Understanding the Components of a Log Splitter Parts Diagram

In the realm of wood processing, the functionality of machinery is paramount. Grasping the intricacies of how these devices operate can greatly enhance efficiency and performance. Each element plays a crucial role, contributing to the overall effectiveness of the equipment.

Recognizing the key elements within these machines allows users to troubleshoot issues and ensure optimal operation. From the primary mechanisms that drive the action to the supportive structures that stabilize and guide, a comprehensive understanding is essential.

Furthermore, delving into the relationships between various components reveals insights into their ultimate purpose. Knowledge of these interconnections not only aids in maintenance but also enhances the user experience, making the process of transforming timber both efficient and safe.

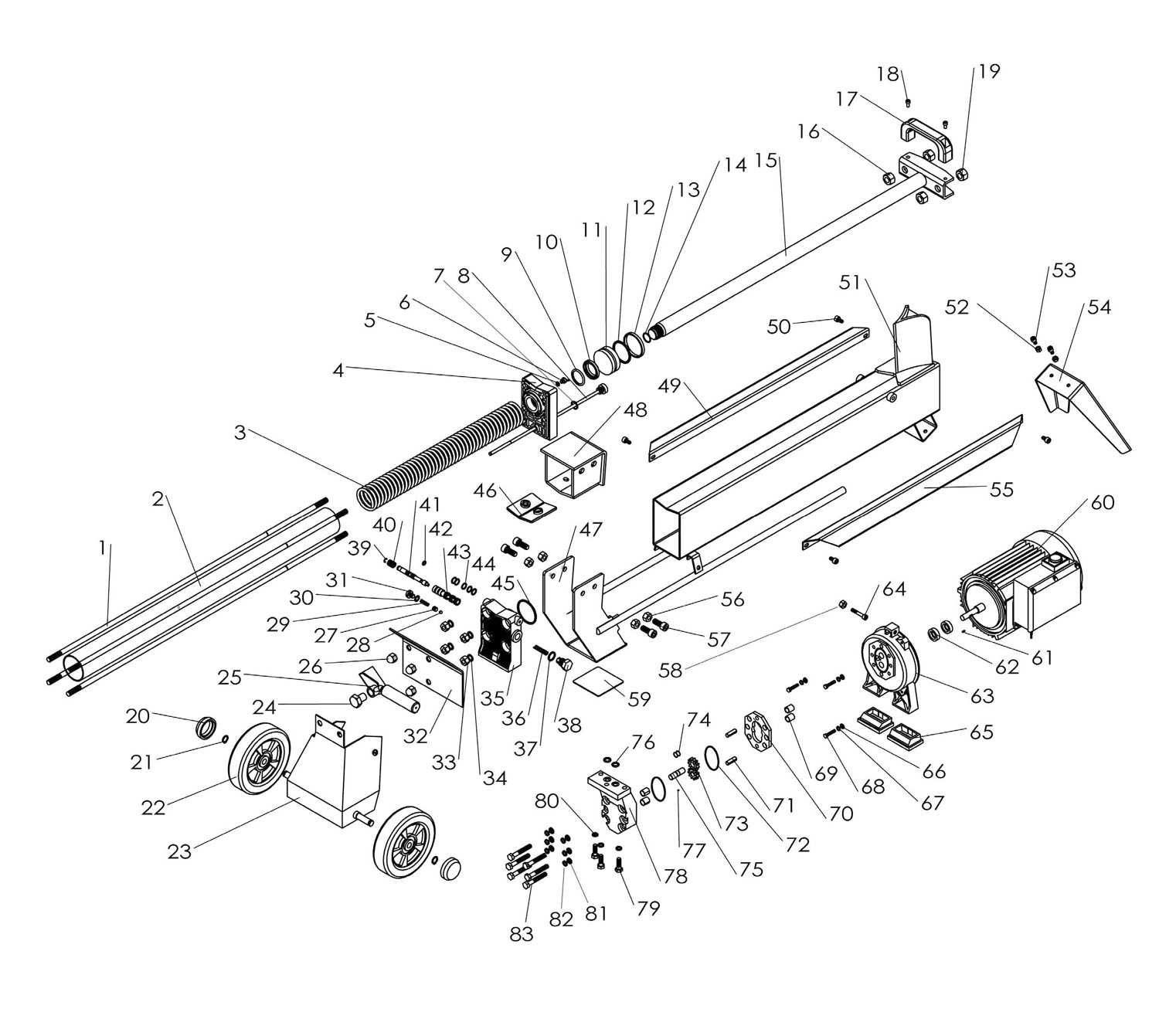

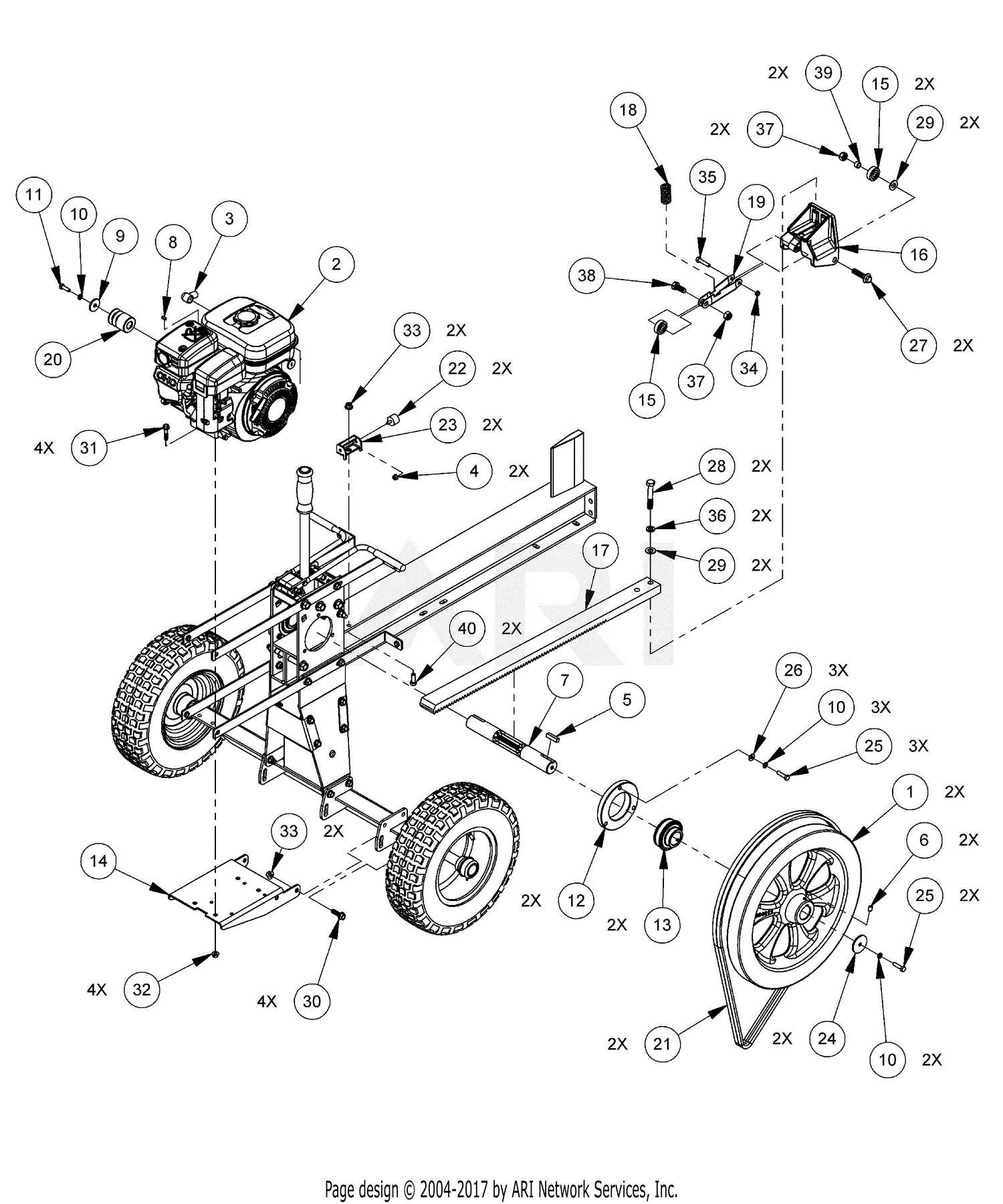

Understanding Log Splitter Components

