Understanding the Graco G40 Parts Diagram for Easy Maintenance

In the realm of maintenance and repair, having a clear visualization of mechanical systems is essential. This understanding not only facilitates effective troubleshooting but also enhances the overall efficiency of the repair process. By breaking down complex assemblies into manageable sections, technicians can quickly identify the necessary elements for their tasks.

Detailed illustrations serve as valuable resources for anyone involved in the upkeep of equipment. They provide insight into the arrangement and functionality of various components, allowing users to grasp how each part interacts within the larger system. This knowledge is crucial for both novice and experienced professionals who aim to ensure optimal performance.

Moreover, accessibility to such visual guides empowers users to take proactive measures in maintenance. By recognizing potential wear points and understanding the layout, individuals can implement timely interventions, ultimately extending the lifespan of their equipment. An organized overview can transform a daunting repair into a straightforward procedure.

Understanding Graco G40 Parts Diagram

Comprehending the intricate layout of components within a specific model is essential for efficient maintenance and repair. A clear representation of these elements not only aids in identifying individual parts but also enhances overall functionality. This section delves into the importance of visual aids in understanding machinery assembly and service.

The Importance of Visual Representation

A visual schematic serves as a crucial tool for both novice and experienced technicians. It simplifies the process of locating and replacing components, reducing the time spent on troubleshooting. By providing a comprehensive view, it enables users to grasp how various elements interact, ensuring more effective repairs.

Key Components and Their Functions

Familiarity with the main elements depicted in the layout can significantly streamline maintenance tasks. Each part plays a unique role, contributing to the overall performance of the equipment. Understanding these roles not only facilitates repairs but also aids in preventative maintenance, prolonging the lifespan of the machine.

Importance of Accurate Parts Identification

Identifying components with precision is crucial for the efficient operation and maintenance of any equipment. Ensuring that the correct elements are recognized can lead to improved performance, extended lifespan, and reduced downtime. Misidentification can result in costly mistakes, delays, and safety hazards.

Benefits of Accurate Identification

- Enhanced Performance: Using the right components ensures that the machinery operates smoothly and efficiently.

- Cost Savings: Proper identification minimizes the risk of purchasing incorrect items, saving time and money.

- Safety Assurance: Accurate recognition of elements is essential for maintaining safety standards, reducing the likelihood of accidents.

- Longevity: Correctly matching components can prolong the overall life of the equipment, reducing the frequency of replacements.

Common Challenges

- Complexity: Some machines have intricate designs, making identification challenging.

- Variability: Differences in model versions can lead to confusion regarding which components are suitable.

- Documentation: Inadequate manuals or diagrams may hinder the identification process.

Addressing these challenges through diligent identification practices fosters operational efficiency and reliability. Recognizing the significance of component accuracy ultimately leads to better maintenance strategies and overall success in equipment management.

Common Components of the G40 System

The system comprises several essential elements that work together to ensure optimal performance and reliability. Understanding these components is crucial for anyone involved in maintenance or operation, as each part plays a significant role in the overall functionality.

Main Elements

- Motor Unit: This is the heart of the system, providing the necessary power for operation.

- Control Module: Responsible for managing various settings and ensuring efficient operation.

- Fluid Pathways: These conduits transport materials throughout the system, ensuring proper flow and delivery.

- Valves: Critical for regulating the flow of materials and maintaining pressure within the system.

- Filter System: Essential for removing impurities from the fluids to protect other components.

Supporting Components

- Hoses: Flexible connections that allow for movement while maintaining a secure flow of materials.

- Couplings: These join different parts of the system, ensuring a tight seal and preventing leaks.

- Pressure Gauges: Instruments used to monitor the pressure levels, allowing for adjustments as needed.

- Reservoir: Stores the necessary fluids, providing a constant supply during operation.

Each of these components is integral to the successful operation of the system, and understanding their functions can greatly enhance maintenance efforts and operational efficiency.

