Understanding the Parts Diagram of the Husky 60 Gallon Air Compressor

In the realm of high-performance machinery, grasping the intricate layout of essential elements is crucial for both maintenance and efficient operation. The visual representation of these components provides a clear roadmap for anyone looking to enhance their knowledge and ensure optimal functionality. This guide aims to illuminate the various sections that make up a robust energy system.

Each segment of this powerful device plays a significant role, from the core engine to the ancillary features that support its overall efficiency. By familiarizing oneself with these individual elements, users can better appreciate how they interact to deliver consistent performance. Understanding these details not only aids in troubleshooting but also fosters confidence in managing repairs and upgrades.

This exploration will delve into the specific configurations and relationships between the different sections, offering insights into their functions. Whether you are a seasoned technician or a curious enthusiast, having a solid grasp of the layout will empower you to tackle any challenges that may arise during operation or maintenance.

Understanding Husky 60 Gallon Air Compressors

Exploring the functionality and components of these powerful machines reveals their significance in various tasks. Their robust design and efficiency make them essential tools for both professionals and hobbyists. By examining their structure and operation, one can appreciate the ultimate benefits they offer in performance and reliability.

Key Features and Benefits

These units are equipped with high-capacity tanks that allow for extended usage without frequent interruptions. Their versatility caters to a wide range of applications, from automotive work to woodworking. Additionally, their energy efficiency contributes to reduced operational costs over time.

Maintenance and Care

Regular upkeep is crucial for longevity and optimal performance. Simple practices such as checking the oil levels and draining moisture can prevent potential issues. Understanding the critical elements involved ensures users maximize their investment and maintain productivity.

Key Components of Air Compressors

Understanding the essential elements of pressure generation systems is crucial for effective operation and maintenance. These systems consist of various components, each playing a vital role in ensuring optimal performance and longevity. Below, we outline the primary elements that contribute to their functionality.

Core Elements

- Motor: Powers the unit, converting electrical energy into mechanical energy.

- Pump: Compresses the gas, creating the necessary pressure for various applications.

- Tank: Stores the compressed gas, providing a reserve for consistent pressure supply.

- Regulator: Controls the output pressure, ensuring it meets specific requirements.

- Pressure Switch: Monitors and maintains set pressure levels within the system.

Supporting Components

- Air Filter: Cleans incoming air, preventing contaminants from entering the system.

- Safety Valve: Protects the system from excessive pressure, ensuring safe operation.

- Drain Valve: Allows for the removal of moisture that accumulates in the tank.

- Hoses and Connectors: Facilitate the transfer of compressed gas to tools and equipment.

- Cooling System: Maintains optimal operating temperatures, preventing overheating.

