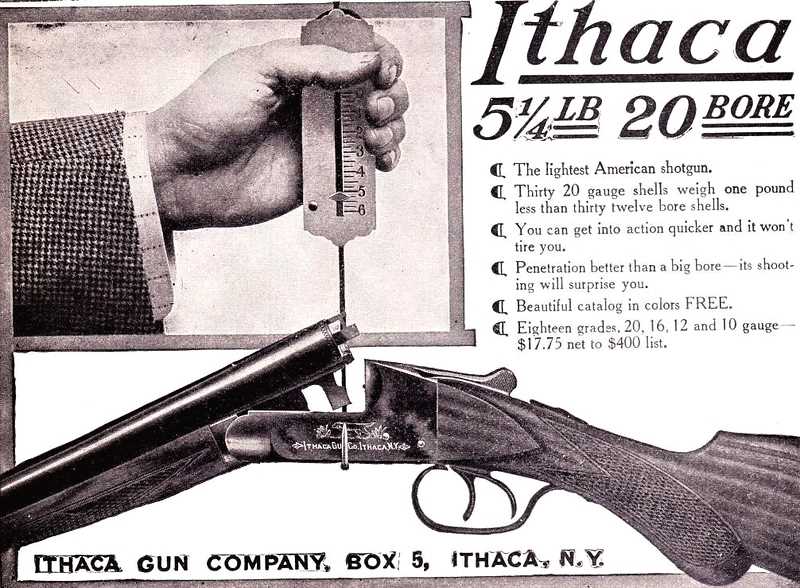

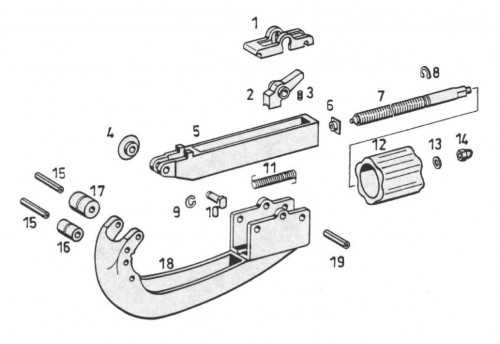

Ithaca Flues Parts Diagram for Easy Reference

In the realm of complex systems, a thorough comprehension of individual elements and their interconnections is vital. This knowledge not only enhances functionality but also contributes to effective maintenance and troubleshooting. By exploring the intricate network of various components, one can gain insights into how these parts synergistically work together to achieve optimal performance.

Every assembly features a unique structure that dictates how elements interact and operate. An in-depth look at this configuration reveals critical relationships that might otherwise go unnoticed. Understanding the layout and function of each element enables users to address issues promptly and ensure longevity in performance.

Whether for enthusiasts or professionals, delving into the specifics of such systems fosters a greater appreciation for the craftsmanship involved. By examining how each unit fits into the broader scheme, one can unlock the potential for enhancements and innovations that elevate the entire assembly’s efficacy.

Ithaca Flues Parts Overview

This section delves into the essential components that contribute to the functionality of a specific system. Understanding these elements is crucial for both maintenance and enhancement, ensuring optimal performance and longevity. Each element plays a vital role, and familiarity with their characteristics can lead to more informed decisions during upgrades or repairs.

Key Components

Among the various elements, some are fundamental for the system’s overall operation. For instance, the connectors facilitate seamless interaction between different sections, while the insulation materials play a critical role in maintaining efficiency. Recognizing the significance of these components helps in troubleshooting issues and implementing improvements.

Maintenance Tips

Regular inspection of the various elements is essential for sustaining performance. Look for signs of wear or damage, and ensure that all connections are secure. Additionally, using appropriate cleaning techniques can prevent buildup that may hinder efficiency. Adopting a proactive approach will ultimately enhance the system’s reliability and functionality.

Understanding Flue System Components

The intricate network responsible for venting gases from combustion processes consists of various essential elements. Each component plays a crucial role in ensuring safety, efficiency, and optimal performance. By grasping the function and significance of these parts, one can better appreciate the overall system’s effectiveness.

Chimneys serve as the primary exit for exhaust, directing harmful byproducts away from living spaces. Proper construction and maintenance are vital to prevent blockages that could lead to dangerous situations.

Vent Pipes connect the appliance to the chimney, facilitating the safe transport of fumes. These tubes must be of the correct diameter and material to withstand high temperatures and corrosive substances.

Cap and Screen assemblies at the top of the chimney prevent rain and debris from entering while allowing gases to escape freely. They are critical for maintaining the system’s integrity and functionality.

Cleanouts are access points that allow for maintenance and cleaning, ensuring that buildup is removed regularly. This prevents chimney fires and promotes efficient operation.