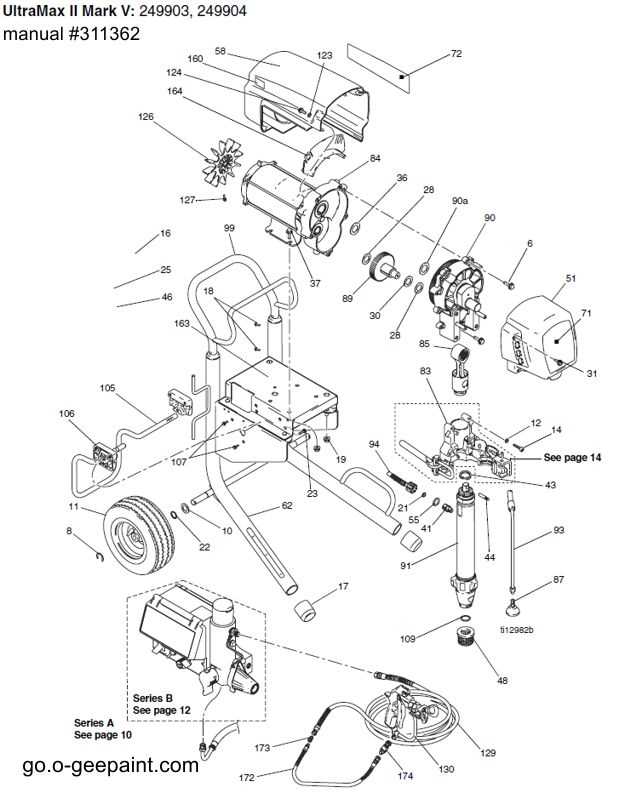

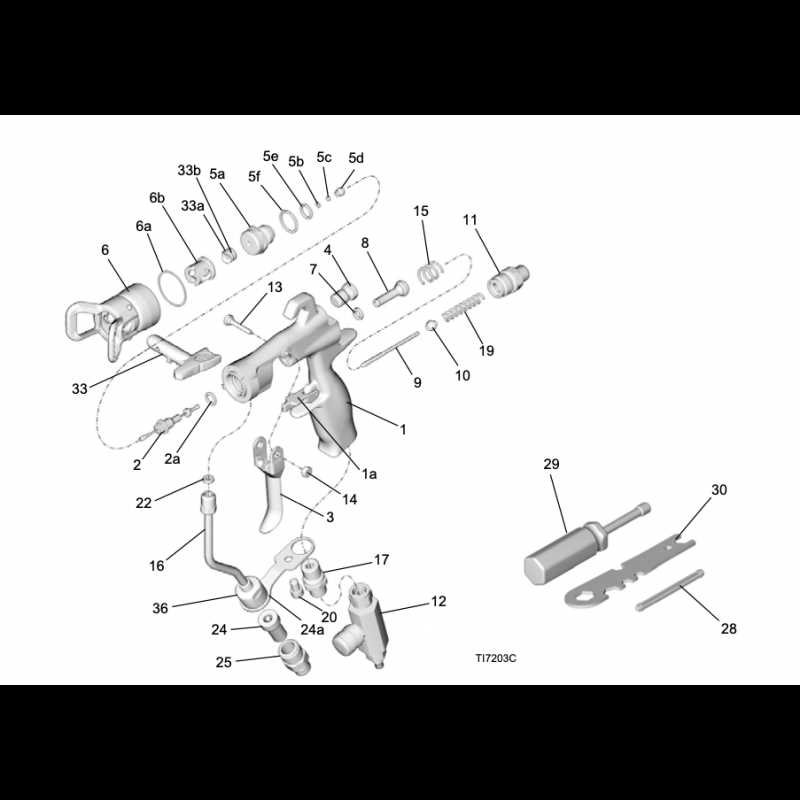

How to Read a Parts Diagram

Understanding an illustration that displays components of a device can greatly enhance your ability to maintain and repair it. These visual guides provide a clear representation of each element, helping users identify what is needed for service or replacement. Familiarity with the layout and symbols used is essential for effective interpretation.

Familiarize Yourself with the Symbols

Most visual aids use specific icons and markings to indicate various elements. Pay attention to these symbols, as they often convey important information about the nature and function of each component. For example, different shapes might represent varying types of items, while lines and arrows can indicate connections or movements.

