Comprehensive Guide to Milwaukee M18 Grease Gun Parts Diagram

In the realm of maintenance and machinery, having a clear grasp of the individual components of your lubrication device is essential for effective operation and longevity. Knowing how each piece interacts can greatly enhance your efficiency and ensure that the tool performs at its best.

From the motor assembly to the dispensing mechanism, every element plays a pivotal role in the functionality of the equipment. Familiarizing yourself with these parts not only aids in troubleshooting but also facilitates smoother repairs and replacements when necessary.

This guide aims to provide a comprehensive overview of the key elements of your lubrication apparatus, empowering users to navigate the complexities of their tools with confidence. By understanding the structure and design, you can optimize usage and maintain peak performance throughout its lifespan.

Understanding the Milwaukee M18 Grease Gun

This section aims to explore a versatile tool designed for efficient lubrication tasks. Its innovative design enhances functionality, making maintenance tasks simpler and quicker for users across various industries.

Key Features

The device is equipped with a powerful motor, delivering consistent pressure for effective application. A convenient battery system ensures portability, allowing users to work in remote locations without the hassle of cords.

Maintenance and Care

Key Features of the M18 Grease Gun

This powerful tool is designed to deliver exceptional performance and convenience in lubrication tasks. With its advanced technology and ergonomic design, it enhances efficiency and ensures a smooth operation for users across various applications.

Innovative Technology

Equipped with a high-output motor, this device ensures a consistent flow of lubricant, minimizing downtime and maximizing productivity. The integrated pressure control system offers precise dispensing, making it suitable for both heavy-duty and light tasks.

User-Friendly Design

The ergonomic handle and lightweight construction allow for easy maneuverability, reducing user fatigue. Additionally, the tool features a bright LED light for improved visibility in dimly lit areas.

| Feature | Description |

|---|---|

| High-Output Motor | Delivers consistent flow for efficient lubrication. |

| Pressure Control | Ensures precise dispensing for various applications. |

| Ergonomic Handle | Reduces user fatigue during prolonged use. |

| LED Light | Enhances visibility in low-light conditions. |

Importance of Regular Maintenance

Consistent upkeep of equipment is crucial for ensuring optimal performance and longevity. Neglecting routine checks can lead to decreased efficiency and potential breakdowns, which may result in costly repairs and downtime. Understanding the significance of this practice helps in preventing unexpected failures and enhances overall productivity.

