Kohler SV830 Parts Diagram Overview

In the realm of small machinery, grasping the intricate layout of engine components is essential for effective maintenance and troubleshooting. Each unit comprises a series of interconnected elements that work harmoniously to ensure optimal performance. Recognizing the specific arrangement and function of these pieces can significantly enhance one’s ability to diagnose issues and carry out repairs.

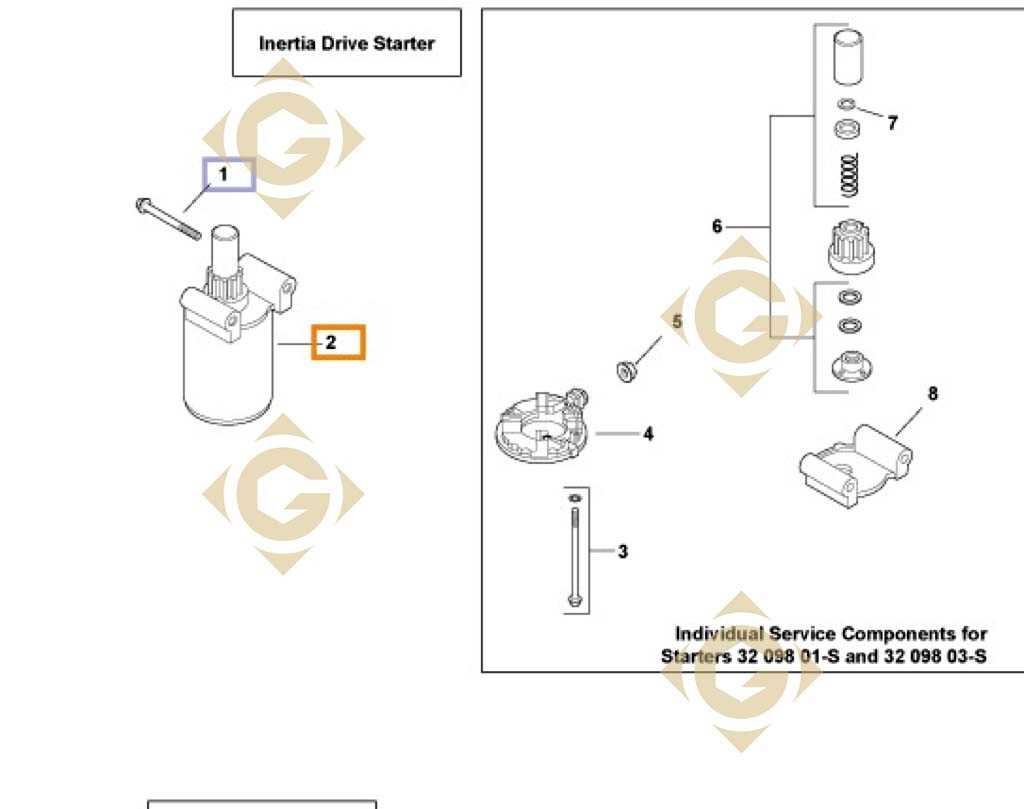

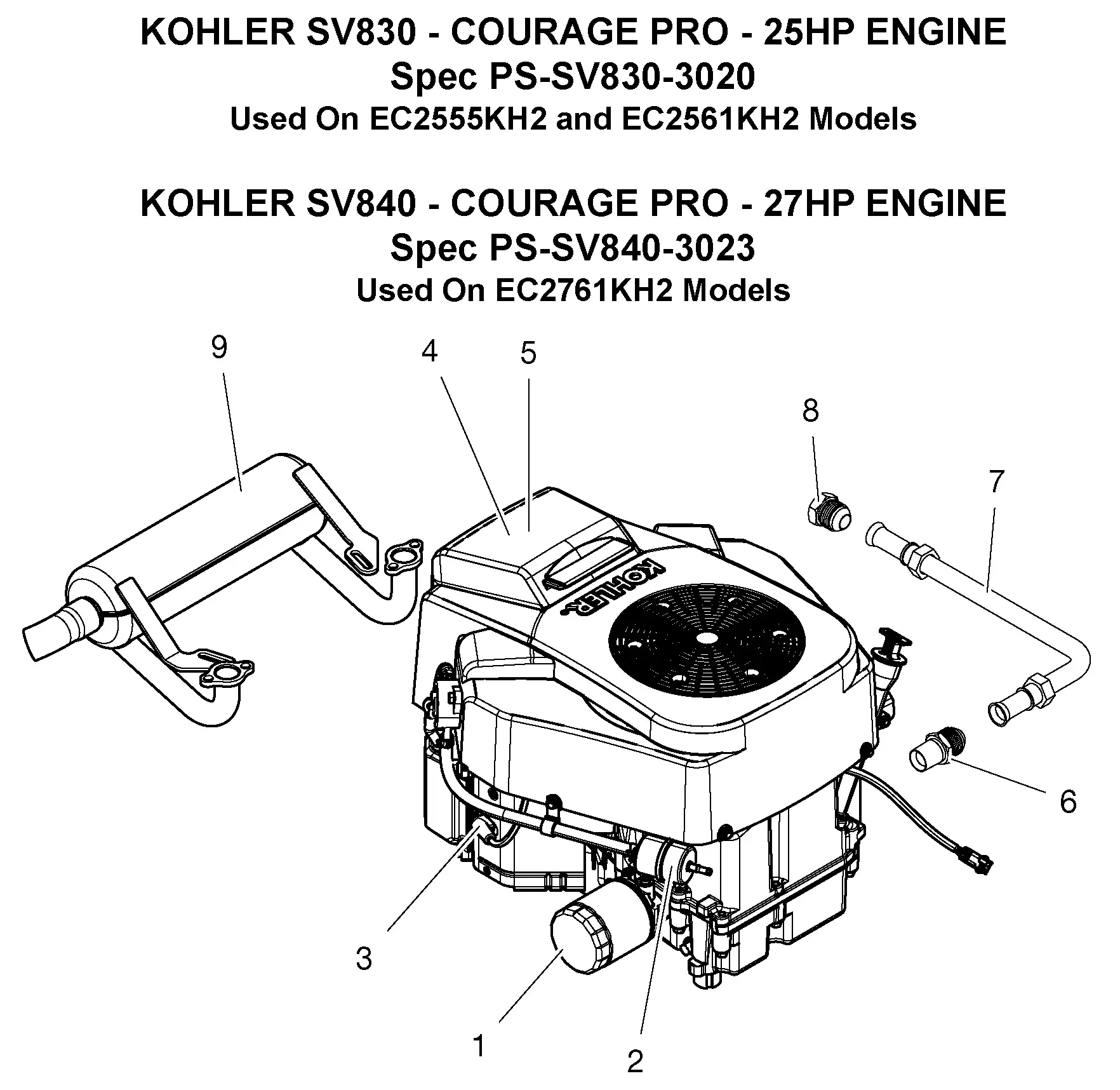

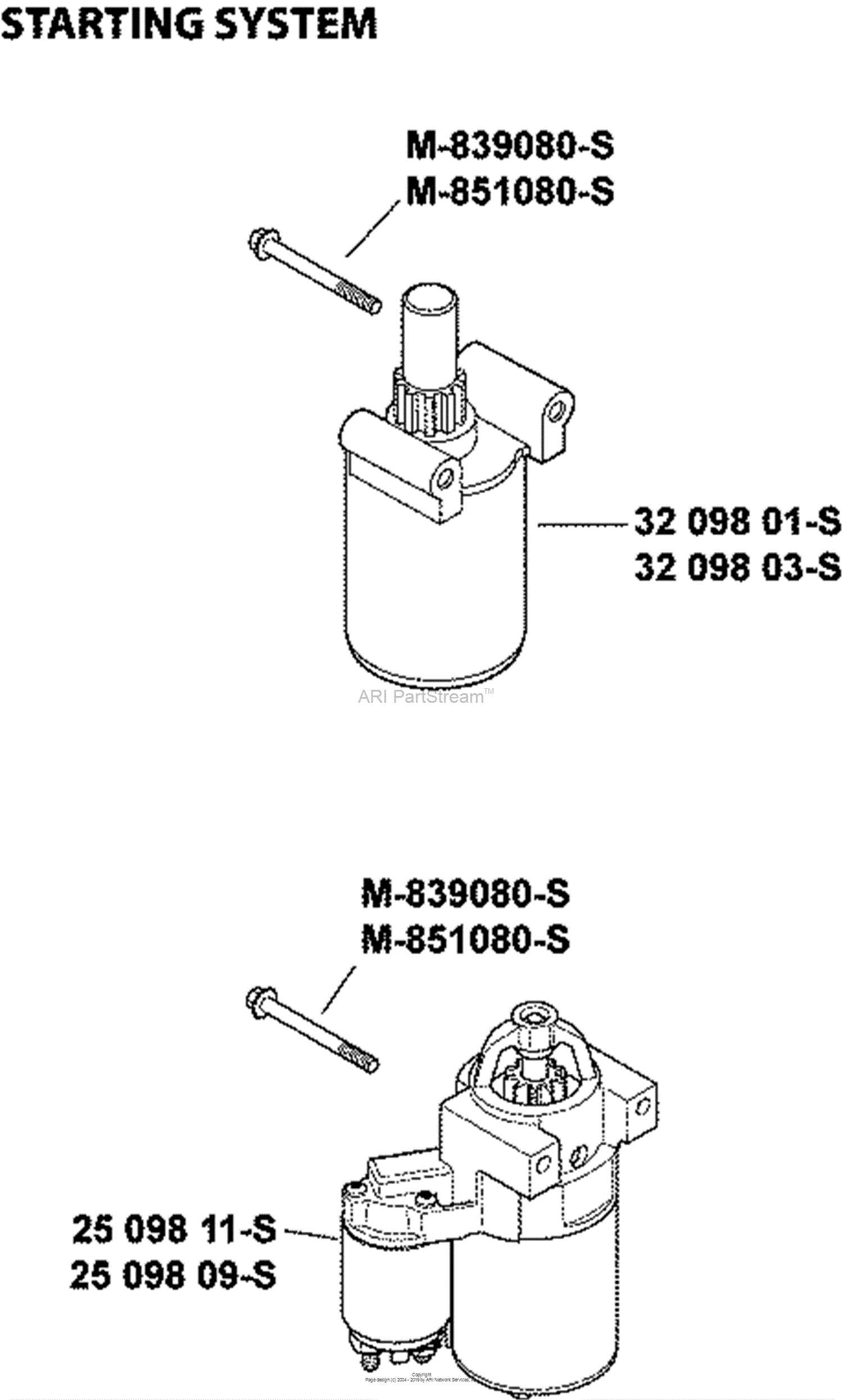

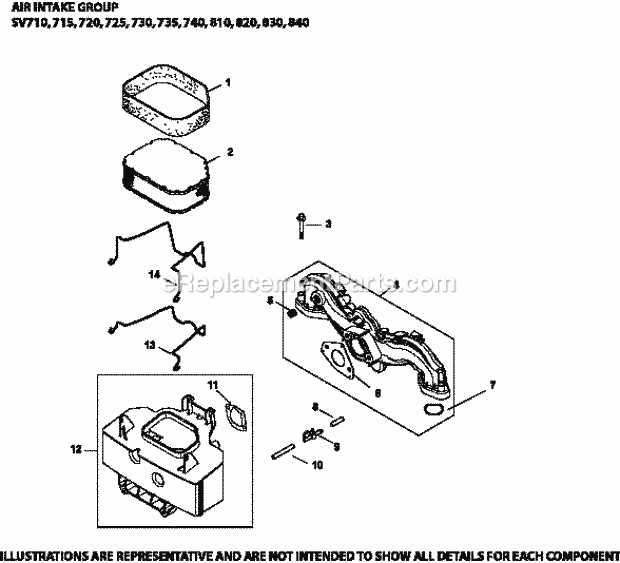

Visual representations of engine assemblies serve as invaluable tools for both novice enthusiasts and seasoned technicians. These illustrations provide clarity, showcasing the relationship between various components and highlighting their individual roles within the larger system. By familiarizing oneself with these layouts, individuals can navigate repairs more confidently and efficiently.

