Understanding the Hesston 3710 Tedder Parts Diagram

In the realm of agricultural machinery, comprehending the various elements that contribute to optimal performance is essential. Each component plays a pivotal role in ensuring efficiency during the haymaking process. Familiarity with these elements not only enhances operational effectiveness but also aids in maintenance and repairs.

Visual aids, such as detailed illustrations, serve as invaluable resources for farmers and equipment operators. These representations clarify the relationships between different components, enabling users to troubleshoot issues with greater ease. Gaining insights into how each piece interacts can significantly impact the overall functionality of the machinery.

By delving into the intricacies of your equipment’s structure, you empower yourself to make informed decisions regarding upgrades or replacements. This understanding ultimately leads to improved productivity and longevity of your machinery, allowing you to tackle seasonal demands with confidence.

Understanding Hesston 3710 Tedder Functionality

The equipment designed for hay management plays a crucial role in optimizing the drying process of forage. By effectively spreading and turning cut grass or hay, this machinery enhances air circulation and exposure to sunlight, ultimately leading to improved quality and reduced drying time.

Key Components

Essential elements of this machine work in harmony to achieve efficient operation. Each part contributes to its overall functionality, ensuring that the process runs smoothly and effectively.

| Component | Function |

|---|---|

| Frame | Provides structural integrity and support. |

| Rotors | Lift and spread the crop material for better drying. |

| Gearbox | Transfers power from the tractor to the rotors. |

| Wheels | Facilitate mobility across various terrains. |

Operational Efficiency

Maximizing the effectiveness of this machinery involves understanding its design and operation. Regular maintenance and timely adjustments can significantly enhance performance, ensuring optimal results in the field.

Key Components of the Tedder

The functionality of a grass aerator relies on several essential elements that work harmoniously to enhance efficiency and performance. Understanding these components is crucial for optimal operation and maintenance.

Rotary Mechanism

The rotary mechanism is fundamental in achieving effective spreading. It consists of rotating arms that gently lift and distribute the crop, ensuring uniform coverage while minimizing damage to the plants.

Drive System

The drive system powers the machine, typically utilizing gears and belts to transmit energy from the tractor. A reliable drive ensures consistent performance, enabling the aerator to adapt to various field conditions while maximizing productivity.

Importance of Regular Maintenance

Consistent upkeep of agricultural machinery is vital for optimal performance and longevity. By prioritizing maintenance, operators can prevent unexpected breakdowns and ensure their equipment operates at peak efficiency.

Benefits of Routine Care

- Enhances operational efficiency

- Reduces repair costs over time

- Extends the lifespan of equipment

- Improves safety for operators

Key Maintenance Practices

- Regular inspection of components

- Timely lubrication of moving parts

- Replacement of worn-out elements

- Cleaning and clearing debris

Common Issues and Solutions

When operating hay equipment, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions is crucial for maintaining optimal functionality and ensuring a smooth workflow. Below are some typical issues along with effective remedies.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Insufficient lifting | Worn components, improper settings | Inspect and replace worn parts; adjust hydraulic settings. |

| Uneven distribution | Faulty adjustments, debris build-up | Check settings for balance; clean the machine thoroughly. |

| Excessive wear on tines | Poor material quality, incorrect usage | Use high-quality materials; adhere to operational guidelines. |

| Hydraulic leaks | Damaged hoses, loose connections | Inspect hoses and fittings; tighten or replace as needed. |

| Noisy operation | Lack of lubrication, misalignment | Lubricate moving parts; realign components to specifications. |

