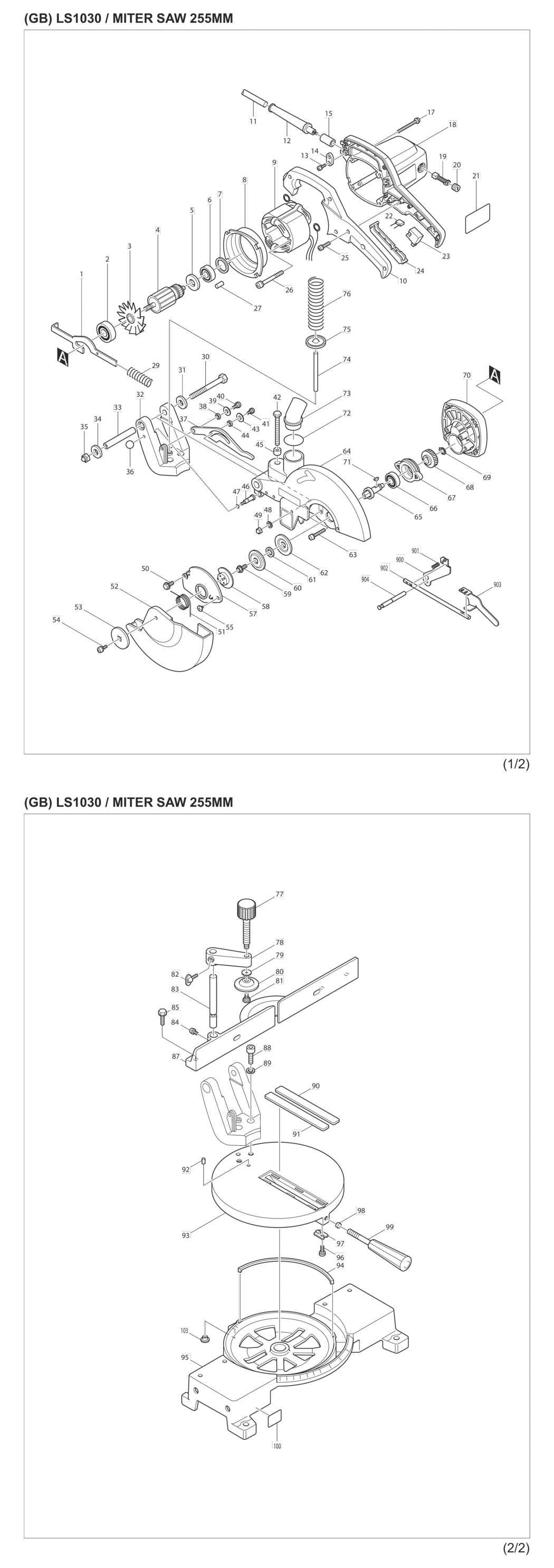

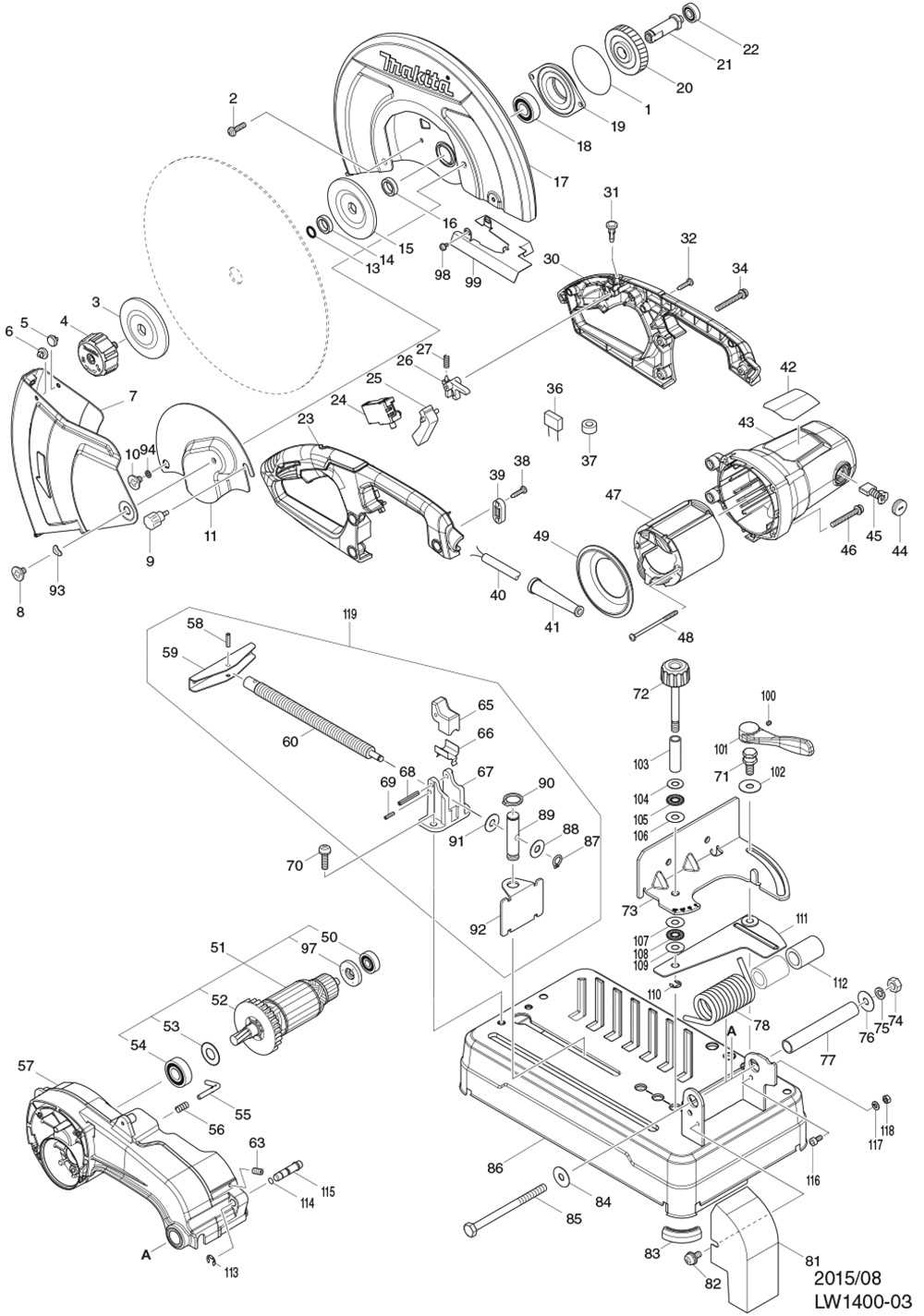

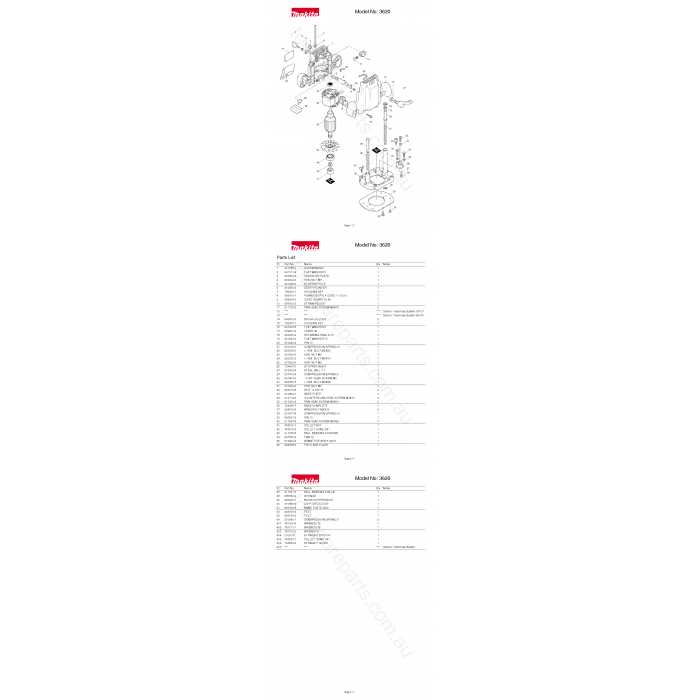

Makita 6906 Parts Diagram Overview

When it comes to effective maintenance and repair of machinery, having a clear understanding of its internal structure is essential. This knowledge not only facilitates efficient troubleshooting but also enhances the overall longevity of the equipment. Each component plays a vital role in ensuring the device operates at optimal performance.

Familiarizing oneself with the layout and relationships between various elements can greatly simplify the repair process. Recognizing how each piece interacts allows users to address issues more accurately and prevent future malfunctions. A comprehensive visual representation of these components serves as a valuable reference for both novices and experienced users alike.