When dealing with wood processing machinery, it’s essential to grasp the various elements that contribute to its efficiency and functionality. Each component plays a specific role, working in harmony to ensure optimal performance. Familiarity with these elements will not only aid in maintenance but also enhance the user experience.

Key Elements of the Machinery

- Frame: The backbone of the device, providing structure and stability.

- Power Source: The engine or motor that drives the operation, available in different types such as electric or gas.

- Cylinder: Responsible for generating the force needed to perform the splitting action.

- Wedge: The sharp metal component that penetrates the wood, facilitating separation.

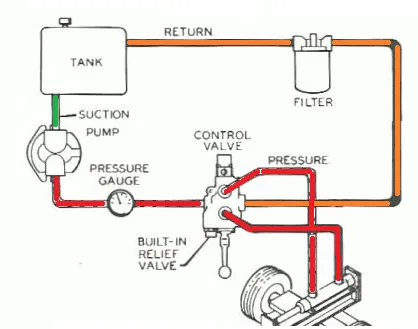

- Hydraulic System: Involves various hoses and pumps that manage the flow of fluid to transfer power.

Supporting Components

- Control Valve: Regulates the movement of the hydraulic fluid, allowing for precise operation.

- Safety Features: Includes guards and emergency shut-off mechanisms to protect the user.

- Wheels: Enhance portability, making it easier to maneuver the equipment around a workspace.