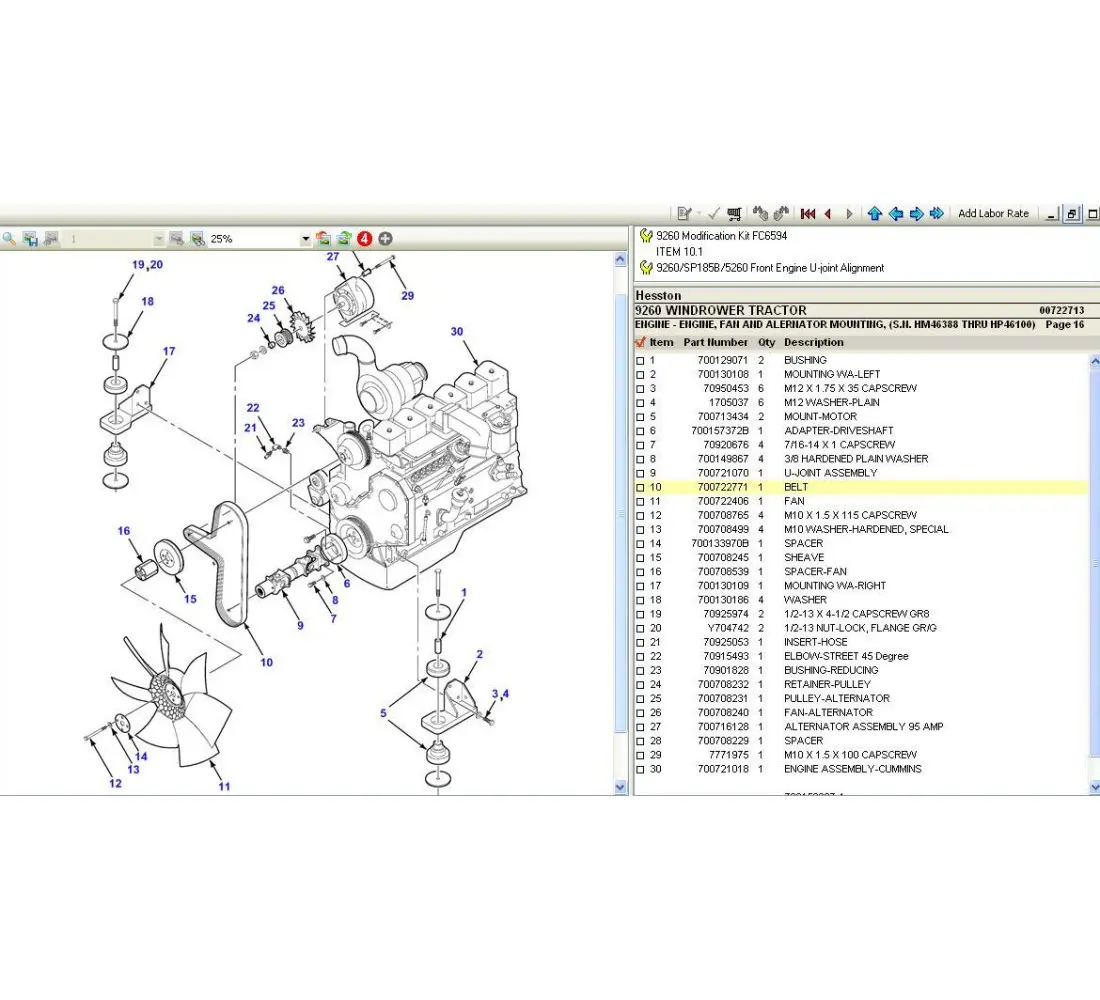

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visual aids provide a detailed representation of components and their relationships, helping users identify and locate specific items within a machine.

Here are some key steps to effectively interpret these illustrations:

- Familiarize Yourself with the Legend:

- Look for a legend or key that explains symbols and lines.

- Different colors or patterns may indicate various categories of components.

- Identify Main Assemblies:

- Locate major groups or sections highlighted in the illustration.

- This helps you understand how components are organized.

- Follow the Connections:

- Trace lines or arrows to see how parts connect and interact.

- This reveals the assembly order and operational flow.

- Pay Attention to Reference Numbers:

- Numbers often correlate with a list of components.

- Ensure you cross-reference these numbers for accuracy in identification.

- Take Notes:

- Document any important findings or questions that arise.

- This will assist you during the repair process or when ordering replacements.

By following these guidelines, you can effectively navigate technical illustrations, making maintenance and repairs more manageable and efficient.

Identifying Replacement Parts Easily

Understanding how to locate essential components for your agricultural equipment can significantly enhance maintenance efficiency. By familiarizing yourself with key features and terminology, you can streamline the search process, ensuring you find the right items without unnecessary delays.

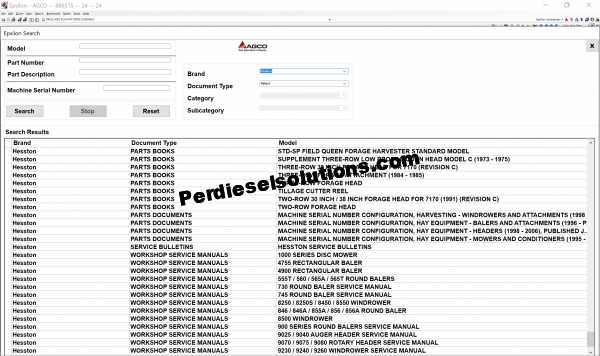

Utilizing Online Resources

The internet offers a plethora of resources, including manufacturer websites and specialized forums, where you can access comprehensive guides and visuals. These tools can help you recognize various components and their specifications, making identification straightforward.

Consulting User Manuals

User manuals serve as invaluable references, often including detailed illustrations and part numbers. Reviewing these documents can clarify which components are compatible with your machine, providing a clear path to sourcing replacements effectively.

Best Practices for Tedder Operation

Efficient management of grass and forage during the drying process is crucial for optimizing yield and quality. Implementing best practices ensures that the equipment operates effectively while maintaining the integrity of the crop. Proper techniques not only enhance performance but also extend the lifespan of the machinery.

Regular maintenance is vital. Before each use, inspect the equipment for wear and tear, ensuring that all components are functioning correctly. Lubrication of moving parts minimizes friction and prevents breakdowns. Additionally, keeping the machine clean from debris will enhance performance and reduce the risk of damage.