Moreover, having a clear reference point can streamline the process of sourcing replacements. Understanding the names and functions of each part aids in identifying the correct components needed for restoration or enhancement. As a result, this knowledge not only supports maintenance efforts but also fosters a deeper appreciation for the engineering behind small engines.

Understanding Kohler SV830 Engines

Grasping the intricacies of these robust power units is essential for both enthusiasts and professionals in the field. These engines are known for their reliability and performance in various applications, making them a staple in the industry. By delving into their components and functionality, one can appreciate the engineering that goes into creating such dependable machinery.

Key Features

These engines come equipped with a variety of features that enhance their efficiency and usability. Among the most notable are their air-cooled design and multiple cylinders, which work together to provide a powerful output while maintaining optimal temperature control. Understanding these attributes helps in recognizing their advantages in different operational contexts.

Component Overview

The inner workings of these engines can be complex, but they are essential for effective maintenance and troubleshooting. Below is a summary table outlining some of the primary components and their functions:

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, converting fuel into mechanical energy. |

| Piston | Moves up and down within the cylinder, creating pressure and enabling power generation. |

| Crankshaft | Transforms linear motion from the piston into rotational energy to drive the machine. |

| Fuel System | Delivers the necessary fuel to the combustion chamber for efficient operation. |

| Ignition System | Initiates combustion, ensuring timely energy release for optimal performance. |

By familiarizing oneself with these components, one can better understand maintenance needs and troubleshooting strategies, ultimately leading to enhanced performance and longevity of the engine.

Parts Overview for SV830 Model

This section provides a comprehensive look at the components of the specific engine model, highlighting their significance and function. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Engine Block: The central structure that houses various internal parts, providing the necessary framework for the engine’s operation. Its durability is essential for maintaining overall stability.

Piston Assembly: This key component converts combustion energy into mechanical movement. The efficiency of the engine relies heavily on the condition and precision of the piston.

Crankshaft: Serving as the core of the engine’s mechanical system, it translates linear motion into rotational energy, powering various systems effectively.

Valves: These regulate the intake of air and fuel as well as the exhaust of combustion gases, playing a pivotal role in the efficiency and power output of the engine.

Fuel System: Comprising injectors and filters, this system is responsible for delivering the right amount of fuel to the combustion chamber, ensuring optimal performance.

Cooling System: Maintaining appropriate operating temperatures, this system prevents overheating, which can lead to severe damage and inefficiencies.

Electrical Components: Including the ignition system and sensors, these elements ensure reliable starting and monitoring of engine functions, contributing to overall performance.

Understanding the individual functions and importance of these components allows for informed maintenance decisions, promoting efficient operation and enhancing the lifespan of the engine.

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding the assembly and functionality of machinery. Such illustrations provide users with a clear overview, making it easier to identify individual elements and their respective positions within the system.

Having access to these visual aids can significantly enhance maintenance procedures. Technicians can quickly locate the necessary items for repairs, ensuring that tasks are completed efficiently and accurately. This reduces downtime and improves overall productivity.

Moreover, a well-crafted illustration fosters better communication among team members. It serves as a universal reference point, allowing individuals to discuss and troubleshoot issues without ambiguity. This collaborative approach ultimately leads to more effective problem-solving and decision-making.

In addition, familiarity with these visuals can empower operators. Understanding the layout and functions of various components can boost confidence in handling machinery, leading to improved operational safety and performance.

Overall, a detailed visual guide is an indispensable tool that supports maintenance, enhances teamwork, and promotes a deeper understanding of equipment operation.