- Table: Provides a surface for positioning the wood, ensuring accurate alignment during the splitting process.

Understanding these essential components can significantly improve maintenance practices and user efficiency, making the task of processing wood more streamlined and effective.

Key Parts of a Log Splitter

Understanding the essential components of a wood processing machine is crucial for effective operation and maintenance. Each element plays a significant role in the overall functionality, contributing to the machine’s efficiency and performance. By familiarizing oneself with these key elements, users can optimize their experience and ensure longevity.

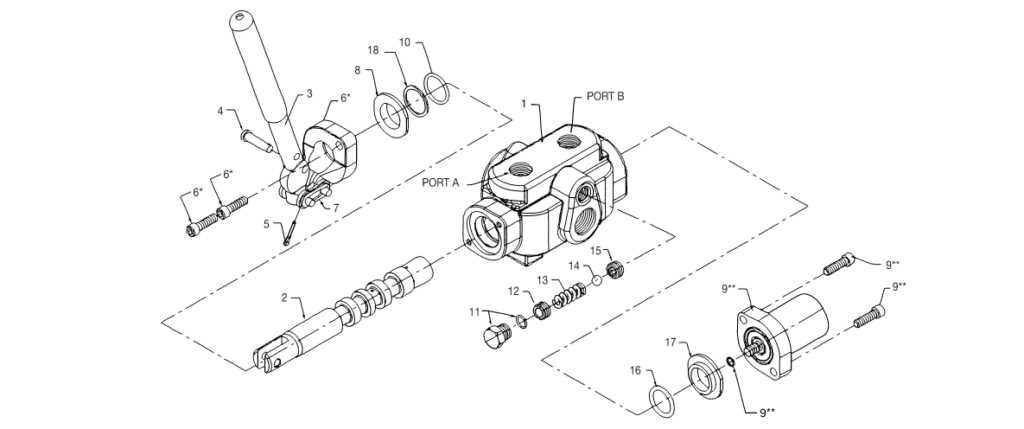

Hydraulic System

The hydraulic system serves as the powerhouse, utilizing fluid pressure to generate the necessary force for cutting. This system typically includes a pump, cylinder, and reservoir, working in unison to deliver optimal performance. Proper maintenance of the hydraulic components is vital for smooth operation.