| Benefits of Maintenance | Consequences of Neglect |

|---|---|

| Improved Efficiency | Decreased Performance |

| Extended Lifespan | Frequent Repairs |

| Cost Savings | Increased Downtime |

| Enhanced Safety | Potential Hazards |

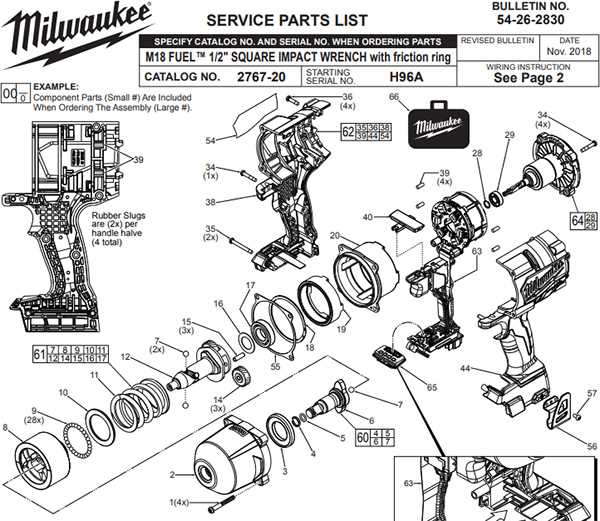

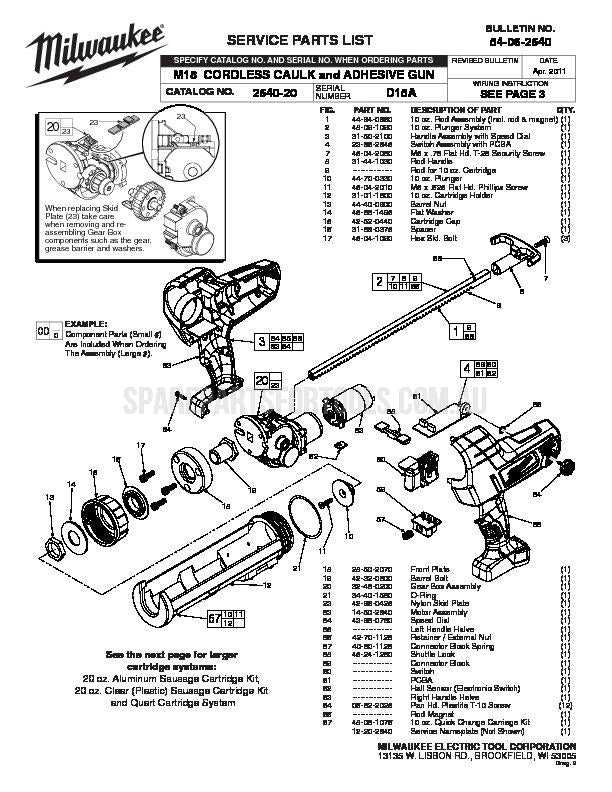

Common Replacement Parts Overview

In the realm of maintenance tools, understanding the essential components that may require replacement is crucial for optimal performance. Regular usage can lead to wear and tear, making it important for users to be familiar with the various elements that ensure effective operation. This overview highlights the most frequently replaced items, enhancing the longevity and functionality of your equipment.

Key Components to Consider

- Seals: These elements prevent leakage and maintain pressure. Damaged seals can lead to inefficient operation.

- Filters: Essential for keeping debris out of the system, ensuring smooth performance.

- Hoses: Over time, hoses can crack or wear, affecting the flow of substances.

- Nozzles: Different tasks may require different nozzle types; wear can lead to uneven distribution.

Maintenance Tips

- Regularly inspect components for signs of damage or wear.

- Keep a replacement inventory for critical items to minimize downtime.

- Follow manufacturer guidelines for installation and maintenance to ensure compatibility.