Equipped with the right information, operators can confidently tackle repairs, making informed decisions regarding replacements or adjustments. This proactive approach not only saves time but also contributes to maintaining the integrity of the tool in the long run.

Understanding the Makita 6906 Components

This section explores the essential elements of a particular power tool, highlighting their functions and interrelations. By grasping the significance of each component, users can enhance their knowledge and effectively maintain their equipment.

Key components include:

- Motor: The powerhouse that drives the tool’s performance.

- Gearbox: Responsible for transferring torque and speed from the motor to the working part.

- Trigger Mechanism: Allows users to control the tool’s operation with precision.

- Housing: Provides protection and structural integrity, housing all internal parts.

Understanding these elements can lead to better handling and longer-lasting functionality. Maintenance and troubleshooting can become more intuitive, enabling efficient use in various tasks.

Key Features of Makita 6906

This model stands out for its remarkable performance and innovative design, making it a preferred choice among professionals and enthusiasts alike. The combination of power and efficiency ensures that tasks are completed swiftly and effectively.

One of the standout aspects is its robust construction, providing durability and longevity even under demanding conditions. The ergonomic design enhances user comfort, allowing for extended usage without fatigue.

Additionally, advanced technology incorporated into the device ensures precision and reliability, contributing to superior results. The intuitive controls facilitate ease of use, making it accessible for both seasoned users and beginners.

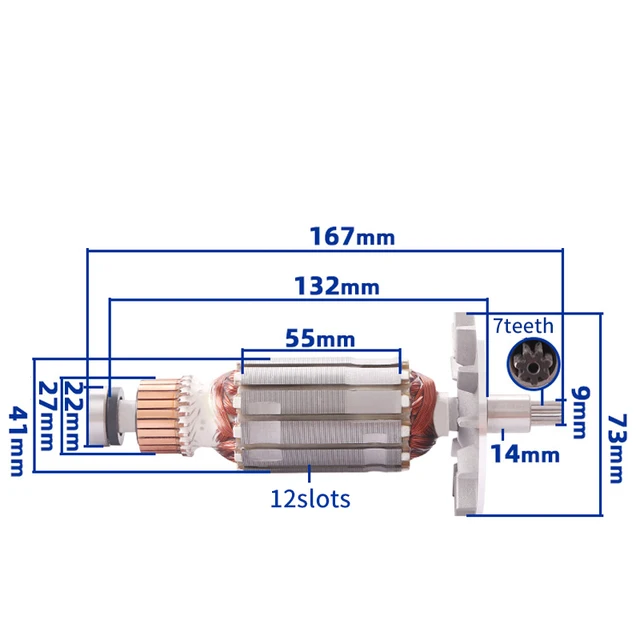

Parts Identification and Functions

This section provides an overview of key components found in the tool, detailing their roles and interconnections. Understanding these elements is crucial for effective maintenance and operation.

Main Components

- Motor: Powers the device, driving its operational capabilities.

- Switch: Controls the on/off functionality, ensuring user safety.

- Housing: Encloses internal mechanisms, providing structural support and protection.

Additional Elements

- Gear Assembly: Facilitates the transfer of power from the motor to the working end.

- Handle: Offers a grip for maneuverability and control during usage.

- Ventilation Ports: Allow heat dissipation to prevent overheating during extended operation.

How to Read the Diagram

Understanding the layout of components is crucial for effective maintenance and repair. This section provides insights on interpreting the visual representation of elements in your tool. Familiarity with the symbols and layout will enhance your ability to identify parts and their functions.

Identifying Symbols

Each symbol on the representation corresponds to a specific element. Here’s how to decode them:

- Shapes: Different shapes represent various types of components.

- Lines: Connecting lines indicate relationships or connections between elements.

- Numbers: Each part is often labeled with a number for easy reference.

Understanding Layout

The arrangement of elements typically follows a logical structure. Pay attention to:

- Flow: Observe how components interact within the system.

- Grouping: Related parts are often clustered together, making it easier to locate them.

- Orientation: The orientation of symbols can indicate their position in the assembly.

Maintenance Tips for Longevity

To ensure the extended lifespan of your tools, regular upkeep is essential. Proper care not only enhances performance but also prevents costly repairs in the future. Adopting a few simple practices can make a significant difference in the longevity of your equipment.