Cutting Mechanism

The cutting mechanism is the heart of the machine, designed to handle various types of wood. It often includes blades or wedges that efficiently process timber into manageable pieces. Selecting the right type of cutting mechanism enhances efficiency and meets specific needs, making this component critical for effective operation.

Types of Log Splitters Explained

Understanding the various mechanisms available for processing timber can greatly enhance efficiency and effectiveness in wood preparation. Each type offers unique features tailored to specific needs and preferences. Below are some common varieties that are widely used.

- Hydraulic Models

These machines utilize hydraulic pressure to exert force, making them powerful and capable of handling large, tough materials. They are often preferred for heavy-duty tasks.

- Electric Variants

Ideal for residential use, these models are quieter and require less maintenance. They are suitable for smaller, softer types of wood.

- Gas-Powered Options

Known for their portability and independence from power sources, gas-powered machines are perfect for outdoor work where electricity may not be available.

- Manual Tools

These include hand-operated mechanisms that offer simplicity and are often used for smaller tasks. They are environmentally friendly and require no power source.

Each type serves distinct purposes, catering to different levels of workload and user preferences. Selecting the right one can make a significant difference in efficiency and productivity during timber processing.

Common Log Splitter Mechanisms

Understanding the various components involved in the operation of wood processing machines is essential for effective maintenance and troubleshooting. These mechanisms work in harmony to transform logs into manageable pieces, each playing a specific role in the overall functionality.

Hydraulic System

The hydraulic system is a critical element that utilizes fluid pressure to create powerful force, enabling efficient cutting through tough wood fibers. This system consists of a pump, cylinder, and fluid reservoir, all working together to generate the necessary pressure for effective operation.

Wedge and Blade Assembly

The wedge and blade assembly is responsible for the actual separation of wood. The design and angle of the wedge determine the efficiency and effectiveness of the cutting action. A well-engineered assembly can significantly reduce the amount of force required, making the process smoother and quicker.

Safety Features in Log Splitters

Ensuring safety during wood processing is crucial for both the operator and bystanders. Advanced machinery is designed with various protective elements that minimize the risk of accidents and enhance the user experience. Understanding these features can significantly contribute to safer operation.

Key Safety Mechanisms

- Emergency Stop Button: This feature allows for immediate cessation of operation in case of an unexpected situation.

- Protective Shields: Covers and guards are strategically placed to prevent accidental contact with moving components.

- Two-Hand Operation: Many devices require the use of both hands to operate, ensuring the operator maintains a safe distance from hazardous areas.

- Overload Protection: This mechanism prevents the machine from operating under excessive stress, reducing the risk of mechanical failure.

Best Practices for Safety

- Always wear appropriate personal protective equipment, including gloves, goggles, and hearing protection.

- Regularly inspect the machinery for wear and tear, ensuring all safety features are functioning properly.

- Keep the work area clean and free from obstructions to maintain a safe environment.

- Read and follow the manufacturer’s instructions thoroughly before operation.

By incorporating these features and practices, operators can enhance safety and efficiency, making the wood processing experience more secure and enjoyable.

Maintenance Tips for Log Splitters

Proper upkeep is essential for ensuring optimal performance and longevity of your wood processing equipment. Regular attention can prevent issues and enhance efficiency, allowing for smoother operation during heavy use.

Here are some key maintenance suggestions:

- Regular Cleaning: Keep the machine free from debris and residue. This helps in preventing overheating and improves functionality.

- Check Fluid Levels: Ensure that hydraulic and oil levels are adequate. Refill or change fluids as necessary to maintain smooth operation.

