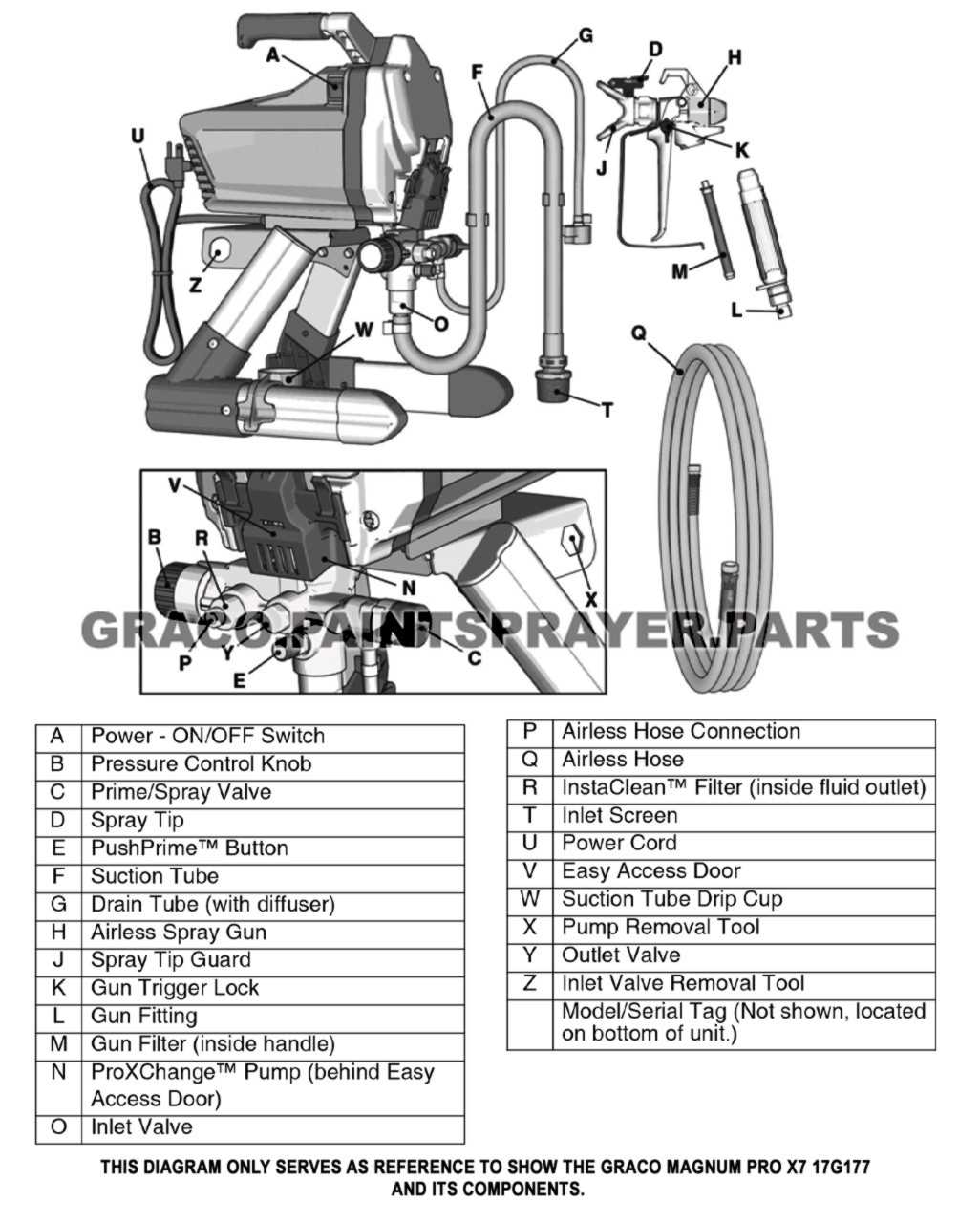

Understanding the Graco Magnum X7 Spray Gun Parts Diagram

In the realm of painting and coating applications, having a thorough comprehension of your equipment’s structure is essential for optimal performance and maintenance. Every device is made up of various elements that work in harmony to deliver outstanding results. Gaining insight into these components can significantly enhance your ability to troubleshoot issues and ensure longevity.

Identifying each segment of the mechanism allows users to perform routine checks and replacements effectively. This not only aids in maintaining efficiency but also minimizes downtime during projects. A clear understanding of how these pieces interact can lead to better overall usage and satisfaction.

Furthermore, familiarizing yourself with the specific arrangement of the individual parts can empower users to make informed decisions about upgrades and modifications. Whether you’re a seasoned professional or a novice, grasping the intricacies of your equipment enhances your skills and fosters greater confidence in your work.

