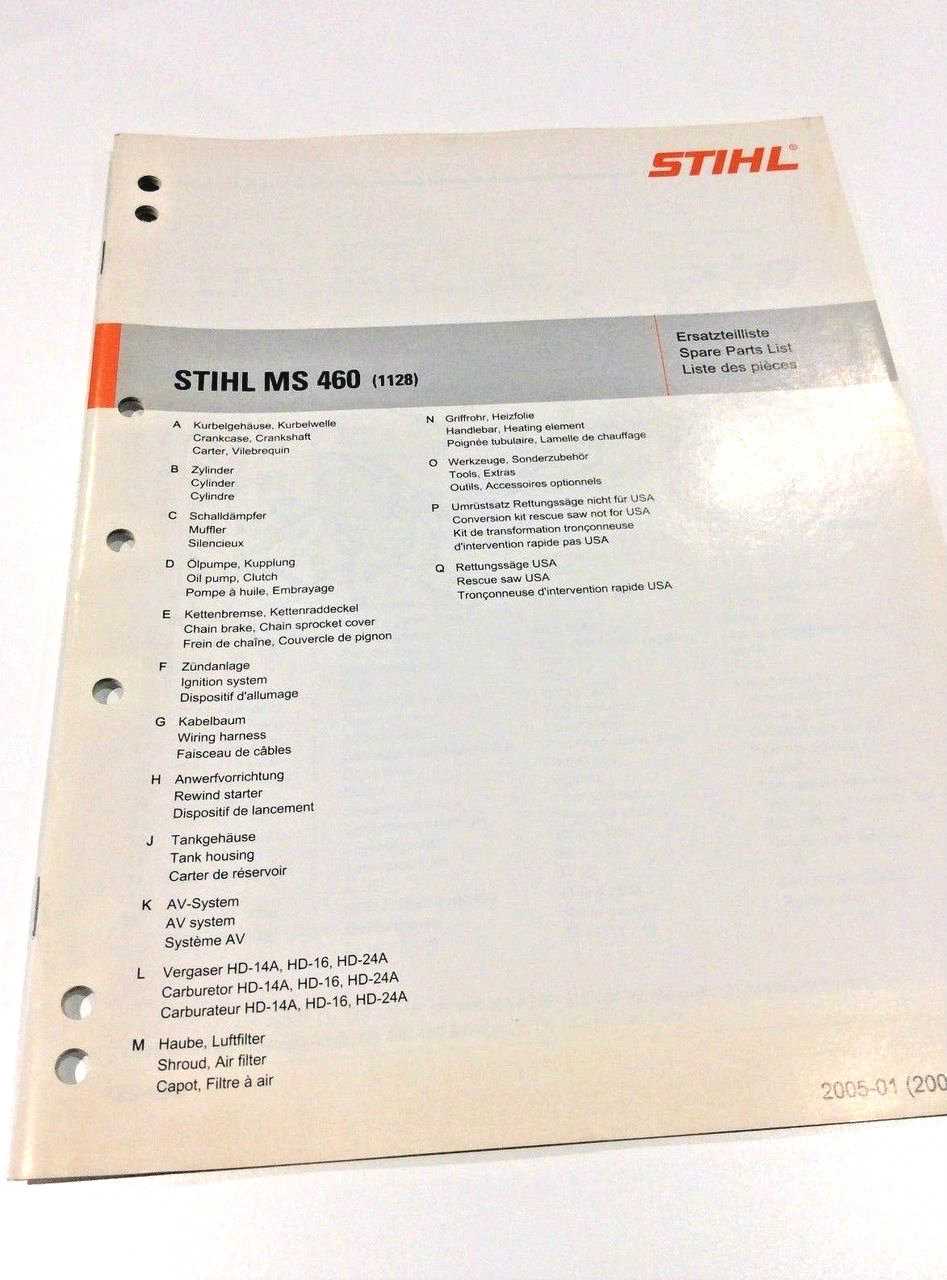

Complete Guide to Ms 460 Parts Diagram

In the realm of machinery, comprehending the intricate arrangement of elements is crucial for optimal performance. Every device consists of various components that work in harmony to ensure functionality. This article aims to explore the visual representation of these essential parts, aiding users in identifying and maintaining their equipment.

