Comprehensive Guide to Hobart A200 Parts Diagram

In the realm of commercial kitchens, the efficiency of machinery plays a crucial role in daily operations. Knowing the intricacies of essential appliances can significantly enhance their functionality and lifespan. A well-structured overview of various elements not only aids in maintenance but also assists operators in making informed decisions regarding repairs and upgrades.

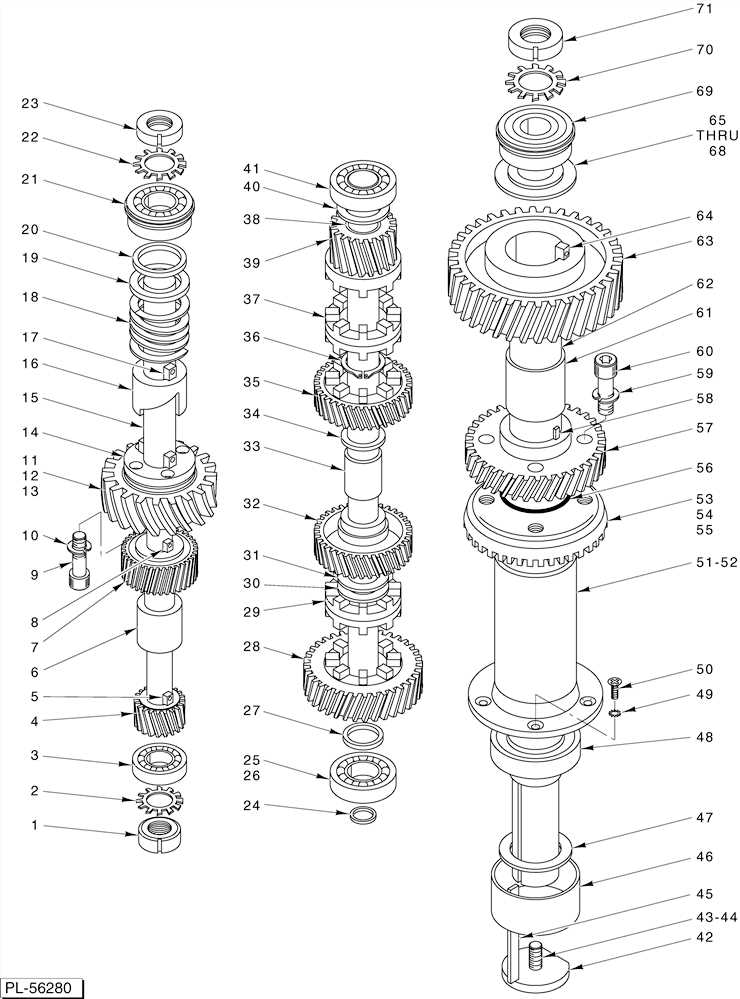

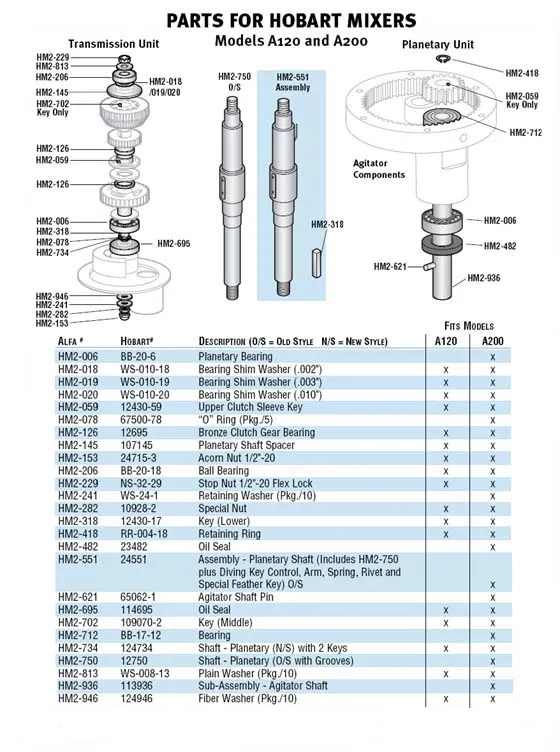

Visual representations of machine components serve as invaluable tools for chefs and technicians alike. By dissecting the intricacies of equipment layout, one can swiftly identify potential issues and implement timely solutions. This clarity not only streamlines workflow but also minimizes downtime in bustling culinary environments.

