Comprehensive Guide to Hoover Steamvac Parts Diagram

In the realm of home maintenance, the functionality of a specific cleaning apparatus is crucial for maintaining a pristine environment. This section aims to explore the intricate assembly of such a device, highlighting its essential elements and their interrelations.

By examining the layout of these components, users can gain a deeper insight into how each part contributes to the machine’s overall effectiveness. Understanding these details is vital for troubleshooting and optimizing performance.

Moreover, this knowledge empowers users to undertake maintenance with confidence, ensuring longevity and reliability in their cleaning routines. Emphasizing the importance of each individual section can lead to more efficient use and better results in household upkeep.

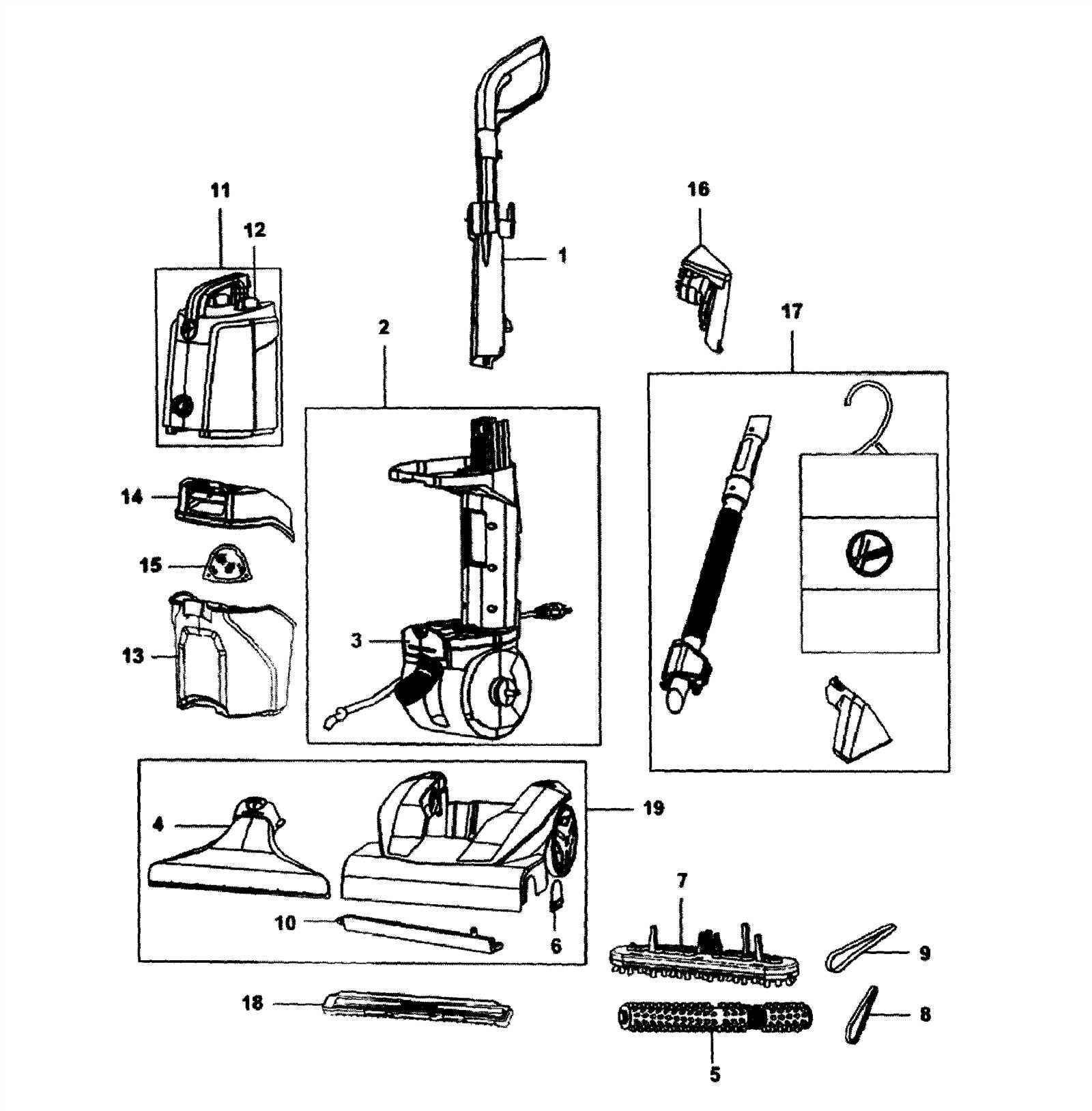

