Understanding the Hrr216k10vkaa Parts Diagram for Efficient Maintenance

In the world of machinery and equipment maintenance, having a clear visual representation of individual elements is crucial. Such illustrations not only enhance understanding but also aid in effective repairs and assembly processes. By breaking down the various sections into manageable parts, users can navigate through complex systems with greater ease.

Familiarity with each component plays a significant role in ensuring optimal functionality. Recognizing the specific roles and connections of different sections allows for more efficient troubleshooting and maintenance. When issues arise, pinpointing the malfunctioning area becomes a straightforward task, saving both time and resources.

Moreover, these visual guides serve as an invaluable reference for both novices and experienced technicians alike. They promote confidence in undertaking repairs, empowering users to tackle challenges head-on. Understanding the intricacies of each element not only enhances proficiency but also fosters a deeper appreciation for the overall machinery.

Understanding Hrr216k10vkaa Components

When delving into the intricacies of a machine, recognizing its individual elements is crucial for effective maintenance and operation. Each component plays a pivotal role in ensuring optimal functionality and performance. By familiarizing oneself with these elements, users can troubleshoot issues more effectively and enhance the longevity of the equipment.

The main elements can be categorized as follows:

- Engine Components:

- Fuel system

- Ignition system

- Cooling system

- Transmission Elements:

- Gears

- Belts

- Shafts

- Structural Parts:

- Frame

- Casing

- Wheels

- Control Mechanisms:

- Levers

- Switches

- Controls

Understanding these components allows users to identify potential wear and tear, enabling proactive maintenance. Additionally, this knowledge aids in selecting appropriate replacement items when necessary, ensuring smooth operation for years to come.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex systems. These illustrations serve as essential tools for both assembly and maintenance, providing clarity and enhancing efficiency. Their structured format allows users to quickly identify individual elements, facilitating better communication and decision-making.

Enhancing Understanding

Clear visuals allow users to:

- Quickly grasp the layout of various elements

- Recognize the function of each component

- Facilitate training for new users

Simplifying Maintenance and Repair

When it comes to servicing equipment, these visual guides are invaluable. They assist in:

- Locating parts that need attention

- Streamlining the replacement process

- Minimizing errors during reassembly

In conclusion, effective visual aids are indispensable for anyone working with intricate machinery, ensuring a thorough understanding and efficient operation.

Common Issues with Hrr216k10vkaa

Many users encounter a variety of challenges when operating this specific lawn care equipment. Understanding these common problems can help in identifying solutions and ensuring smoother performance. From mechanical failures to maintenance oversights, awareness of these issues is crucial for optimal operation.

