Comprehensive Guide to Hisun 700 UTV Parts Diagram

When it comes to maintaining a vehicle for off-road adventures, knowing the layout of its essential mechanisms is crucial. Every element plays a specific role in ensuring smooth operation, from the drive system to the smallest connectors. Being familiar with how these elements fit together can greatly assist in both repairs and enhancements.

In this guide, we’ll explore the structure and function of major systems that contribute to overall performance. By examining the layout, you’ll gain a deeper understanding of how each component interacts with others, ultimately improving your ability to troubleshoot and maintain your vehicle effectively.

Whether you’re dealing with engine maintenance, suspension tuning, or electrical systems, recognizing the position and connection of each part is key to optimizing performance. This overview will provide a clear path to understanding how the entire system operates as a cohesive unit.

Understanding the Structure of Hisun 700 UTV

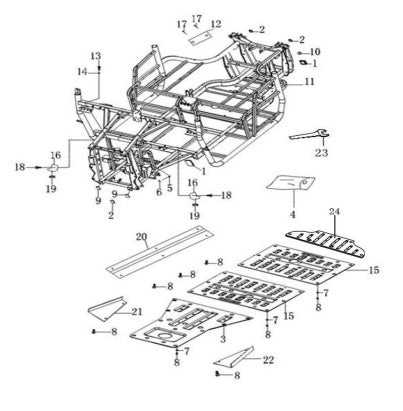

The mechanical design of this off-road vehicle is a perfect balance between functionality and durability. Its framework and essential systems are crafted to withstand challenging terrains while providing smooth handling. This section explores the overall construction and key elements that make this all-terrain machine a reliable choice for enthusiasts and professionals alike.

Key Components Overview

- Chassis: The robust foundation that supports the entire vehicle, ensuring stability and safety during operation.

- Suspension System: Designed to absorb shocks from uneven surfaces, enhancing comfort and control.

- Engine Assembly: The heart of the vehicle, engineered for efficient power delivery and longevity.

- Transmission: Seamlessly transfers power from the engine to the wheels, allowing for smooth gear shifts.

- Master Cylinder: The heart of the system, responsible for converting pedal pressure into hydraulic force.

- Brake Pads: Friction elements that press against rotors to slow down or stop the motion.

- Rotors: The discs that interact with brake pads, providing the necessary friction to stop the wheels.

- Fuel Tank: Stores the fuel and provides it to the system.

- Fuel Pump: Moves the fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Fuel Injectors: Atomize the fuel for optimal combustion within the engine.

- Fuel Lines: Transport fuel between components.

- Headlights

- Taillights

- Turn Signals

- Brake Lights

- Auxiliary Lights

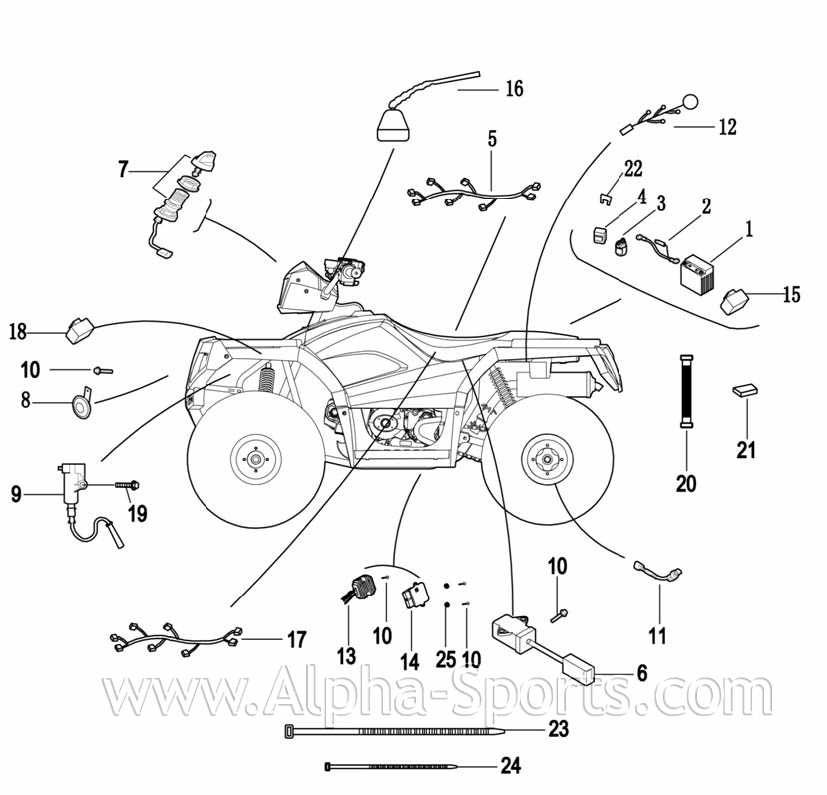

- Wiring Harness: A centralized unit that connects all lighting elements, ensuring they function cohesively.