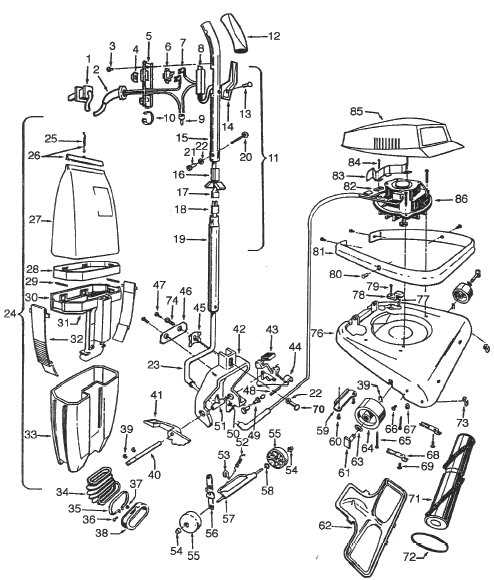

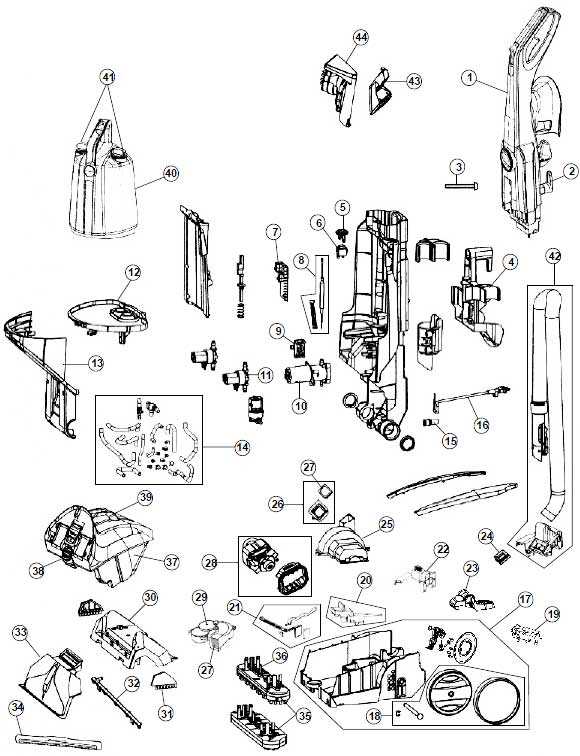

Understanding Hoover SteamVac Components

Gaining insight into the various elements of a carpet cleaning machine enhances both its usage and maintenance. Each component plays a crucial role in the overall functionality, ensuring optimal performance during cleaning tasks.

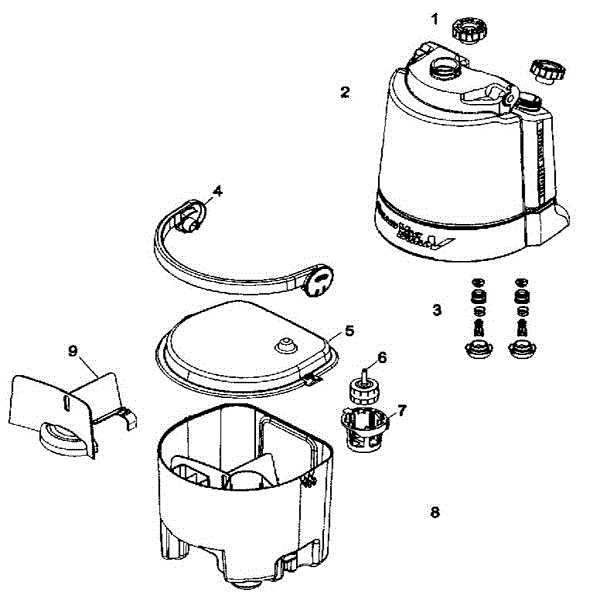

Main Components

- Water Tank: Stores cleaning solution and water.

- Brush System: Agitates dirt and grime from carpet fibers.

- Recovery Tank: Collects dirty water after cleaning.

- Hose Assembly: Allows for spot cleaning and reaching tight spaces.

Maintenance Tips

- Regularly empty and clean the recovery tank.

- Inspect and replace brushes as needed for effective cleaning.

- Check hoses for clogs to ensure optimal suction.

- Clean the water tank periodically to prevent residue buildup.