Understanding Graco Magnum X7 Components

The exploration of essential components within a painting system reveals the intricacies that enhance its functionality. By examining these elements, one gains insight into how each piece contributes to the overall performance, ensuring efficiency and precision in application.

Key Elements: At the heart of any successful apparatus lies the motor, responsible for generating the necessary pressure. Coupled with a robust hose, this allows for the smooth transfer of material. Additionally, the nozzle plays a crucial role in determining the spray pattern and finish quality.

Maintenance and Care: Understanding these components not only aids in troubleshooting but also emphasizes the importance of regular upkeep. Familiarity with each part fosters longevity and optimal performance, ultimately enhancing user experience.

Key Features of the Spray Gun

This section explores the essential characteristics that define an effective application tool. Understanding these features can significantly enhance the user experience and improve the quality of work.

- Adjustable Pressure: Allows for customization based on the material being used.

- Quick Connect: Facilitates easy attachment and detachment of hoses.

- Durable Construction: Designed to withstand rigorous use and environmental conditions.

- Lightweight Design: Ensures ease of handling and reduces user fatigue.

- Easy Cleanup: Simplifies the maintenance process after use.

Each of these features contributes to the ultimate efficiency and effectiveness of the tool, making it a valuable asset for both professionals and DIY enthusiasts.

Common Issues with Spray Gun Parts

When working with equipment designed for fluid application, users often encounter a range of challenges that can affect performance. Understanding these common problems is crucial for maintaining efficiency and achieving optimal results. From blockages to wear and tear, various factors can impede the functionality of these tools.

One frequent issue involves the buildup of materials within the nozzle, leading to uneven application and reduced pressure. This can often be resolved through regular cleaning, ensuring that all residue is removed after each use.

Another challenge is air leaks, which can significantly impact the flow and consistency of the material being applied. Identifying the source of these leaks, whether from seals or connections, is essential for troubleshooting and restoring proper function.

Furthermore, users may experience issues related to inconsistent spray patterns. This can stem from worn components or incorrect adjustments. Regular inspection and timely replacement of any damaged elements can help maintain a smooth operation.

Lastly, inadequate maintenance can lead to premature failures, emphasizing the importance of following the manufacturer’s recommendations for care and servicing. By addressing these common concerns proactively, users can ensure longevity and reliability in their equipment.

How to Maintain Your Spray Gun

Proper upkeep of your application tool is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances the quality of your work but also prevents costly repairs down the line. Follow these guidelines to keep your equipment in excellent condition.

Daily Cleaning Routine

After each use, follow this simple cleaning process:

- Disassemble the tool according to the manufacturer’s guidelines.

- Rinse all components with appropriate solvent to remove any residue.

- Use a soft brush to clean hard-to-reach areas.

- Dry all parts thoroughly before reassembling.

Periodic Inspections

Regular checks can help identify potential issues early:

- Inspect all seals and gaskets for wear and tear.

- Examine hoses for cracks or leaks.

- Check the nozzle for clogs and clean as needed.

- Ensure all connections are tight and secure.

By implementing these maintenance practices, you can ensure your tool remains reliable and efficient for years to come.

Replacing Worn-Out Components

Over time, various elements of your equipment may wear down, affecting performance and efficiency. Addressing these issues promptly ensures your tool operates optimally, extending its lifespan and maintaining quality results.

Identifying Worn Components

Recognizing signs of deterioration is essential. Here are common indicators:

- Unusual noises during operation

- Inconsistent flow or output

- Visible wear or damage on surfaces

- Leaking fluids

Steps to Replace Components

When it’s time to replace worn items, follow these steps:

- Turn off and disconnect the device for safety.

- Refer to the user manual for specific replacement guidelines.

- Carefully remove the damaged component.

- Install the new part, ensuring a secure fit.

- Reconnect and test the equipment to verify proper function.

Regular maintenance and timely replacement of components will help keep your tool in excellent working condition, allowing you to achieve the best results in your projects.

