Understanding the Makita Router Parts Diagram for Efficient Repairs

The exploration of power equipment reveals a complex network of elements that contribute to its functionality. Each piece plays a vital role in ensuring optimal performance and reliability. A comprehensive understanding of these components is essential for maintenance and troubleshooting.

By examining the intricate arrangements and relationships among the various elements, one can appreciate how they work together to achieve precise results. This knowledge not only enhances the user experience but also empowers individuals to take charge of their tools.

Furthermore, familiarizing oneself with the construction and function of each segment opens the door to deeper insights into modifications and repairs. This ultimate guide aims to delve into the specifics of these essential components, fostering greater competence and confidence in tool management.

Understanding Makita Router Functionality

This section explores the essential mechanisms that drive the precision tools designed for woodworking and craftsmanship. By examining their operation, one can appreciate the intricate balance between power and control that allows for a variety of applications.

Core Components and Their Roles

The main elements of these tools include the motor, base, and cutting bits. Each component plays a vital role in achieving accurate and clean results. The motor provides the necessary power, while the base stabilizes the device, ensuring consistent depth and angle during use.

Applications and Versatility

These versatile instruments are used for shaping, trimming, and hollowing materials. Their adaptability makes them suitable for both detailed work and larger projects, allowing users to delve into various techniques and styles, ultimately enhancing their craftsmanship.

Key Components of Makita Routers

Understanding the essential elements of these powerful tools is crucial for both maintenance and effective usage. Each component plays a significant role in ensuring performance and durability, making it vital for users to familiarize themselves with their functionality.

Motor and Power Supply

The heart of any cutting tool is its motor, which provides the necessary power for various tasks. A reliable energy source ensures consistent operation, allowing for smooth cuts and efficiency during work. High-performance motors typically offer variable speed settings, catering to different materials and techniques.

Base and Collet Assembly

The base serves as the foundation, stabilizing the tool during operation. It often features adjustments for depth control, enhancing precision. Meanwhile, the collet assembly secures the cutting bits, allowing for quick changes and maintaining accuracy. Proper maintenance of these components is essential for optimal performance.

Importance of Router Parts Identification

Understanding the components of a cutting tool is crucial for effective maintenance and optimal performance. Identifying each element ensures that users can troubleshoot issues, replace worn-out pieces, and enhance the overall functionality of their equipment.

Benefits of Accurate Identification

When users are familiar with the various elements of their tool, they can significantly reduce downtime and avoid costly repairs. Knowing the correct components allows for efficient replacements and better-informed purchasing decisions.

