Understanding the Hunter TCX57 Parts Diagram

In any complex system, the precise placement and role of each element play a crucial part in ensuring smooth functionality. These configurations can vary depending on the specific equipment, but understanding how they interact is key to effective maintenance and troubleshooting.

Key components serve distinct functions, and knowing their exact location can significantly ease the process of repair or upgrade. By examining the overall structure, we can gain insights into the inner workings of the machinery and its essential units.

Identifying the positions and roles of individual mechanical elements not only aids in repairs but also helps with optimizing performance. A clear visual representation of these elements offers clarity for both novice and experienced users alike, ensuring accuracy in handling technical tasks.

Understanding Key Components of the TCX57

When delving into the design and functionality of this advanced machine, it’s important to familiarize yourself with its essential elements. Each part plays a crucial role in the overall operation, ensuring smooth and efficient performance.

Below is an overview of the major components that make up the system, emphasizing their roles and contributions:

- Drive System: The main mechanism responsible for motion control and precision handling, enabling the device to execute various operations.

- Control Interface: This unit allows operators to manage settings and adjustments, ensuring optimal performance through intuitive controls.

- Power Unit: The central source of energy, providing the necessary force to keep the system running smoothly.

- Safety Mechanisms: Integrated features designed to protect both the equipment and the user, ensuring that operations are carried out securely.

- Support Structure: The foundational frame that provides stability and houses key components, ensuring proper alignment and balance during use.

Understanding how these components interact helps in maintaining and troubleshooting the system effectively, enhancing both its lifespan and reliability.

Exploring Mechanical Elements and Function

The mechanical design of modern equipment involves numerous components working together to perform various tasks. Understanding the function and relationship between these elements is essential for ensuring smooth operation and maintaining the system’s longevity. Each part plays a critical role, contributing to the overall performance, and any failure can disrupt the entire process.

Key Components in Motion

Within the system, several key elements are responsible for movement and stability. These include rotating mechanisms, balancing structures, and load-bearing units. The interaction between these parts is crucial in maintaining efficiency, minimizing wear, and ensuring precision in every operation. Proper alignment and lubrication are essential to reduce friction and extend operational life.

Energy Transfer and Control

Mechanical systems also rely heavily on efficient energy transfer. Power is distributed through various means, such as belts, gears, and pulleys, which are designed to handle specific loads. The control of this energy flow allows for precise movement, ensuring that the system responds accurately to the demands placed on it. Consistent monitoring and adjustment of these components can prevent issues and enhance overall performance.

Electrical Systems and Their Importance

In modern machinery, electrical systems form the backbone of efficient operation. These networks of components ensure that all functions are synchronized and that every mechanism works in harmony. Their complexity varies depending on the specific equipment, but they share a common goal: maintaining performance and reliability.

Key Components of Electrical Systems

The primary elements of an electrical system include power sources, conductors, and control units. Each of these plays a critical role in ensuring stable operation. The power source provides the necessary energy, conductors distribute it throughout the system, and control units regulate the flow to ensure optimal functionality.

The Role of Electrical Systems in Safety

Beyond performance, electrical systems are essential for safety. They manage the flow of power and prevent malfunctions that could lead to equipment damage or hazardous situations. Properly functioning electrical networks not only extend the lifespan of machinery but also protect operators from potential risks.

Maintenance Tips for Longevity

Ensuring the long-term performance of your equipment requires regular care and attention. By adhering to a consistent maintenance routine, you can prevent premature wear and extend its usability, avoiding costly repairs down the road.

Regular Cleaning

To keep your system functioning optimally, it is important to clean it routinely. Dust and debris can accumulate over time, leading to inefficiencies or potential damage.

- Wipe down surfaces with a soft, dry cloth to remove dust.

- Check moving components for signs of buildup and clean them as necessary.

- Avoid using harsh chemicals that might degrade materials.

Inspection and Lubrication

Frequent inspection of key components is crucial for early detection of potential issues. Additionally, ensuring that parts remain well-lubricated helps maintain smooth operation and reduces wear.

- Inspect belts and fasteners for signs of wear or looseness.

- Lubricate moving parts according to the manufacturer’s guidelines to reduce friction.

- Replace worn-out elements to avoid further damage to the system.

Common Wear Parts to Replace

Over time, certain components in mechanical systems are subject to regular wear and may require replacement to ensure continued smooth operation. These elements are typically the most susceptible to friction, stress, and environmental factors, which can lead to gradual deterioration.

Belts and rollers are often the first to show signs of aging. Their exposure to constant movement and pressure can cause them to stretch, crack, or lose efficiency, making replacements necessary to maintain peak performance.

Another key element to monitor is the bearings, which are critical for minimizing friction in rotating parts. Over time, they can wear down due to continuous use, leading to noise or vibrations that signal it’s time for a change.