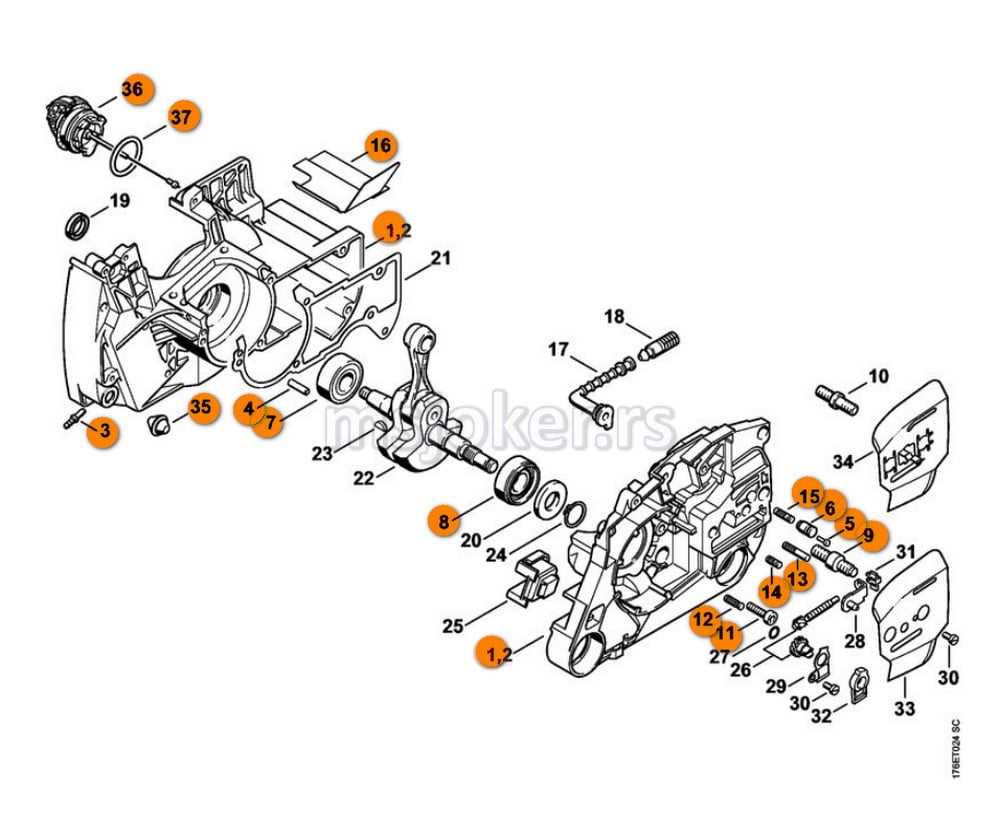

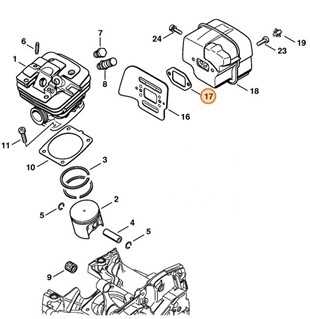

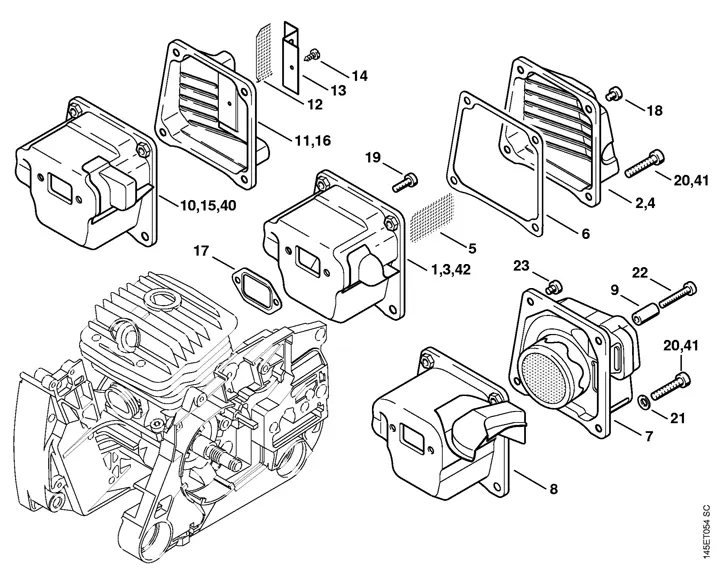

Dissecting the Assembly allows enthusiasts and professionals alike to delve into the specifics of each piece. By familiarizing oneself with how these elements interact, one can troubleshoot effectively and enhance overall efficiency. The structured layout serves as a valuable reference for those seeking to understand the assembly better.

Ultimately, having access to a comprehensive visual guide empowers users to make informed decisions regarding repairs and upgrades. This understanding is vital for prolonging the lifespan of machinery and ensuring it operates at peak performance.

Understanding the Ms 460 Model

The Ms 460 model represents a pinnacle of engineering in its category, known for its robustness and reliability. It embodies advanced technology that enhances performance, making it a favored choice among professionals and enthusiasts alike. This machine’s design integrates various components that work harmoniously to deliver exceptional results in demanding environments.