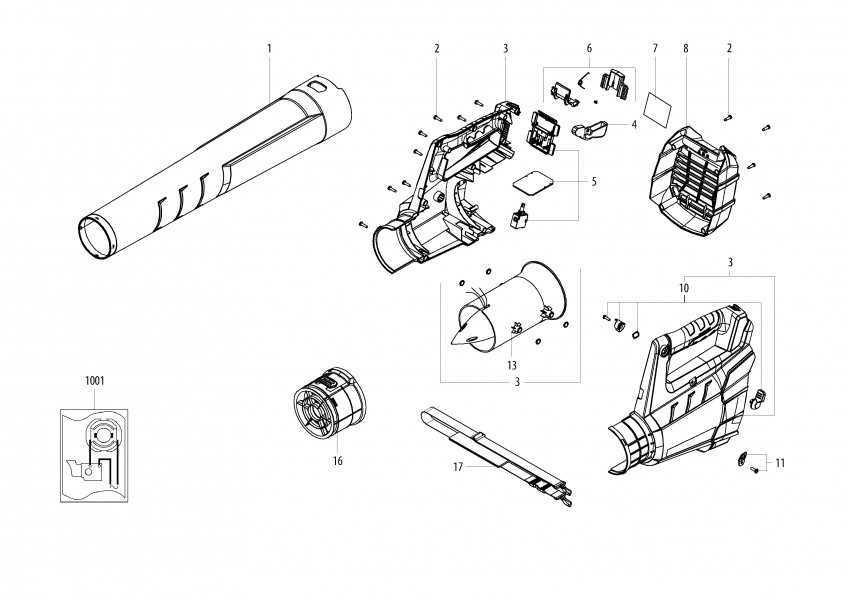

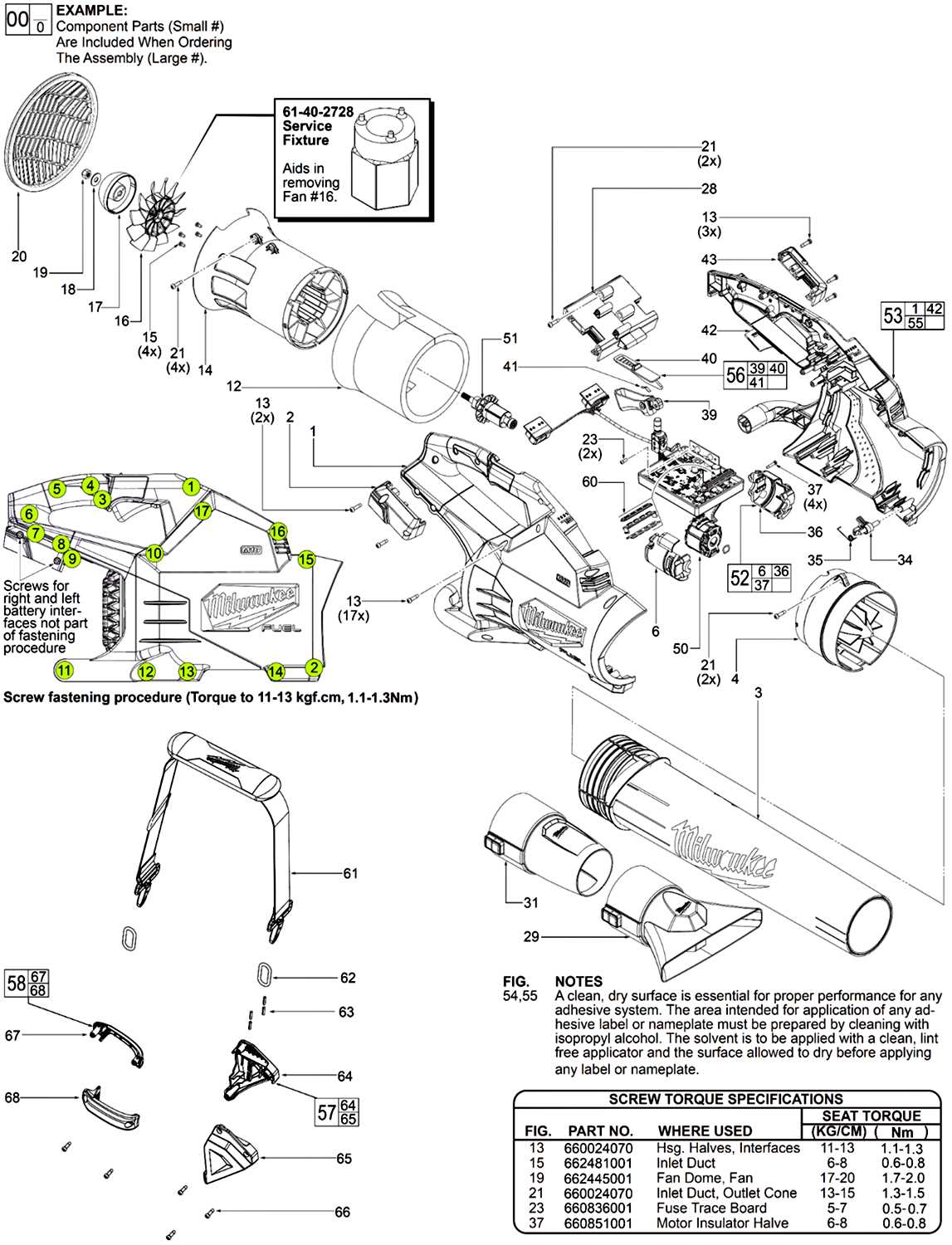

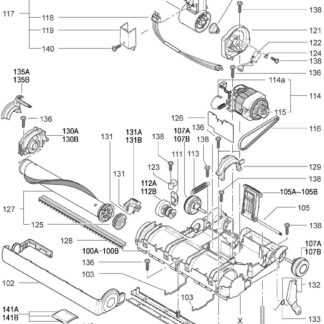

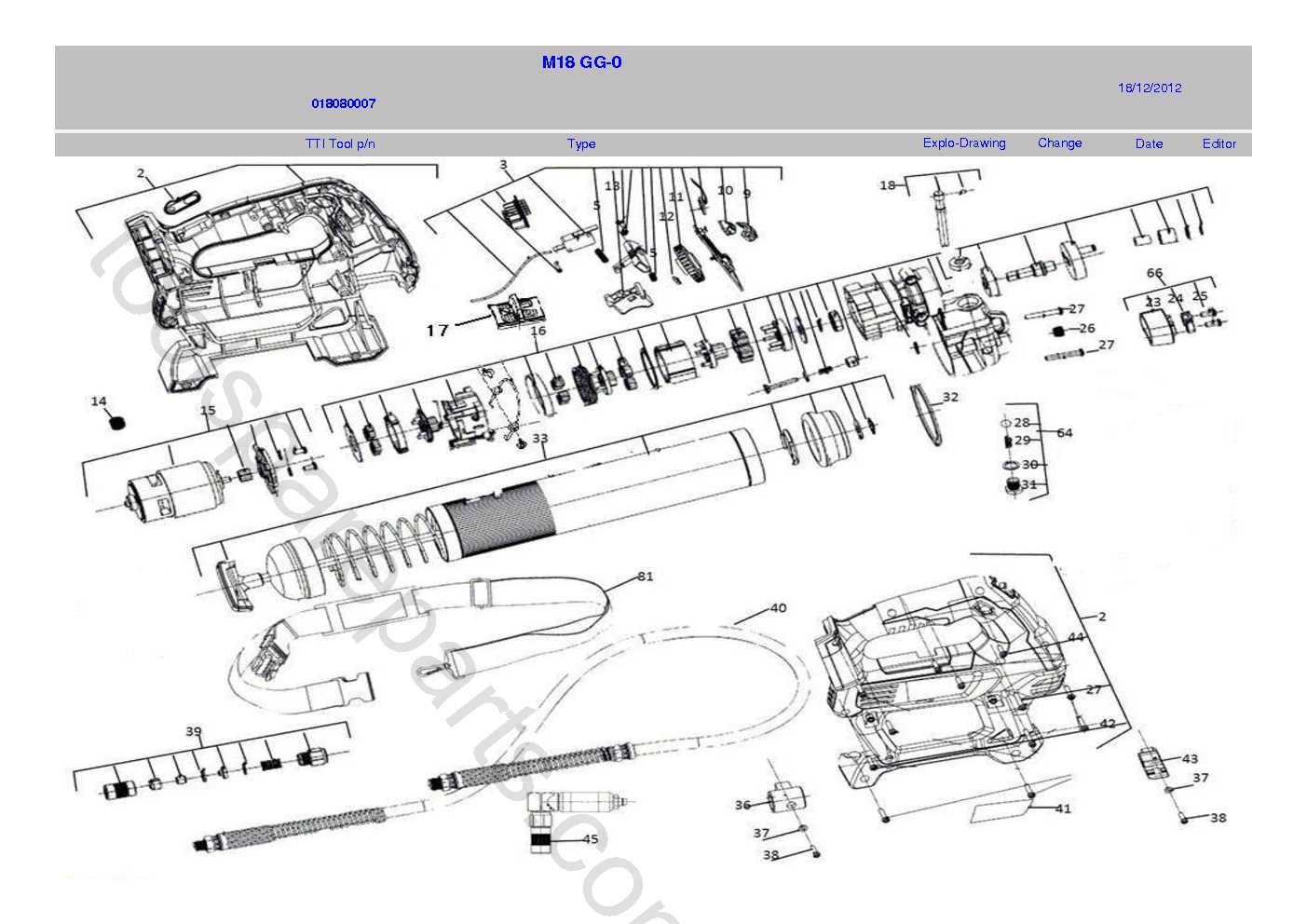

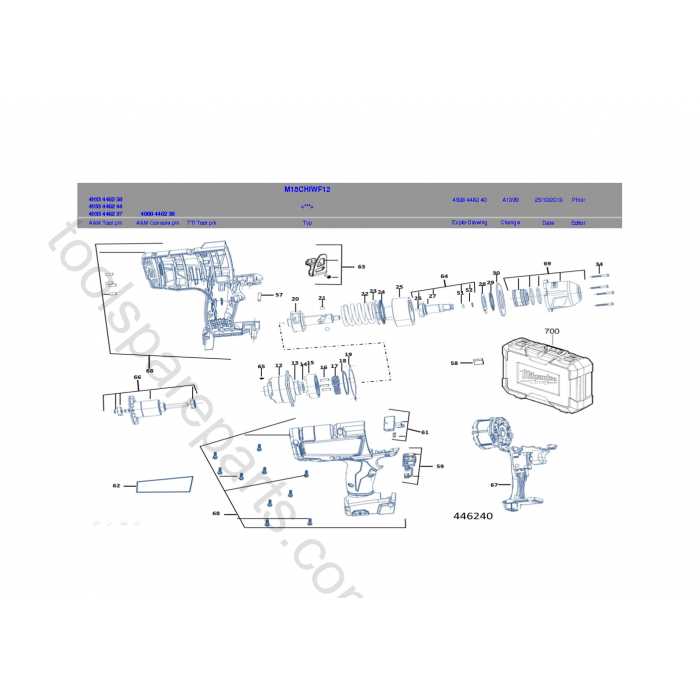

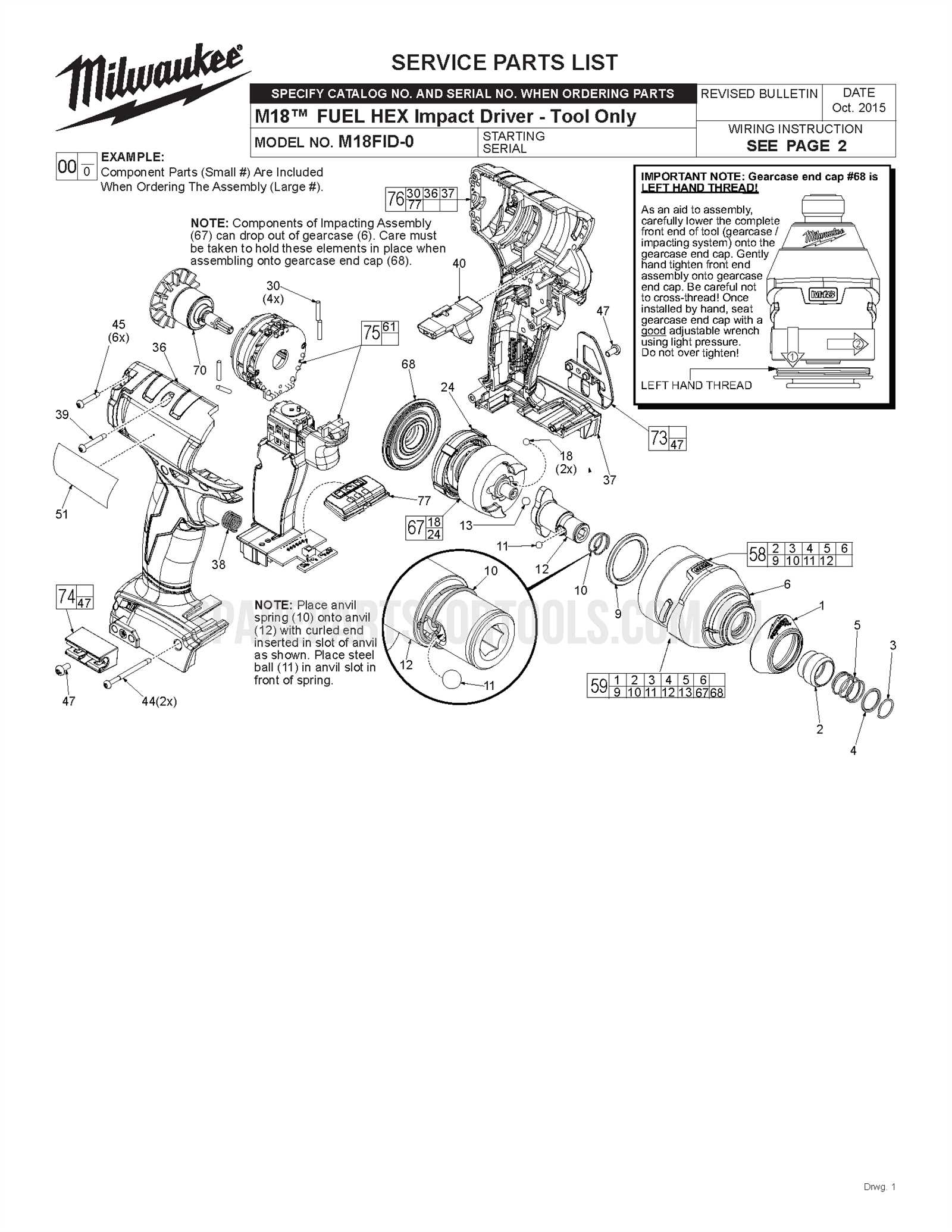

How to Read Parts Diagrams

Understanding technical illustrations is essential for efficient maintenance and repair. These visuals provide a clear representation of components, helping users identify and locate specific elements within a device. Mastering the ability to interpret these diagrams can significantly enhance your troubleshooting skills.

First, familiarize yourself with the symbols and notations used in the illustration. Each component is usually marked with a unique identifier, which corresponds to a list or legend detailing specifications and part numbers. Pay attention to these identifiers, as they guide you in sourcing replacements or understanding function.

Next, examine the layout of the image. Components are often arranged in a logical manner, reflecting their actual positioning within the device. Taking note of the arrangement can provide insights into assembly and disassembly processes, making repairs more intuitive.

Lastly, cross-reference the visual with the accompanying documentation. This will deepen your understanding and ensure you have a comprehensive grasp of how each element interacts within the larger system. By developing these skills, you’ll gain the confidence needed to tackle repairs and modifications effectively.

