Ih 1086 Parts Diagram Overview

The exploration of a renowned agricultural machine reveals the intricate network of elements that contribute to its functionality. Each segment plays a pivotal role, ensuring optimal performance and durability under various operating conditions.

By examining the layout and connections among these individual units, enthusiasts and operators can gain valuable insights into maintenance and troubleshooting. This knowledge is crucial for preserving the longevity and efficiency of such a vital tool in modern farming.

In this discussion, we will delve into the various features and assembly of this iconic model, highlighting the ultimate importance of comprehending its construction for both novice users and seasoned professionals alike.

Understanding the Ih 1086 Parts Diagram

Grasping the intricate layout of machinery components is essential for effective maintenance and repair. A visual representation helps to clarify the relationships and functions of various elements, providing a roadmap for technicians and enthusiasts alike.

This illustration serves as a crucial tool for those looking to enhance their understanding of the machine’s architecture. By analyzing each segment, users can identify essential parts and their interconnections, ultimately leading to improved performance and longevity.

| Component | Description |

|---|---|

| Engine | Powers the entire system, converting fuel into mechanical energy. |

| Transmission | Transfers power from the engine to the wheels, ensuring smooth operation. |

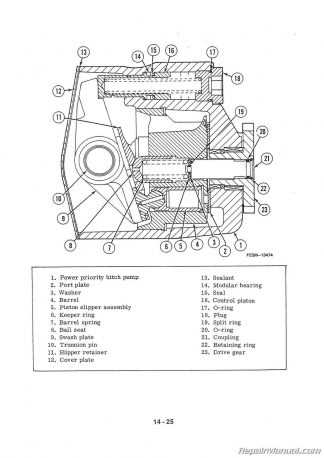

| Hydraulic System | Facilitates movement and control of various attachments and implements. |

| Chassis | Provides the structural framework that supports all components. |

Key Components of the Ih 1086

This section explores the essential elements that contribute to the functionality and efficiency of the machinery, highlighting their roles and significance in the overall performance. Understanding these components can enhance maintenance and operational practices.

Major Elements

- Engine System

- Transmission Mechanism

- Hydraulic Components

- Electrical Systems

Supportive Structures

- Chassis Framework

- Cab Assembly

- Cooling System

- Fuel System

Each of these components plays a pivotal role, ensuring optimal performance and longevity of the equipment.

Benefits of Using a Parts Diagram

Utilizing a visual representation of components can greatly enhance the understanding and maintenance of complex machinery. This approach simplifies the identification of individual elements, streamlining the repair or assembly processes. By providing clarity, such visuals enable users to engage with the equipment more effectively, reducing the risk of errors.

Improved Clarity

A visual schematic serves as an essential tool for both seasoned professionals and novices. The benefits include:

- Quick reference to locate specific components

- Enhanced comprehension of assembly sequences

- Clear differentiation between similar parts

Efficiency in Maintenance

Leveraging these visual aids can lead to significant time savings during upkeep tasks. Key advantages include:

- Minimized downtime through accurate identification

- Facilitated ordering of replacements

- Streamlined troubleshooting processes

Common Issues and Solutions

In the realm of machinery and equipment, various challenges can arise, affecting performance and efficiency. Understanding these common problems and their remedies is essential for maintaining optimal functionality and prolonging the lifespan of your unit.

Performance Deterioration

A decline in efficiency often signals underlying issues, such as wear and tear or misalignment. Regular maintenance checks and timely replacements of worn components can effectively restore performance levels.

Operational Failures

Unexpected breakdowns can occur due to electrical faults or insufficient lubrication. Conducting routine inspections and ensuring proper maintenance practices are in place can prevent these failures, keeping your machinery running smoothly.