Timing plays a significant role in achieving optimal results. Operate the equipment during the warmest part of the day when moisture levels are lowest. This will facilitate faster drying and improve the quality of the harvested material. Monitoring weather conditions and adjusting operations accordingly can further enhance efficiency.

Adjusting the settings to match the specific type of crop and terrain is essential. The working height and speed should be tailored to prevent damage to the plants while ensuring effective handling. Experimenting with different configurations can lead to better outcomes based on unique field conditions.

Lastly, training operators is crucial for maximizing the effectiveness of the equipment. Knowledgeable users can make real-time adjustments and identify potential issues before they escalate. Investing in operator education ultimately contributes to more productive and safer operations.

Safety Precautions When Using Tedders

Ensuring safety during the operation of grass handling equipment is crucial for preventing accidents and injuries. Operators must be aware of the potential hazards and implement appropriate measures to mitigate risks. Proper training and adherence to safety guidelines are essential components of safe equipment usage.

General Safety Guidelines

- Always read the operator’s manual before using the equipment.

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and sturdy footwear.

- Conduct a pre-operation inspection to identify any issues or maintenance needs.

- Ensure that all guards and safety devices are in place and functioning properly.

Operational Safety Tips

- Keep bystanders, especially children, at a safe distance from the working area.

- Be aware of the terrain and avoid operating on steep slopes or uneven ground.

- Operate the machinery at safe speeds to maintain control and prevent tipping.

- Never attempt to clear jams or blockages while the equipment is in motion.

By following these safety precautions, operators can significantly reduce the risk of accidents and ensure a more efficient and safe working environment.

Finding Quality Replacement Parts

When seeking high-quality components for your agricultural machinery, it’s crucial to ensure durability and reliability. The right selections can enhance performance and extend the lifespan of your equipment, ultimately leading to greater efficiency in your operations.

Researching Suppliers

Start by identifying reputable vendors known for their commitment to quality. Look for reviews and testimonials from other users to gauge their experiences. A trustworthy supplier often provides detailed information about the products, ensuring you make informed decisions.

Assessing Compatibility

Ensure the components you consider are compatible with your machinery. Consulting manuals or technical guides can help you understand specifications. Matching the correct items not only enhances functionality but also prevents potential issues down the line.

Comparing Models and Their Features

When evaluating different agricultural equipment, understanding the nuances between various models is essential for making informed decisions. Each version offers distinct attributes that cater to specific operational needs, thereby enhancing efficiency and productivity in the field.

Key Specifications

Examining key specifications such as width, weight, and operational speed provides insight into how each variant performs under different conditions. These factors significantly influence the machine’s overall effectiveness and suitability for various tasks.

Technological Advancements

Technological innovations play a crucial role in differentiating models. Features like advanced control systems, improved energy efficiency, and user-friendly interfaces can elevate the user experience. Ultimately, assessing these advancements helps in choosing the most appropriate equipment for specific agricultural applications.

Assembly Tips for New Parts

When integrating new components into your machinery, careful attention to detail can significantly enhance performance and longevity. Proper assembly not only ensures functionality but also minimizes wear and tear on the entire system. Here are some essential tips to guide you through the process.

Preparation and Organization

Before beginning assembly, gather all necessary tools and components. Organizing parts in a clean, designated workspace reduces the risk of misplacing items and helps maintain focus. Consider laying out each component in the order they will be assembled, which can streamline the process and ensure nothing is overlooked.

Step-by-Step Assembly

Follow the manufacturer’s instructions meticulously. Begin with the foundation, ensuring that all base components are secure and properly aligned. Take your time with each step, double-checking connections and fittings. Utilizing a torque wrench can help achieve the correct tightness, preventing future issues. If any component feels forced or misaligned, reassess and make the necessary adjustments before proceeding.

Expert Insights on Tedder Upgrades

Enhancing the performance and efficiency of your hay handling equipment can significantly impact your productivity. Experts recommend a few key areas for improvement that can lead to better results in your agricultural operations.

- Quality of Components: Upgrading to higher-quality materials can improve durability and reduce maintenance costs.

- Improved Tine Design: Opting for innovative tine configurations can enhance the uniformity of the spread and decrease crop damage.

- Enhanced Drive Systems: Implementing more efficient drive systems can boost overall performance and reduce fuel consumption.

- Adjustable Settings: Features that allow for easy adjustments can help tailor the equipment to specific field conditions and crop types.

By focusing on these areas, operators can not only extend the lifespan of their machinery but also optimize their overall workflow.

- Regular Maintenance: Keeping equipment in top shape is crucial for long-term efficiency.

- Up-to-Date Technology: Investing in the latest technological advancements can provide a competitive edge.

- Operator Training: Ensuring that operators are well-trained on new features and upgrades maximizes effectiveness.

Incorporating these insights can lead to smarter investments and a more productive farming operation.