Follow the Sequence

Each visual guide typically follows a logical order, often leading from the main assembly to individual elements. Take your time to trace the sequence, ensuring you understand how each piece interacts with others. This can reveal not only the arrangement but also potential troubleshooting pathways if something is malfunctioning. Remember, a thorough comprehension of the overall structure will aid you significantly in any maintenance tasks.

Finding Replacement Parts for Graco G40

When it comes to maintaining your equipment, sourcing the right components is essential for optimal performance. Whether you are dealing with wear and tear or simply upgrading, knowing where to find the necessary items can save time and ensure a smooth operation.

Here are some effective strategies to locate the required components:

- Manufacturer’s Website: Start by visiting the official site. Many manufacturers provide detailed catalogs that include specifications and availability.

- Authorized Dealers: Check with certified distributors. They often carry a range of original items and can offer expert advice.

- Online Marketplaces: Websites like eBay or Amazon may have listings for specific components. Ensure to read reviews to confirm the seller’s credibility.

- Local Hardware Stores: Sometimes, local shops may have what you need. Building a relationship with local suppliers can also lead to finding rare components.

Additionally, consider reaching out to user forums and online communities dedicated to equipment maintenance. Fellow users often share their experiences and can recommend reliable sources for components.

Lastly, keep a record of the model numbers and specifications for future reference. This will simplify the process of finding replacements and ensure you get exactly what you need.

Common Issues and Solutions

When dealing with equipment in any setting, users may encounter various challenges that can hinder performance. Understanding these frequent problems and their solutions is essential for maintaining efficiency and ensuring longevity. Below are some typical concerns along with practical remedies to help keep your device functioning optimally.

1. Inconsistent Performance: One common issue is irregular operation, which can be caused by blockages or worn components. To address this, regularly inspect and clean the system, ensuring all parts are free from debris. Replacing any damaged elements can also restore smooth functionality.

2. Leakage: Another prevalent problem is leakage, often stemming from faulty seals or connections. Check all joints and seals for wear and tear. Replacing worn gaskets or tightening loose fittings can often resolve this issue effectively.

3. Noisy Operation: Excessive noise during operation may indicate loose parts or inadequate lubrication. Inspect the device for any loose screws or components. Applying the appropriate lubricant to moving parts can significantly reduce noise levels.

4. Overheating: Overheating can lead to reduced efficiency and potential damage. Ensure that airflow is unobstructed and that filters are clean. If overheating persists, consider assessing the cooling mechanisms or consulting a technician.

By addressing these common challenges with the suggested solutions, users can enhance the reliability and performance of their equipment, leading to better results and reduced downtime.

Maintenance Tips for G40 Equipment

Proper upkeep of your machinery is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps in preventing unexpected breakdowns. Here are some essential tips to keep your equipment in top shape.

- Regular Cleaning: Dust and debris can accumulate, affecting functionality. Clean the surfaces and components regularly to prevent buildup.

- Check Fluid Levels: Ensure that all necessary fluids, such as lubricants and hydraulic fluids, are at appropriate levels. Top them off as needed.

- Inspect for Wear: Periodically examine all parts for signs of wear and tear. Look for cracks, leaks, or any other abnormalities that could hinder performance.

- Replace Filters: Change air and fluid filters regularly to maintain optimal performance and prevent contaminants from causing damage.

- Calibrate Settings: Regularly check and calibrate settings to ensure that the equipment operates according to specifications.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule recommended by the manufacturer to ensure the best care for your equipment.

By following these tips, you can significantly extend the life of your machinery and maintain its efficiency, ensuring that it performs at its best for years to come.

Tools Required for G40 Repairs

Proper maintenance and repairs of any equipment necessitate specific instruments to ensure efficiency and safety. Utilizing the right tools not only simplifies the process but also enhances the quality of the work performed. This section outlines the essential instruments needed for effective troubleshooting and repair tasks.

Basic Hand Tools

For initial assessments and routine maintenance, a set of basic hand tools is indispensable. This typically includes wrenches, screwdrivers, pliers, and sockets. These tools enable users to easily disassemble components, tighten connections, and perform minor adjustments. Having a well-organized toolbox with these essential items can significantly streamline repair activities.