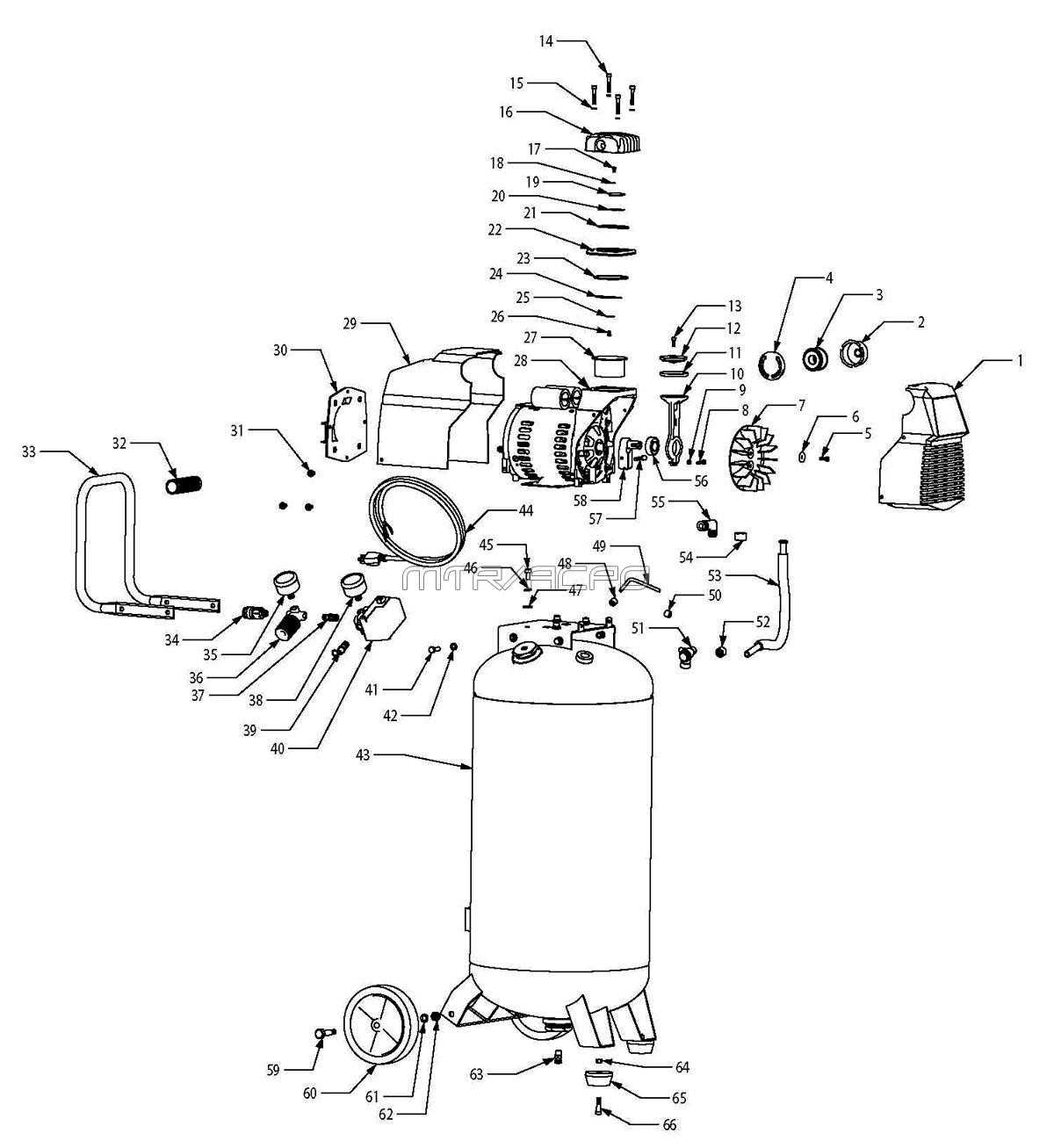

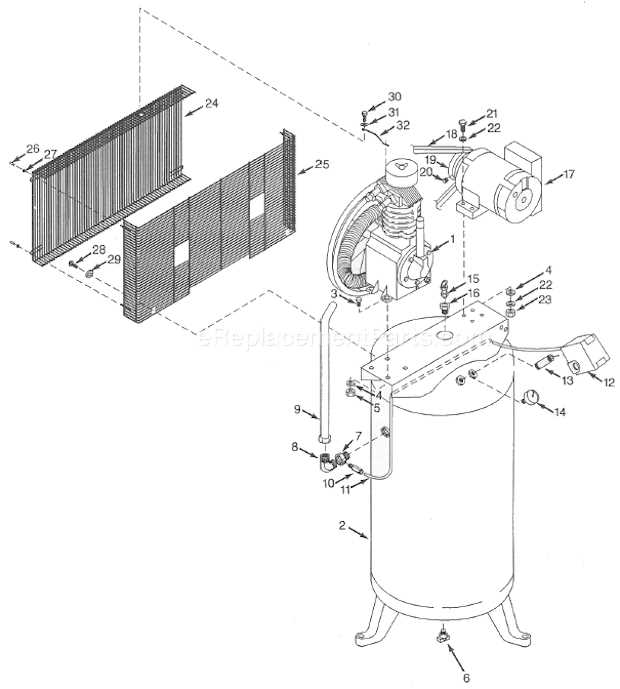

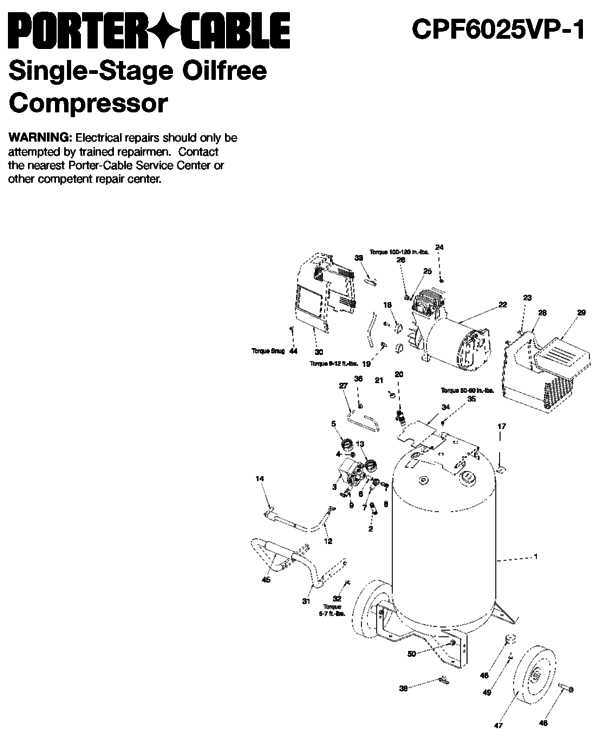

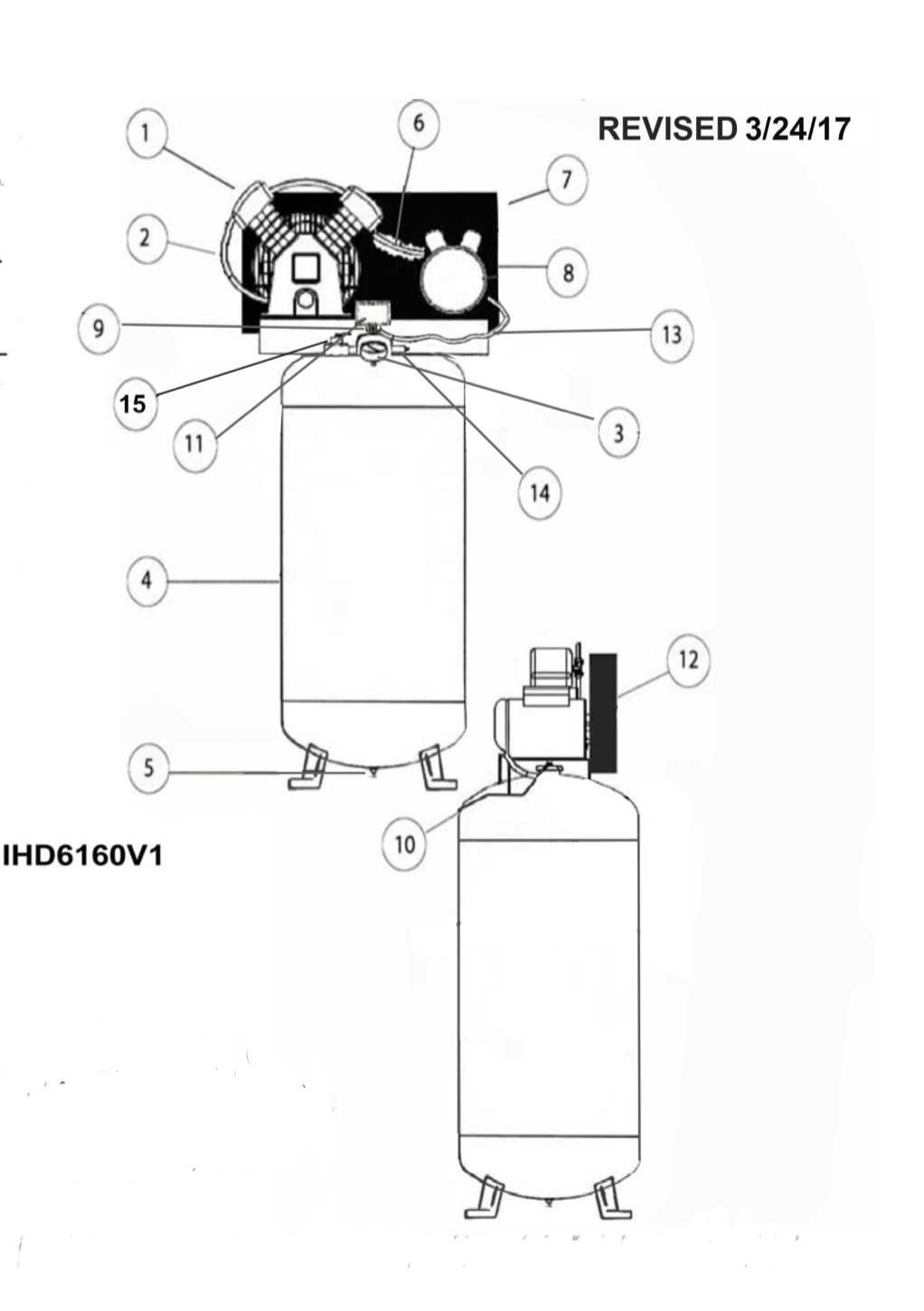