- Switches: Controls for activating various lighting systems, typically located on the dashboard or steering column.

- Relays and Fuses: Protective devices that manage the electrical load and prevent system failures.

- Connectors: Ensure secure and efficient connections between wiring, switches, and lighting components.

Key Components and Their Functions

The functionality of a complex off-road vehicle relies on the integration of several critical elements. These components work together to ensure efficient performance, stability, and durability in various environments. Understanding the role of each part is essential for maintaining the overall reliability of the machine and optimizing its capabilities.

Engine and Transmission System

The power unit and the gearbox are central to the vehicle’s movement and efficiency. The engine generates the necessary force, while the transmission system ensures that power is delivered to the wheels in a controlled manner. Together, these systems allow for smooth operation across different terrains and driving conditions.

Suspension and Steering Mechanisms

Both the suspension and steering mechanisms are crucial for handling and ride comfort. The suspension system absorbs shocks and maintains tire contact with the ground, while the steering system provides the necessary control for directional changes. These components are designed to work in tandem, improving the vehicle’s responsiveness and overall ride quality.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting and powering the vehicle. |

| Alternator | Generates electricity while the engine is running, recharging the battery. |

| Starter Motor | Engages the engine to initiate combustion. |

| Fuse Box | Protects the electrical circuits by preventing overloads. |

| Wiring Harness | Connects various electrical components, ensuring proper signal transmission. |

By grasping the relationships and functions of these elements, operators can diagnose issues more effectively, leading to improved performance and longevity of the vehicle.

Transmission Diagram and Gear System Operation

This section delves into the intricacies of the drivetrain mechanism, illustrating how power is effectively transmitted from the engine to the wheels. Understanding the arrangement and functionality of the various components involved is crucial for maintaining optimal performance and ensuring smooth operation.

The transmission plays a pivotal role in modulating the vehicle’s speed and torque, allowing it to adapt to different driving conditions. The gear system consists of several gears that engage and disengage as needed, facilitating a range of speeds and enhancing overall control.

| Component | Description | Function |

|---|---|---|

| Input Shaft | The shaft that receives power from the engine. | Transmits rotational energy to the gear assembly. |

| Gear Set | A series of interlocking gears. | Adjusts torque and speed based on driving needs. |

| Output Shaft | The shaft that delivers power to the wheels. | Transfers rotational force to the drive system. |

| Clutch | A device that engages or disengages the engine from the transmission. | Allows smooth gear shifting and prevents stalling. |

By comprehensively understanding these elements, operators can better appreciate how the drivetrain functions as a cohesive unit, leading to informed maintenance decisions and enhanced vehicle longevity.

Cooling System Layout for Temperature Control

Effective temperature management is crucial for the optimal performance and longevity of any vehicle’s engine. A well-designed cooling mechanism not only prevents overheating but also ensures that the engine operates within its ideal temperature range. This section explores the configuration of components involved in regulating temperature, emphasizing their interconnections and functionality.

Key Components of the Cooling Mechanism

The cooling arrangement typically consists of several essential elements, including the radiator, water pump, coolant reservoir, and thermostat. The radiator plays a vital role in dissipating heat by transferring it from the coolant to the air. The water pump circulates the coolant throughout the system, ensuring that heat is efficiently absorbed from the engine and expelled through the radiator. The coolant reservoir maintains the proper fluid level, while the thermostat regulates the temperature by controlling the flow of coolant based on the engine’s needs.

Flow Dynamics and Efficiency

Understanding the flow dynamics of the cooling system is key to enhancing its efficiency. Proper coolant circulation is necessary to ensure that all engine components receive adequate cooling. A well-maintained system minimizes the risk of blockages and leaks, which can significantly impair temperature regulation. Regular inspection and maintenance of hoses and connections help ensure that the entire layout functions harmoniously, thus promoting optimal thermal management.

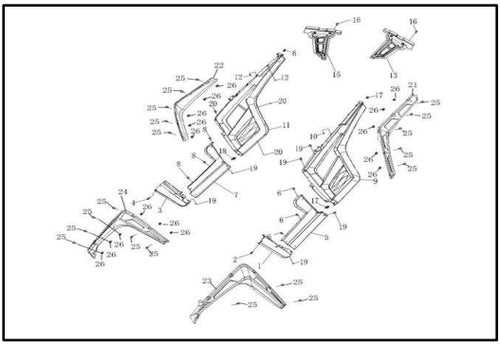

Steering Mechanism Breakdown and Adjustments

The steering system plays a crucial role in the overall performance and handling of any off-road vehicle. Understanding its components and how they function together is essential for maintaining optimal control and maneuverability. This section delves into the intricacies of the steering assembly, highlighting its key elements and the adjustments necessary to ensure smooth operation.