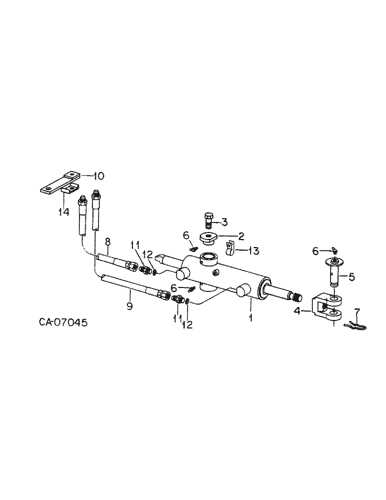

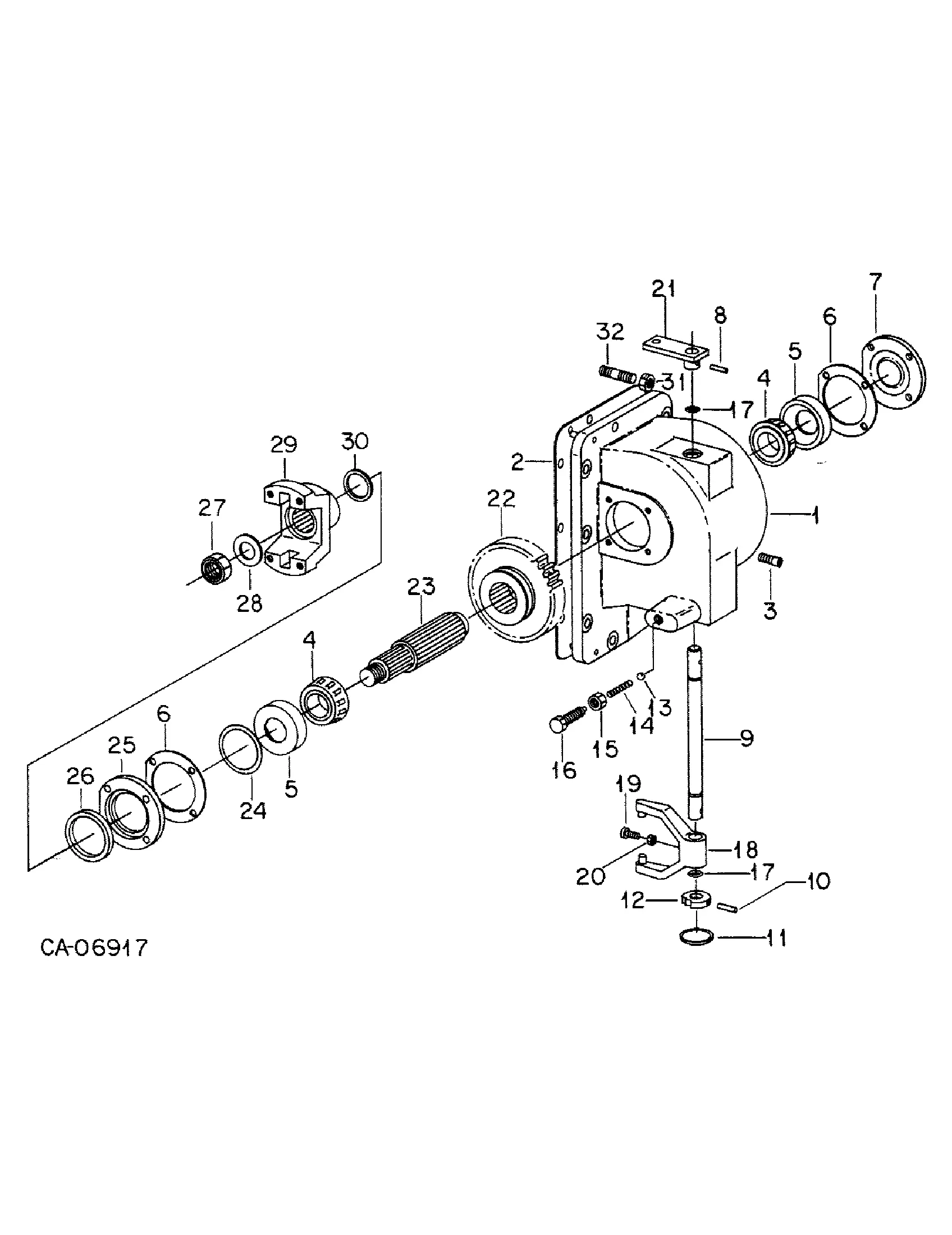

How to Read a Parts Diagram

Understanding the layout of components is crucial for effective assembly and maintenance. Familiarity with symbols and labels can significantly enhance your ability to navigate complex visuals. This guide will provide insights into interpreting these illustrations accurately.

Key Elements to Observe

When examining a visual representation, pay attention to the following elements:

| Element | Description |

|---|---|

| Labels | Identify the names and numbers corresponding to each piece. |

| Connections | Look for lines or arrows indicating how components interact. |

| Legend | A guide that explains symbols used in the illustration. |

Step-by-Step Approach

Begin by familiarizing yourself with the overall layout. Next, focus on each individual component, referencing the labels and connection lines. This systematic approach will enable you to piece together the entire assembly with greater confidence.

Maintenance Tips for Ih 1086

Proper upkeep of your machinery is essential for optimal performance and longevity. Regular maintenance not only prevents breakdowns but also ensures efficient operation. This section outlines key practices that will enhance the reliability of your equipment.

1. Regular Oil Changes: Keep your engine running smoothly by changing the oil and filter at recommended intervals. Fresh oil reduces wear and improves overall efficiency.

2. Check Fluid Levels: Frequently inspect coolant, hydraulic fluid, and fuel levels. Maintaining these fluids at appropriate levels is vital for effective functioning.

3. Tire Maintenance: Ensure tires are properly inflated and aligned. This promotes better traction and extends tire life, ultimately enhancing performance.

4. Inspect Belts and Hoses: Regularly examine belts and hoses for signs of wear or damage. Replacing them promptly can prevent unexpected failures.