Key features of this model include its powerful engine, which provides the necessary torque for heavy-duty tasks, alongside an ergonomic design that ensures comfort during extended use. The intuitive controls and thoughtful layout allow for seamless operation, catering to users of all skill levels.

Moreover, the model is built with durability in mind, using high-quality materials that withstand the rigors of intense applications. Maintenance is straightforward, with many elements designed for easy access, ensuring that users can keep their equipment in optimal condition without hassle.

In summary, understanding this particular model involves appreciating its combination of strength, user-friendly features, and longevity, making it a valuable asset for various applications.

Key Features of Ms 460 Chainsaw

The chainsaw model in focus is designed for both professional and amateur users, delivering a blend of power, efficiency, and versatility. Its construction reflects a commitment to quality, ensuring reliable performance across a variety of tasks.

- Powerful Engine: Equipped with a robust motor, this tool is capable of handling demanding cutting jobs with ease.

- Lightweight Design: The ergonomic build reduces fatigue during prolonged use, making it easier to maneuver.

- Advanced Chain System: Features a high-quality chain that offers smooth cuts and quick adjustments, enhancing user experience.

- Durable Components: Crafted with high-grade materials, ensuring longevity and resistance to wear and tear.

- Easy Maintenance: Designed for hassle-free upkeep, allowing users to maintain peak performance without extensive effort.

This chainsaw stands out for its combination of cutting-edge technology and user-friendly features, making it a reliable choice for a range of applications.