In addition, seals and gaskets can degrade, especially in environments exposed to extreme temperatures or fluids. These components prevent leaks and ensure smooth operation, but their materials can harden or crack over time, necessitating timely replacements.

Troubleshooting Parts and Solutions

When dealing with mechanical systems, it’s important to understand the potential issues that may arise over time. Identifying malfunctioning components and addressing them promptly can save both time and resources. Regular maintenance and attentive inspection are key to ensuring smooth operation.

Common Issues: Many systems experience wear and tear that can lead to decreased performance. Problems often include noise, failure to engage, or unexpected stoppages. These symptoms can point to issues with individual components that require attention.

Recommended Solutions: To resolve such complications, it’s essential to focus on cleaning, tightening loose connections, or replacing worn-out elements. In more complex cases, consulting a manual or expert advice can provide clarity on the exact cause and solution.

Detailed Look at Hydraulic Systems

Hydraulic systems are integral to numerous machinery and equipment, providing essential power through the controlled movement of fluids. These systems operate by transmitting force via pressurized liquid, enabling effective mechanical actions and precise control in various applications.

Components of Hydraulic Systems

Understanding the fundamental components of hydraulic systems is crucial for effective maintenance and operation. The primary elements include pumps, actuators, valves, and reservoirs, each playing a vital role in the system’s overall functionality.

| Component | Function |

|---|---|

| Pump | Converts mechanical energy into hydraulic energy by moving fluid through the system. |

| Actuator | Transforms hydraulic energy back into mechanical energy to perform work. |

| Valve | Regulates the flow and pressure of the hydraulic fluid, ensuring controlled movement. |

| Reservoir | Stores hydraulic fluid and helps in maintaining the system’s pressure. |

Advantages of Hydraulic Technology

Hydraulic systems offer numerous benefits, including high power density, precise control, and the ability to transmit force over considerable distances. Their adaptability makes them suitable for various applications, from construction machinery to automotive systems, highlighting their significance in modern engineering.

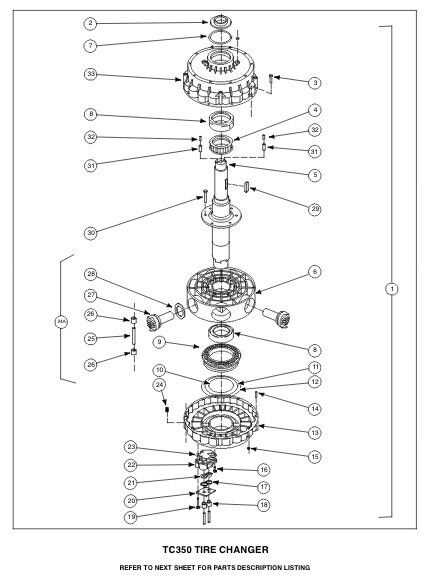

How to Identify Parts by Diagram

Understanding the various components of a system can be greatly simplified through the use of visual representations. These illustrations serve as a valuable resource for both novices and experienced individuals, aiding in the recognition and categorization of different elements. By following a systematic approach, one can efficiently interpret these visuals to enhance their knowledge and maintenance capabilities.

To effectively identify components using an illustration, consider the following steps:

- Familiarize Yourself with the Layout: Begin by examining the overall structure of the visual. Note the arrangement and any labels that may indicate specific functions.

- Cross-reference with Documentation: If available, consult any accompanying manuals or guides that explain the features of each part. This information can provide context and clarity.

- Highlight Key Elements: Use a highlighter or digital tool to mark significant components. This technique can help in focusing on areas of interest during troubleshooting or repairs.

- Take Notes: Document any observations or questions that arise while studying the illustration. This practice can assist in discussions with knowledgeable peers or professionals.

By applying these methods, one can gain a deeper understanding of a system’s components and improve their ability to address any issues that may arise.