Troubleshooting Common Issues

Understanding and resolving frequent challenges with equipment can enhance performance and prolong lifespan. This section aims to address typical malfunctions and provide guidance for effective solutions.

Identifying Blockages

One prevalent issue is the obstruction in the delivery system. If you notice reduced flow, inspect for clogs. Cleaning the nozzle and checking the inlet can often resolve this issue. Regular maintenance is essential to prevent buildup.

Power Supply Problems

Another common concern is the power source. If the unit fails to operate, check the battery connection and ensure it is fully charged. Replace the battery if necessary, as old batteries may not hold a charge effectively.

Benefits of Using Genuine Parts

Utilizing authentic components in your equipment ensures optimal performance and longevity. While alternatives may seem tempting due to lower costs, genuine parts provide significant advantages that can ultimately save you time and money.

Quality Assurance

Original components are manufactured to strict specifications, ensuring they meet high standards of quality and reliability. This consistency means that your machinery operates smoothly, reducing the risk of unexpected breakdowns.

Enhanced Compatibility

Genuine parts are designed specifically for your equipment, ensuring perfect fit and functionality. This compatibility prevents issues that can arise from using generic alternatives, such as misalignment or improper operation.

| Benefit | Description |

|---|---|

| Durability | Authentic components are built to last, reducing the frequency of replacements. |

| Warranty Protection | Using original parts often keeps your warranty valid, protecting your investment. |

| Performance | Genuine parts optimize the overall efficiency and effectiveness of your equipment. |

| Safety | Original components adhere to safety standards, minimizing risks during operation. |

Assembly Instructions for New Users

Assembling your new tool can seem daunting, but following a clear set of steps will ensure a smooth process. This guide aims to simplify your experience, helping you to become familiar with the components and their functions.

- Begin by gathering all components listed in the manual.

- Identify the main body and its attachments.

- Follow these steps for assembly:

- Attach the handle securely to the main unit.

- Insert the designated nozzle at the front, ensuring a tight fit.

- Connect any necessary hoses or extensions.

Once assembled, perform a brief inspection to confirm everything is correctly attached. Familiarize yourself with the operation guidelines for optimal use.

Comparing M18 Models and Variants

This section explores the various models and their unique features within a specific line of tools. Understanding the distinctions among these options helps users select the right tool for their tasks, considering factors like performance, durability, and user-friendliness.

Performance and Specifications

Each variant comes equipped with different power levels and capabilities, catering to diverse applications. While some models excel in torque and speed, others prioritize battery life and efficiency. Evaluating these specifications is crucial for making an informed choice.

Design and Ergonomics

The design elements, including weight and grip, significantly impact user experience. Some versions feature more compact designs for tight spaces, while others offer enhanced comfort for extended use. Choosing the right ergonomics can lead to increased productivity and reduced fatigue.

Safety Tips for Grease Gun Operation

Operating lubrication equipment requires attention to detail and adherence to safety protocols. Ensuring the safety of both the user and the surrounding environment is paramount when handling these tools.

1. Personal Protective Equipment: Always wear appropriate protective gear, including gloves and goggles, to shield against potential spills or splashes.

2. Proper Handling: Maintain a firm grip on the tool and avoid overexerting yourself. Ensure that your hands are dry to prevent slippage.

3. Workspace Organization: Keep the work area clean and free from clutter to prevent accidents. Ensure that all tools and materials are stored safely when not in use.

4. Follow Manufacturer Instructions: Adhere to the operating manual provided by the manufacturer for safe usage and maintenance.

5. Regular Inspections: Frequently check the equipment for any signs of wear or damage. Address any issues immediately to avoid malfunction.

6. Avoid Overfilling: Be cautious not to overfill the reservoir, as this can lead to leaks and unintended messes.

7. Secure Connections: Ensure that all connections are tight and secure before starting operation to prevent leaks during use.

Where to Purchase Replacement Parts

Finding the right components for your tools can enhance their performance and longevity. Knowing where to seek these essential elements is crucial for maintaining functionality and efficiency.

Authorized Retailers

One of the best options is to visit authorized dealers, as they typically carry a wide selection of original components. This ensures that you receive high-quality items designed specifically for your equipment.

Online Marketplaces

Another convenient avenue is online platforms. Websites like Amazon or specialized tool retailers often provide detailed listings, allowing you to compare prices and read customer reviews. Always check for the reliability of the seller to guarantee a satisfactory purchase.