Specialized Equipment

In addition to standard hand tools, some repairs may require specialized equipment. This can include torque wrenches for precise tightening, diagnostic tools for identifying issues, and cleaning supplies to maintain optimal functionality. Ensuring access to these specialized instruments will facilitate more thorough repairs and prolong the lifespan of the equipment.

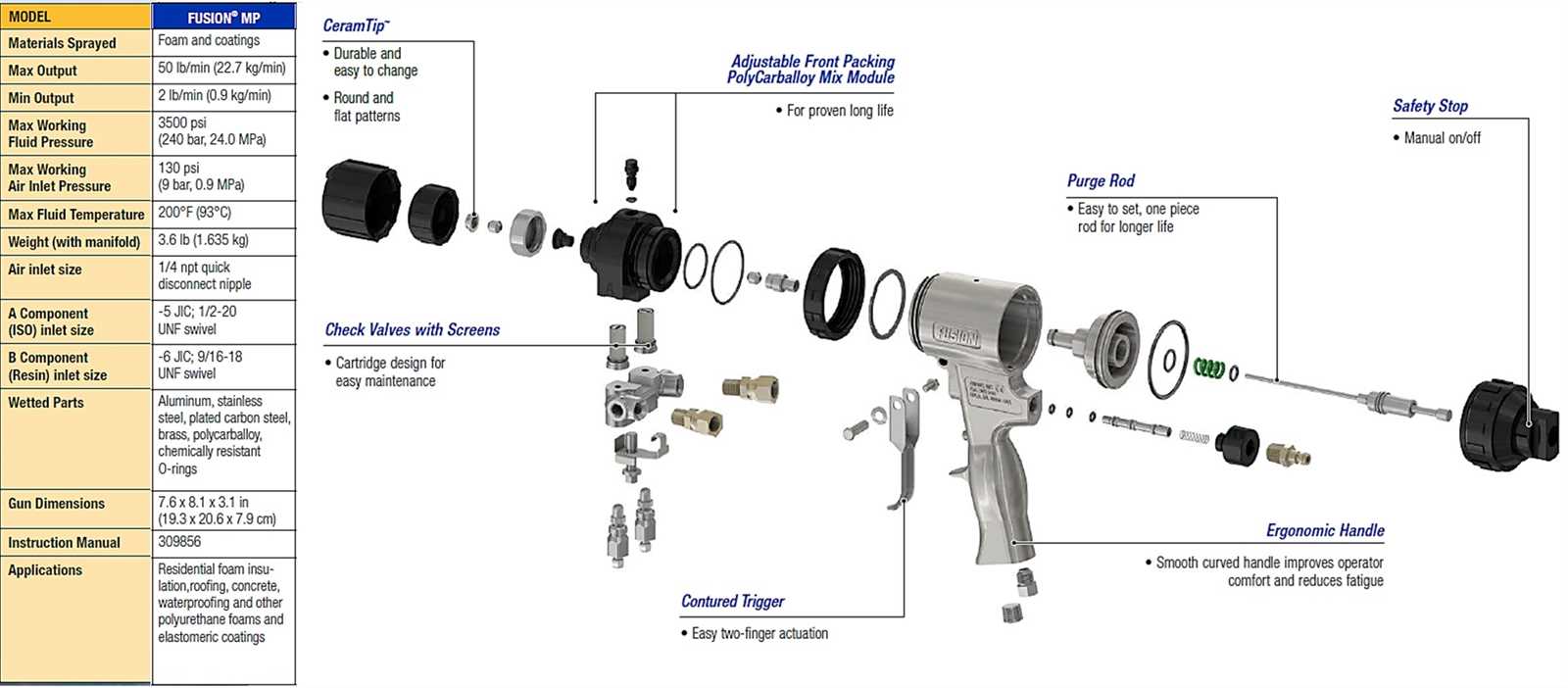

Visual Guide to G40 Components

This section aims to provide an insightful overview of the various elements that make up the equipment in question. Understanding these components will enhance your ability to maintain and operate the device effectively.

Below, you will find a structured representation of the main constituents, along with their functions and relationships.

- Motor Assembly

- Drives the main functionality of the unit.

- Includes electrical connections for optimal performance.

- Fluid Delivery System

- Responsible for the transfer of materials.

- Comprises hoses and fittings ensuring efficient flow.

