Meyer Salt Spreader Parts Diagram Guide

In the realm of outdoor maintenance, effective tools play a crucial role in ensuring optimal performance and longevity. A comprehensive knowledge of the various elements that comprise these machines not only enhances their functionality but also simplifies the process of troubleshooting and repairs. Each component is integral to the overall operation, contributing to efficiency and reliability during usage.

Familiarity with the structural layout and individual functionalities of these units can greatly improve the user experience. By dissecting the arrangement of parts and their specific roles, operators can gain insights into potential issues and solutions, leading to better upkeep practices. This understanding ultimately empowers users to maintain their equipment in peak condition.

Whether you are a seasoned professional or a novice in the field, delving into the intricacies of these essential tools will prove invaluable. Recognizing how each section interacts with others fosters a deeper appreciation of the machinery, paving the way for enhanced performance during demanding tasks. Knowledge is not just power; it is the key to operational excellence.

Meyer Salt Spreader Overview

This section provides a comprehensive look at essential equipment designed for efficient material distribution. With a focus on functionality, various components work together to ensure optimal performance during operations. Understanding these elements is crucial for maintaining and enhancing efficiency.

Key Features

Durability and reliability are at the forefront of this equipment’s design. Robust construction materials withstand harsh conditions, while innovative technology allows for precise control of material flow. Users benefit from features that improve handling and ease of use, making operations seamless.

Maintenance Insights

Regular upkeep is vital for longevity and effectiveness. Periodic checks on mechanical systems and control components ensure that everything functions smoothly. Understanding how each part contributes to overall operation aids in troubleshooting and enhances performance over time.

Understanding Salt Spreader Functionality

Effective winter maintenance relies on a thorough grasp of how these devices operate. Their primary goal is to enhance safety and mobility during adverse weather conditions by distributing granular materials efficiently.

- Mechanism: The central system often includes a rotating element that evenly disperses the material across surfaces.

- Components: Key elements such as the hopper, auger, and drive system work together to ensure optimal performance.

- Control: Operators can adjust settings to manage the flow rate and coverage area depending on environmental factors.

Understanding these fundamentals allows users to maximize effectiveness and maintain safe conditions throughout the winter months.