Comprehending the interplay between different elements is vital for ensuring optimal performance. From the motor systems to the exterior casings, each segment contributes to the overall efficacy of the device. Thus, a thorough understanding of these components equips users with the knowledge necessary to maintain peak operational standards.

Understanding the Hobart A200 Mixer

This section delves into the essential components of a renowned mixing machine, focusing on its functionality and design. Understanding the intricate elements that contribute to its operation can enhance user experience and maintenance practices.

Key Components

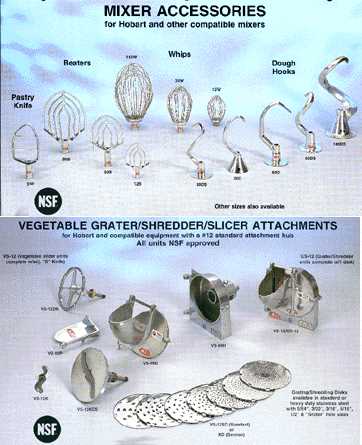

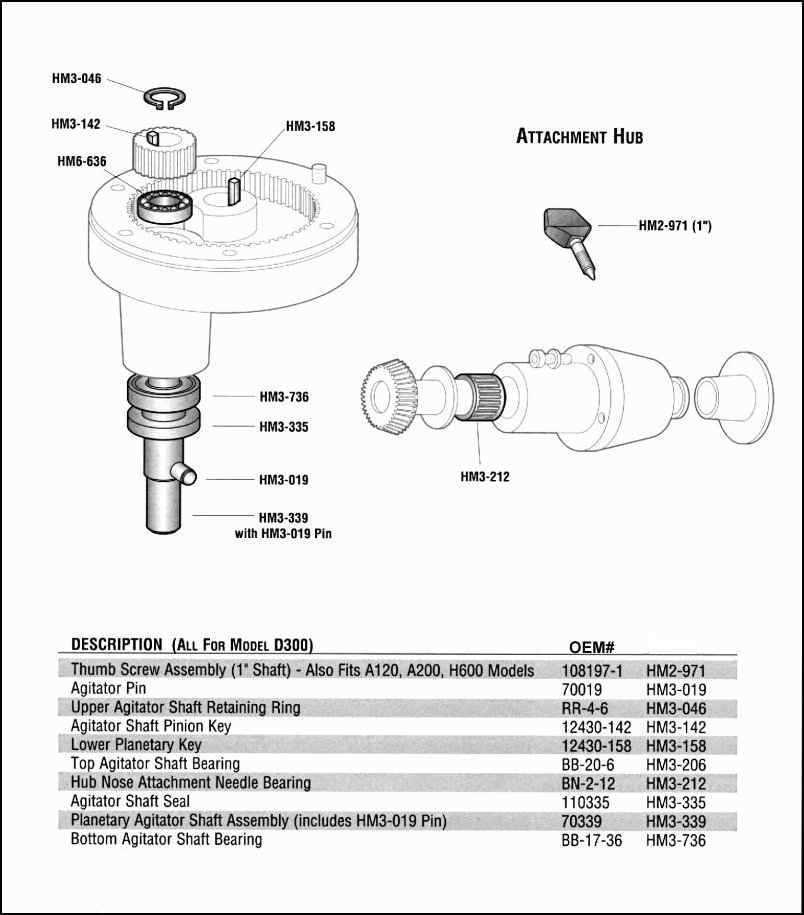

The core of this mixing device includes a robust motor, transmission system, and various attachments that serve different culinary tasks. Each part is designed to work harmoniously, ensuring optimal performance during food preparation.