- Control Panel

- Interface for user commands and settings.

- Displays operational status and alerts.

- Safety Features

- Includes emergency shut-off mechanisms.

- Ensures user protection during operation.

- Chassis

- Provides structural support for the entire system.

- Facilitates mobility and stability during use.

By familiarizing yourself with these key components, you will be better prepared to troubleshoot issues and perform necessary maintenance. Each part plays a critical role in the overall functionality and efficiency of the machinery.

Frequently Asked Questions About G40

This section addresses common inquiries regarding a specific model, focusing on its components, maintenance, and usage. The aim is to provide clear and concise answers to enhance understanding and assist users in troubleshooting and optimizing their experience.

| Question | Answer |

|---|---|

| What are the main components of this model? | The primary elements include the motor, nozzle, and hose, each playing a crucial role in the overall functionality. |

| How can I troubleshoot common issues? | Start by checking the power source, ensuring all connections are secure, and examining for any visible damage to the hoses or components. |

| What maintenance is required? | Regular cleaning of the nozzle and hose, along with periodic inspection of the motor, is recommended to ensure optimal performance. |

| Where can I find replacement components? | Replacement parts can be sourced from authorized dealers or online retailers specializing in equipment supplies. |

| Is there a warranty available? | Most models come with a limited warranty; please refer to the user manual for specific details regarding coverage and duration. |

Where to Buy Graco Parts Online

Finding high-quality components for your equipment can be a straightforward process if you know where to look. Numerous online retailers specialize in providing a wide selection of accessories and replacements, ensuring you have access to everything you need to maintain optimal performance. From official distributors to trusted third-party sellers, there are various platforms available that cater to different needs and budgets.

One of the most reliable options is the manufacturer’s official website. They often have a comprehensive inventory of the latest items and offer support for any inquiries you might have. Additionally, authorized dealers provide genuine products and can assist you in identifying the correct pieces for your specific model.

For those seeking more competitive prices, various online marketplaces host numerous vendors selling compatible items. Customer reviews and ratings can guide you in selecting trustworthy suppliers, ensuring you receive quality components. Furthermore, some websites offer warranty options, adding an extra layer of security to your purchase.

Don’t overlook specialized equipment retailers that focus on the niche market of your equipment. These suppliers typically have knowledgeable staff who can provide expert advice and help you find exactly what you need. Lastly, consider checking out auction sites where you might find great deals on both new and used items.

Benefits of Regular Equipment Maintenance

Regular upkeep of machinery plays a crucial role in ensuring efficiency and longevity. By implementing a consistent maintenance schedule, operators can prevent minor issues from escalating into significant problems, ultimately enhancing overall performance and reliability.

Improved Performance

- Regular checks help identify inefficiencies early, ensuring optimal operation.

- Well-maintained equipment tends to function at higher capacity, leading to increased productivity.

- Routine servicing can reduce the likelihood of unexpected downtime, keeping operations smooth.

Cost Savings

- Preventative maintenance can extend the lifespan of machinery, reducing replacement costs.

- Addressing small issues promptly can prevent more expensive repairs in the future.

- Efficient equipment consumes less energy, contributing to lower operating costs.

In conclusion, adhering to a structured maintenance program not only enhances performance but also promotes significant financial savings over time. Investing in regular servicing is essential for any operation aiming for sustainability and success.

How to Improve G40 Performance

Enhancing the efficiency of your equipment requires a combination of maintenance, upgrades, and operational adjustments. By focusing on several key aspects, you can ensure optimal functionality and extend the lifespan of your machinery.

Regular Maintenance Practices

- Conduct routine inspections to identify wear and tear.

- Clean filters and replace them as necessary to maintain airflow.

- Lubricate moving parts to reduce friction and prevent overheating.

- Check fluid levels regularly and top off as needed to ensure proper operation.

Upgrades and Modifications

- Consider investing in high-quality components that offer better performance.

- Upgrade software to the latest version to improve efficiency and functionality.

- Evaluate the potential for adding enhancements that can increase output or speed.

- Implement automation tools that can streamline processes and reduce manual effort.

By prioritizing these strategies, you can significantly boost the performance of your machinery and achieve better results in your projects.