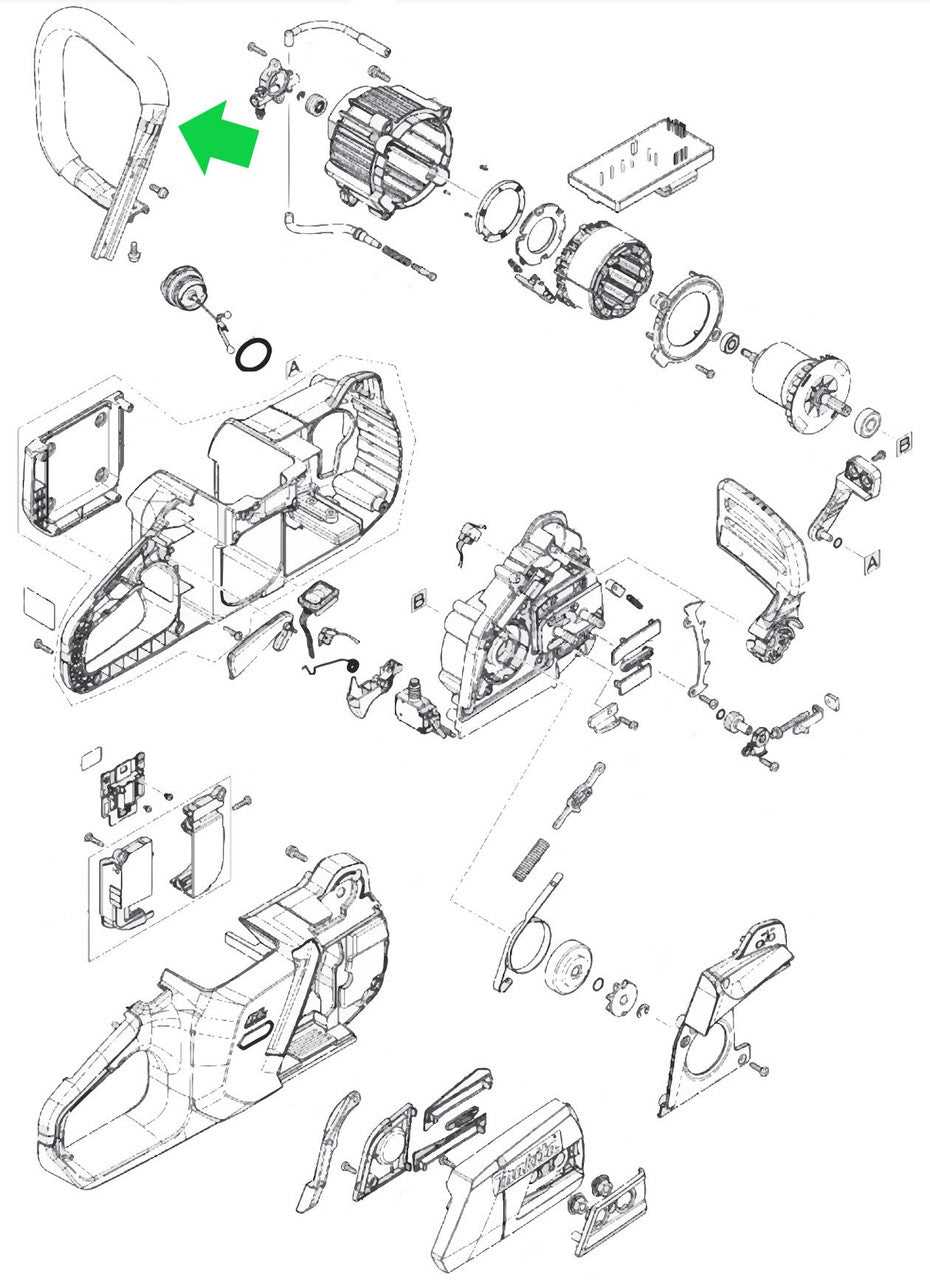

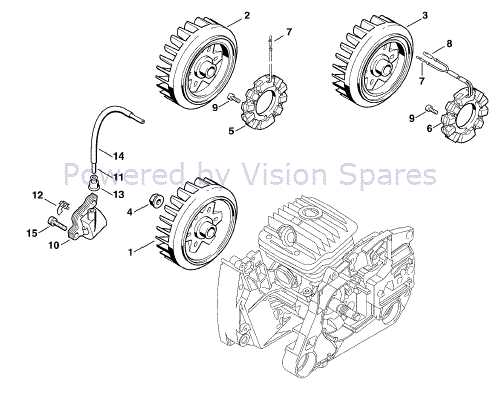

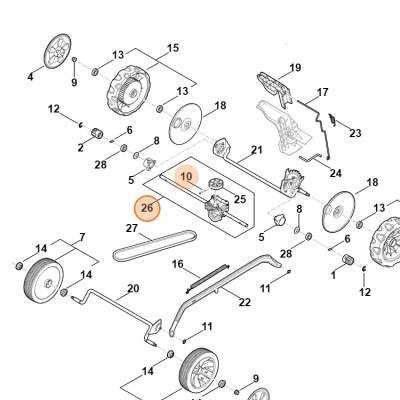

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate details of machinery and tools. They serve as essential guides for users, providing clarity on how different elements interact and function together. This knowledge is vital for effective maintenance, repair, and assembly processes, ensuring that equipment operates smoothly and efficiently.