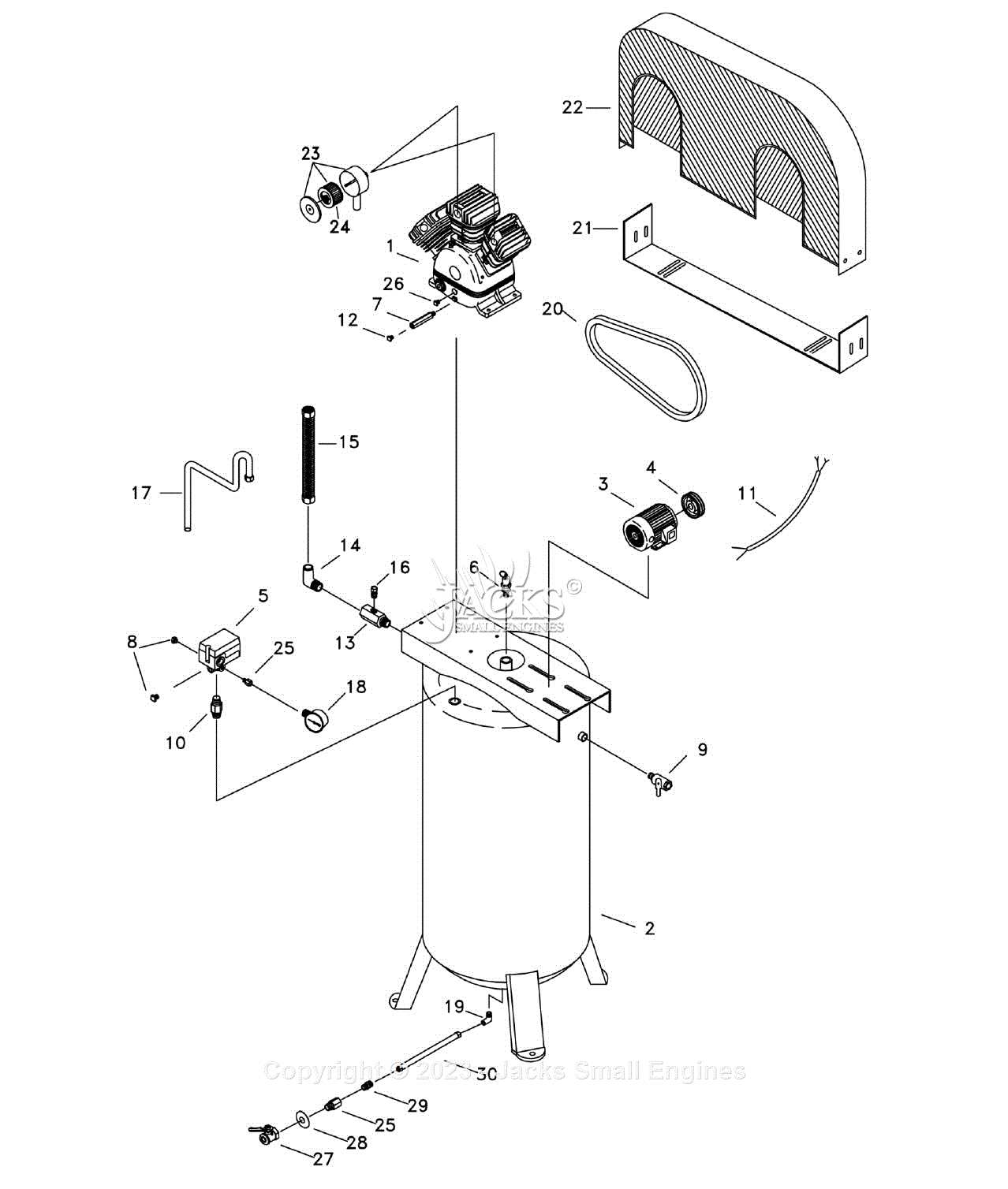

Parts Identification in Diagrams

Understanding the components represented in schematics is crucial for effective maintenance and repair. Accurate identification allows users to troubleshoot issues, replace worn elements, and ensure optimal performance of their equipment. This section will explore how to decipher these visual guides effectively.