Understanding these vital elements is the ultimate key to ensuring the safe and effective operation of any venting system, leading to a healthier environment. Proper knowledge and maintenance can make all the difference in performance and longevity.

Common Issues in Flue Systems

Flue systems play a crucial role in venting gases and ensuring safe operation of heating appliances. However, several challenges can arise, affecting efficiency and safety. Understanding these common problems is essential for maintaining optimal performance.

Blockages

One frequent issue involves obstructions that hinder airflow. These can result from debris, animal nests, or soot buildup, leading to dangerous conditions.

Leaks

Another significant concern is the presence of leaks in the structure. Such breaches can allow harmful gases to escape into living spaces, posing serious health risks.

| Issue | Potential Causes | Consequences |

|---|---|---|

| Blockages | Debris, animal nests, soot | Reduced efficiency, risk of backdraft |

| Leaks | Wear and tear, poor installation | Gas exposure, health hazards |

Maintenance Tips for Ithaca Flues

Regular upkeep is essential for ensuring the optimal performance and longevity of your system. By following a few simple guidelines, you can prevent issues and enhance efficiency, leading to a more reliable experience.

Routine Inspection

Conducting frequent examinations can help identify wear and tear early. Look for signs of corrosion, blockages, or any unusual sounds that may indicate underlying problems.

Cleaning Procedures

Keeping the components clean is vital. Accumulation of debris can hinder performance. Use appropriate tools and techniques to ensure all surfaces are clear and functioning effectively.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Deep Cleaning | Seasonally |