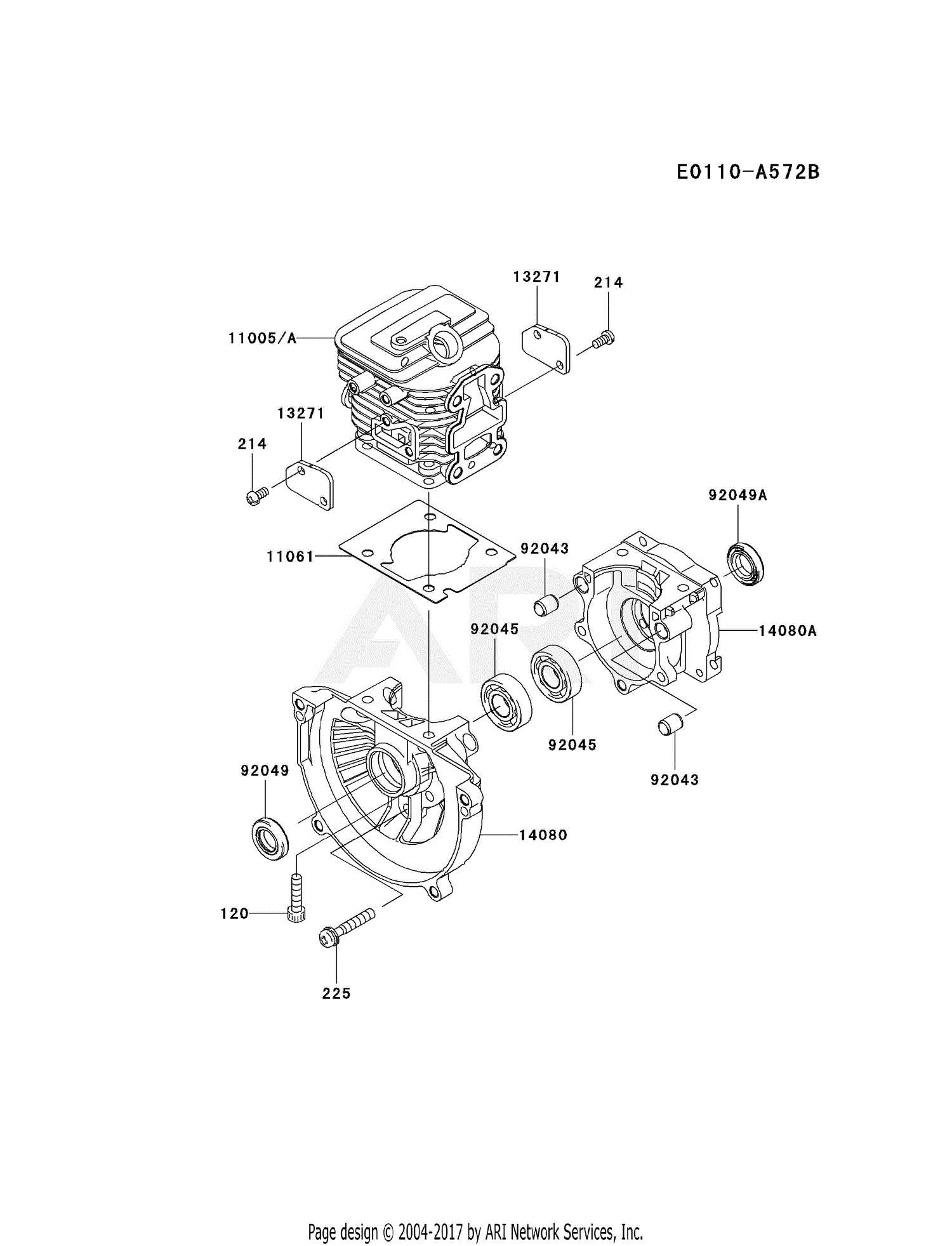

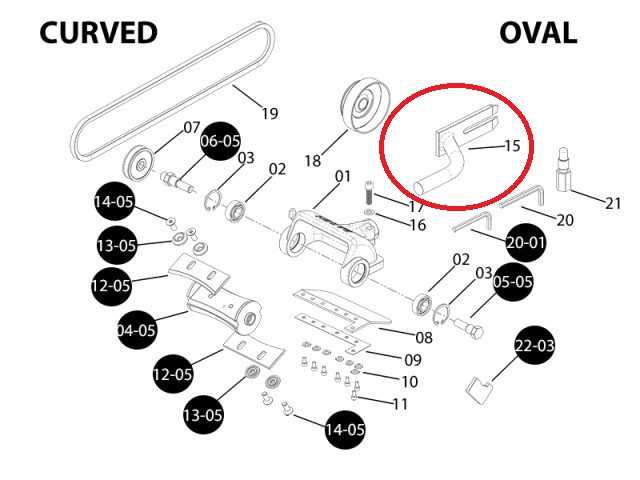

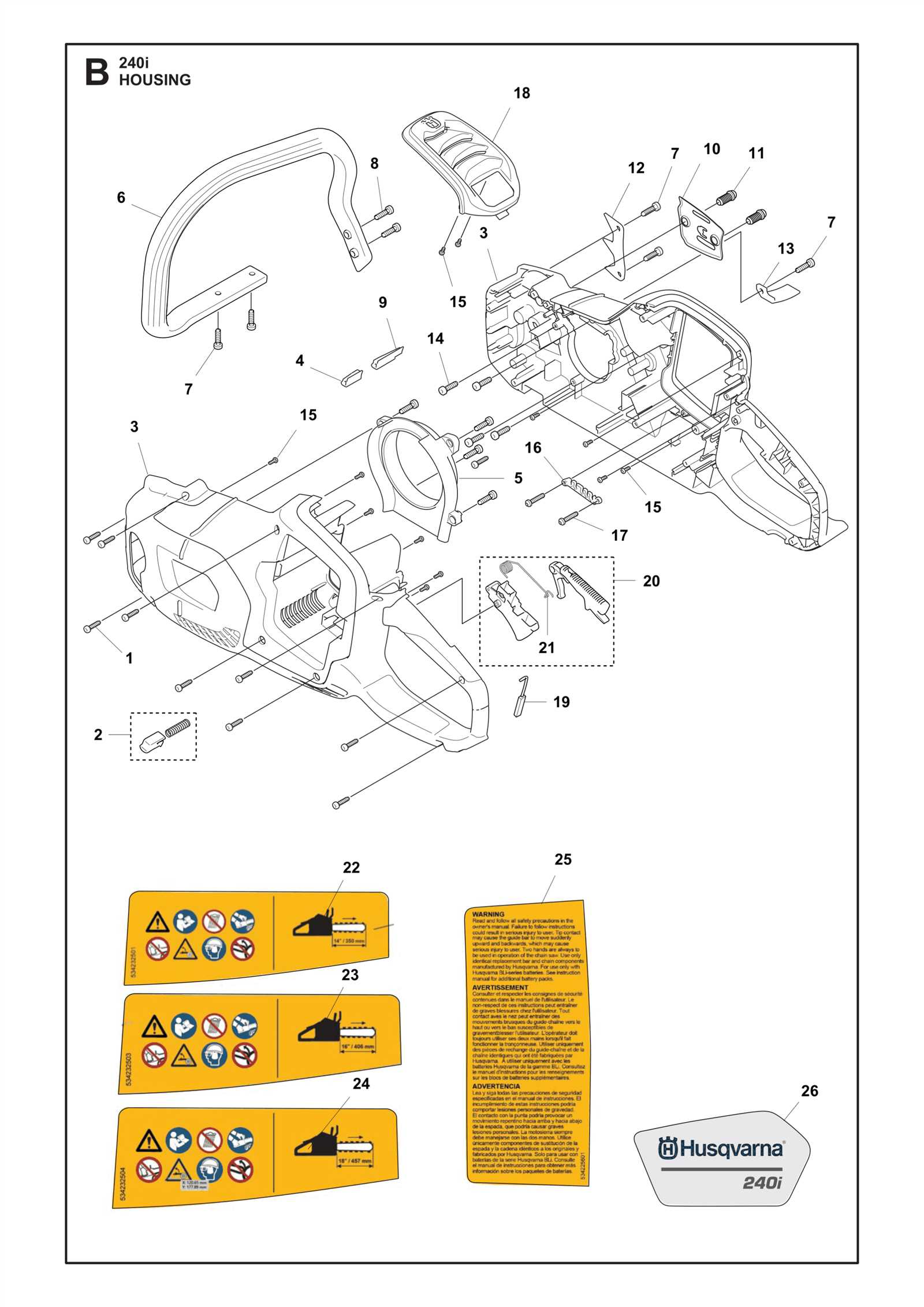

Enhanced Understanding

These visual aids simplify complex structures, allowing users to quickly grasp the layout and arrangement of individual elements. By breaking down the assembly into manageable sections, individuals can identify specific components and their roles within the whole system, making it easier to troubleshoot issues or perform upgrades.

Facilitating Maintenance

Access to clear visual information greatly assists in maintenance tasks. Users can reference the illustrations to locate and replace worn or damaged pieces without unnecessary guesswork. This precision not only saves time but also reduces the risk of errors that could lead to further complications, ultimately prolonging the lifespan of the equipment.

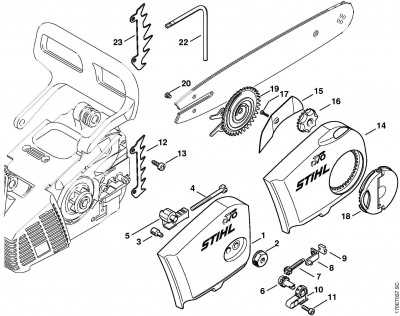

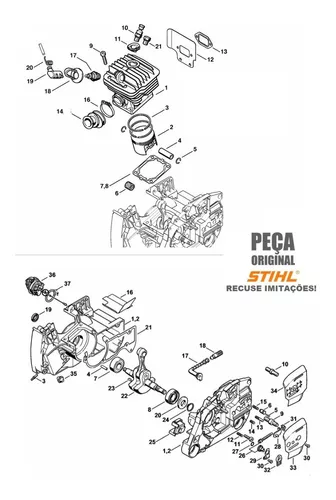

Identifying Ms 460 Components Easily

Understanding the various elements of your equipment is crucial for effective maintenance and troubleshooting. By recognizing each piece’s function and interrelation, you can enhance the overall performance and longevity of your machine. This guide aims to simplify the identification process, ensuring that you can swiftly locate and address any issues that may arise.

Key Elements to Recognize

Familiarize yourself with essential components such as the engine assembly, ignition system, and fuel delivery mechanisms. Each of these parts plays a pivotal role in the operation of your device, and knowing their locations and purposes can streamline repairs and replacements.

Tools for Efficient Identification

Utilizing reference materials like manuals and online resources can significantly aid in pinpointing each component. Diagrams and schematics offer visual cues that make it easier to understand how each piece fits into the larger system, ultimately enhancing your efficiency in maintenance tasks.

Common Repairs for Ms 460

Maintaining high-performance tools often involves addressing typical issues that arise during use. Understanding these frequent repairs can enhance functionality and longevity. Whether it’s routine maintenance or specific malfunctions, knowing what to expect is crucial for efficient operation.

Fuel System Troubles: One of the primary concerns is the fuel system, which may require cleaning or replacement of filters to ensure optimal flow.

Ignition Problems: Another common issue lies within the ignition components. Regularly checking and replacing spark plugs can prevent starting difficulties.

Chain and Bar Wear: The cutting mechanism can also experience wear over time. It’s important to inspect and sharpen the chain, or replace it if necessary, to maintain cutting efficiency.

Air Filter Maintenance: Keeping the air filter clean is essential for proper airflow. A clogged filter can lead to performance issues, so routine cleaning or replacement is recommended.

Lubrication System Checks: Lastly, ensuring the lubrication system is functioning correctly will prevent overheating and extend the life of the tool. Regular checks can help identify leaks or blockages.