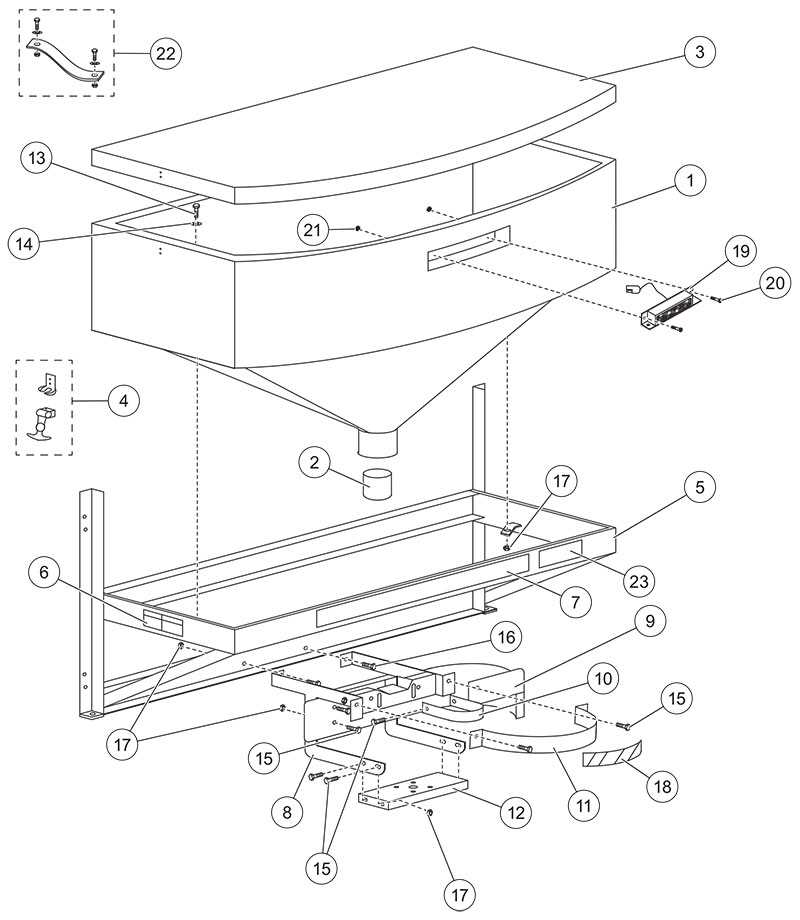

Key Components of Meyer Spreaders

Understanding the essential elements of these dispersal devices is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the optimal performance and longevity of the equipment. Familiarity with these parts will not only enhance functionality but also aid in troubleshooting and repairs when necessary.

1. Dispersal Mechanism

The dispersal mechanism is the heart of the system, responsible for the even distribution of materials. It typically involves a rotating assembly that propels the substance outward, ensuring a consistent coverage area. Proper calibration of this element is vital for achieving the desired spread rate and avoiding waste.

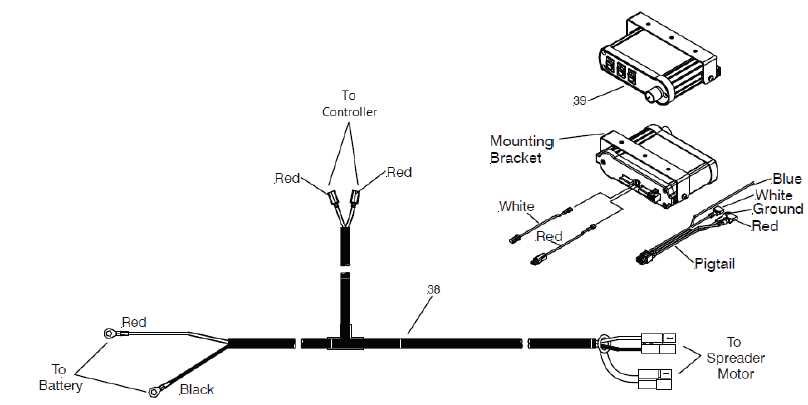

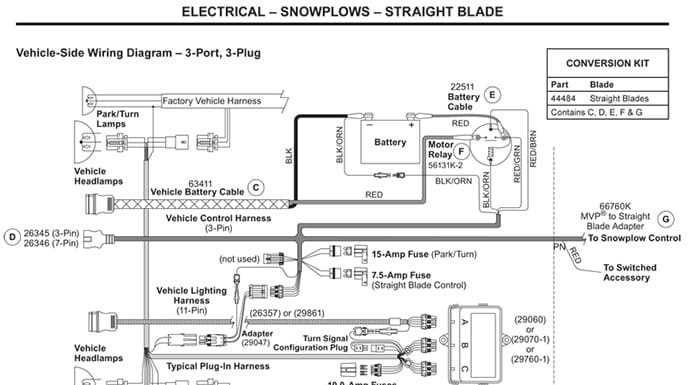

2. Control System

The control system allows the operator to manage the flow and rate of material being dispensed. This component can vary from manual levers to advanced electronic interfaces, providing flexibility and precision. Regular checks on this system can help prevent issues that may affect performance and efficiency.