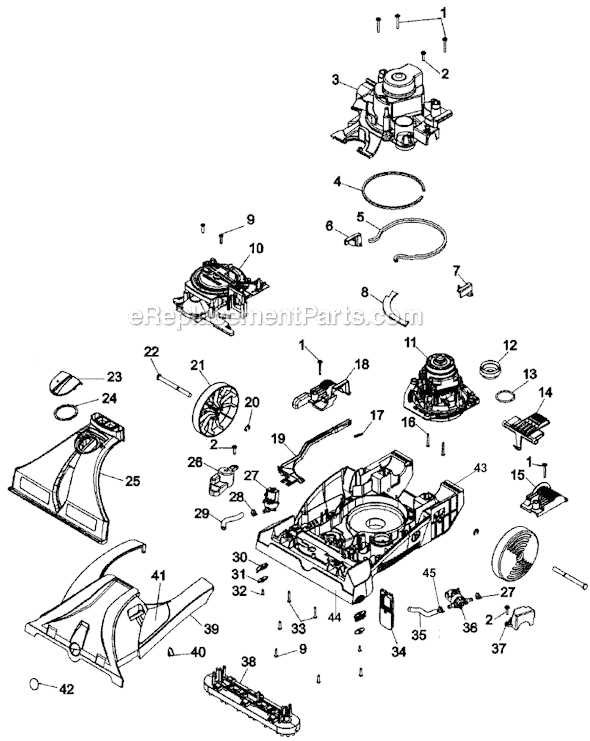

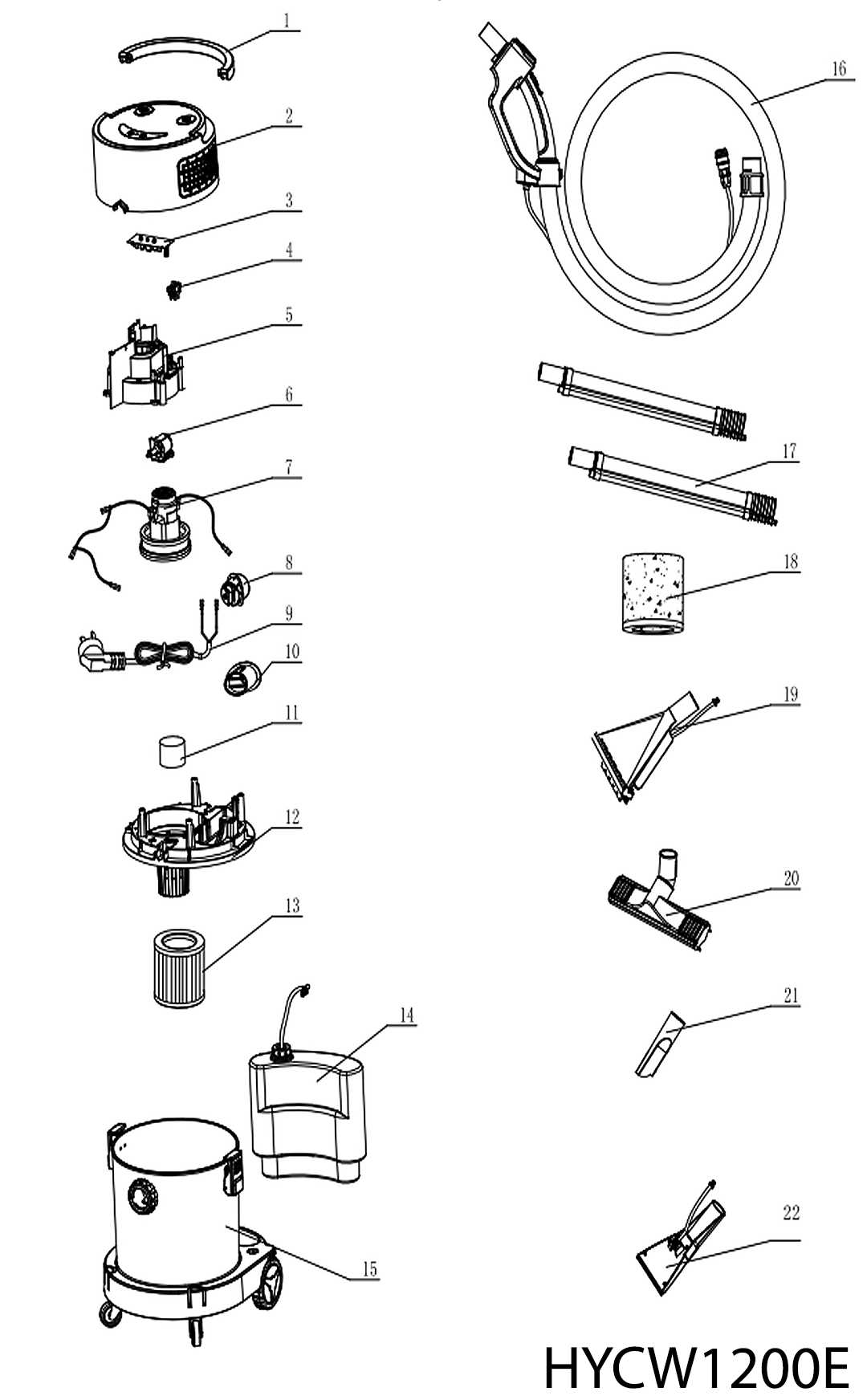

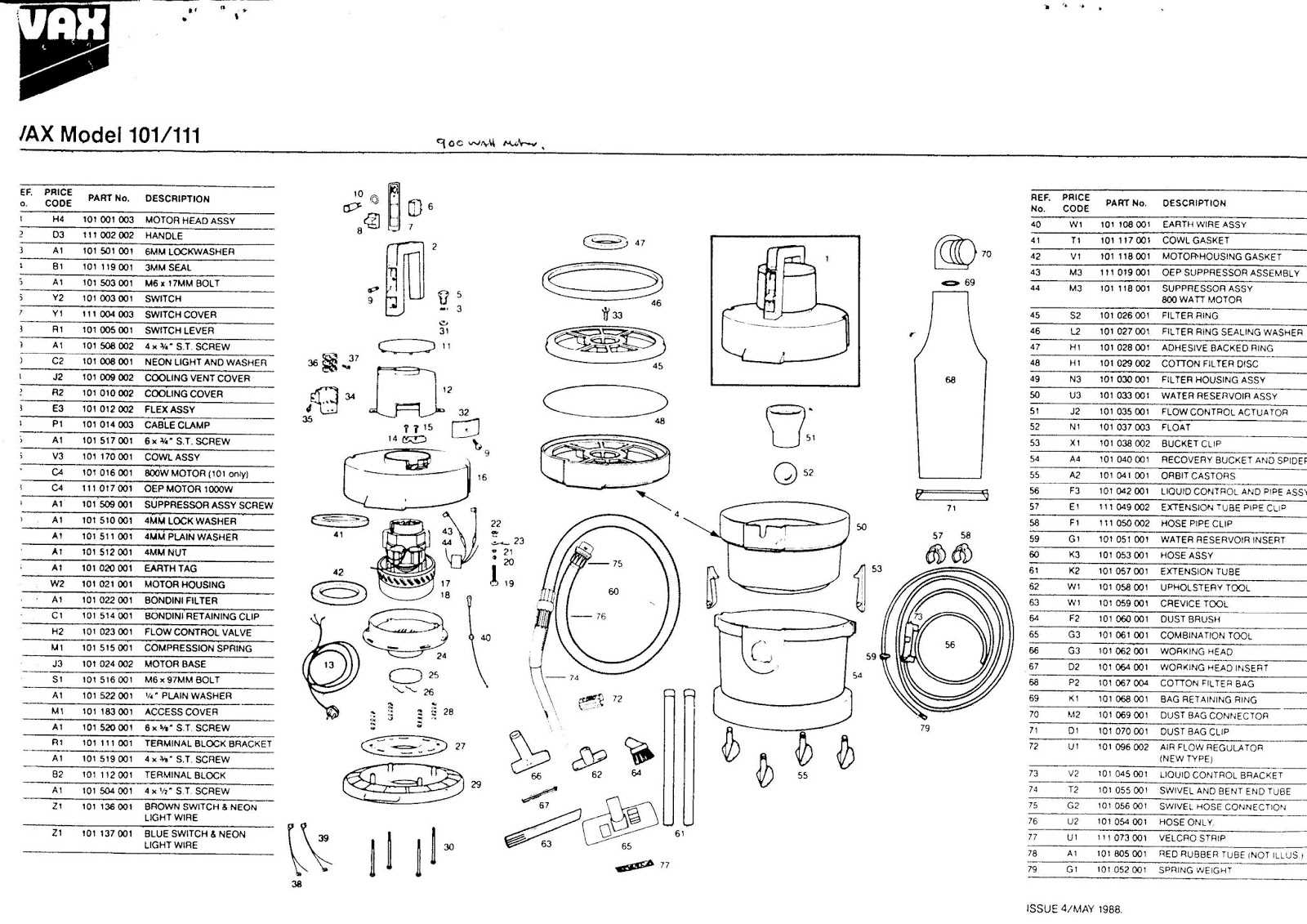

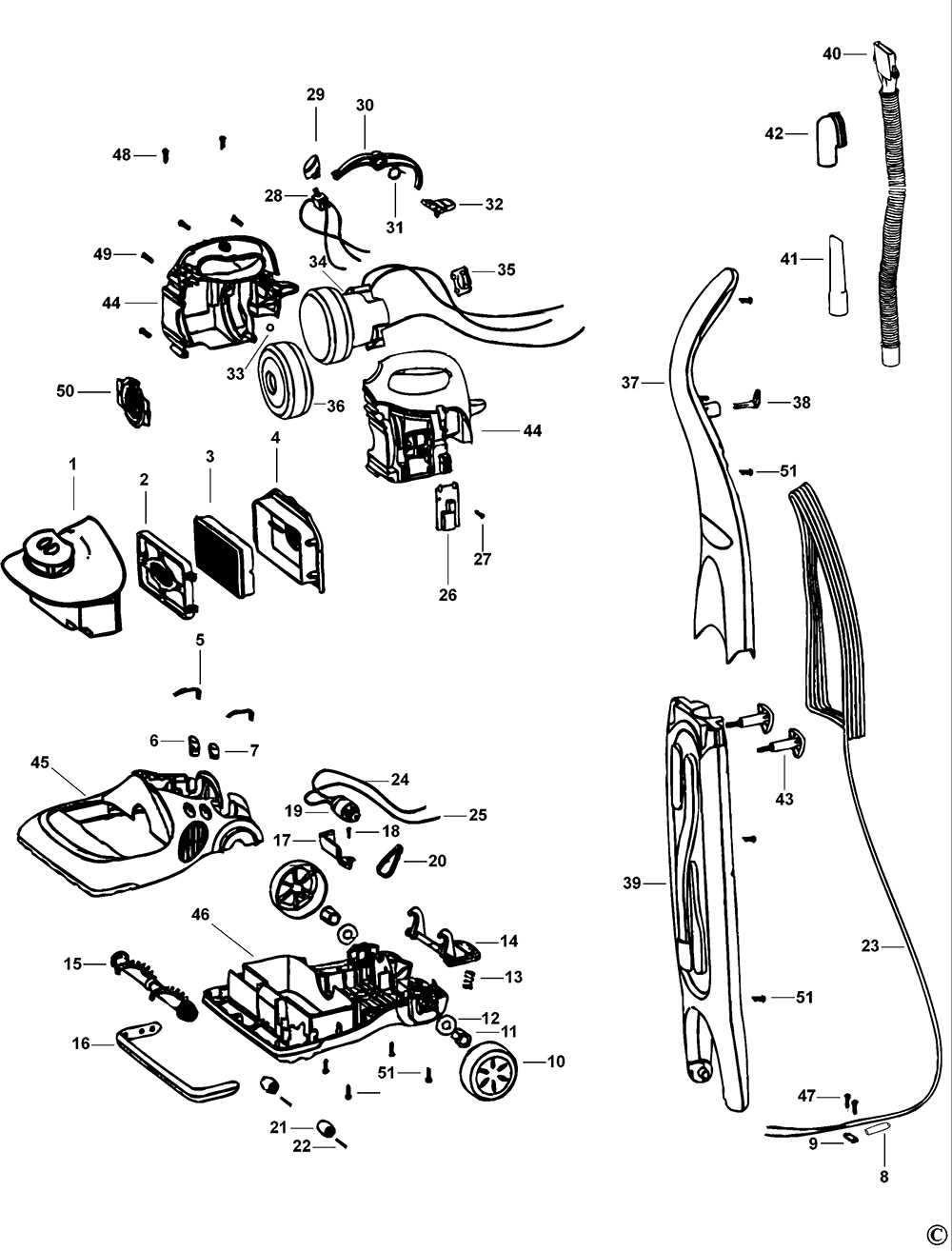

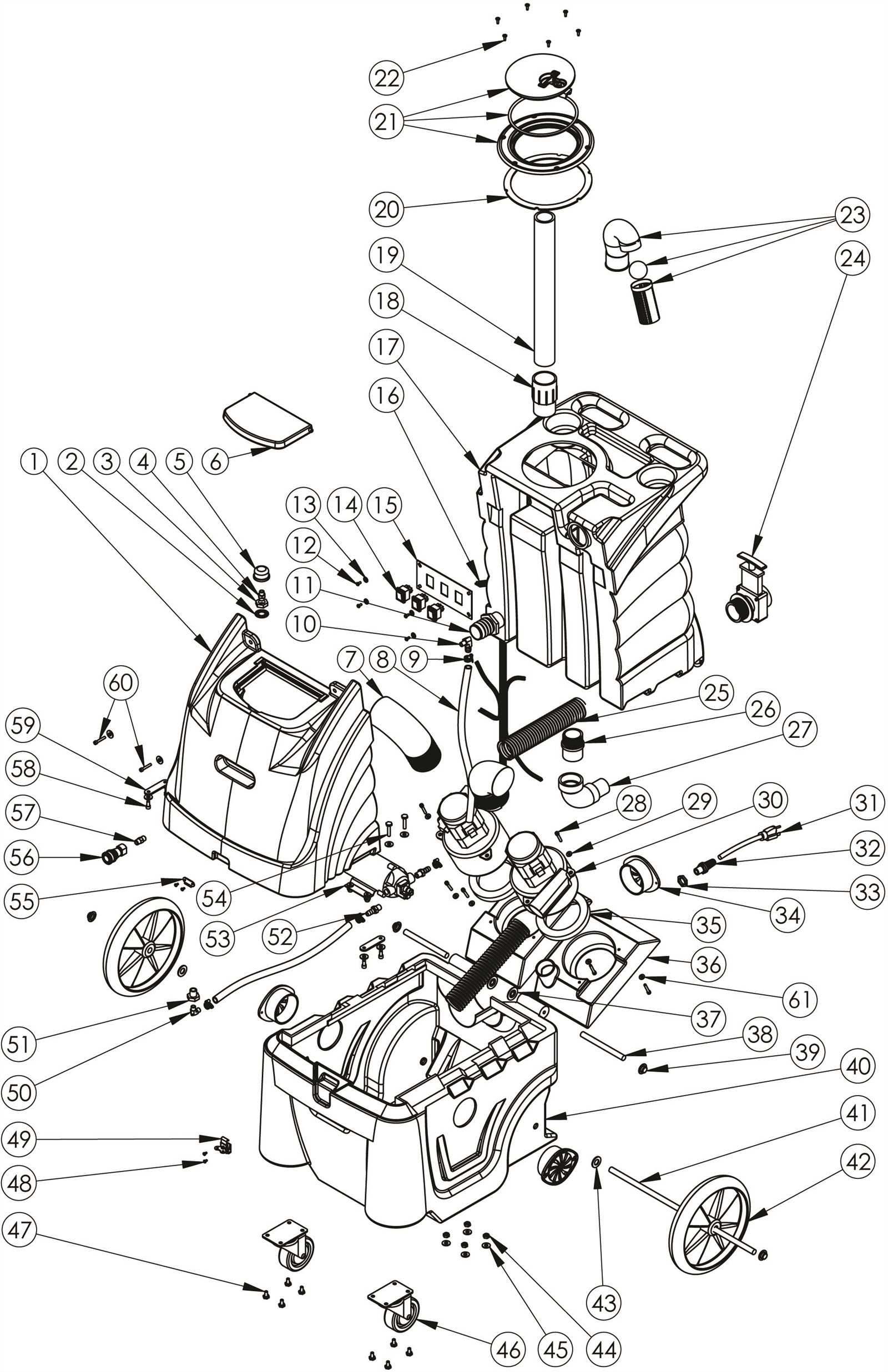

How to Read a Parts Diagram

Understanding the layout of components is essential for effective maintenance and repairs. This guide will help you interpret visual representations of machine elements, ensuring you can identify each piece and its role in the overall function.

Begin by familiarizing yourself with the legend or key, which often indicates the symbols used for various components. Next, focus on the arrangement, noting how parts connect and interact with each other.

| Symbol | Description |

|---|---|

| ◉ | Motor unit |

| ▭ | Housing |

| ➖ | Connector |

| ⧉ | Filter |

Pay attention to any numbers or letters next to the symbols, as they typically refer to specific models or configurations. This detail is crucial for acquiring the correct replacements.

Common Issues with Hoover SteamVacs