| Component Replacement | As Needed |

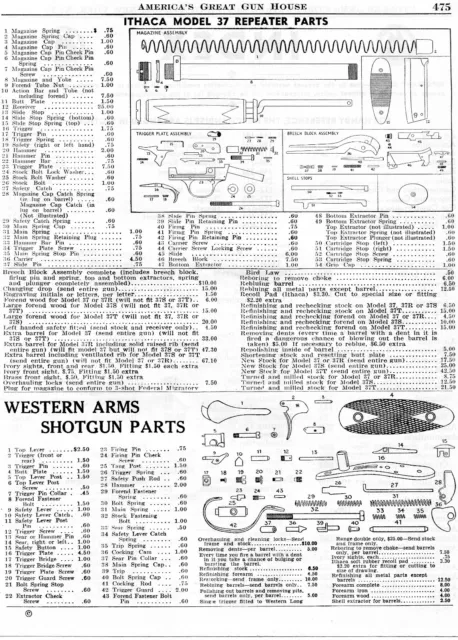

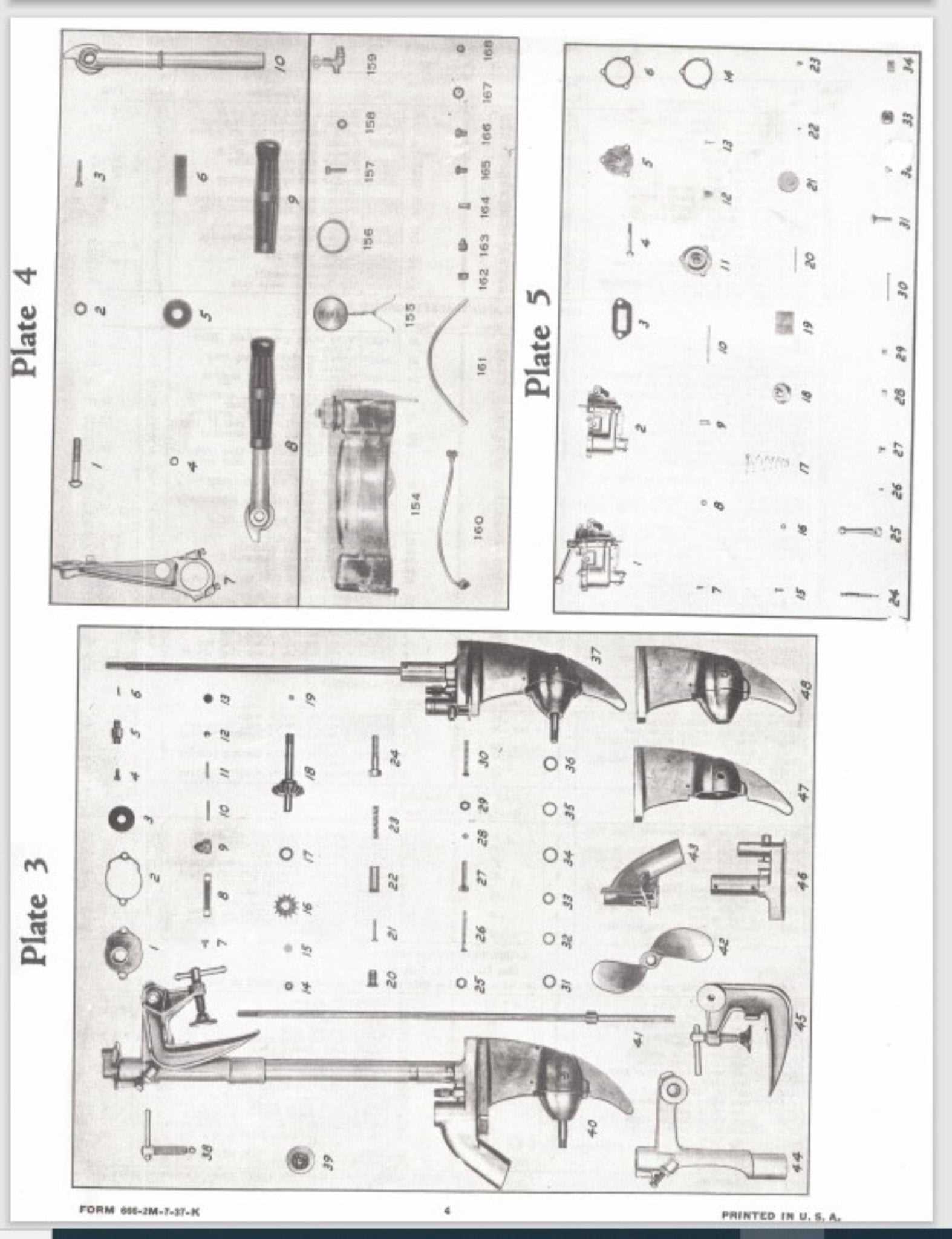

Identifying Replacement Parts Easily

Understanding how to locate and recognize essential components can significantly enhance maintenance and repair efforts. A clear approach enables individuals to swiftly find the right items, reducing downtime and ensuring efficient operation. This guide emphasizes key strategies for streamlining the identification process, making it accessible for everyone.

Utilizing Visual Resources

Visual aids, such as charts and illustrations, play a crucial role in simplifying the identification of components. These tools allow users to connect names with images, facilitating a quicker understanding of each item’s function and placement within the system.

Consulting Detailed Manuals

Comprehensive manuals provide valuable insights into the specifics of each component. By referring to these resources, individuals can gain a deeper understanding of compatibility and technical requirements, ensuring that replacements meet the necessary standards for performance and reliability.

Safety Precautions for Flue Repairs

When undertaking maintenance tasks related to ventilation systems, ensuring safety is paramount. Proper precautions can prevent accidents and injuries while ensuring a successful repair process.

First, always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks, to shield yourself from harmful debris and fumes. Additionally, ensure that the area is well-ventilated to minimize exposure to hazardous substances.

Before starting any work, disconnect all power sources and ensure the system is completely cool. This step is crucial to avoid electrical shocks and burns. Moreover, it’s advisable to have a fire extinguisher nearby in case of emergencies.

Lastly, if you encounter significant damage or are unsure about the repair process, consult a professional. Seeking expert advice can prevent further complications and ensure compliance with safety standards.

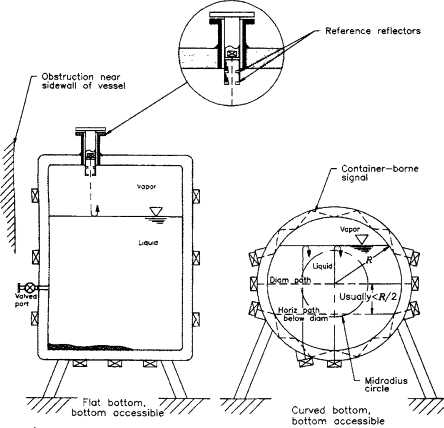

Diagram Interpretation for Flue Systems

Understanding the layout and components of exhaust systems is essential for effective installation and maintenance. By analyzing the visual representations of these structures, one can gain insights into their functionality and interrelationships. This knowledge aids in identifying potential issues and ensuring optimal performance.

Each segment depicted serves a specific role in the overall system, contributing to efficient ventilation and emission control. Recognizing how various elements connect and operate together helps in troubleshooting and enhances safety protocols. Moreover, familiarity with these schematics is crucial for professionals who work with such configurations regularly.

When reviewing the visual outlines, attention should be paid to labels and annotations that clarify each component’s purpose. Understanding the flow of air and gases within these systems is vital for maintaining compliance with regulatory standards. Clear interpretation of these visuals not only supports effective maintenance but also ensures that installations adhere to best practices.

Tools Needed for Flue Maintenance

Proper upkeep of your ventilation system is crucial for ensuring safety and efficiency. A variety of specialized instruments are essential for thorough inspection and maintenance, helping to prevent potential hazards and improve overall performance.

Essential Instruments

Among the key tools required are inspection cameras, which allow for a clear view of internal components. Additionally, brushes of various sizes are vital for clearing blockages and buildup. A reliable vacuum is also important for removing debris and ensuring a clean working environment.