- Inspect Blades: Examine cutting components for wear and tear. Sharpen or replace them to ensure clean cuts and prevent strain on the motor.

- Examine Belts and Hoses: Look for signs of damage or wear. Replace any frayed or cracked belts and hoses to avoid operational failures.

- Lubrication: Regularly apply lubricant to moving parts to reduce friction and enhance performance.

Implementing these practices will help you achieve the ultimate efficiency and reliability from your equipment.

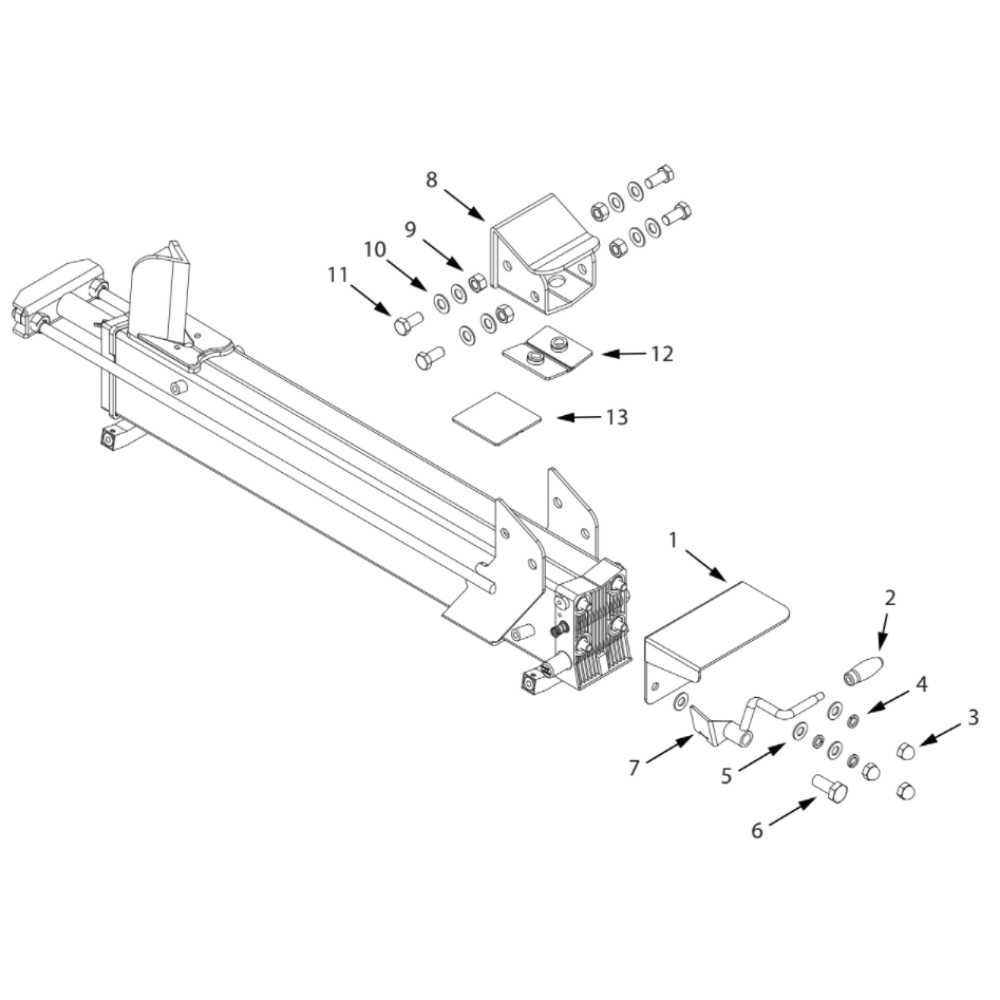

Identifying Faulty Components

Recognizing malfunctioning elements within your machinery is crucial for maintaining optimal performance. By pinpointing issues early, you can avoid costly repairs and ensure smooth operation. Understanding how each component functions aids in the diagnosis of potential failures.