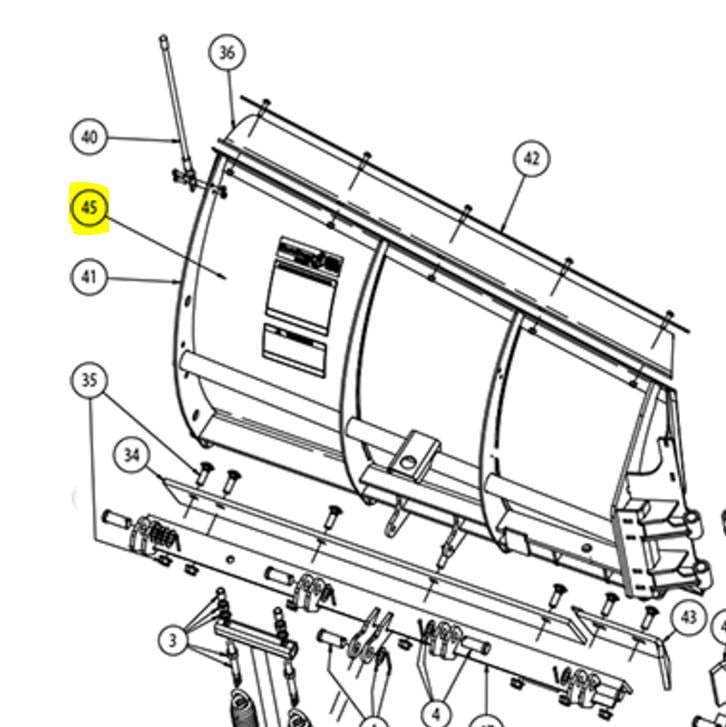

Parts Diagram: An Illustrated Guide

This section provides a comprehensive visual representation of essential components, enhancing understanding of their function and interaction. Through detailed illustrations, users can familiarize themselves with the various elements involved in the machinery, facilitating effective maintenance and troubleshooting.

Understanding Components: Each element plays a crucial role in the overall performance. Recognizing these components not only aids in efficient operation but also extends the lifespan of the equipment.

Illustrative Breakdown: The accompanying visuals depict key parts, highlighting their placement and relationship to one another. This graphical approach simplifies complex assemblies, making it easier for users to identify specific areas of interest.

Maintenance Insights: By studying the illustrated guide, users can better plan for routine checks and repairs, ensuring optimal functionality throughout the equipment’s life cycle.

Conclusion: An illustrated reference is invaluable for anyone looking to enhance their knowledge and skills related to machinery management. This guide serves as a helpful tool for both novice and experienced operators alike.

Importance of Regular Maintenance

Benefits of Routine Checks

Conducting regular inspections not only extends the lifespan of your machinery but also improves safety during operation. Consistent maintenance helps identify potential problems early, enabling timely interventions that can prevent accidents and malfunctions. Additionally, it ensures that the equipment operates at peak efficiency, which can lead to better results in various tasks.

Maintenance Schedule Recommendations

Establishing a consistent maintenance schedule is crucial for maximizing performance. Here’s a simple table outlining suggested maintenance tasks and their frequencies:

| Maintenance Task | Frequency |

|---|---|

| Check fluid levels | Weekly |

| Inspect belts and hoses | Monthly |

| Clean components | Every 3 months |

| Lubricate moving parts | Every 6 months |

| Full inspection | Annually |

By adhering to a structured maintenance plan, operators can ensure that their equipment remains in top condition, ultimately leading to enhanced performance and reliability over time.

Common Issues and Troubleshooting Tips

Understanding the frequent challenges that arise with equipment maintenance is crucial for efficient operation. By identifying common faults and applying practical solutions, users can enhance performance and extend the lifespan of their machinery.

Frequent Problems

| Issue | Description |

|---|---|

| Inconsistent Dispensing | The material is not being spread evenly, leading to gaps or excess. |

| Mechanical Blockages | Materials may clog within the system, preventing proper flow. |

| Power Failures | The unit fails to operate due to electrical issues or dead batteries. |

Troubleshooting Steps

To address these challenges, start by checking for clogs or obstructions, ensuring that all moving parts are well-lubricated and functional. For power issues, inspect connections and battery levels. Regular maintenance and cleaning can prevent many common malfunctions.