Maintenance Tips

To ensure longevity, regular cleaning and inspection of the main components are crucial. Proper care not only enhances efficiency but also prevents potential malfunctions. Users should refer to manuals for specific guidance on maintenance routines.

Overview of Hobart A200 Parts

This section provides a comprehensive examination of the various components found in a popular commercial mixer model. Understanding these elements is essential for maintenance and repair, ensuring optimal performance in kitchen environments.

| Component | Description |

|---|---|

| Motor | Powers the mixer, providing the necessary force to blend ingredients. |

| Bowl | Holds the mixture, designed to accommodate various quantities. |

| Attachment Hub | Allows for the connection of various tools, enhancing versatility. |

| Control Panel | Facilitates operation through speed settings and power controls. |

| Whisk | Used for incorporating air into mixtures, ideal for whipping cream or egg whites. |

| Flat Beater | Perfect for mixing batters and heavy doughs. |

| Dough Hook | Specifically designed for kneading dough, ensuring thorough mixing. |

Each of these components plays a vital role in the machine’s overall functionality, making familiarity with them crucial for any user or technician. Regular maintenance and timely replacement of worn-out elements can significantly enhance the longevity and efficiency of the equipment.

Common Issues with A200 Components

When dealing with kitchen equipment, several components may present challenges that can hinder performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and prolonging the lifespan of the machine. Identifying and addressing these issues early can prevent costly repairs and ensure smooth operation.