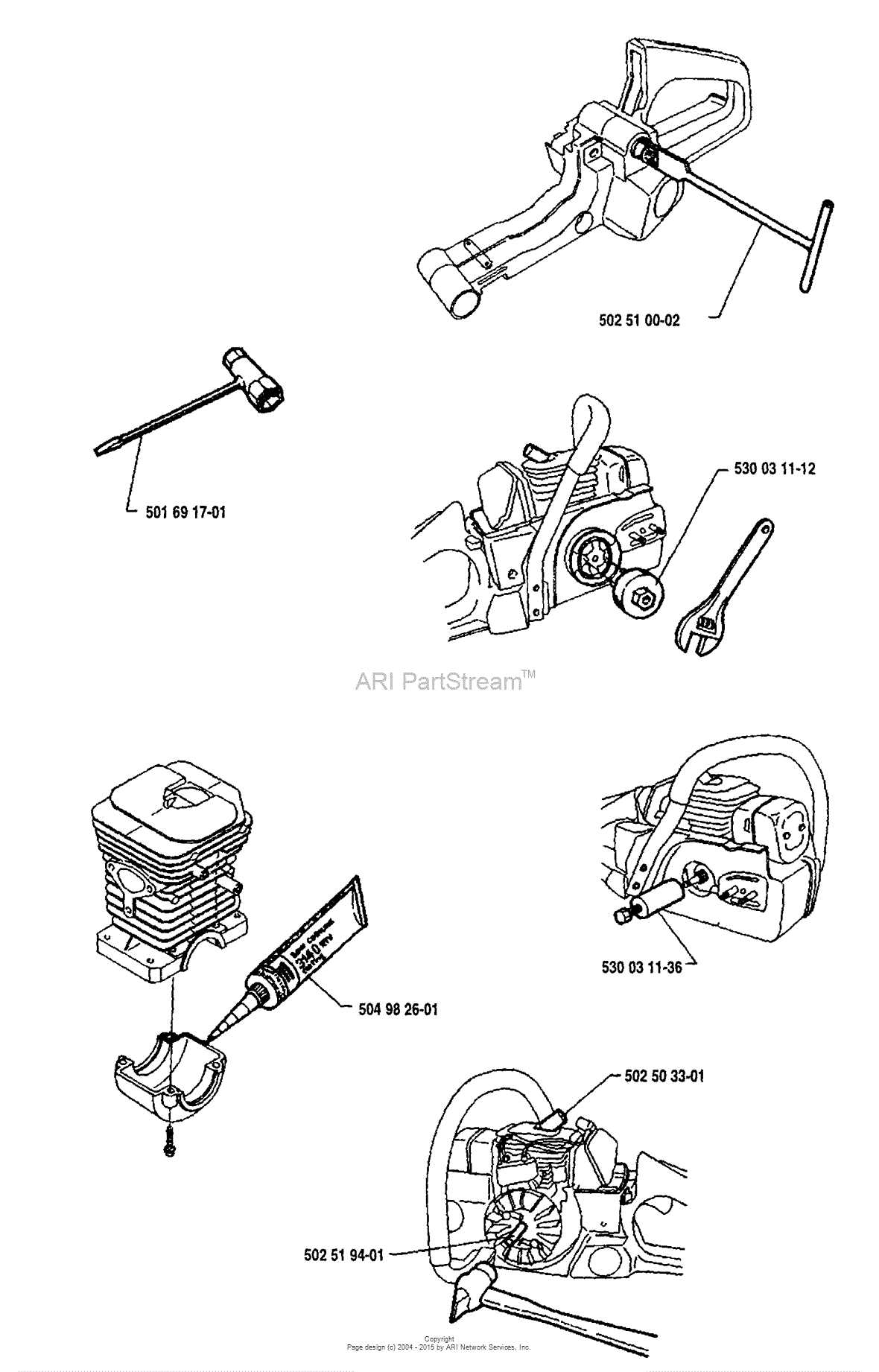

Tools Needed for Ms 460 Maintenance

Proper upkeep of your equipment requires a selection of essential implements. Having the right tools on hand not only enhances efficiency but also ensures longevity and optimal performance. Whether for routine checks or repairs, being prepared is key to a successful maintenance experience.

Essential Implements

Basic tools include wrenches, screwdrivers, and pliers, which allow for adjustments and minor repairs. Additionally, a fuel mixture container and a cleaning brush can help maintain cleanliness and functionality.

Advanced Equipment

For more intricate tasks, consider investing in specialized tools such as torque wrenches and diagnostic kits. These can significantly aid in delving deeper into performance issues and ensuring your machine operates at its best.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a daunting task, but with the right resources, it becomes manageable. Numerous outlets offer various options, ensuring you find what you need efficiently. Whether you’re seeking original pieces or quality alternatives, understanding where to look is essential for smooth maintenance and repair.