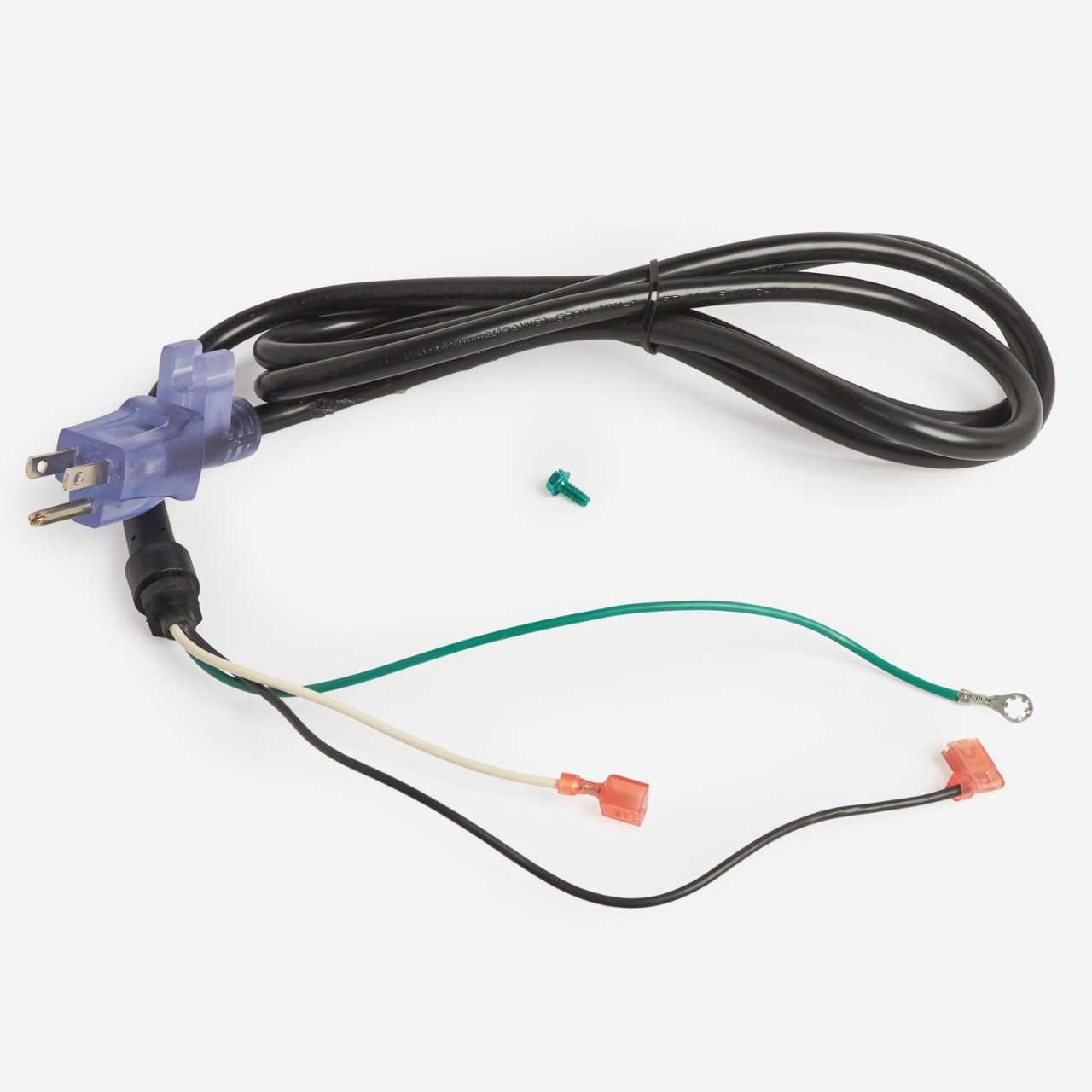

Essential Tools for Repairing Parts

Having the right tools is crucial for effectively maintaining and fixing any equipment. Proper instruments not only facilitate the repair process but also ensure that tasks are completed efficiently and safely. Here, we outline the fundamental tools needed for effective repairs.

Basic Hand Tools

- Screwdrivers: A set of various sizes and types, including flathead and Phillips, is essential for loosening and tightening screws.

- Wrenches: Both adjustable and fixed wrenches are necessary for handling nuts and bolts of different sizes.

- Pliers: Needle-nose and slip-joint pliers help in gripping and manipulating small components.

- Cutters: Wire cutters and snips are useful for trimming cables and small parts.

Specialized Equipment

- Multimeter: This device is crucial for checking electrical connections and diagnosing issues.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from overtightening.

- Cleaning Tools: Brushes and cloths are important for maintaining cleanliness and preventing debris buildup during repairs.

Investing in these essential tools will prepare you for most maintenance tasks, making the repair process smoother and more effective.

Comparing Models: X7 vs. Others

When evaluating different models within the same category, it’s essential to understand their distinct features, performance capabilities, and suitability for various tasks. This comparison highlights the strengths and weaknesses of the X7 model in relation to its competitors, enabling users to make informed decisions based on their specific needs.