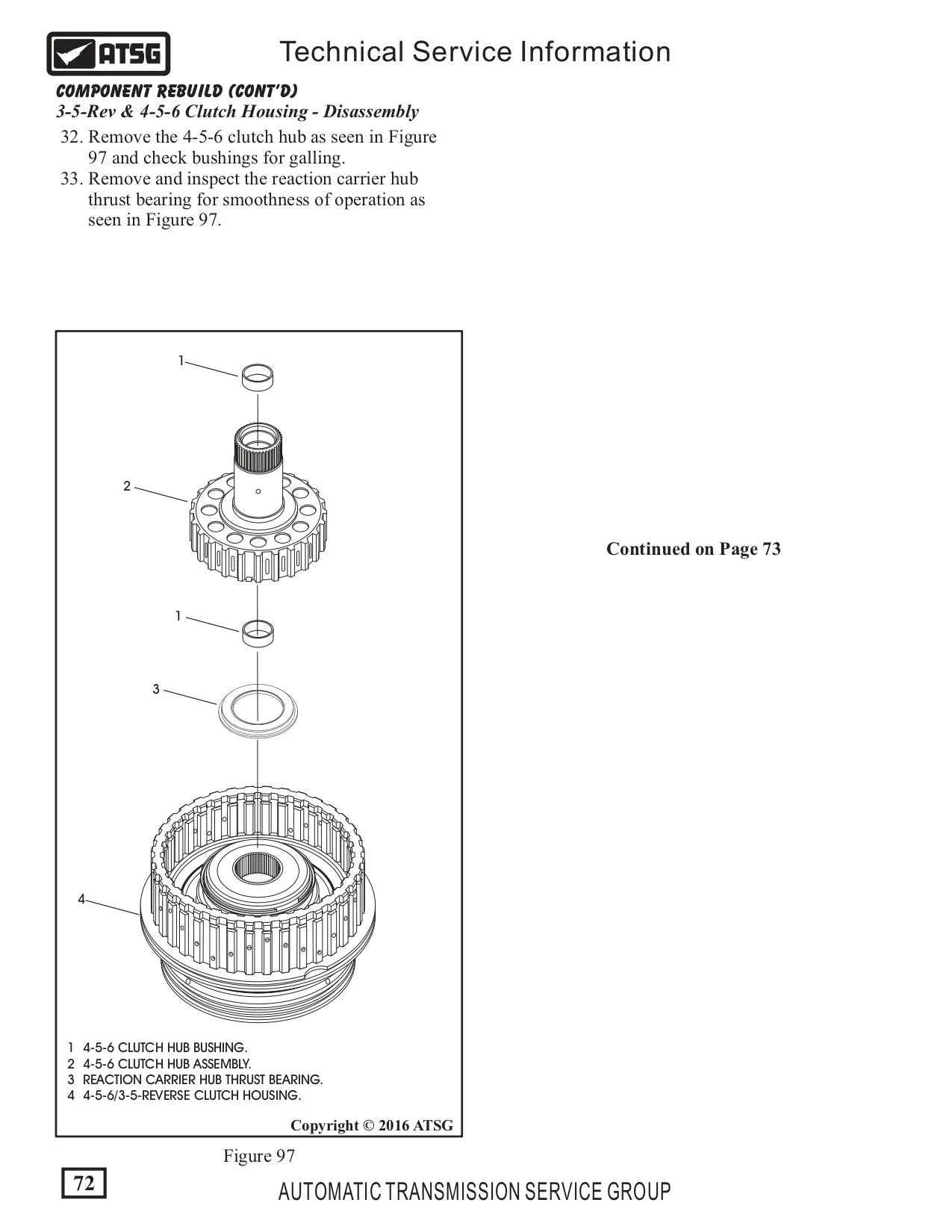

One frequent concern involves electrical components, which may experience malfunctions due to wear or faulty connections. Additionally, mechanical parts such as gears and bearings can suffer from excessive friction or misalignment, leading to reduced efficiency. Moreover, wear and tear on seals and gaskets can result in leaks, affecting both performance and hygiene.

Regular inspections and maintenance are crucial in mitigating these issues. By recognizing the signs of potential problems early on, operators can take proactive measures to ensure their equipment remains in top condition.

Importance of Accurate Parts Diagrams

Precise visual representations of components are essential in various fields, particularly in manufacturing and maintenance. These illustrations serve as crucial references that enhance understanding and ensure efficient assembly, repair, and replacement processes.

Enhancing Efficiency

When technicians have access to detailed schematics, they can:

- Quickly identify required elements for tasks.

- Minimize the risk of errors during assembly or repair.

- Streamline workflows by reducing the time spent searching for information.

Ensuring Safety and Reliability

Accurate illustrations play a vital role in maintaining safety standards. By providing clear guidance, they help to:

- Avoid potential hazards associated with incorrect installations.

- Facilitate proper maintenance practices, leading to longer lifespan of equipment.

- Ensure compliance with industry regulations and best practices.

Identifying Key Components in Diagrams

Understanding the fundamental elements in technical illustrations is crucial for effective maintenance and troubleshooting. Recognizing these components allows for a clearer interpretation of how systems function and interact.

Key aspects to consider include:

- Labels: Identifying what each part represents.

- Connections: Understanding how various elements link together.

- Dimensions: Noting the sizes and scales of different components.

- Symbols: Familiarizing oneself with standard representations used in the illustration.

By focusing on these areas, one can delve deeper into the mechanics of the equipment and enhance overall operational efficiency.

Maintenance Tips for A200 Parts

Regular upkeep is essential for the longevity and efficiency of your equipment. Implementing a systematic approach can prevent issues and enhance performance. Here are some practical strategies to keep everything in top shape.

Routine Checks

- Inspect components for wear and tear.

- Ensure all fasteners are tightened properly.

- Clean surfaces to prevent buildup of debris.

Lubrication and Care

- Apply appropriate lubricants to moving parts as recommended.

- Replace any worn seals or gaskets to avoid leaks.

- Store equipment in a dry place to prevent corrosion.

Where to Find Replacement Parts

Locating suitable components for your kitchen equipment can significantly enhance its longevity and performance. It’s essential to know reliable sources where you can acquire these essential elements, ensuring your machinery runs smoothly.

| Source | Description |

|---|---|

| Manufacturer’s Website | Often the best option, providing original items and detailed information. |

| Authorized Dealers | Resellers with a direct connection to the manufacturer, ensuring quality and compatibility. |

| Online Marketplaces | Websites like eBay and Amazon can have both new and used options, sometimes at lower prices. |

| Local Supply Stores | Physical shops that specialize in restaurant equipment may carry various components. |

| Repair Services | Professionals may offer replacement components along with their repair services, ensuring a perfect fit. |

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide crucial information about each element’s function and arrangement, enabling users to identify and locate necessary items quickly.