Common Components in SV830 Engines

Understanding the essential elements of these engines is crucial for maintenance and performance optimization. Various parts work together to ensure smooth operation and reliability, contributing to the overall efficiency of the machine.

| Component | Description |

|---|---|

| Cylinder Head | Encloses the combustion chamber, housing valves and spark plugs. |

| Piston | Moves up and down within the cylinder, converting pressure into mechanical energy. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Fuel System | Delivers the necessary fuel for combustion, including filters and injectors. |

| Ignition System | Initiates combustion through spark generation. |

| Cooling System | Maintains optimal operating temperatures to prevent overheating. |

How to Interpret Parts Diagrams

Understanding technical illustrations can be a daunting task for many. However, these visual representations serve as essential tools for identifying components and their relationships within a system. Mastering the ability to read and analyze these schematics enables users to diagnose issues and facilitate maintenance effectively.

Familiarizing with Symbols and Notations

Each illustration contains specific symbols that denote various elements. Recognizing these icons is crucial, as they often differ from one model to another. Pay attention to the legends provided, which explain the meaning of each symbol. Additionally, some diagrams may include color codes that indicate particular functions or conditions, further aiding in the comprehension of the layout.

Understanding Relationships and Layout

Analyzing the arrangement of components within the illustration is equally important. Look for connections that illustrate how parts interact with one another. Identifying these relationships allows for a deeper understanding of how the entire system operates. Consider the flow of energy or materials, as this insight can help pinpoint potential issues and enhance troubleshooting efforts.

Key Maintenance Tips for SV830

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Following a consistent maintenance routine can help prevent issues and enhance efficiency. Here are some crucial tips to keep in mind.

- Regularly check and change the oil to maintain engine health and performance.

- Inspect air filters frequently; clean or replace them as necessary to ensure adequate airflow.

- Monitor the spark plug condition; replace them if they show signs of wear or fouling.

- Keep the cooling system clean and free of debris to prevent overheating.

- Examine belts and hoses for wear, cracking, or leaks, replacing them if needed.

In addition to these tasks, always refer to the manufacturer’s guidelines for specific maintenance schedules and recommendations. By staying proactive with maintenance, you can significantly extend the life of your machinery and enhance its reliability.

Identifying Replacement Parts Easily

When it comes to maintaining machinery, knowing how to efficiently locate components is essential for seamless operation. Understanding the layout and organization of elements within a system can save time and reduce frustration. By familiarizing oneself with the structure and function of various parts, one can swiftly identify what needs to be replaced and ensure that the equipment runs smoothly.

Utilizing Reference Materials

One of the most effective methods for pinpointing necessary components is through reference materials. These can include manuals or comprehensive guides that outline the specifics of each element. By consulting these resources, you can quickly gain insights into the role and location of different parts, which facilitates a more straightforward identification process.

Visual Aids and Resources

In addition to written guides, visual aids such as charts and illustrations play a crucial role. These resources provide a clear representation of the configuration, allowing for easier recognition of the items in need of replacement. Investing time in understanding these visual tools can lead to more informed decisions when it comes to repairs or upgrades.

Ultimately, becoming proficient in identifying components requires a combination of knowledge, resources, and a methodical approach. By leveraging both written and visual information, you can enhance your ability to maintain and repair machinery effectively.

Where to Find Authentic Parts

Finding genuine components for your machinery is crucial for ensuring optimal performance and longevity. There are several reliable sources that can provide you with the quality items you need, whether for repairs or maintenance.

- Authorized Dealers: Purchasing from certified dealers guarantees authenticity. They often have access to the latest inventory and can provide expert advice.

- Manufacturer’s Website: The official site typically offers a catalog of available items, along with specifications and compatibility information.

- Specialty Retailers: Some retailers specialize in specific brands or types of equipment, offering a curated selection of authentic components.

- Online Marketplaces: Established e-commerce platforms may host sellers that provide genuine items, but always check reviews and seller ratings.

- Local Repair Shops: Many repair professionals have access to authentic inventory and can source parts directly from manufacturers.

