction experience.

Step-by-step Visualization: Each phase of the process is outlined with clear illustrations, ensuring that users can easily follow along. The sequential approach allows for a systematic assembly, reducing the likelihood of errors.

Key Components Identification: Recognizing the various elements is crucial for successful assembly. This guide highlights the importance of each piece and its role within the entire framework, enabling a comprehensive grasp of how they fit together.

Practical Tips: Alongside the visual aids, practical advice is provided to tackle common challenges encountered during assembly. This information serves to empower users, helping them to overcome potential obstacles effectively.

By utilizing this visual guide, users will gain confidence and clarity, transforming the assembly process into a more enjoyable and efficient endeavor.

Importance of Genuine Parts

The significance of using authentic components in any machinery cannot be overstated. These items are specifically designed to fit and function seamlessly, ensuring optimal performance and longevity of the equipment. Choosing genuine products over alternatives often translates to enhanced reliability and safety.

Authenticity guarantees that every element adheres to the manufacturer’s standards, minimizing the risk of malfunctions or failures. Additionally, using non-genuine items may lead to increased wear and tear, ultimately affecting overall efficiency and leading to costly repairs.

Moreover, the investment in original components often reflects a commitment to quality and performance. By opting for these genuine solutions, users can delve into peace of mind, knowing they are maximizing the lifespan and functionality of their equipment.

FAQs about Fs 55 Parts

This section addresses common inquiries related to components of the Fs 55 model. Understanding these queries can enhance user experience and facilitate maintenance, ensuring optimal performance.

Common Questions

- What are the essential components of the Fs 55?

- How often should I replace specific elements?

- Where can I find quality replacements?

Maintenance Tips

- Regularly inspect for wear and tear.

- Clean components to prevent build-up.

- Follow manufacturer guidelines for replacement intervals.