Key Elements to Consider

- Labels: Always look for annotations that specify the part names and numbers.

- Symbols: Familiarize yourself with common icons representing various components.

- Sections: Diagrams are often divided into segments, making it easier to focus on specific areas.

Steps to Interpret Visuals

- Examine the overall layout to get a sense of the assembly.

- Identify each labeled part and its corresponding function.

- Cross-reference with a list of components to ensure accuracy.

Benefits of Genuine Hobart Parts

Using authentic components in your equipment ensures optimal performance and longevity. These high-quality pieces are designed specifically for your model, reducing the risk of malfunctions and enhancing overall efficiency.

Enhanced Durability

Original replacements are crafted from superior materials, which significantly extends the lifespan of your machinery. This durability minimizes the frequency of repairs, ultimately saving time and costs associated with downtime.

Improved Performance

Genuine components provide a perfect fit and compatibility, which translates into better functionality. When all parts work seamlessly together, it leads to enhanced productivity and a more reliable operation, ensuring your investment pays off.

Popular Upgrades for A200 Mixer

Enhancing your mixer can significantly improve its performance and versatility in the kitchen. Numerous modifications can transform a standard model into a powerful tool, catering to various culinary needs. From increasing efficiency to adding functionality, the right upgrades can elevate your mixing experience.

Stainless Steel Bowl: Upgrading to a stainless steel bowl not only enhances durability but also improves hygiene. This material resists rust and stains, ensuring a long-lasting addition to your kitchen.

Enhanced Beater Attachments: Investing in high-quality beater attachments, such as spiral dough hooks or flex edge beaters, can optimize mixing for different types of ingredients, providing superior results.

Variable Speed Control: Adding a variable speed control feature allows for greater precision in mixing. This upgrade enables you to tailor the speed according to your specific tasks, ensuring perfect textures.

Powerful Motor: A more robust motor can significantly increase mixing efficiency, making it easier to handle larger batches or denser mixtures without straining the machine.

Exploring these upgrades can lead to the ultimate enhancement of your mixing capabilities, making your kitchen endeavors more enjoyable and successful.

Repair vs. Replacement: A Guide

When faced with equipment issues, the decision to fix or replace can be challenging. Understanding the advantages and disadvantages of each option is essential for making an informed choice. This guide explores key factors to consider, helping you determine the best course of action for your machinery.

Evaluating Costs

Cost is often the primary factor in the decision-making process. Repairing equipment may seem less expensive upfront, but it’s crucial to assess long-term implications. Frequent repairs can accumulate costs, potentially surpassing the price of a new unit. On the other hand, investing in replacement might provide better reliability and efficiency, ultimately saving money over time.

Assessing Lifespan and Performance

Another critical aspect is the expected lifespan and performance of the equipment. If the current machine has a history of problems or shows significant wear, replacement may be the more viable option. Newer models often incorporate advanced technology that enhances productivity and safety. Conversely, if the machinery is relatively new and repairable, repair might be a sensible choice, extending its usability without the need for significant investment.

Understanding Warranty on Parts

When it comes to the replacement of components in machinery, comprehending the warranty terms is crucial for ensuring reliability and peace of mind. A warranty serves as a guarantee from the manufacturer regarding the quality and longevity of the item, outlining the conditions under which repairs or replacements are covered.

Typically, warranties can vary significantly in terms of duration and coverage. Some may offer a limited timeframe during which defects or failures are addressed without cost, while others might include specific conditions that must be met for the warranty to remain valid. It is essential to carefully review these details to avoid unexpected expenses.

Additionally, the warranty often stipulates that only authorized service providers should perform repairs or installations. This requirement is intended to maintain the integrity of the component and ensure that any issues arising from improper handling do not void the warranty.

Understanding these aspects helps users make informed decisions, ultimately leading to better maintenance practices and a more efficient operation. Knowing what is covered and the responsibilities involved can significantly impact the longevity of the equipment and the satisfaction of the owner.