When using carpet cleaning machines, users may encounter several frequent challenges that affect performance. Understanding these issues can lead to better maintenance and enhanced efficiency during cleaning tasks.

Clogging Problems

One of the most common difficulties is clogging, which can occur in various parts of the equipment. This often leads to reduced suction power and inefficient cleaning.

Water Leakage

Another prevalent issue is water leakage, which can create a mess and may indicate problems with seals or hoses. Identifying the source of the leak is crucial for effective repair.

| Issue | Possible Cause | Solution |

|---|---|---|

| Clogging | Debris in hoses | Clean out hoses and filters |

| Water Leakage | Damaged seals | Replace seals or hoses |

| Poor Suction | Full tank | Empty tank regularly |

| Nozzle Issues | Blockages in the nozzle | Clear any blockages |

Finding Replacement Parts Online

In the quest for maintaining and enhancing the efficiency of your cleaning equipment, sourcing suitable components online can be a straightforward process. The digital marketplace offers a plethora of options, making it easier to locate exactly what you need without the hassle of visiting multiple stores.

Start by identifying the specific components required for your appliance. Having the model number and any relevant specifications on hand will significantly streamline your search. Various online retailers, including dedicated home appliance sites and general e-commerce platforms, provide extensive inventories. Utilizing the search functionality effectively will yield better results.

Additionally, consider checking user reviews and ratings for both the products and the sellers. This insight can help you gauge the reliability and quality of the items you are interested in. Comparing prices across different websites is also advisable, as this can lead to savings on your purchases.

Exploring forums and community groups dedicated to home maintenance can also provide valuable information. Fellow users often share their experiences and recommendations for trustworthy sources, which can save you time and effort.

In conclusion, with a bit of research and attention to detail, you can successfully navigate the online marketplace to find the components necessary for your equipment, ensuring it operates at peak performance.

Tools Needed for Maintenance

Proper upkeep of your cleaning equipment requires a set of essential instruments to ensure optimal performance and longevity. These tools facilitate routine checks and minor repairs, enabling users to maintain their devices effectively.

Basic toolkit: A screwdriver set is crucial for tightening and adjusting screws. Wrenches are necessary for dealing with various fittings, while pliers can assist in gripping and manipulating small parts.

Cleaning supplies: Microfiber cloths are ideal for dusting and wiping surfaces, while brushes help in clearing out debris from hard-to-reach areas. Additionally, having a vacuum cleaner on hand can aid in keeping the workspace tidy.

