Understanding the Graco Nova 395 Parts Diagram

In the realm of machinery, the clarity of component arrangement is essential for effective maintenance and operation. An intricate understanding of how each part interacts with the whole system can significantly enhance performance and longevity. This section delves into the various elements that comprise a specific model, offering insights into their configuration and functionality.

Exploring the layout not only aids in identifying individual components but also assists in troubleshooting potential issues. By comprehending the placement and role of each element, users can ensure that their equipment runs smoothly and efficiently. This knowledge is crucial for both seasoned professionals and those new to the field.

Furthermore, having access to a detailed representation of the assembly fosters a more intuitive approach to repairs and upgrades. This comprehensive understanding empowers operators to make informed decisions, ultimately leading to improved operational outcomes. Let’s take a closer look at the intricate relationships between these components and how they contribute to the overall performance of the machinery.

Understanding Graco Nova 395 Components

Every piece of equipment is made up of essential elements that work together to achieve optimal performance. Understanding these components is crucial for effective maintenance and operation. By grasping how each part functions, users can enhance the longevity and efficiency of their machinery.

Key Elements: Various parts contribute to the overall functionality, including motors, pumps, and valves. Each component plays a specific role, ensuring that the system operates smoothly and efficiently.

Maintenance Tips: Regular inspection of these elements can prevent potential issues. Familiarizing oneself with the layout and functionality will ultimately lead to more informed decisions regarding repairs and replacements.

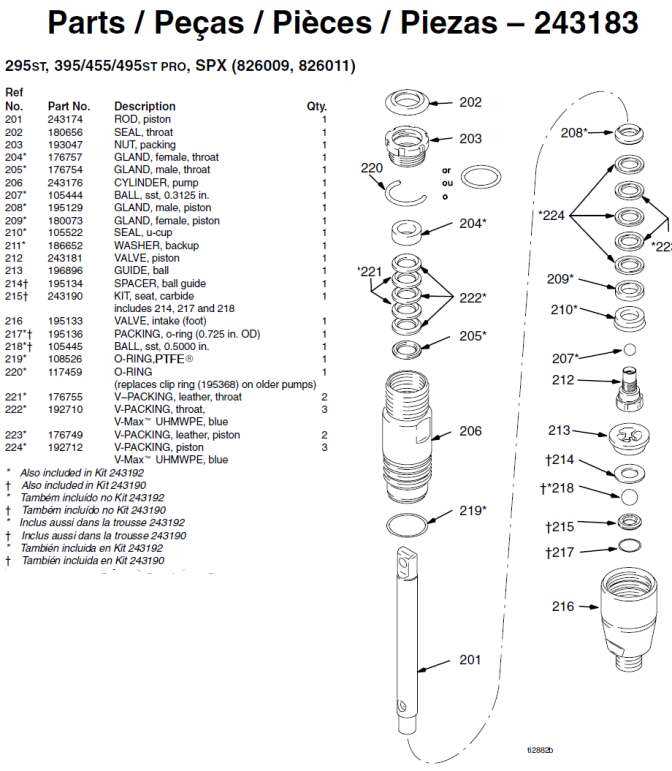

Parts Overview for Nova 395 Model

This section provides a comprehensive understanding of the components essential for the operation of the specified model. Familiarizing yourself with each element can enhance maintenance and efficiency.

Essential Components

- Motor Assembly

- Fluid Delivery System

- Pressure Control Valve

- Filter Mechanism

Maintenance Recommendations

- Regularly inspect the motor for wear.

- Clean the fluid delivery pathways frequently.

- Check pressure settings to ensure optimal performance.

- Replace filters as needed to prevent clogging.

Importance of Using Genuine Parts

Utilizing authentic components is crucial for ensuring optimal performance and longevity of equipment. Substituting these with inferior alternatives can lead to various issues, affecting both efficiency and safety.

Benefits of Authentic Components

- Enhanced durability and reliability

- Better compatibility with existing machinery

- Improved safety standards

Consequences of Using Counterfeit Parts

- Increased risk of breakdowns

- Higher maintenance costs over time

- Potential safety hazards for users

Common Issues with Nova 395 Equipment

When operating high-performance spray equipment, users often encounter a variety of challenges that can affect efficiency and output quality. Understanding these common problems is essential for maintaining optimal functionality and ensuring smooth operation.