Safety Gear

While focusing on maintenance tools, don’t overlook safety equipment. Gloves and goggles protect against harmful particles, while respirators ensure clean air during cleaning tasks. Prioritizing safety will enhance your maintenance efforts and protect your health.

Where to Find Parts Online

In today’s digital age, locating specific components for various systems has become increasingly convenient. Numerous online platforms cater to individuals seeking replacements or upgrades for their equipment. These resources provide a wealth of options, often featuring detailed descriptions and specifications to aid in the selection process.

One effective approach is to explore specialized websites dedicated to the industry. These platforms typically offer a vast inventory and can connect users with knowledgeable representatives. Additionally, online marketplaces can serve as valuable hubs for both new and used items, allowing for price comparisons and customer reviews to ensure informed decisions.

Furthermore, forums and community groups dedicated to enthusiasts can provide insights and recommendations for reliable sources. Engaging with fellow users can lead to discovering lesser-known vendors who may offer unique products or competitive pricing.

Finally, it’s advisable to check the official websites of manufacturers. Many provide direct sales options or can direct customers to authorized retailers. This ensures authenticity and quality, which are crucial when selecting components for maintenance or enhancement.

Installation Process for Flue Parts

Ensuring a proper setup for ventilation systems is crucial for optimal performance and safety. This section outlines the essential steps to effectively install components that facilitate the safe expulsion of gases. Each stage requires careful attention to detail and adherence to guidelines to prevent potential hazards.

Begin by gathering all necessary components and tools. Review the manufacturer’s instructions to familiarize yourself with the required specifications and recommendations. It is advisable to conduct a thorough inspection of the existing structure to identify any necessary modifications or preparations needed prior to installation.

Next, prepare the location for installation. This may involve clearing the area of debris and ensuring that all surfaces are clean and dry. Mark the placement of each element according to the guidelines, making sure to account for adequate spacing and alignment.

As you proceed, connect the components following the specified sequence. Ensure that all connections are secure and watertight. Utilize appropriate sealing materials to prevent leaks, which can compromise the system’s efficiency and safety. It is also important to verify that all elements are properly supported to withstand operational stresses.

Once the assembly is complete, conduct a thorough inspection to confirm that everything is installed according to the guidelines. Perform tests to ensure proper functionality, checking for any signs of leaks or improper airflow. If issues arise, make necessary adjustments before concluding the installation.

Finally, maintain a comprehensive record of the installation process, including any modifications made and the materials used. Regular maintenance checks will help to ensure ongoing performance and safety, providing peace of mind for all users.

Flue System Performance Optimization

Enhancing the efficiency of exhaust pathways is crucial for ensuring optimal operation in various heating and ventilation systems. By focusing on design, maintenance, and airflow dynamics, significant improvements can be achieved. This not only boosts performance but also contributes to energy savings and reduced emissions.

Effective airflow management is a key component in achieving superior functionality. Ensuring unobstructed passageways and minimizing bends can significantly reduce resistance, allowing for a smoother exit of combustion byproducts. Regular inspections are essential to identify blockages or damages that could impair system efficiency.

Material selection also plays a vital role in enhancing the durability and effectiveness of these systems. Utilizing high-quality, corrosion-resistant materials can prevent degradation over time, ensuring a longer lifespan and better performance. Furthermore, incorporating thermal insulation can help maintain optimal temperatures, reducing heat loss.

System balancing is another important aspect to consider. Properly calibrated components ensure that each part operates harmoniously, maximizing overall system effectiveness. This may involve adjusting fans, dampers, or other mechanisms to achieve a balanced flow throughout the entire setup.

Lastly, regular maintenance and timely upgrades are necessary to adapt to changing demands and technological advancements. By proactively addressing any inefficiencies, users can ensure that their systems operate at peak performance while adhering to current standards and regulations.

Historical Context of Ithaca Flues

The evolution of heating and ventilation systems reflects significant technological advancements and cultural shifts over the centuries. Understanding the historical backdrop provides insight into how these innovations have shaped domestic and industrial environments.

During the late 19th and early 20th centuries, the demand for efficient heating solutions surged. This era marked a transition from traditional methods to more sophisticated designs, aimed at enhancing energy efficiency and improving air quality. Manufacturers began to experiment with various materials and configurations, leading to the development of more reliable systems.

Moreover, the rise of urbanization and the industrial revolution played a pivotal role. As cities expanded, the need for effective heating systems became paramount to accommodate the growing population. Societal changes influenced preferences and requirements, prompting innovations that catered to both residential and commercial needs.

In summary, the historical landscape surrounding these systems is characterized by a blend of technological innovation, societal demands, and evolving environmental considerations, all contributing to the ultimate design and functionality we see today.