Understanding the Lt166 Parts Diagram for Effective Maintenance

The intricate arrangement of machinery elements plays a crucial role in the efficiency and functionality of various devices. Each segment serves a specific purpose, contributing to the overall operation and performance. Gaining insight into these configurations can significantly enhance maintenance and repair efforts.

By examining the visual representations of these assemblies, one can identify how individual pieces interconnect and interact. This knowledge is essential for troubleshooting and optimizing the use of equipment. A clear understanding empowers users to make informed decisions regarding replacements and upgrades.

In this exploration, we will delve into the essential visuals that highlight the structure of these systems. This examination aims to provide a comprehensive overview, guiding enthusiasts and professionals alike in mastering their understanding of mechanical layouts.

Understanding the Lt166 Parts Diagram

Comprehending the layout of components in machinery is crucial for effective maintenance and repair. A visual representation aids in identifying each element’s function and location, streamlining the troubleshooting process. This knowledge empowers operators and technicians to work more efficiently.

Key Components Overview

The following table outlines essential elements found within the assembly, showcasing their primary roles:

| Component | Description |

|---|---|

| Element A | Responsible for initiating operations. |

| Element B | Regulates fluid flow throughout the system. |

| Element C | Facilitates energy transfer between parts. |

Importance of Accurate Representation

A precise visualization ensures that technicians can effectively diagnose issues. Recognizing each piece’s role fosters better understanding and ultimately enhances overall performance, leading to more reliable operations.

Overview of Lt166 Model Features

This section presents a comprehensive examination of the distinctive characteristics that define this particular model. It highlights the innovative aspects and functional elements that contribute to its performance and user experience.

Design and Efficiency: The model boasts an ergonomic design that enhances usability, making operations smoother and more intuitive. Additionally, its efficiency in resource management ensures optimal performance under various conditions.

Advanced Technology: Equipped with cutting-edge technology, this model integrates modern features that streamline processes and improve overall functionality. Users benefit from enhanced connectivity options and sophisticated control systems.

Durability and Reliability: Constructed with high-quality materials, this model is built to withstand demanding environments. Its reliability is a significant factor for users seeking long-term performance and minimal maintenance.

Versatility: The adaptability of this model allows it to cater to a wide range of applications, making it a valuable asset in diverse settings. This flexibility enhances its appeal across various industries.

Key Components Explained

Understanding the essential elements of a complex system is crucial for effective maintenance and operation. Each part plays a significant role, contributing to the overall functionality and efficiency of the machinery. In this section, we will delve into the primary components, highlighting their functions and interrelationships.

Major Elements

The major elements of any system include mechanisms for power transfer, control systems, and structural components. Each of these elements works in harmony to ensure optimal performance.

| Component | Function |

|---|---|

| Power Unit | Generates and supplies energy necessary for operation. |

| Control Module | Regulates the operations and processes of the machinery. |

| Framework | Provides structural integrity and support for all components. |

Supporting Features

In addition to the major components, various supporting features enhance the system’s reliability and effectiveness. These include safety mechanisms, feedback systems, and connectors that ensure smooth interaction among parts.

Importance of Accurate Diagrams

Precise representations are crucial for effective communication in technical fields. They provide clarity, ensuring that all stakeholders have a unified understanding of complex systems. Accurate visuals not only facilitate problem-solving but also enhance efficiency by minimizing misunderstandings.

Without well-crafted visuals, the risk of errors increases significantly. Clear illustrations help in identifying components and their relationships, ultimately leading to better maintenance and troubleshooting processes. Additionally, they serve as invaluable references during training and onboarding, allowing newcomers to grasp intricate concepts quickly.

In conclusion, investing time in developing accurate representations pays off through improved collaboration and streamlined operations, making them an essential tool in any technical discipline.

Common Issues with Lt166 Parts

When dealing with mechanical components, certain challenges frequently arise that can affect overall performance and reliability. Understanding these common problems is essential for effective maintenance and repair.

Wear and Tear: Over time, frequent usage can lead to deterioration. Components may show signs of wear, resulting in decreased efficiency.