Clogged Spray Tips: One frequent issue involves the obstruction of spray tips, which can lead to uneven application and reduced performance. Regular cleaning and maintenance can help mitigate this problem.

Pump Malfunctions: Users may experience difficulties with the pump, resulting in inconsistent pressure or failure to draw material. Regular inspection and timely replacement of worn components are crucial to prevent these issues.

Air Leaks: Air leaks within the system can cause a range of problems, including reduced efficiency and increased wear on components. Ensuring all connections are secure and free from damage is vital for optimal performance.

Inconsistent Coating: Variations in coating thickness can arise from several factors, such as improper adjustment of settings or equipment malfunction. Regular calibration and testing can help maintain consistency in application.

Electrical Issues: Electrical components may fail due to wear or environmental factors, leading to operational disruptions. Regular checks of wiring and connections can help identify potential problems before they escalate.

How to Identify Replacement Parts

When seeking to replace components in your equipment, understanding how to pinpoint the correct items is essential. Proper identification ensures that your machinery operates efficiently and safely. This process often involves examining the model’s specifications, compatibility, and unique features.

Start by consulting the manufacturer’s documentation, which typically includes detailed descriptions and images of each component. If the manual is unavailable, online resources or forums can provide valuable insights from other users. Cross-referencing these resources helps in confirming the specific requirements for your machinery.

Additionally, take note of any serial numbers or model identifiers on the equipment itself, as these can greatly aid in locating the right items. When unsure, contacting customer support for guidance is a wise choice. Ultimately, thorough research and attention to detail will lead to successful identification of the necessary components.

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential for optimal performance and longevity. Following a systematic approach can help identify issues early and ensure that your device operates smoothly. This guide provides a clear pathway for maintaining your apparatus effectively, covering key aspects from inspection to replacement of worn components.

Initial Inspection

Begin by examining the exterior for any visible damage or wear. Check all connections and ensure they are secure. Pay close attention to hoses and seals, as leaks can often stem from these areas. A thorough visual assessment will help pinpoint potential problems before they escalate.

Cleaning and Lubrication

Once the inspection is complete, clean all surfaces using appropriate cleaning agents. Remove any debris that may obstruct moving parts. After cleaning, apply suitable lubricants to enhance performance and reduce friction. Regular cleaning and lubrication not only improve functionality but also extend the lifespan of your device.

