Understanding the Jungheinrich EJE 120 Parts Diagram

In the realm of industrial machinery, having a comprehensive understanding of the arrangement and functionality of various elements is crucial. This knowledge empowers operators and technicians to maintain efficiency and address issues effectively. A clear visual representation of these components enhances troubleshooting and facilitates seamless operations.

Illustrative schematics serve as essential tools, enabling users to identify each piece’s role within the system. By delving into these diagrams, one can uncover the ultimate relationships and connections among different parts, leading to improved maintenance strategies and enhanced performance.

Moreover, these detailed representations not only assist in identifying wear and tear but also guide users in the assembly and disassembly processes. Such clarity is invaluable, especially in complex systems where precision is paramount for optimal functionality.

Understanding Jungheinrich EJE 120 Components

Gaining insight into the various elements of a material handling vehicle is essential for optimal performance and maintenance. Each component plays a crucial role in the overall functionality, ensuring efficiency and safety in operations. Familiarity with these parts not only aids in troubleshooting but also enhances the ability to make informed decisions regarding repairs and replacements.

Key Elements of the Equipment

Among the primary components are the lifting mechanism, which facilitates vertical movement of loads, and the steering system that ensures maneuverability in tight spaces. Additionally, the power unit, typically comprising electric motors and batteries, provides the necessary energy for operations. Understanding the interplay between these parts is vital for maintaining operational efficiency.

Maintenance Considerations

Regular inspections of these elements can prevent unexpected breakdowns and extend the lifespan of the equipment. Lubrication of moving parts and checking electrical connections are fundamental tasks. Identifying wear and tear early can save time and resources in the long run. A proactive approach to maintenance will ultimately lead to enhanced reliability and productivity in the workplace.

Overview of EJE 120 Parts Diagram

This section provides a comprehensive look at the components of a specific model, highlighting their arrangement and function. Understanding the layout is essential for maintenance and troubleshooting, allowing users to identify and access individual elements effectively.

Importance of Component Arrangement

The configuration of elements plays a crucial role in the overall performance and reliability of the machine. A clear representation helps technicians quickly locate parts, ensuring timely repairs and minimizing downtime.

Key Elements and Their Functions

Each component serves a distinct purpose, contributing to the efficient operation of the equipment. Familiarity with these parts aids users in making informed decisions regarding maintenance and replacement, ultimately enhancing the longevity of the machinery.

Key Features of EJE 120 Model

The innovative design of this electric pallet truck emphasizes efficiency, reliability, and user-friendliness. It is engineered to facilitate smooth operations in various settings, providing both operators and businesses with optimal performance and productivity. The focus is on creating a machine that not only meets but exceeds the expectations of modern logistics.

Ergonomic Design

The truck’s ergonomic features significantly enhance user comfort. With an adjustable tiller arm and intuitive controls, operators can navigate with ease, reducing fatigue during prolonged use. This design prioritizes safety and operational efficiency.

Advanced Technology

Incorporating cutting-edge technology, this model boasts enhanced battery management and energy efficiency. The intelligent systems allow for seamless operation while maximizing the lifespan of the equipment. These technological advancements ensure that the truck can handle demanding tasks while maintaining optimal performance.

| Feature | Description |

|---|---|

| Load Capacity | Designed to support substantial loads, facilitating heavy lifting with ease. |

| Battery Life | Equipped with a high-capacity battery for extended operational hours. |

| Compact Design | Ideal for navigating narrow aisles and tight spaces. |

| Safety Features | Includes multiple safety mechanisms to protect both the operator and the load. |

Importance of Accurate Parts Identification

Correctly identifying components is crucial for ensuring efficiency and longevity in machinery. Accurate recognition prevents costly mistakes and enhances operational performance, allowing for smooth functionality and reduced downtime.

Benefits of Proper Component Recognition

- Minimizes downtime by ensuring the right parts are used during repairs.

- Improves safety by preventing mismatched components that could lead to malfunctions.

- Enhances maintenance processes, allowing for timely interventions and upgrades.

Consequences of Misidentification

- Increased repair costs due to unnecessary replacements.

- Potential damage to equipment, leading to further operational issues.

- Decreased productivity from unexpected breakdowns.