At the core of the steering mechanism are the steering wheel, column, and linkages, which work in harmony to translate the driver’s input into directional movement. Regular inspection of these components is vital, as wear and tear can lead to imprecise handling and diminished responsiveness. Moreover, adjusting the alignment and tension of various parts can enhance steering performance, providing a more comfortable driving experience.

Proper maintenance also involves checking for any loose connections or damaged elements within the steering system. Tightening bolts, lubricating joints, and replacing worn parts are essential practices that can significantly improve handling capabilities. By routinely assessing and adjusting the steering mechanism, drivers can ensure their vehicle remains reliable and enjoyable to operate, even in challenging terrains.

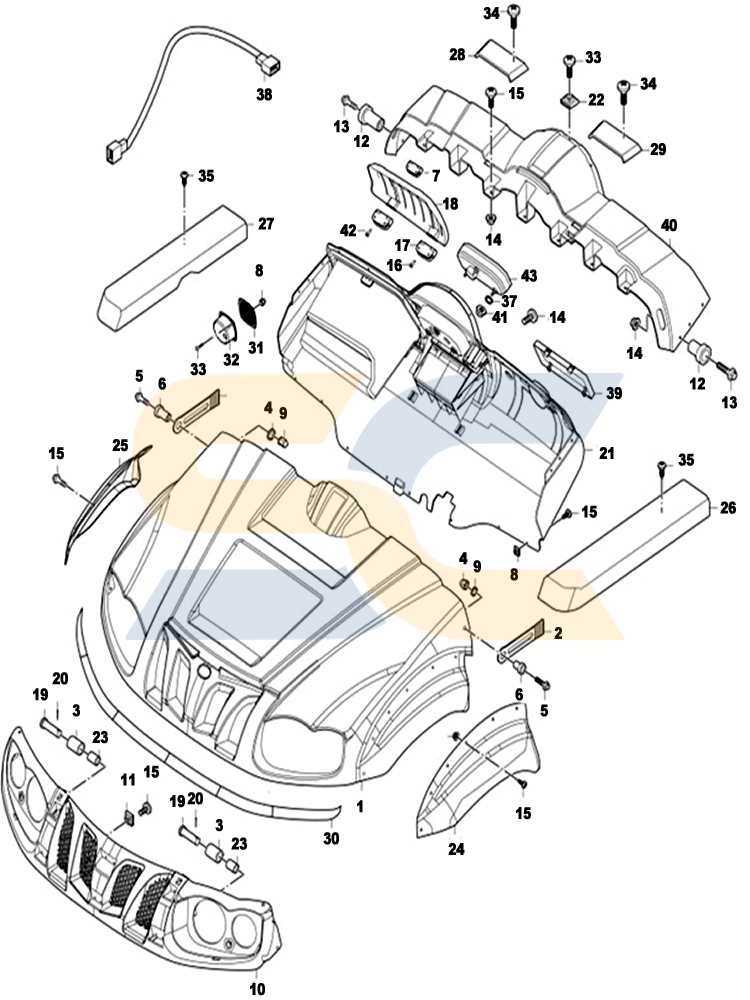

Fuel System Pathway and Parts Interaction

The fuel delivery mechanism plays a crucial role in the overall performance and efficiency of any off-road vehicle. Understanding how various components within this system work together can help diagnose issues and improve functionality. This section outlines the key elements of the fuel system and their interactions, providing insights into their roles and significance.

Key Components of the Fuel Delivery Mechanism

Interaction Between Components

Each part of the fuel system has a specific function that contributes to the overall operation. The flow of fuel begins at the tank, where the pump draws it up and pushes it through the filter, ensuring that only clean fuel reaches the injectors. Properly functioning injectors then deliver the correct amount of fuel into the combustion chamber, allowing for efficient engine performance.

Regular maintenance and checks are vital for this system. Blockages in fuel lines or a malfunctioning pump can disrupt the fuel flow, leading to reduced performance or engine issues. Understanding this interplay of components is essential for anyone looking to enhance their vehicle’s performance.

Lighting and Signal Systems Connections

This section delves into the essential connections within illumination and signaling frameworks, highlighting their significance in ensuring optimal visibility and communication during operation. Proper integration of these systems is crucial for enhancing safety and functionality in off-road vehicles.

The lighting and signal systems are comprised of various components, each serving a specific role in facilitating clear communication and visibility. Understanding how these elements interact is vital for effective maintenance and troubleshooting.

Key Components

Connection Overview

By paying close attention to these connections and components, one can maintain an effective lighting and signaling system, which is crucial for safe navigation and operation in diverse environments.