Common Indicators of Malfunction

- Unusual noises during operation

- Decreased efficiency in performance

- Visible wear or damage on key components

- Inconsistent operation or frequent stoppages

Steps to Diagnose Issues

- Inspect each element for physical damage.

- Test functionality in a controlled environment.

- Consult the user manual for troubleshooting guidelines.

- Replace any worn or broken components as necessary.

Choosing the Right Log Splitter Parts

Selecting the appropriate components for your firewood processing machine is essential for ensuring optimal performance and longevity. With a variety of options available, understanding the key features and functions of each element can help you make informed choices that enhance efficiency and safety.

Key Considerations

- Compatibility: Ensure that the components are compatible with your specific model. Mismatched items can lead to reduced effectiveness or even damage.

- Quality: Opt for high-quality materials that can withstand heavy use. Investing in durable components can save you time and money in the long run.

- Power Requirements: Consider the power specifications needed for various elements. Selecting parts that align with the machine’s power capacity is crucial.

- Ease of Maintenance: Choose items that are easy to maintain and replace. Simplified upkeep will enhance the overall lifespan of your equipment.

Recommended Components

- Hydraulic System: Ensure the hydraulic components are efficient and suitable for your workload. High-performance hydraulics can significantly boost productivity.

- Cutting Wedge: The design of the wedge plays a vital role in efficiency. Opt for one that suits the type of wood you are processing.

- Frame Structure: A robust frame ensures stability and safety during operation. Check for materials that provide both strength and lightweight properties.

- Safety Features: Incorporate essential safety elements such as guards and emergency shut-off mechanisms to protect users during operation.

Upgrading Your Log Splitter

Enhancing your wood processing machine can significantly improve its performance and efficiency. Whether you’re looking to increase power, reduce operational noise, or add new features, there are various approaches to consider. This guide will help you navigate the options available for elevating your equipment’s capabilities.

Power and Performance Enhancements

To boost the overall output and efficiency, consider the following modifications:

- Engine Upgrade: Replacing the engine with a more powerful model can lead to faster processing times.

- Hydraulic System Improvements: Installing a more efficient hydraulic pump can enhance pressure and speed.

- Wedge Types: Switching to a different wedge design can improve splitting efficiency, especially for tougher logs.

Comfort and Usability Features

Improving user comfort and ease of operation is essential for long-term usage:

- Ergonomic Handles: Adding padded or adjustable handles can reduce strain during operation.

- Noise Reduction: Implementing sound-dampening materials can create a quieter working environment.

- Mobility Enhancements: Adding larger wheels or a tow hitch can make transportation easier.

By strategically upgrading your equipment, you can achieve significant improvements in both performance and user experience. Take the time to evaluate your current setup and identify the best modifications to suit your needs.

DIY Repairs for Log Splitters

Taking on repairs for your outdoor equipment can be a rewarding experience. Understanding the components and their functions will enable you to troubleshoot issues and carry out effective fixes without professional help.

Common Issues and Solutions

- Hydraulic Problems: Check fluid levels and inspect hoses for leaks.

- Blade Dullness: Sharpen or replace blades to maintain cutting efficiency.

- Electrical Failures: Test the power supply and replace any faulty wiring.

Maintenance Tips

- Regularly clean the machine to prevent buildup.

- Inspect connections and fasteners to ensure everything is secure.

- Follow the manufacturer’s recommendations for lubricating moving parts.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is essential for optimal performance. Whether you’re looking for specific elements or general accessories, various avenues are available to ensure you find what you need.

Online Retailers

The internet offers a plethora of platforms specializing in various machine components. Popular sites provide user-friendly interfaces, allowing you to search by model or type, ensuring that you can easily locate suitable replacements.

Local Dealers and Repair Shops

Your neighborhood dealerships or service centers can be invaluable resources. They often carry a selection of essentials and can assist in identifying the correct elements for your equipment, while also offering expert advice on installation.