Key Features

- Performance: The X7 is known for its efficiency and consistency, making it suitable for both professionals and DIY enthusiasts.

- Durability: Designed with robust materials, it offers longevity compared to some other models that may require frequent replacements.

- User-Friendliness: The X7 features intuitive controls that simplify operation, appealing to users of varying skill levels.

Comparative Analysis

- Versatility:

- X7 can handle a wider range of materials than many competitors.

- Some alternatives may excel in specific applications but lack overall flexibility.

- Cost-Effectiveness:

- The X7 offers great value for its performance, while some other models might have lower upfront costs but offer less functionality.

- Investing in the X7 can lead to savings in the long run due to its reliability and lower maintenance needs.

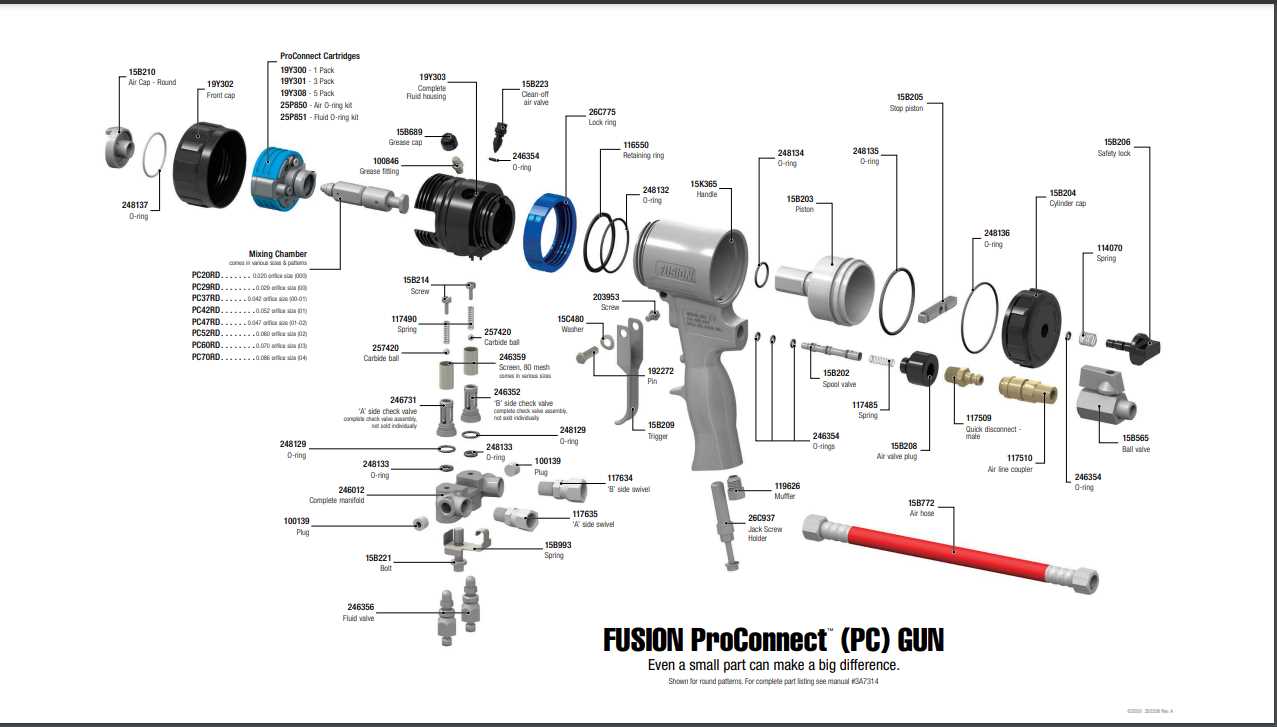

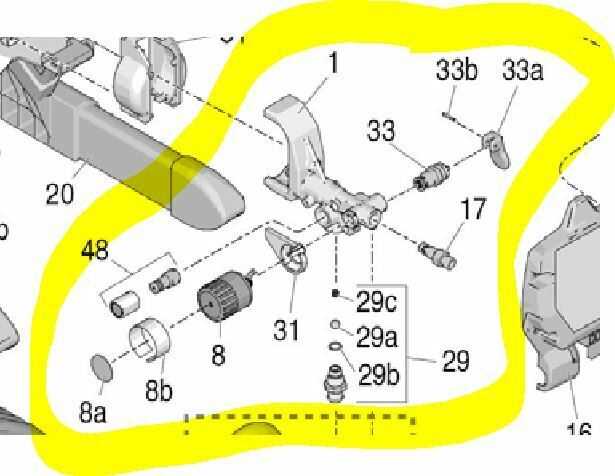

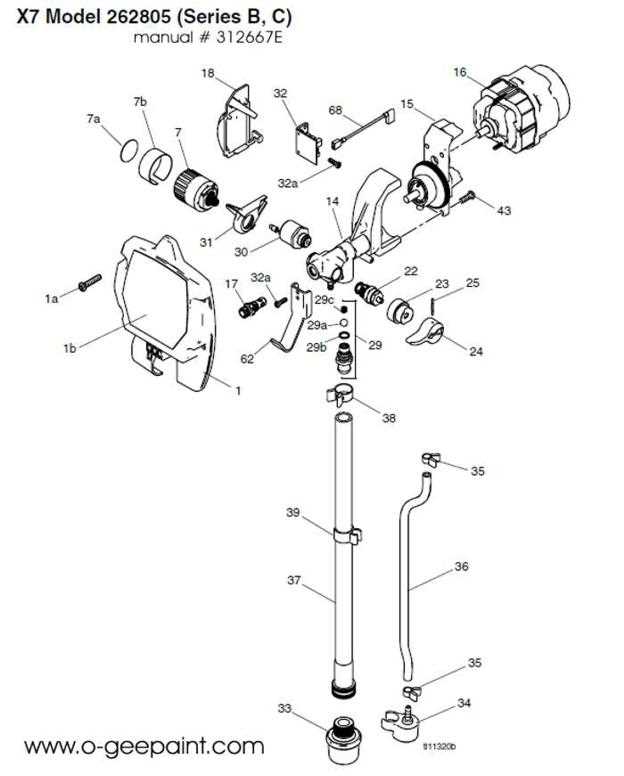

Using the Parts Diagram Effectively

Understanding the layout and components of your equipment can significantly enhance your maintenance and repair process. A visual representation allows users to quickly identify and locate various elements, making troubleshooting and replacements more straightforward.

Benefits of Utilizing the Visual Guide

- Streamlined repairs by pinpointing exact components.

- Enhanced comprehension of the overall assembly.

- Efficient ordering of replacements by identifying part numbers.

Tips for Effective Usage

- Familiarize yourself with each section of the illustration.

- Use it alongside the user manual for comprehensive guidance.

- Keep a digital or printed copy for quick reference during projects.

Safety Tips for Using the Spray Gun

Ensuring safety while operating painting equipment is crucial for both personal protection and achieving optimal results. Following best practices can prevent accidents and enhance the overall experience.

- Always wear appropriate personal protective equipment, including masks, goggles, and gloves.

- Work in a well-ventilated area to minimize inhalation of fumes.

- Keep flammable materials away from the workspace to reduce fire hazards.

- Regularly inspect the equipment for any signs of wear or damage before use.

- Read and understand the manufacturer’s instructions thoroughly prior to operation.