Regular Cleaning

Keeping your tools clean is fundamental. After each use, remove any debris or dust that may have accumulated. Use a soft brush or cloth to wipe surfaces, ensuring that moving parts remain unobstructed. This routine helps to prevent wear and tear, allowing your equipment to operate efficiently.

Routine Inspections

Conducting periodic checks on your tools can identify potential issues before they escalate. Look for signs of damage or wear, such as cracks or fraying. By addressing these problems early, you can maintain optimal functionality and extend the overall lifespan of your equipment.

Common Issues and Solutions

In any mechanical tool, users may encounter various challenges that can impact performance and efficiency. Understanding these issues and their corresponding remedies is essential for maintaining optimal operation.

Frequent Problems

Some typical difficulties faced include overheating, inconsistent power output, and unusual noises during operation. Identifying these signs early can prevent more severe malfunctions.

Troubleshooting Guide

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Overheating | Blocked ventilation | Ensure vents are clear and clean |

| Inconsistent power | Worn components | Inspect and replace damaged parts |

| Unusual noises | Lack of lubrication | Apply appropriate lubricant to moving parts |

Replacing Worn-Out Parts

Maintaining optimal performance requires the timely replacement of deteriorated components. Over time, tools can experience wear that affects functionality and safety. Regular inspection and proactive measures ensure that equipment operates efficiently.

Follow these steps for successful component replacement:

- Identify the damaged or worn items through a thorough examination.

- Consult the manufacturer’s resources for guidance on compatible replacements.

- Gather necessary tools and new components before starting the replacement process.

- Carefully disassemble the unit, noting the arrangement of parts for easier reassembly.

- Replace the faulty parts with new ones, ensuring proper alignment and fitting.

- Reassemble the tool, double-checking that all components are secure.

- Test the equipment to verify that it functions as expected.

Following these guidelines not only extends the lifespan of your equipment but also enhances its performance, ensuring reliability for various tasks.

Finding Original Replacement Parts

Locating authentic components for your tool can significantly enhance its longevity and performance. Using original elements ensures compatibility and reliability, allowing your equipment to function as intended.

Start by identifying the specific model you are working with. This step is crucial, as it will guide you in sourcing the correct items. Many manufacturers provide detailed resources online, including catalogs and manuals that list all available components.

Another effective method is to visit authorized retailers or service centers. These establishments typically carry genuine items and can assist you in finding what you need. Additionally, consulting with professionals who specialize in tool maintenance can provide valuable insights into sourcing the right components.

Lastly, consider joining online forums or communities dedicated to tool enthusiasts. Here, you can exchange information and recommendations on where to find reliable sources for original replacements. Engaging with fellow users can lead to discovering hidden gems in terms of vendors and distributors.

Tools Required for Repairs

When undertaking maintenance tasks, having the right tools is essential for efficient and successful repairs. Proper equipment not only simplifies the process but also enhances safety and effectiveness.

Essential Equipment

- Socket set

- Screwdriver set

- Wrench set

- Plier set

Additional Supplies

- Cleaning cloths

- Lubricants

- Replacement fasteners

- Safety goggles

Safety Precautions During Maintenance

Ensuring safety during equipment upkeep is essential to prevent accidents and injuries. By following proper guidelines, users can maintain a secure working environment while addressing machinery needs.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Disconnect power sources before beginning any maintenance tasks to eliminate electrical hazards.

- Use tools that are specifically designed for the equipment being serviced to avoid damage or malfunctions.

- Keep the workspace clean and organized to minimize tripping hazards and ensure easy access to tools.

- Read and understand the manufacturer’s instructions thoroughly before proceeding with maintenance activities.

By adhering to these safety measures, users can significantly reduce the risk associated with maintenance procedures, ensuring a safer and more efficient workflow.

Resources for Further Information

For those seeking additional knowledge and insights regarding specific tools and their components, a variety of resources are available. These materials can enhance understanding and aid in maintenance or repair tasks.

Online Forums and Communities

Engaging with online platforms dedicated to tool enthusiasts can be invaluable. Participants often share their experiences, troubleshooting tips, and recommendations for optimal usage. Websites such as specialized forums or social media groups serve as excellent venues for exchanging information and advice.

Manufacturer’s Documentation

Consulting the official documentation provided by the manufacturer is crucial. This may include user manuals, service guides, and technical bulletins. These resources typically offer detailed instructions, specifications, and safety information, ensuring that users can effectively operate and maintain their tools.