Common Components to Recognize

| Component | Function |

|---|---|

| Base Plate | Stabilizes the tool during operation |

| Collet | Secures the cutting bit |

| Motor Housing | Encases the motor for protection |

| Depth Adjustment | Controls the depth of the cut |

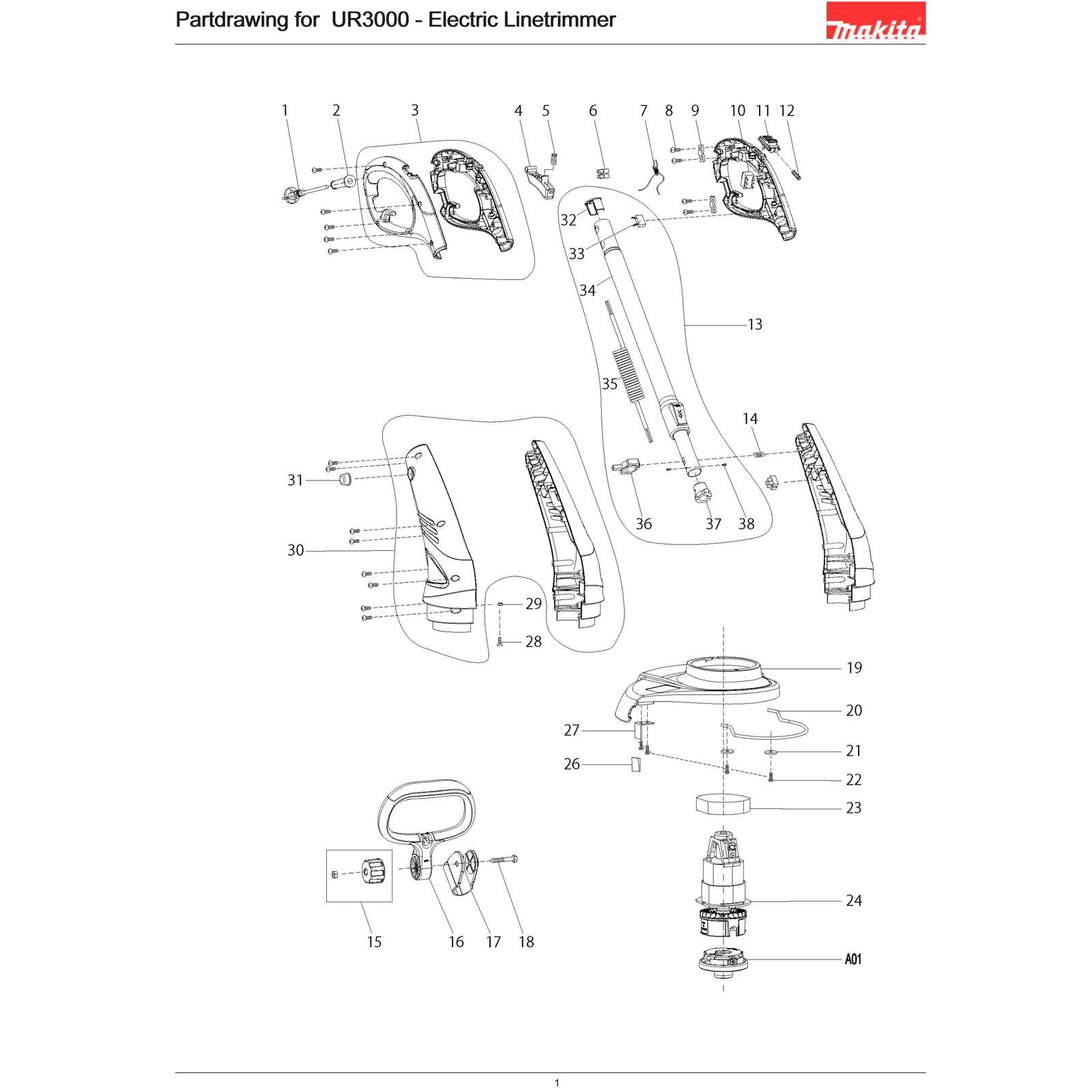

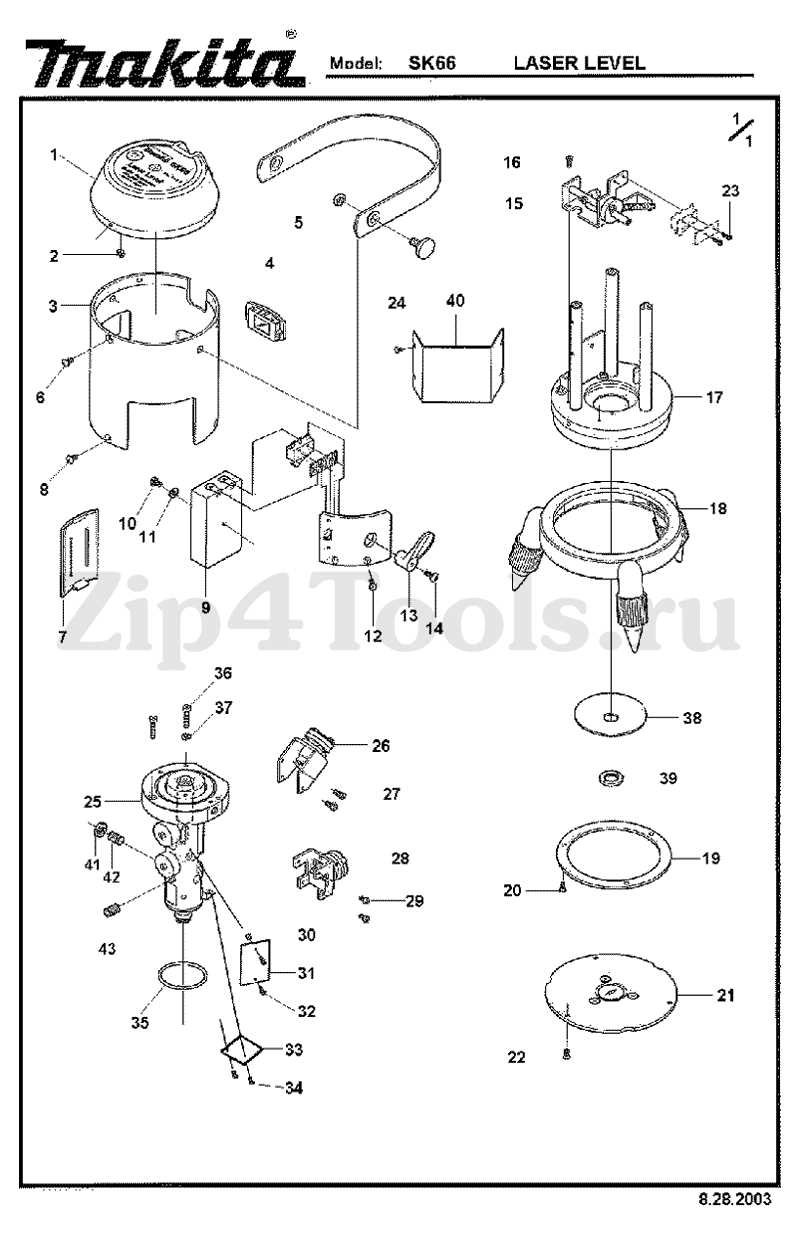

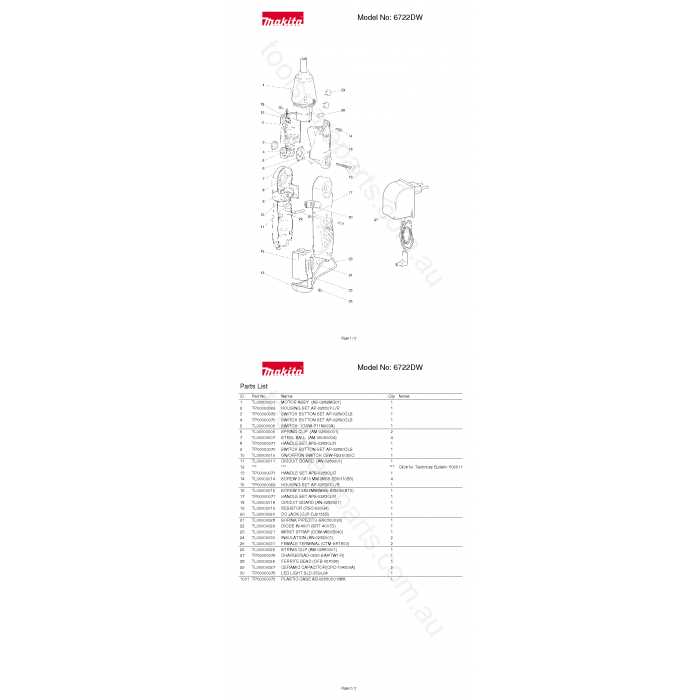

How to Read Parts Diagrams

Understanding schematic representations of tools can significantly enhance your repair and maintenance skills. These visual guides provide a clear overview of components and their relationships, allowing for effective troubleshooting and assembly. Mastering this skill can ultimately save time and resources.

Key Elements to Identify

- Labels: Each component is usually marked with a unique identifier for easy reference.

- Connections: Arrows or lines often indicate how parts fit together or interact.

- Legend: A guide may explain symbols used within the illustration.

Steps to Interpret Effectively

- Start by familiarizing yourself with the legend and labels.

- Trace the connections to understand the assembly process.

- Note any part numbers for ordering replacements.

- Refer back to the diagram as needed during repairs.

Common Issues with Router Components

Understanding frequent problems associated with various components can significantly enhance the longevity and performance of your tools. Many users encounter similar challenges that can stem from wear, improper maintenance, or assembly errors. Recognizing these issues early can prevent further damage and ensure smooth operation.

| Component | Common Issue | Potential Solution |

|---|---|---|

| Base | Unstable operation | Check for debris and ensure secure attachment to the main body. |

| Collet | Bit slippage | Inspect for wear and clean or replace as necessary. |

| Motor | Overheating | Ensure proper ventilation and avoid prolonged use without breaks. |

| Switch | Non-responsive | Test the connection and replace the switch if faulty. |

| Guide | Inaccurate cuts | Align correctly and secure firmly before operation. |

Regular inspection and maintenance of these components will not only improve functionality but also enhance safety during usage. Addressing these common concerns proactively can lead to a more efficient and enjoyable experience.