Misalignment: Improper installation or adjustments can cause misalignment, leading to operational issues. This often results in abnormal noise or vibration.

Corrosion: Exposure to moisture and environmental factors can lead to rust and corrosion, compromising the integrity of the components.

Compatibility Issues: Using non-compatible elements can lead to malfunctions. It’s crucial to ensure all parts work harmoniously together.

Inadequate Lubrication: Insufficient lubrication can cause friction and overheating, accelerating wear and potentially leading to failure.

Addressing these common challenges can enhance longevity and improve functionality, ensuring a smoother operational experience.

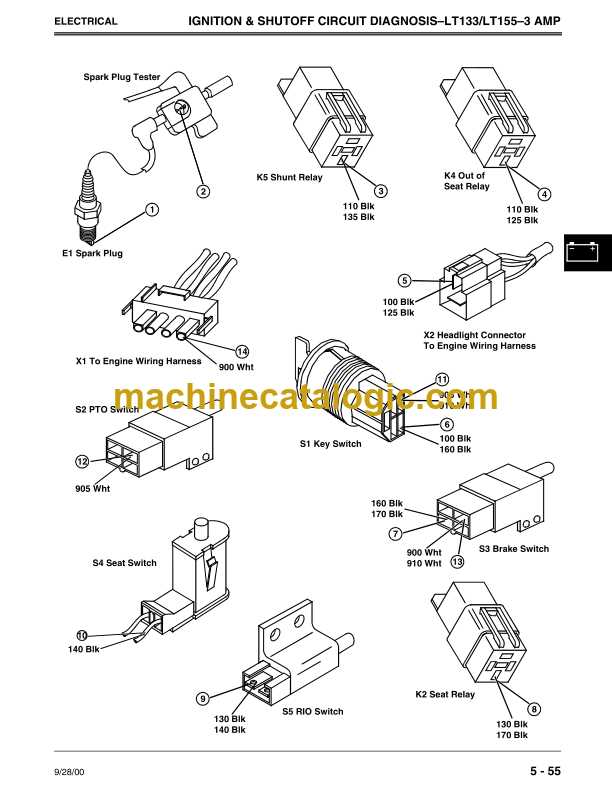

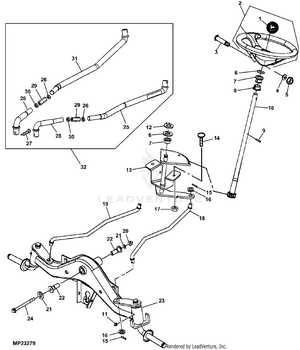

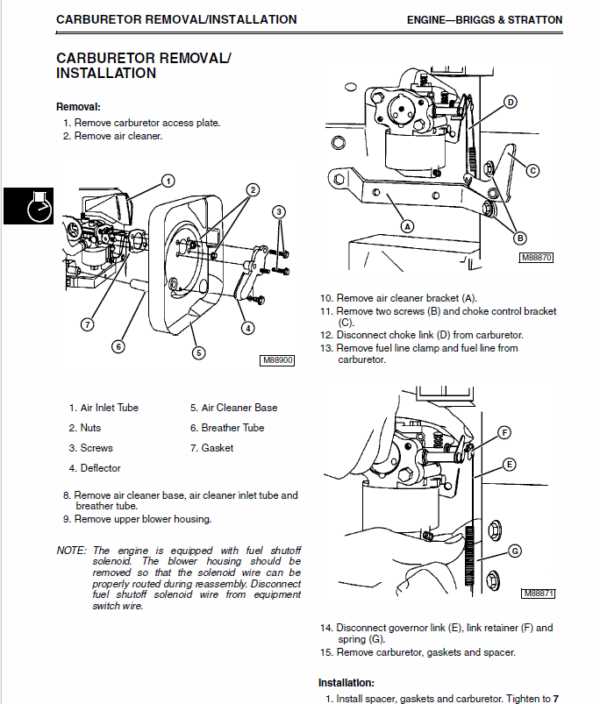

How to Read a Parts Diagram

Understanding the visual representation of components can significantly enhance your ability to identify and assemble various elements effectively. Familiarity with these illustrations is essential for both troubleshooting and maintaining equipment.