5. Clean Air Filters: Keep air filters clean to maintain optimal airflow to the engine. A clean filter improves combustion and efficiency.

6. Battery Care: Check battery connections and clean any corrosion. Ensuring good electrical contact can prevent starting issues.

7. Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations for service intervals and procedures. This ensures you’re taking the right steps for your specific model.

By incorporating these practices into your maintenance routine, you can delve deeper into enhancing the performance and durability of your equipment.

Replacement Parts Availability

In the world of machinery maintenance, having access to essential components is crucial for optimal performance and longevity. When equipment experiences wear or damage, the ability to source reliable substitutes can significantly reduce downtime and enhance operational efficiency.

Availability of these essential items often varies by supplier and region, making it vital for operators to establish strong connections with trusted vendors. Reliable sources not only provide high-quality replacements but also ensure compatibility with existing systems.

Additionally, inventory management plays a pivotal role. Keeping a record of frequently used components helps in anticipating needs and minimizing delays. Regular communication with suppliers can also lead to timely updates on stock and new product offerings.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for achieving effective results. Various instruments play a significant role in ensuring that repairs are performed efficiently and safely. Understanding the tools available and their specific functions can greatly enhance the overall repair experience.

Basic Hand Tools

Hand tools are fundamental to any repair job. A reliable set of wrenches, screwdrivers, and pliers is essential for tackling a wide range of issues. These instruments allow for precision work and facilitate access to tight spaces, making them invaluable for both professionals and DIY enthusiasts. Having a quality toolset at your disposal can make the difference between a simple fix and a frustrating ordeal.

Power Tools for Efficiency

For larger or more complex tasks, power tools are indispensable. Drills, saws, and grinders enable users to complete repairs in a fraction of the time it would take with manual tools. The advantages of using power tools extend beyond speed; they also offer enhanced accuracy and the ability to handle tougher materials. Investing in these tools can significantly improve the quality and efficiency of repair projects.

Assembly Instructions for New Parts

When it comes to integrating new components into your machinery, having clear guidelines is essential for ensuring proper functionality and longevity. This section aims to provide a comprehensive approach to assembling fresh elements, facilitating a smooth and efficient process.

Step 1: Preparation

Before you begin, gather all necessary tools and materials. Ensure your workspace is clean and organized to avoid losing any small items during the assembly. Review any accompanying documentation that outlines specifications or requirements for the new components.

Step 2: Familiarization

Take a moment to understand the structure and design of the components you are working with. Identifying key features and connections will help streamline the assembly process. Pay attention to any labels or identifiers that may guide you in correctly positioning each piece.

Step 3: Assembly Process

Start by connecting larger elements first, ensuring they are securely fastened. Gradually add smaller components, checking that each is aligned properly. Use appropriate fasteners and tools to avoid damaging the materials. Double-check your work as you go along to prevent issues later on.

Step 4: Final Inspection

Once the assembly is complete, conduct a thorough inspection. Verify that all connections are tight and that there are no loose items. It is also beneficial to test the functionality of the newly integrated components before putting the machinery into regular use.

By following these structured instructions, you can ensure that your new elements are assembled effectively, contributing to the overall performance of your equipment.

Upgrading Your Ih 1086 Model

Enhancing the performance and functionality of your agricultural machinery can significantly boost efficiency and productivity. This section will explore various strategies to elevate your equipment, ensuring it meets modern demands and operates at peak levels.

Key Areas for Enhancement

- Engine Optimization: Consider upgrading to a more powerful engine or enhancing fuel efficiency through advanced tuning techniques.

- Hydraulic System Improvements: Implementing upgraded hydraulic components can increase lifting capacity and responsiveness.

- Transmission Upgrades: Explore options for smoother shifting and improved torque transfer to enhance overall drive quality.

Steps to Implement Upgrades

- Assess the current state of your machinery to identify specific needs and potential improvements.

- Research compatible components and technologies that align with your performance goals.

- Consult with professionals or experienced users for recommendations on reputable suppliers and installers.

- Plan and execute upgrades systematically, ensuring minimal downtime and thorough testing after each enhancement.

By focusing on these critical areas and following a structured approach, you can significantly improve the capabilities of your machinery, adapting it to meet contemporary agricultural challenges.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionalities. Understanding these elements is crucial for effective maintenance and operation. Below, we provide answers to frequently posed questions that can help clarify doubts and enhance knowledge about these essential items.

What Should I Consider When Selecting Components?

When choosing elements for your equipment, it’s vital to consider compatibility, quality, and specifications. Ensure that the selected components match your model’s requirements to avoid any operational issues. Additionally, researching manufacturers can provide insight into reliability and performance.

How Can I Identify a Faulty Component?

Identifying a malfunctioning item often involves observing performance discrepancies or unusual noises. Regular inspections can help catch early signs of wear and tear. Consulting a manual or professional can assist in diagnosing issues accurately and determining the best course of action for replacement or repair.