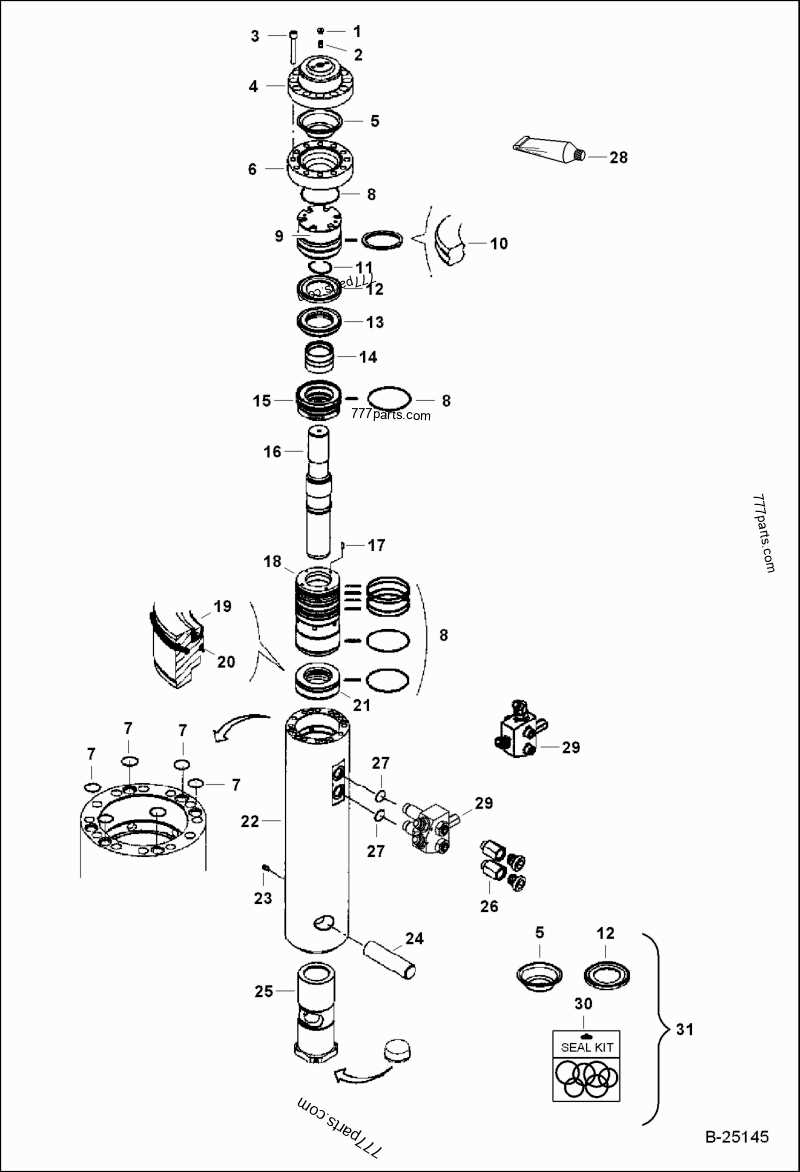

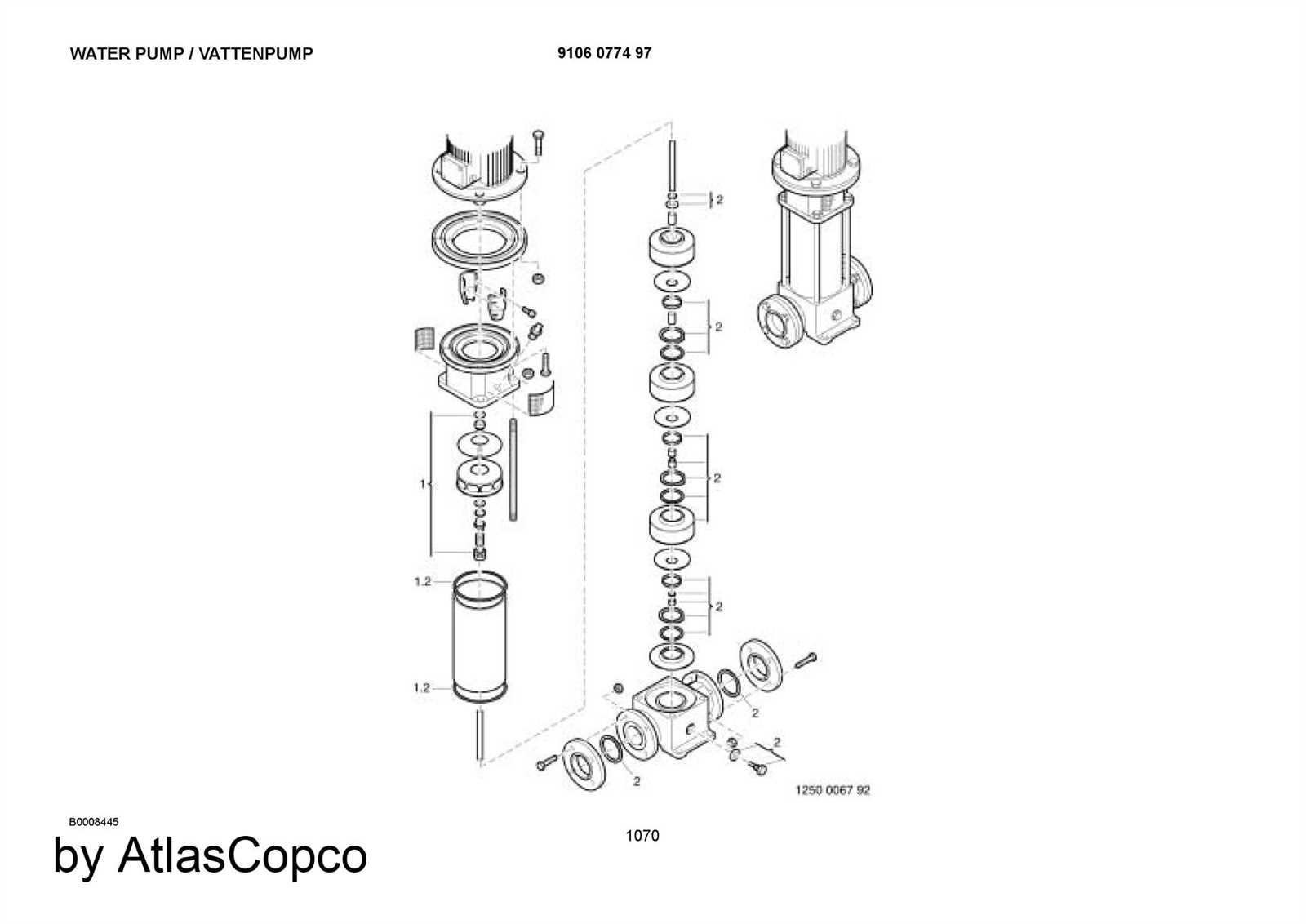

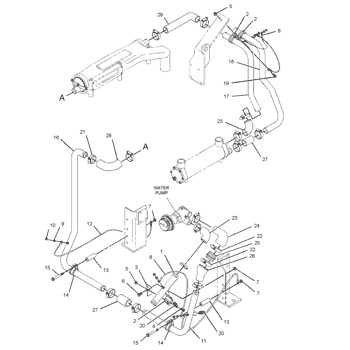

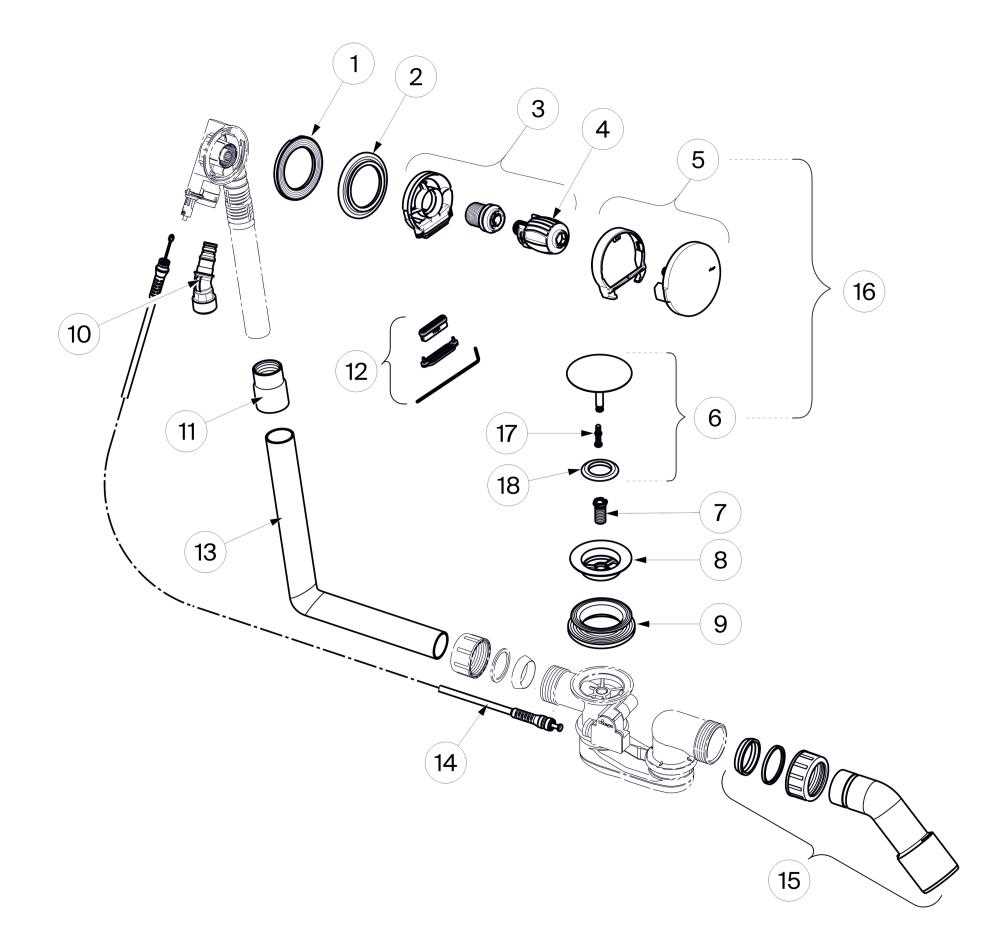

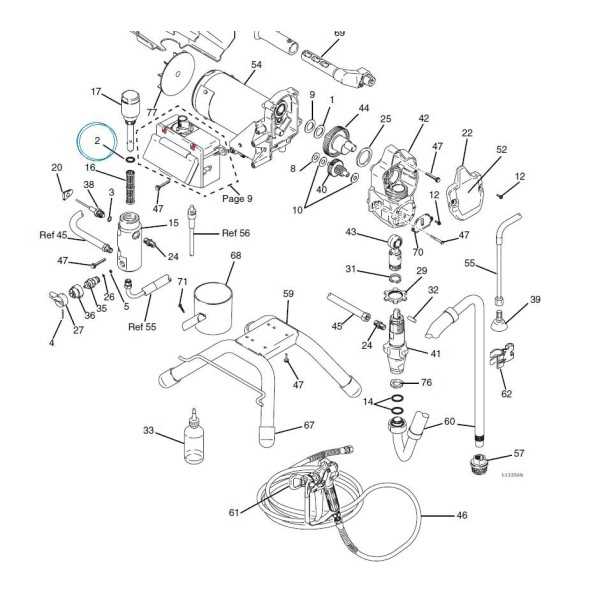

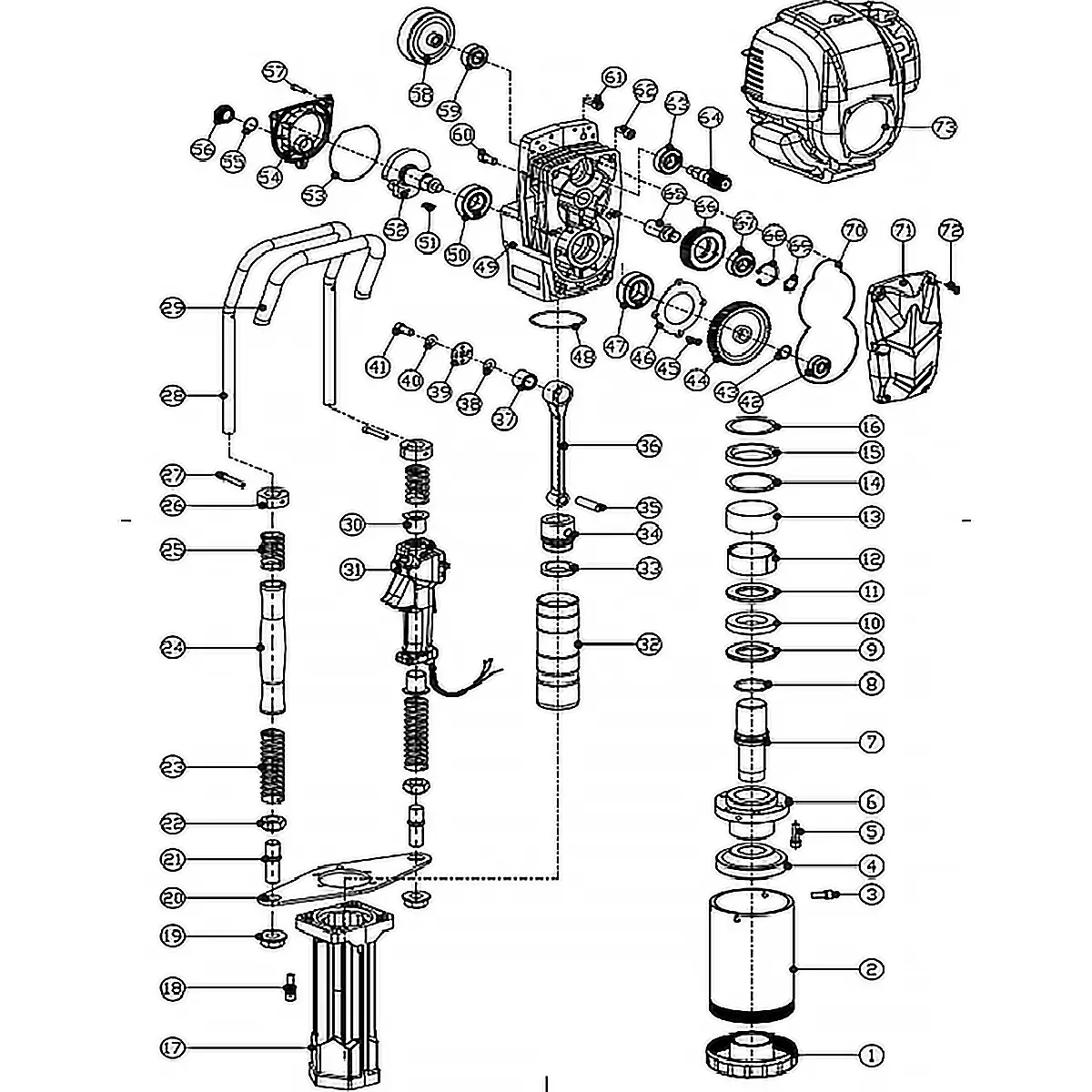

Diagrams: Visualizing the Nova 395

Visual representations play a crucial role in understanding complex machinery. By illustrating components and their relationships, these visual aids facilitate better comprehension and effective troubleshooting. They serve as a roadmap, guiding users through the intricacies of the equipment while highlighting essential elements.

These illustrations provide clarity, showing how various pieces fit together and function as a cohesive unit. Each diagram emphasizes critical sections, allowing users to identify potential issues and maintenance needs. Whether for training, repairs, or general operation, these visual tools enhance the overall experience and knowledge of the system.

Furthermore, well-structured visuals can simplify communication among technicians, engineers, and operators. By referring to a common graphical language, all parties can ensure that discussions are focused and productive. This visual approach not only aids in immediate tasks but also fosters a deeper understanding of the equipment’s overall functionality.