Key Components of the Visual Representation

- Labels: Each part typically has a specific label or number for easy identification.

- Legend: Often included, a legend provides definitions for symbols used in the illustration.

- Connections: Lines or arrows indicate how components interact or connect to one another.

Steps to Interpret Effectively

- Start by reviewing the legend to understand the symbols.

- Identify the key components and their respective labels.

- Follow the connections to see how elements relate and interact.

- Refer to the manufacturer’s documentation for specific details.

Replacing Components Effectively

Efficiently swapping out elements within machinery or devices requires a systematic approach. Understanding the intricacies of each component and how they interact is essential for a seamless transition. This section will outline the best practices to ensure a smooth replacement process.

| Step | Description |

|---|---|

| 1 | Identify the component that needs replacement. |

| 2 | Gather the necessary tools and replacement items. |

| 3 | Follow safety protocols to avoid accidents. |

| 4 | Carefully remove the faulty element. |

| 5 | Install the new component, ensuring proper alignment. |

| 6 | Test the system to confirm functionality. |

By adhering to these guidelines, one can minimize downtime and enhance the reliability of the entire system.

Maintaining Your Lt166 Equipment

- Perform routine inspections to identify wear and tear.

- Clean components regularly to avoid dirt accumulation.

- Lubricate moving parts to reduce friction.

- Replace any worn or damaged components promptly.

Establishing a maintenance schedule can significantly enhance efficiency. Consider the following steps:

- Refer to the manufacturer’s guidelines for recommended service intervals.

- Document all maintenance activities for future reference.

- Train operators on basic maintenance procedures.

By dedicating time to regular care, you can ultimately extend the lifespan of your equipment and ensure it operates at peak efficiency.

Where to Find Authentic Parts

Locating genuine components for machinery can significantly enhance performance and longevity. Understanding the best sources for these essential items is crucial for any user seeking reliability and quality.

Trusted Sources

- Manufacturer’s Official Website

- Authorized Distributors

- Reputable Retailers

Online Resources

- Specialized E-commerce Platforms

- Forums and Community Groups

- Social Media Marketplaces

DIY Repairs: Safety Considerations

Engaging in self-repair activities can be rewarding, yet it comes with inherent risks that should never be overlooked. Ensuring a secure environment is crucial to avoid accidents and injuries while working on projects at home.

First and foremost, personal protective equipment (PPE) is essential. Wearing gloves, goggles, and sturdy footwear can significantly reduce the likelihood of injury. Additionally, keeping your workspace organized and free from clutter minimizes hazards.

Moreover, it is vital to understand the tools and materials you are working with. Familiarize yourself with the instructions and safety features of any equipment to enhance your safety. In case of uncertainty, do not hesitate to seek guidance or consult professionals.

Lastly, always ensure that your workspace is well-ventilated and that any electrical components are handled with care. Taking these precautions will help you delve into your repair tasks with confidence, making the experience both enjoyable and safe.

Comparing Lt166 to Other Models

When evaluating different machinery, it’s essential to understand the nuances that set each model apart. This comparison highlights the distinctive features, performance capabilities, and suitability for various tasks across different units.

Performance Capabilities

- Engine efficiency and power output

- Speed and handling in various conditions

- Load capacity and durability

Design and Features

- Ergonomics and user-friendliness

- Technological integrations and enhancements

- Maintenance ease and availability of components

By delving into these aspects, one can determine which model ultimately aligns with their specific needs and preferences.

Expert Tips for Longevity

Maintaining optimal performance and extending the life of your equipment involves a combination of routine maintenance, attentive usage, and understanding the essential components that contribute to efficiency. Implementing best practices can significantly enhance durability and reliability.

Regular Maintenance Checks

Consistent inspections are crucial. Regularly examine key elements for wear and tear, and replace any parts showing signs of damage. This proactive approach can prevent major breakdowns and costly repairs.

Optimal Usage Practices

Understanding the limitations and specifications of your machinery will help ensure that it operates within safe parameters. Avoid overloading and adhere to recommended guidelines for usage, as this can prevent premature failure and enhance overall longevity.