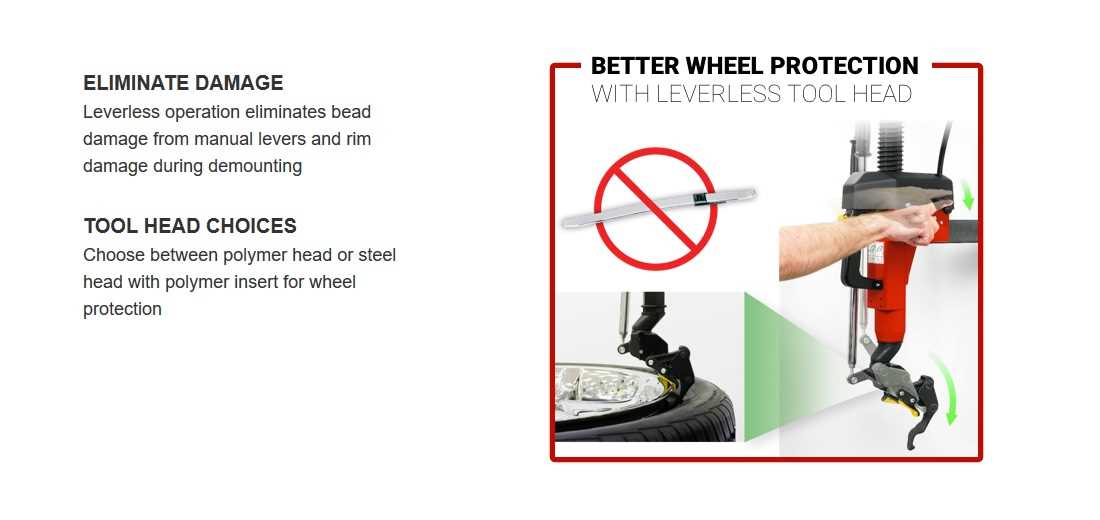

Upgrading and Modifying TCX57 Components

Enhancing and customizing various elements of your equipment can significantly improve its performance and longevity. By selecting high-quality upgrades, users can tailor their devices to meet specific operational needs and preferences. Modifications not only boost functionality but also contribute to a more enjoyable experience during use.

Evaluation of Existing Elements: Before proceeding with any upgrades, it is essential to thoroughly assess the current components. Identifying weaknesses or areas for improvement will help determine the best course of action. Take note of any limitations that may hinder optimal performance.

Choosing Compatible Alternatives: When looking for replacements, it is crucial to select compatible options that align with the original specifications. Consider materials, dimensions, and intended use to ensure seamless integration. Enhanced materials can lead to increased durability and efficiency.

Installation Considerations: Proper installation of upgraded components is vital for achieving the desired results. Follow guidelines meticulously to avoid potential issues. In some cases, professional assistance may be beneficial to ensure that modifications are executed correctly and safely.

Testing and Fine-Tuning: After upgrades are made, conducting thorough testing is necessary to verify functionality and performance improvements. Fine-tuning settings may be required to maximize the benefits of new components. Regular maintenance checks will help maintain optimal conditions over time.

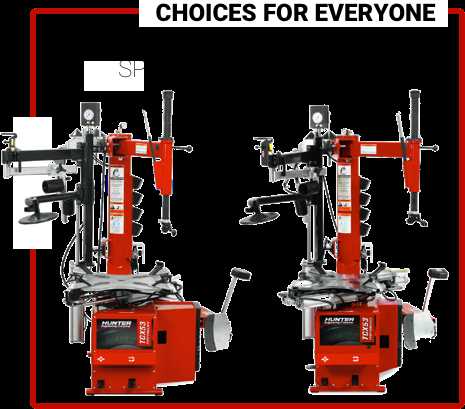

Choosing Quality Replacement Parts

Selecting high-grade components is essential for ensuring the longevity and performance of any system. When it comes to maintenance or restoration, utilizing superior materials not only enhances efficiency but also minimizes the need for frequent repairs. Understanding the significance of quality in replacements can greatly impact overall functionality.

Factors to Consider

- Material Quality: Look for durable and reliable materials that withstand wear and tear.

- Compatibility: Ensure that the components are suitable for the specific model to avoid operational issues.

- Manufacturer Reputation: Research and choose components from reputable manufacturers known for their reliability.

Benefits of Quality Components

- Enhanced Performance: Superior components contribute to improved efficiency and effectiveness.

- Longevity: High-quality materials generally offer a longer lifespan, reducing the frequency of replacements.

- Cost-Effectiveness: Investing in quality upfront can save money over time by minimizing repairs and replacements.

Best Practices for Part Installation

Ensuring a successful assembly of components is essential for optimal performance and longevity of any system. Adhering to specific guidelines can facilitate a smoother installation process, reducing the likelihood of errors and enhancing efficiency. By following established methods, one can achieve a seamless integration of elements, contributing to the overall functionality of the device.

Prioritize Preparation: Before commencing the installation, gather all necessary tools and components. Familiarize yourself with the user manual and understand the layout and connection points to minimize confusion during the process.

Maintain Cleanliness: Keeping the workspace clean and organized is crucial. Dust, debris, or contaminants can interfere with the proper seating of components and lead to malfunctions. Ensure that surfaces are free of any obstruction prior to installation.

Follow Manufacturer Guidelines: Always adhere to the instructions provided by the manufacturer. These guidelines are designed to ensure that each component is installed correctly and functions as intended. Deviating from these instructions can result in damage or decreased efficiency.

Utilize Proper Tools: Using the right tools for the job is vital. Employing incorrect or makeshift tools can lead to improper installation and potential harm to components. Invest in high-quality tools that are appropriate for the tasks at hand.

Perform Regular Checks: After installation, conduct thorough inspections to verify that all components are securely attached and functioning correctly. Regular maintenance checks can help identify potential issues early, ensuring long-term reliability.