Here are some reliable sources to consider:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers often provide genuine items, ensuring compatibility and reliability. |

| Online Marketplaces | Websites like eBay or Amazon offer a wide range of options, often at competitive prices. |

| Local Repair Shops | These establishments may stock necessary components or assist in sourcing them. |

| Manufacturer’s Website | Direct purchases from the maker can guarantee authenticity and quality. |

| Forums and Community Groups | Engaging with fellow users can provide insights on where to find specific items or alternatives. |

By exploring these avenues, you can effectively track down the components required for optimal performance and longevity of your equipment.

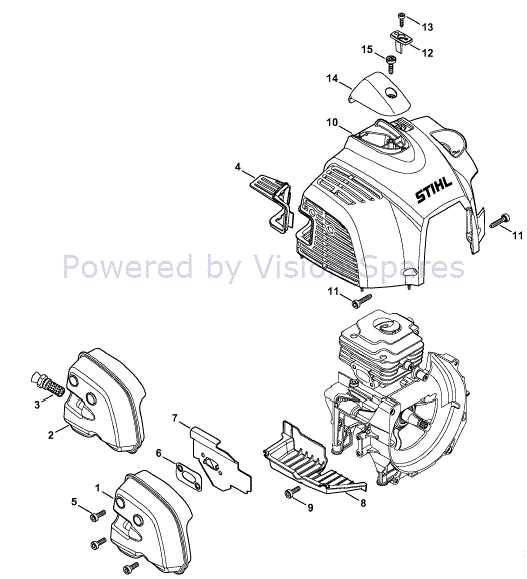

Visual Guides for Assembly and Disassembly

Effective visual aids can significantly enhance the understanding and execution of complex assembly and disassembly processes. By providing clear illustrations and step-by-step instructions, these guides facilitate a smoother workflow, minimize errors, and save valuable time. Whether for maintenance or repairs, utilizing such resources ensures that users can easily follow the required procedures.

Importance of Clear Illustrations

High-quality images and diagrams play a crucial role in comprehending the various components involved in the process. They help users to visualize the arrangement and connection of each element, reducing the chances of misplacement or confusion. Additionally, annotated visuals can highlight key features or potential pitfalls, further aiding in the successful completion of the task.

Step-by-Step Instructions

Accompanying the visuals with concise, sequential directions allows individuals to follow along without unnecessary difficulty. This structured approach not only enhances learning but also boosts confidence, enabling even novice users to tackle more advanced projects. By breaking down the process into manageable steps, the assembly and disassembly become more accessible and less daunting.

Troubleshooting Ms 460 Issues

Addressing common challenges with your equipment is essential for maintaining its efficiency and longevity. Understanding the signs of potential malfunctions and knowing how to tackle them can significantly improve performance and prevent further damage. Below are some typical issues and their corresponding solutions.

Common Problems and Solutions

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine Won’t Start | Fuel blockage, spark plug failure, air filter obstruction | Check fuel supply, replace spark plug, clean or replace air filter |

| Overheating | Lack of lubrication, clogged cooling fins, faulty ignition timing | Add oil, clean cooling fins, adjust ignition timing |

| Poor Performance | Dirty carburetor, worn components, improper fuel mixture | Clean or rebuild carburetor, inspect and replace worn parts, adjust fuel mixture |

Preventive Measures

Regular maintenance is key to avoiding issues. Ensure timely inspections, clean filters, and replace worn components as needed. Keeping a maintenance log can help you track what has been done and when, ensuring your equipment operates at its best.

Safety Tips for Using the Chainsaw

Operating a power saw requires careful attention to safety protocols to prevent accidents and injuries. Proper preparation and awareness of your surroundings can significantly enhance your experience and minimize risks. Following essential guidelines will ensure that you use the tool effectively and safely.

Preparation Before Use

- Always wear appropriate protective gear, including gloves, goggles, hearing protection, and a hard hat.

- Inspect the equipment thoroughly before starting. Check for any signs of wear or damage.

- Ensure you have a first aid kit readily available in case of emergencies.

- Read the manufacturer’s manual to familiarize yourself with the specific features and safety recommendations.

Safe Operating Practices

- Maintain a firm grip on the saw with both hands during operation.

- Keep a safe distance from others; ensure bystanders are at least 10 feet away.

- Be aware of your surroundings and avoid working on slopes or unstable surfaces.

- Always cut at waist height and avoid overreaching.

- Shut off the tool when not in use, and never leave it running unattended.

By adhering to these safety tips, you can ensure a safer working environment and enjoy the efficiency that a power saw offers.