Replacement components: It’s wise to have a stock of common spare parts, such as filters and belts, ready for quick replacement when needed. This preparedness minimizes downtime and enhances the overall efficiency of your machine.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your cleaning appliance, ensuring optimal functionality. Follow the outlined steps to identify issues and execute effective solutions with ease.

Tools Needed

- Screwdriver set

- Replacement components

- Cleaning cloths

- Multimeter

- Lubricant

Repair Steps

- Unplug the device and ensure it is cool before beginning any work.

- Inspect the exterior for visible damage or wear.

- Open the housing using the appropriate screwdriver.

- Check internal connections and wiring for signs of wear or breakage.

- Replace any faulty components identified during your inspection.

- Clean any debris or dust from internal parts to improve performance.

- Reassemble the unit carefully, ensuring all parts are securely in place.

- Test the appliance to confirm it operates correctly.

Cleaning and Care Tips

Maintaining your cleaning device is essential for its longevity and performance. Regular upkeep ensures optimal functionality and prevents common issues that may arise from neglect. Following a few simple guidelines can help keep your machine running smoothly.

Regular Maintenance: Check and empty the water tank frequently to avoid buildup of residue. A clean tank promotes better cleaning efficiency.

Filter Care: Clean or replace filters as recommended. Clogged filters can reduce suction power and affect overall effectiveness.

Brush Roll Attention: Inspect the brush roll for tangled hair and debris. Keeping it free of obstructions enhances cleaning performance.

Storage Practices: Store your equipment in a dry, cool place to prevent damage from moisture. Proper storage extends the life of your machine.

By adhering to these practices, you ensure that your cleaning device remains in top condition, ready to tackle any mess with ease.