By exploring these options, you can ensure that you obtain the right components to maintain the efficiency and reliability of your equipment.

Benefits of Using Original Components

Utilizing genuine components offers numerous advantages that enhance performance and longevity. Authentic parts are engineered to fit seamlessly, ensuring optimal functionality and reducing the risk of failures. Their reliability plays a critical role in maintaining equipment efficiency and overall user satisfaction.

Enhanced Durability

Original elements are designed with high-quality materials that withstand wear and tear, ultimately prolonging the lifespan of the machinery. This durability minimizes the need for frequent replacements, leading to cost savings in the long run.

Improved Performance

By choosing genuine components, users can expect superior performance due to precise manufacturing standards. These parts contribute to the ultimate efficiency of the system, ensuring it operates at its best without unexpected interruptions.

Troubleshooting Common Issues

When dealing with engine performance problems, understanding typical complications can save time and effort. Identifying symptoms early on allows for quicker resolution, ensuring smooth operation and longevity. This section will guide you through common concerns and their potential fixes.

Engine Won’t Start

If the engine fails to start, check the fuel supply first. Ensure the tank is filled and that the fuel is clean. Inspect the ignition system for any faults, such as worn spark plugs or defective wiring. A weak battery can also prevent ignition; testing it with a multimeter can help confirm its status.

Overheating Issues

Overheating can lead to serious damage if not addressed. Begin by examining the coolant levels and the condition of hoses and radiators. A blocked air intake or a malfunctioning thermostat may also contribute to excessive temperatures. Regular maintenance of these components is essential to prevent this issue from recurring.

Repair vs. Replacement Decisions

When faced with malfunctioning machinery, determining whether to fix or replace components is crucial. Each choice carries implications for cost, time, and performance, making it essential to evaluate various factors before arriving at a decision.

Factors to Consider

- Cost: Analyze the financial implications of both repairing and replacing. Repairs may be less expensive initially, but long-term costs could vary.

- Frequency of Issues: If problems are recurrent, replacement might be a more viable solution.

- Performance: Consider whether repairs will restore optimal functionality or if new parts will offer superior performance.

- Availability of Parts: Assess the ease of obtaining necessary components for repairs.

Making the Decision

Weighing the benefits and drawbacks is essential. If repairs can prolong the lifespan effectively, they might be ideal. However, for long-term reliability, investing in new components could ultimately be the smarter choice.

Resources for SV830 Owners

For individuals managing the upkeep of their outdoor power equipment, accessing the right materials and support can significantly enhance the ownership experience. Whether you’re looking for technical assistance, replacement components, or maintenance tips, having reliable resources at your fingertips is essential.

Online Communities and Forums

Joining online groups can provide valuable insights and peer support. Here are some popular options:

- Facebook Groups dedicated to outdoor equipment enthusiasts

- Reddit communities focused on small engines and maintenance

- Specialized forums where users share advice and troubleshooting tips

Official Documentation and Guides

Consulting official manuals and resources can help ensure proper handling and maintenance of your machinery. Consider these sources:

- User manuals available on manufacturer websites

- Maintenance and troubleshooting guides provided by experts

- Video tutorials on platforms like YouTube for visual learners

By leveraging these resources, owners can ensure their equipment remains in optimal condition and enjoy a more efficient maintenance process.

Understanding Warranty and Support

When investing in machinery, understanding the associated guarantees and support services is crucial for ensuring longevity and performance. These elements serve as a safety net, providing reassurance to users that they are protected against potential defects and can access assistance when needed.

Warranty coverage typically outlines the conditions under which repairs or replacements are offered. It is essential to familiarize yourself with the specific terms, including the duration of coverage and the components that are included. This knowledge enables users to navigate any issues that may arise effectively.

Support services play a vital role in maintaining equipment efficiency. Access to knowledgeable technicians and resources can greatly enhance the user experience. Understanding how to reach out for assistance and what resources are available can mitigate downtime and ensure optimal operation.