Key Elements to Consider

- Labels: Most illustrations include annotations that specify each component. Familiarizing oneself with these labels is essential for clarity.

- Color Coding: Different colors may signify specific functions or types of parts, aiding in quicker identification.

- Shapes and Symbols: Understanding the geometric representations can help distinguish between various parts.

Steps for Effective Identification

- Start with the overview of the schematic to grasp the layout.

- Identify the major components first before delving into smaller elements.

- Cross-reference the identified parts with a catalog or manual for precise information.

By mastering these techniques, users can navigate schematics with confidence and enhance their troubleshooting skills significantly.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficient performance of any equipment. Implementing a structured maintenance routine not only enhances functionality but also extends the lifespan of the machinery, preventing costly repairs and downtime.

Routine Inspections

Conduct periodic checks to identify any signs of wear or potential issues. Look for leaks, loose connections, and unusual noises. Addressing these concerns early can prevent further damage.

Proper Lubrication

Ensure that all moving components are adequately lubricated. Using the right type of lubricant reduces friction, minimizing wear and tear. Follow the manufacturer’s recommendations for lubrication intervals and products.

Emphasizing maintenance and attention to detail will ultimately yield a reliable and long-lasting investment, enhancing overall performance.

Common Issues with Air Compressors

Understanding the typical challenges encountered with these machines is essential for optimal performance and longevity. By recognizing common malfunctions, users can take proactive measures to prevent downtime.

- Insufficient Pressure: Often caused by leaks or clogged filters.

- Overheating: Results from prolonged use without breaks or inadequate ventilation.

- Unusual Noises: Could indicate loose components or mechanical wear.

- Frequent Cycling: May point to a faulty pressure switch or tank issues.

Addressing these problems promptly can enhance efficiency and extend the machine’s life.

How to Read Technical Diagrams

Understanding technical illustrations is essential for anyone working with complex systems or machinery. These representations convey intricate information visually, making it easier to grasp the structure and functionality of components. Mastering this skill can significantly enhance your ability to troubleshoot, maintain, and assemble various devices.

To effectively interpret these illustrations, follow these key steps:

- Familiarize Yourself with Symbols: Technical visuals often utilize specific icons to represent components. Spend time learning these symbols to understand what each one signifies.

- Study the Legend: Most diagrams include a legend or key that explains the symbols used. Refer to it frequently to clarify any uncertainties.

- Identify Connections: Pay attention to lines and arrows that indicate how parts are linked. This will help you visualize the flow of processes or energy.

- Follow the Sequence: Many illustrations depict a sequence of operations. Recognize the order in which tasks should be performed for optimal results.

By applying these techniques, you’ll improve your ability to decode technical visuals and enhance your overall proficiency in working with complex equipment.

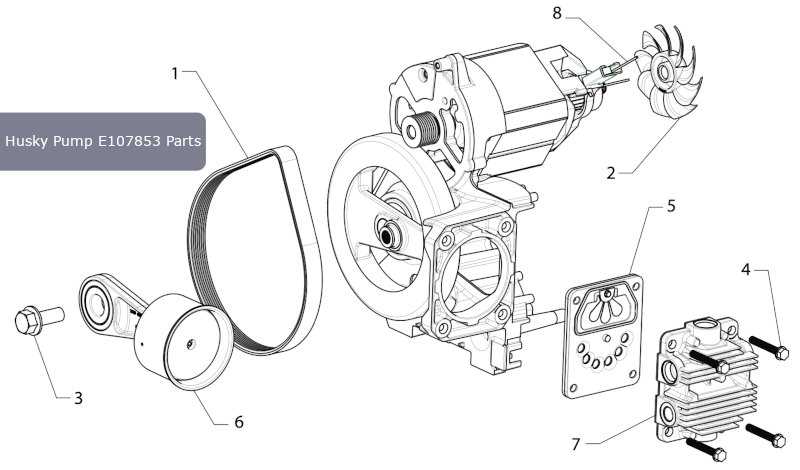

Replacement Parts for Husky Compressors

Ensuring optimal performance of your equipment requires attention to its components. Understanding the availability and functionality of various replacements is essential for maintaining efficiency and longevity. With the right elements, users can enhance their tools and tackle tasks with confidence.

Common Replacement Components

Several essential components are frequently sought after for maintenance. These include motors, pistons, and valves. Each plays a vital role in the functionality of the unit, and having reliable replacements ensures uninterrupted operation.