Where to Buy Replacement Parts

Finding suitable components for your equipment can enhance its longevity and performance. Various options are available to ensure you obtain the right replacements efficiently.

Authorized Retailers

- Check local dealers who specialize in your equipment brand.

- Visit their official websites for online ordering options.

Online Marketplaces

- Explore platforms like Amazon and eBay for a wide selection.

- Look for specialized websites that focus on machinery components.

By utilizing these resources, you can ensure that your equipment operates at its ultimate potential with the right replacements.

Upgrades and Enhancements Available

Improving the efficiency and functionality of your equipment can significantly enhance your overall experience. Numerous options exist that cater to varying needs, allowing users to customize and elevate their tools.

- Advanced nozzle designs for improved spray patterns

- Ergonomic handles to reduce fatigue during prolonged use

- Upgraded filters for better material flow

- Enhanced pressure control systems for precise application

Investing in these enhancements not only boosts performance but also extends the lifespan of your device. Consider these upgrades to achieve the ultimate results in your projects.

Safety Tips for Handling Equipment

Ensuring safety while managing machinery is crucial to prevent accidents and injuries. Proper understanding and precautions can significantly mitigate risks associated with equipment operation. This section outlines essential practices to enhance safety in the workplace.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always don appropriate safety equipment, including helmets, gloves, and goggles, to shield against potential hazards. |

| Follow Operating Procedures | Adhere strictly to the manufacturer’s guidelines and safety protocols to ensure correct usage of machinery. |

| Maintain a Clean Work Area | Keep the workspace tidy to avoid slips, trips, and falls, which can lead to serious injuries. |

| Inspect Equipment Regularly | Conduct routine checks on machinery for any signs of wear or malfunction, addressing issues promptly. |

| Be Aware of Your Surroundings | Stay alert and mindful of colleagues and potential obstacles while operating machinery. |

Resources for Further Learning

Enhancing your understanding of equipment maintenance and repair can significantly improve your skills and confidence. Whether you’re a novice or an experienced technician, there are numerous resources available to help you dive deeper into the intricacies of machinery. From manuals to online tutorials, these materials can provide invaluable insights.

Recommended Books

Books remain a timeless source of knowledge. Here are a few essential reads that cover various aspects of equipment operation and upkeep:

| Title | Author | Focus Area |

|---|---|---|

| The Complete Guide to Equipment Maintenance | Jane Smith | General Maintenance Practices |

| Understanding Machinery: A Practical Approach | John Doe | Technical Operation and Repair |

| Advanced Techniques for Equipment Management | Emily Johnson | Management and Optimization |

Online Learning Platforms

In addition to books, various online platforms offer courses and tutorials that cater to different learning styles. Here are a few notable sites:

| Platform | Course Type | Focus Area |

|---|---|---|

| Udemy | Video Courses | General Maintenance Techniques |

| Coursera | Specialized Certifications | Engineering and Technical Skills |

| YouTube | Tutorial Videos | Hands-on Repair Guidance |