Common Issues with EJE 120 Parts

When operating electric pallet trucks, users may encounter various challenges related to components. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the equipment. Key areas often require attention, including wear and tear, electrical malfunctions, and mechanical failures.

Wear and Tear: Frequent use can lead to significant deterioration of essential elements. Components such as wheels and forks may suffer from abrasion, impacting performance. Regular inspections and timely replacements are crucial to prevent operational disruptions.

Electrical Issues: Malfunctions in the electrical system can lead to erratic behavior or complete failure. Common symptoms include inconsistent power delivery or issues with the battery. Ensuring proper maintenance of the wiring and connections can mitigate these risks.

Mechanical Failures: Problems such as misalignment or lubrication deficiencies can cause operational inefficiencies. Components might not function smoothly, leading to increased wear or even breakdowns. Routine checks and proper lubrication are essential to keep the equipment running smoothly.

Addressing these issues promptly can enhance the reliability and efficiency of your equipment, ultimately supporting a more productive work environment.

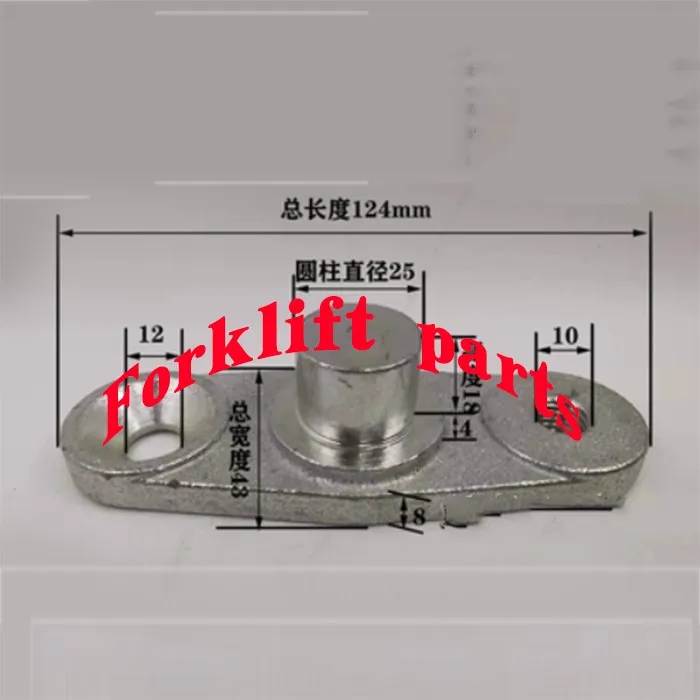

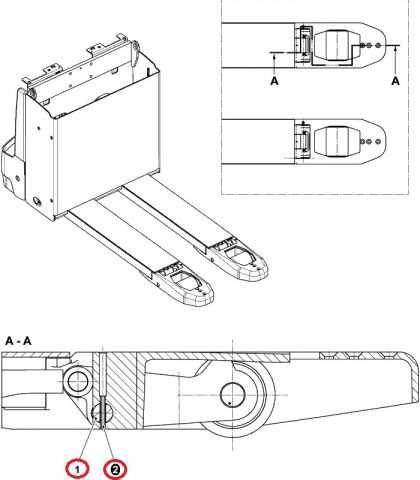

How to Read the Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair tasks. These visual guides provide a detailed representation of various components, enabling users to identify, locate, and comprehend each element’s function within a larger system.

Identifying Components

Begin by familiarizing yourself with the symbols and labels used in the illustration. Each part is usually numbered or marked, allowing for easy cross-reference with the corresponding list of components. Pay attention to the scale and orientation to accurately visualize the layout.

Interpreting Relationships

Next, delve into the connections between different elements. Understanding how parts interact and fit together is essential for troubleshooting and assembly. Look for arrows or lines that indicate movement or linkage, as these can provide insights into the operational mechanics.

Essential Tools for Maintenance

Proper upkeep of machinery is crucial for optimal performance and longevity. A well-equipped toolkit ensures that any necessary repairs or adjustments can be made efficiently, preventing costly downtime and extending the life of the equipment.

Basic Hand Tools

- Wrenches: Essential for tightening and loosening bolts.

- Screwdrivers: Necessary for various fastening tasks.

- Pliers: Useful for gripping and bending components.

Specialized Equipment

- Multimeter: For electrical diagnostics and troubleshooting.