How to Identify Parts by Model

Understanding how to recognize components based on their specific models is essential for effective maintenance and repairs. Each model typically has a unique set of features and identifiers that help users distinguish between various elements. Familiarity with these identifiers can greatly enhance the efficiency of any project.

Checking Model Numbers

One of the primary steps in identifying components is locating the model number. This number is often found on the device itself, usually on a label or stamped into the body. By referencing the model number, users can access manuals and documentation that provide detailed information about compatible elements.

Consulting Manufacturer Resources

Utilizing resources provided by the manufacturer is another effective method for identification. Many companies offer online databases or customer support services where users can enter their model number to retrieve specific information. This can include diagrams, specifications, and recommendations for replacements, ensuring the right selections are made.

Replacement Parts: Where to Buy

Finding suitable components for your equipment is essential for maintaining optimal performance. Numerous retailers offer a variety of options, ensuring you can locate the necessary items quickly and efficiently.

Online Retailers

Numerous e-commerce platforms specialize in equipment accessories, providing a wide selection at competitive prices. Websites like Amazon and eBay often feature both new and refurbished options, giving you the flexibility to choose based on your budget and needs.

Local Suppliers

Visiting local hardware stores or specialized equipment suppliers can also be beneficial. These establishments typically have knowledgeable staff who can assist you in identifying the correct items, ensuring you get the right fit for your machinery.

Installation Guide for New Parts

This section outlines the essential steps for properly fitting new components into your equipment. Ensuring accurate installation is crucial for optimal performance and longevity.

Follow these steps for a seamless integration:

| Step | Description |

|---|---|

| 1 | Begin by gathering all necessary tools and new components. |

| 2 | Refer to the user manual for specific instructions related to your model. |

| 3 | Carefully remove old components, taking note of their placement. |

| 4 | Install the new parts, ensuring a secure fit to avoid future issues. |

| 5 | Test the equipment to confirm everything functions correctly after installation. |

Upgrading Your Meyer Spreader

Enhancing the performance and efficiency of your equipment can significantly improve your overall experience. By focusing on key components and upgrades, you can ensure optimal functionality for various tasks.

- Consider replacing outdated components with newer, high-quality alternatives.

- Evaluate the benefits of adding a control system for better precision.

- Examine your current spreading mechanism and look for enhancements.

These modifications not only boost productivity but also extend the lifespan of your device. Careful selection and installation of upgraded elements can lead to the ultimate performance you desire.

Safety Precautions During Use

Ensuring safety while operating equipment is crucial to prevent accidents and injuries. Awareness of potential hazards and proper handling techniques can significantly reduce risks. Following established guidelines and using appropriate protective gear are essential for a safe working environment.

Personal Protective Equipment

Wearing suitable personal protective equipment (PPE) is vital. This includes gloves, goggles, and sturdy footwear to shield against any debris or chemicals. Proper attire not only enhances safety but also promotes confidence while working.

Equipment Maintenance

Regularly inspecting and maintaining machinery is necessary to ensure optimal functionality. Check for any wear or damage before use, and make necessary repairs promptly. Keeping equipment in top condition reduces the likelihood of malfunctions that could lead to dangerous situations.

Customer Reviews and Experiences

This section aims to provide insights into user feedback and personal accounts regarding a specific piece of equipment used for winter maintenance. Through various testimonials, potential buyers can gain a better understanding of the performance, reliability, and overall satisfaction associated with this machinery.

Many users appreciate the efficiency of the equipment during harsh weather conditions. One customer noted how it significantly reduced the time needed for snow management, allowing for more productivity. Another highlighted the user-friendly design, making it accessible for operators of all experience levels.

However, some reviews pointed out areas for improvement. Issues with durability in extreme temperatures were mentioned, leading to occasional repairs. Yet, many users found the customer service to be responsive and helpful in addressing these concerns.

Overall, the feedback presents a balanced view, with many users recommending the equipment for its performance while suggesting potential enhancements for future models.