Maintenance Tips for Makita Routers

Proper upkeep of your power tools is essential for their longevity and optimal performance. Regular maintenance not only enhances efficiency but also ensures safety during use. Implementing a consistent care routine will help you achieve the best results in your projects.

| Task | Frequency | Details |

|---|---|---|

| Clean the tool | After each use | Remove dust and debris to prevent buildup. |

| Inspect for damage | Monthly | Check for wear on components and replace as needed. |

| Lubricate moving parts | Every 3 months | Use appropriate lubricants to ensure smooth operation. |

| Check power cords | Monthly | Look for frays or cuts to ensure safety during operation. |

| Sharpen bits | As needed | Keep cutting edges sharp for clean cuts. |

Replacement Parts for Makita Routers

Ensuring optimal performance of your woodworking tools often requires timely replacements of essential components. Understanding the various elements that can wear out or break is crucial for maintaining efficiency and extending the life of your equipment.

| Component | Description | Function |

|---|---|---|

| Collet | Holds the cutting bit securely in place. | Ensures precision during operation. |

| Base Plate | Provides stability and support. | Enhances control and accuracy. |

| Motor Assembly | The core unit that drives the tool. | Generates power for cutting and shaping materials. |

| Switch | Controls the operation of the device. | Allows for easy start and stop functionality. |

Choosing the Right Router Model

Selecting the appropriate model for your woodworking projects can significantly impact both the quality of your work and your overall experience. With a variety of options available, it is essential to consider several factors before making a decision.

First, assess the types of tasks you plan to undertake. Different models offer varying power levels and features suited for specific applications, from simple edge finishing to more intricate designs. Additionally, evaluate the size and weight of the tool, as this can affect maneuverability and ease of use, especially during prolonged periods of operation.

Another crucial aspect is the range of accessories and attachments available. A versatile unit that accommodates various bits and attachments will expand your capabilities, allowing for more creative projects. Furthermore, consider the brand’s reputation for durability and reliability, as investing in a high-quality option can save you time and money in the long run.

Lastly, don’t overlook user reviews and expert recommendations. Gaining insight from those who have firsthand experience with the equipment can provide valuable guidance in your selection process, ensuring you choose a model that meets your specific needs.

Safety Precautions for Router Use

When working with power tools that involve cutting and shaping materials, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the inherent risks and implementing preventive measures can ensure a secure and productive experience. Proper preparation, protective gear, and adherence to guidelines are essential components of safe operation.

Always wear appropriate personal protective equipment, including safety goggles, ear protection, and dust masks, to safeguard against flying debris and noise. Ensure that the workspace is clean and well-lit to minimize hazards. It is advisable to keep your hands and body away from the cutting area and to secure the workpiece firmly to prevent movement during operation.

Before starting, familiarize yourself with the equipment’s controls and functions. Inspect the tool for any damage or wear, and ensure that all components are properly assembled. When changing bits or making adjustments, always disconnect the power source to avoid unintentional activation.

Maintain a steady grip and posture while operating, and avoid distractions to stay focused on the task at hand. Follow the manufacturer’s guidelines for depth and speed settings to ensure optimal performance and safety. If you are unsure about any aspect of the operation, seek guidance or assistance to enhance safety and efficiency.

Upgrading Your Router’s Performance

Enhancing the capabilities of your tool can significantly impact its efficiency and the quality of your work. By implementing a few strategic upgrades, you can unlock the ultimate potential of your device, leading to smoother operations and improved results.

Here are some effective ways to boost performance:

- Invest in high-quality bits to achieve cleaner cuts and greater precision.

- Consider adding variable speed controls for enhanced versatility.

- Upgrade to a more powerful motor to handle tougher materials effortlessly.

- Implement better dust collection systems to maintain a clean workspace.

- Replace the base plate with a more stable option to improve stability during use.

Delve into these upgrades and enjoy the enhanced functionality and efficiency they bring to your projects.