- Torque Wrench: Ensures proper tension on fasteners.

- Grease Gun: Important for lubrication of moving parts.

Having these tools readily available can make maintenance tasks more manageable and effective.

Where to Find Replacement Parts

When it comes to sourcing components for your equipment, identifying reliable avenues is crucial. Numerous options exist for acquiring the necessary items, ensuring your machinery remains operational and efficient.

Online marketplaces offer a vast selection of components, often with competitive pricing. Websites dedicated to industrial equipment typically feature a range of products and may provide useful filters to help narrow down your search. Additionally, these platforms often include customer reviews, enhancing confidence in your purchase.

Local suppliers can also be a valuable resource. Establishing a relationship with nearby distributors not only allows for immediate access to items but can also lead to expert advice and support. Many suppliers maintain inventories of essential components, enabling quick turnaround times.

Manufacturer representatives often have extensive knowledge about their products and can guide you in selecting the right items. Reaching out directly can also reveal exclusive offers or promotions that might not be advertised elsewhere.

Finally, consider engaging with online forums and communities. Enthusiasts and professionals often share insights and recommendations on where to find specific components. These platforms can serve as a treasure trove of information, connecting you with trusted sources and additional resources.

Impact of Regular Maintenance Practices

Consistent upkeep of machinery is crucial for ensuring optimal performance and longevity. By adhering to a structured maintenance routine, operators can significantly reduce the likelihood of breakdowns and enhance efficiency. This proactive approach not only preserves equipment integrity but also fosters a safer working environment.

| Benefits | Description |

|---|---|

| Increased Lifespan | Regular checks and repairs extend the operational life of equipment. |

| Cost Efficiency | Preventative measures can minimize unexpected repair costs. |

| Safety Enhancement | Routine inspections help identify potential hazards before they escalate. |

| Operational Reliability | Well-maintained machines perform consistently and efficiently. |

Safety Considerations During Repairs

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Proper precautions and awareness of potential hazards can significantly reduce risks associated with mechanical servicing. Prioritizing safety not only protects personnel but also enhances the efficiency of repair processes.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and hard hats. These items serve as a barrier against injuries from sharp objects, flying debris, or chemical exposure, creating a safer work environment.

Work Area Organization

Keep the work area tidy and well-organized. A clutter-free space minimizes tripping hazards and allows for quick access to tools and materials. Additionally, ensuring adequate lighting can enhance visibility, further promoting safe practices during repair tasks.

Understanding Warranty and Support Options

When investing in industrial machinery, it’s essential to consider the available protection plans and assistance services. These options ensure that users have access to resources that enhance the longevity and performance of their equipment. Understanding the specifics of these services can significantly impact the overall efficiency and reliability of operations.

Warranty coverage typically encompasses repairs or replacements for defective components within a specified timeframe. This safety net provides peace of mind, knowing that unexpected issues won’t lead to significant financial burdens. It’s crucial to review the terms and conditions, as different models may offer varying levels of protection.

Additionally, support services play a vital role in maintaining equipment functionality. These services can include technical assistance, troubleshooting, and routine maintenance. Establishing a solid relationship with a support team can help resolve potential problems swiftly, minimizing downtime and enhancing productivity.

Ultimately, understanding both warranty and support options empowers users to make informed decisions that align with their operational needs. By ensuring comprehensive coverage and reliable assistance, companies can safeguard their investments and streamline their workflows.

Upgrading Your EJE 120 Efficiently

Enhancing the performance of your equipment can lead to improved productivity and longevity. By focusing on key components and implementing strategic upgrades, you can ensure that your machinery operates at its best. Understanding the various options available will allow you to make informed decisions that optimize functionality.

Assessing Current Components: Begin by evaluating the existing parts of your machine. Identify any wear and tear or inefficiencies that could be addressed through upgrades.

Researching Upgrades: Investigate available enhancements tailored to your specific model. This might include modern technologies or higher-grade materials that can significantly improve performance.

Installation and Maintenance: Proper installation of new components is crucial. Ensure that you follow manufacturer guidelines and consider professional assistance if needed. Regular maintenance post-upgrade will further enhance durability and efficiency.

Evaluating Cost vs. Benefit: Finally, analyze the financial implications of the upgrades. Weigh the costs against the potential gains in efficiency and productivity to determine the ultimate value of your investments.