By adhering to these guidelines, users can create a safer environment and enjoy the ultimate efficiency in their projects.

Upgrades for Enhanced Performance

Improving the functionality of your equipment can significantly elevate the quality of your projects. By integrating advanced components and features, users can achieve better efficiency, precision, and overall output. This section explores several upgrades that can lead to noticeable enhancements in performance.

One of the most impactful improvements involves upgrading the nozzle system. Opting for high-quality nozzles can result in a finer finish and more controlled application, reducing the need for touch-ups and saving time on each task. Additionally, selecting the appropriate size based on the material being used can optimize the flow and coverage.

Another area worth considering is the addition of an adjustable pressure regulator. This feature allows users to fine-tune the output, ensuring that different surfaces are treated with the right amount of force. It not only helps in conserving materials but also minimizes the risk of overspray and damage to surrounding areas.

Investing in a more robust motor can also yield benefits, particularly in terms of durability and reliability. A powerful motor ensures consistent performance, even when handling thicker substances, allowing for a smoother and uninterrupted workflow.

Lastly, exploring ergonomic enhancements can lead to increased comfort during extended use. Upgrades such as padded grips or improved weight distribution can alleviate fatigue, enabling users to maintain focus and accuracy throughout their projects.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is essential for optimal performance. Various avenues exist for acquiring the necessary items, ensuring that your tools remain in top condition.

Online Retailers

Many websites specialize in offering a wide selection of components. Searching through these platforms can help you locate specific items quickly. Look for trusted vendors with positive customer reviews to ensure quality.

Local Supply Stores

Your nearby hardware or specialty shops may stock essential items. Visiting these stores allows you to physically inspect the components before purchasing. Additionally, knowledgeable staff can provide valuable advice on compatible replacements.