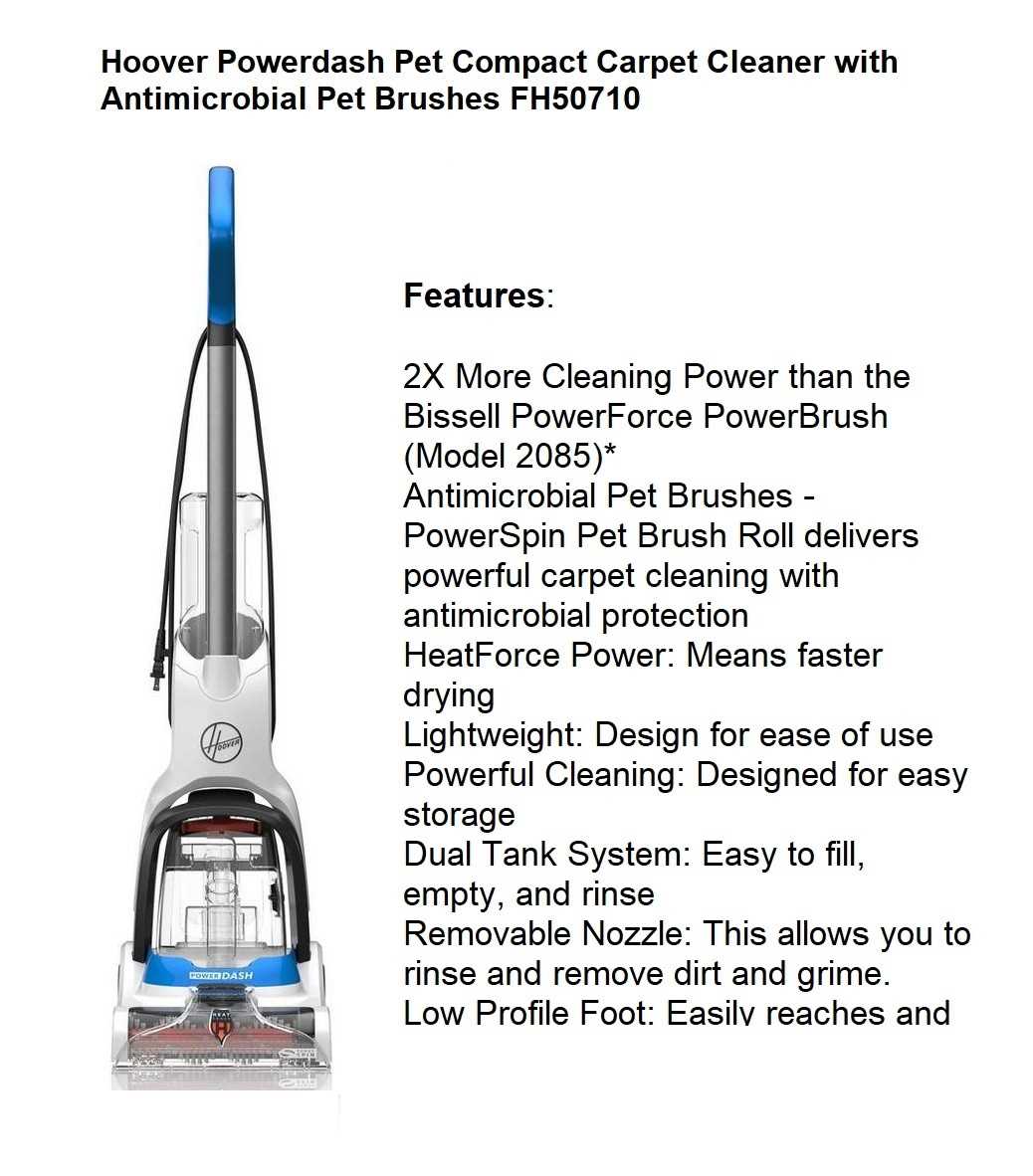

Identifying Model Variations

When exploring different variations of cleaning machines, it’s essential to understand the unique features that distinguish each model. This can include differences in design, functionality, and specifications, which may impact performance and usability.

Model identification often requires close examination of physical attributes such as size, color, and button layout. Additionally, serial numbers and labels can provide crucial insights into the specific version of the device.

Familiarizing yourself with the distinctions between models enables users to make informed decisions regarding repairs and maintenance, ensuring optimal performance of their cleaning equipment.

Compatibility of Parts Across Models

Understanding the interchangeability of components among different models can significantly enhance the maintenance and repair processes. Compatibility plays a crucial role in ensuring that users can easily replace or upgrade their equipment without facing major obstacles.

Several factors influence the compatibility of components:

- Design Similarities: Models that share similar designs often have interchangeable elements.

- Manufacturing Standards: Adherence to common industry standards facilitates the use of the same components across various models.

- Model Variations: Certain series may have slight modifications, impacting part usability.

It’s advisable to check specific guidelines or consult with experts to confirm compatibility before making replacements. This ensures optimal functionality and longevity of the equipment.

Upgrading Your SteamVac Efficiency

Enhancing the performance of your cleaning machine can lead to remarkable results, transforming your cleaning routine into a more effective and enjoyable experience. By implementing a few strategic upgrades, you can significantly boost its functionality and efficiency.

Essential Upgrades

- Replace Worn Components: Regularly check and substitute any frayed or damaged pieces to maintain optimal operation.

- Upgrade Cleaning Solutions: Utilize high-quality cleaning agents tailored for your specific needs, improving stain removal and freshness.

- Regular Maintenance: Establish a routine for cleaning and inspecting the unit to prevent clogs and ensure consistent performance.

Maximizing Efficiency

- Utilize hot water for better cleaning results, as heat can enhance the effectiveness of detergents.

- Optimize your technique by overlapping passes and adjusting speed based on the level of dirt.

- Store the machine properly to prevent damage and ensure it’s ready for use when needed.

Frequently Asked Questions on Repairs

This section addresses common inquiries related to maintenance and fixing of cleaning appliances. Understanding these frequently asked questions can help users troubleshoot issues effectively and extend the lifespan of their equipment.

Common Issues

- What should I do if the machine won’t turn on?

- How can I fix a loss of suction?

- What causes leaks during operation?

Repair Process

- Identify the problem based on the symptoms.

- Consult the user manual for guidance.

- Gather necessary tools for repairs.

- Follow safety precautions before attempting fixes.

Customer Reviews on Replacement Parts

When it comes to ensuring the longevity of cleaning devices, user feedback on components is invaluable. Many individuals share their experiences regarding the effectiveness, durability, and overall satisfaction with various replacements available on the market. These insights help prospective buyers make informed decisions and enhance their maintenance efforts.

| Component | Rating | Customer Comments |

|---|---|---|

| Brush Roll | 4.5/5 | “Significantly improved cleaning efficiency!” |

| Hose Assembly | 4.0/5 | “Easy to install, but could be sturdier.” |

| Solution Tank | 4.8/5 | “Perfect fit and great capacity!” |

| Filter | 4.2/5 | “Helps maintain suction; worth the investment.” |

Expert Advice on Troubleshooting

When faced with performance issues in your cleaning device, it’s essential to adopt a systematic approach. This section provides valuable insights to help identify and resolve common challenges effectively, ensuring your equipment operates at its ultimate potential.

First, assess the power source: Ensure that the device is properly plugged in and that the outlet is functional. A simple check can often resolve the issue without further intervention.

Next, inspect the cleaning solution: Using the appropriate cleaning fluid is crucial. If the mixture is too diluted or incorrect, it may hinder the machine’s efficiency.

Regular maintenance: Make it a habit to clean filters and brushes frequently. This practice not only prolongs the lifespan of your equipment but also enhances its performance.

Listen for unusual sounds: Any strange noises during operation could indicate a blockage or malfunction. Investigate these sounds promptly to prevent further damage.

Consult the manual: Always refer to the user guide for specific troubleshooting tips tailored to your model. It often contains invaluable information that can save time and effort.