Where to Find Quality Replacements

Locating high-quality components can significantly impact your equipment’s performance. Authorized retailers and specialized online platforms offer a wide selection of reliable options. Always prioritize verified suppliers to guarantee compatibility and durability of the items.

Safety Features of Air Compressors

Ensuring safety is paramount when working with pressurized equipment. Various mechanisms are incorporated to minimize risks and enhance user protection. These features are designed to prevent accidents and ensure smooth operation, making the equipment safer for both operators and surrounding environments.

| Feature | Description |

|---|---|

| Pressure Relief Valve | This component prevents excessive pressure buildup by releasing air when a set limit is reached. |

| Automatic Shut-off | Automatically turns off the unit when the desired pressure level is achieved, preventing over-inflation. |

| Safety Guard | A protective cover that shields users from moving parts and potential hazards during operation. |

| Thermal Overload Protection | This feature shuts down the unit if it overheats, preventing damage and potential fire hazards. |

| Low Oil Shutdown | Automatically stops operation if oil levels drop too low, protecting the internal components from damage. |

By incorporating these critical safety elements, the risk of injury or equipment failure is significantly reduced, allowing for a safer work environment. Proper maintenance and adherence to safety guidelines further enhance the effectiveness of these protective measures.

Tools Needed for Repairing Parts

Repairing machinery requires a specific set of instruments to ensure efficiency and accuracy. Having the right tools not only simplifies the process but also enhances the quality of the repairs. Below is a list of essential instruments commonly used in maintenance tasks.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening fasteners. |

| Screwdriver Set | For adjusting screws in various components. |

| Pliers | For gripping and bending materials. |

| Torque Wrench | To apply precise torque to fasteners. |

| Multimeter | For testing electrical connections. |

Upgrading Your Air Compressor

Enhancing the performance of your machine can lead to significant improvements in efficiency and functionality. Whether you’re aiming for higher pressure, faster recovery times, or extended lifespan, a thoughtful upgrade strategy can yield impressive results. Understanding the components that contribute to your unit’s operation is crucial for making informed decisions that align with your specific needs.

Choosing the Right Components

Selecting appropriate upgrades begins with identifying the key elements that impact performance. Consider options such as enhanced motors, improved tanks, or advanced regulators. Each component plays a vital role in how effectively your unit operates, so it’s essential to research compatibility and benefits before proceeding.

Installation and Maintenance Tips

Proper installation is paramount to ensure that upgrades perform as intended. Follow manufacturer guidelines carefully and consider consulting professionals if needed. Regular maintenance will also prolong the life of your enhanced system, so establish a routine for checking parts and performing necessary adjustments. This proactive approach will keep your equipment running smoothly for years to come.

Comparing Different Air Compressor Models

When it comes to choosing the right equipment for your needs, exploring various models can significantly impact performance and efficiency. Each unit presents unique features and specifications that cater to different applications, making it essential to understand their distinct advantages and limitations.

Key Features to Consider

Evaluating capabilities such as pressure output, tank size, and motor power is crucial. These elements determine how well the machine performs in specific tasks, whether it’s for professional or home use. A model with higher output may be ideal for heavy-duty projects, while a compact version could suit lighter applications.

Cost vs. Performance

Balancing price and efficiency is vital in the decision-making process. Higher-end models often come with advanced features that enhance durability and functionality, yet budget-friendly options can still provide satisfactory results for everyday tasks. It’s important to assess your requirements and choose accordingly.

Resources for Further Information

For those seeking to deepen their understanding and knowledge of equipment maintenance and repair, a variety of resources are available. These materials provide valuable insights into technical specifications, troubleshooting tips, and enhancement strategies. Whether you are a novice or an experienced user, these resources can guide you through complex tasks and help you make informed decisions.

Online Communities and Forums

Engaging with online communities can be an excellent way to gather information and share experiences. Platforms dedicated to machinery enthusiasts often host discussions, tips, and troubleshooting advice from fellow users. Participating in these forums allows for real-time problem-solving and networking with individuals who have faced similar challenges.

Manufacturer’s Manuals and Guides

Consulting the manufacturer’s documentation is crucial for accessing detailed information regarding operation and maintenance. These guides typically include schematics, recommended practices, and safety protocols. Having a copy of the manual on hand can streamline repairs and ensure adherence to best practices, prolonging the lifespan of the equipment.