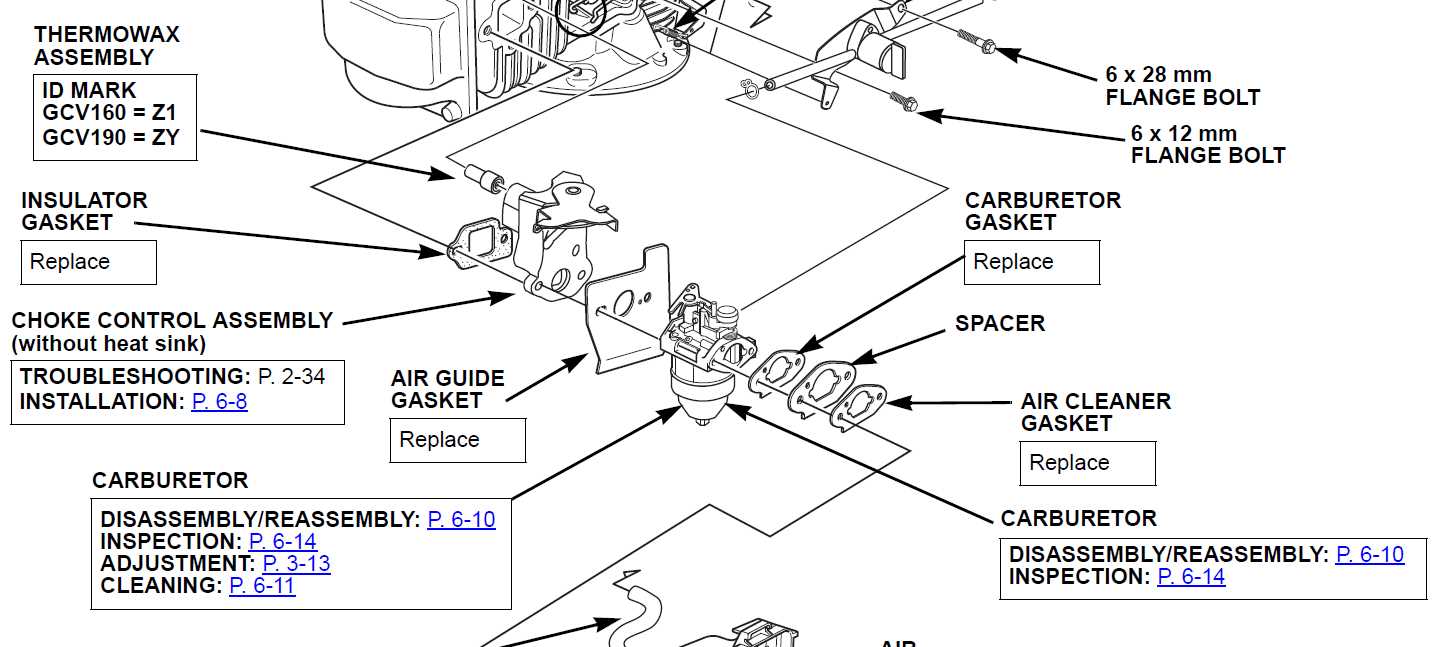

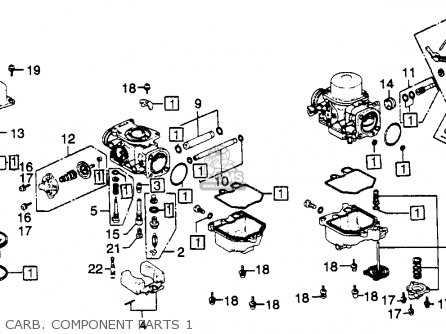

Starting Difficulties: One of the most frequent concerns involves trouble starting the machine. This can stem from a variety of sources, including fuel quality, battery health, or ignition components. Regular checks and maintenance can mitigate these issues.

Cutting Performance: Users often report inconsistencies in cutting effectiveness. Factors contributing to this may include dull blades, improper height settings, or clogged components. Ensuring blades are sharp and clean can significantly improve results.

Overheating: Another prevalent issue is overheating, which can lead to significant operational disruptions. This problem is typically caused by inadequate lubrication or airflow restrictions. Regularly checking oil levels and cleaning air filters can help prevent overheating.

Vibration and Noise: Excessive vibration or unusual noises can indicate underlying mechanical problems. Loose screws, worn parts, or imbalanced components may be the culprits. Conducting routine inspections can help catch these issues early.

Fuel Efficiency: Decreased fuel efficiency is a common complaint among operators. This may result from improper carburetor settings or air-fuel mixture issues. Regular tuning and adjustments can enhance fuel consumption.

Addressing these common challenges not only improves performance but also extends the lifespan of the equipment, ensuring a better experience for users.

Step-by-Step Assembly Guide

This guide provides a comprehensive approach to assembling the components of your machine efficiently and effectively. By following these steps closely, you can ensure a smooth assembly process and achieve optimal performance from your equipment.

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools required for the assembly. Ensure everything is clean and free from defects. |

| 2 | Begin with the base structure. Align the pieces correctly according to the layout provided in your reference material. |

| 3 | Secure the base using appropriate fasteners. Make sure each connection is tight to ensure stability. |

| 4 | Attach the support elements, ensuring they are positioned accurately to provide balance and strength. |

| 5 | Integrate the moving parts, taking care to lubricate where necessary to allow for smooth operation. |

| 6 | Check all connections and tighten any loose screws or bolts. This step is crucial for long-term reliability. |

| 7 | Conduct a final inspection of the entire assembly, ensuring that everything is in its correct position and functions properly. |

| 8 | Power on the machine to test its operation. Make adjustments as needed for optimal performance. |

Tools Required for Repairs

Having the right equipment on hand ensures that maintenance tasks can be completed smoothly and efficiently. A variety of essential instruments are needed for handling different components and ensuring proper adjustments during the restoration process.

Basic Handheld Instruments

A set of reliable handheld tools is fundamental for any repair work. This typically includes screwdrivers with different head types, pliers for gripping and cutting, and a socket wrench set for fastening bolts and nuts. These items help tackle most standard adjustments and removals with ease.

Specialized Equipment for Precision

Certain repair tasks demand greater accuracy, making specialized devices necessary. Torque wrenches are crucial for tightening parts to the correct specifications, while needle-nose pliers are ideal for reaching tight spaces. For electrical checks, a multimeter is indispensable, providing precise measurements for diagnosing potential issues.

Identifying Each Component

This section offers a closer look at the various elements that make up the system, explaining their roles and how they interact with one another. Understanding these elements is crucial for efficient maintenance and troubleshooting, ensuring each piece is recognized and properly managed.

| Component | Description | |||||

|---|---|---|---|---|---|---|

| Engine Assembly | The power source that drives the entire unit, responsible for converting fuel into mechanical energy. | |||||

| Control Mechanism | Handles the adjustment of speed and direction, allowing for precise operation and user control. | |||||

| Cutting Unit | The primary section responsible for performing the main function, featuring sharp edges designed for clean results. | |||||

| Drive System | Transmits power from the main source to the operational parts, enabling smooth and consistent performance. | |||||

| Safety Features | Includes elements that ensure safe operation, preventing accidental damage or injury during use. | |||||

| Structural Frame | Provides support and stability, holding all other elements

Maintenance Tips for LongevityEnsuring a prolonged lifespan for your equipment involves regular care and attention to detail. A few simple practices can significantly enhance durability and performance over time, reducing the need for repairs or replacements. Regular CleaningKeeping the equipment clean prevents debris buildup, which can affect its functionality. Pay attention to the exterior as well as internal components to avoid clogs and potential damage.

Periodic Inspections

Frequent checks help identify minor issues before they escalate. A visual assessment can reveal wear and tear that might require early intervention.

By incorporating these routine practices, you can ensure smooth How to Source Replacement PartsFinding suitable components for equipment maintenance or repair can be a straightforward process if approached with the right strategies. This involves understanding where to look, what to consider, and the key criteria for ensuring compatibility and quality. By following some simple guidelines, you can ensure a smoother search and selection process.

|