Understanding the Ms193t Parts Diagram for Efficient Repairs

In the realm of machinery and equipment, grasping the intricacies of how individual elements interact is crucial for effective maintenance and operation. This knowledge not only enhances performance but also extends the lifespan of the device, ensuring it functions optimally. A clear visual representation serves as an invaluable resource for technicians and enthusiasts alike.

Delving into the specifics of mechanical assemblies unveils a wealth of information about how each segment contributes to the overall functionality. By analyzing these illustrations, one can identify potential issues, streamline repairs, and even improve the efficiency of various processes. Such insights are essential for anyone looking to deepen their understanding of their equipment.

Moreover, these visuals are not just for experts; they are equally beneficial for novices eager to learn. Engaging with these layouts fosters a greater appreciation for the craftsmanship involved in machinery design. As we explore the details, it becomes clear that mastery over these components can lead to significant improvements in both performance and reliability.

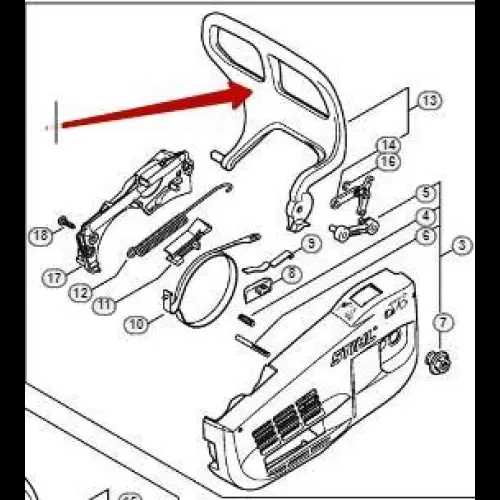

Understanding the Ms193t Parts Diagram

Comprehending the intricacies of mechanical assemblies is crucial for effective maintenance and repair. A visual representation of components provides invaluable insight into their relationships and functions. This guide aims to unravel the complexity of such illustrations, enabling users to approach tasks with confidence.

Key Components and Their Functions

Each element in a mechanical layout plays a specific role, contributing to the overall performance of the device. Familiarizing oneself with these elements enhances troubleshooting and repairs. Below is a table outlining some essential components along with their primary functions:

| Component Name | Function |

|---|---|

| Engine | Drives the system, providing necessary power. |

| Handle | Enables user control and maneuverability. |

| Chain | Transmits power from the engine to the cutting mechanism. |

| Bar | Supports the cutting chain and assists in cutting tasks. |

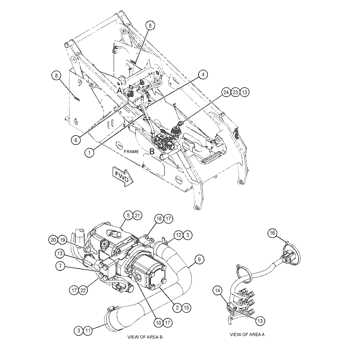

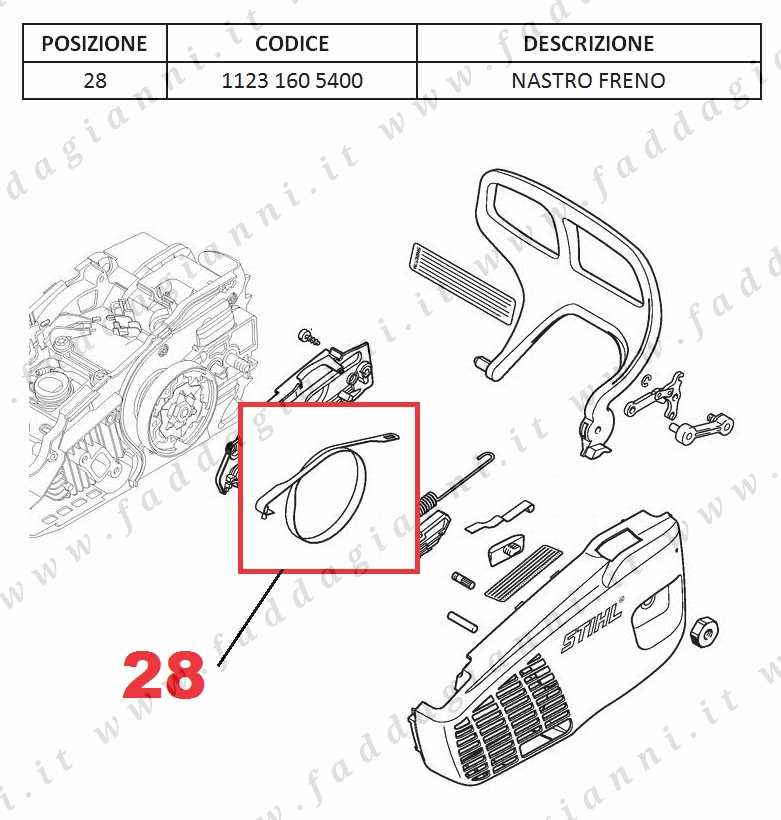

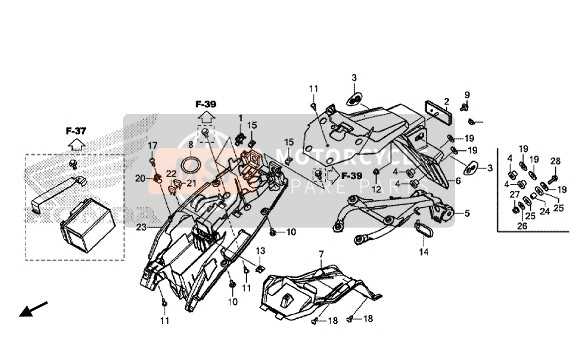

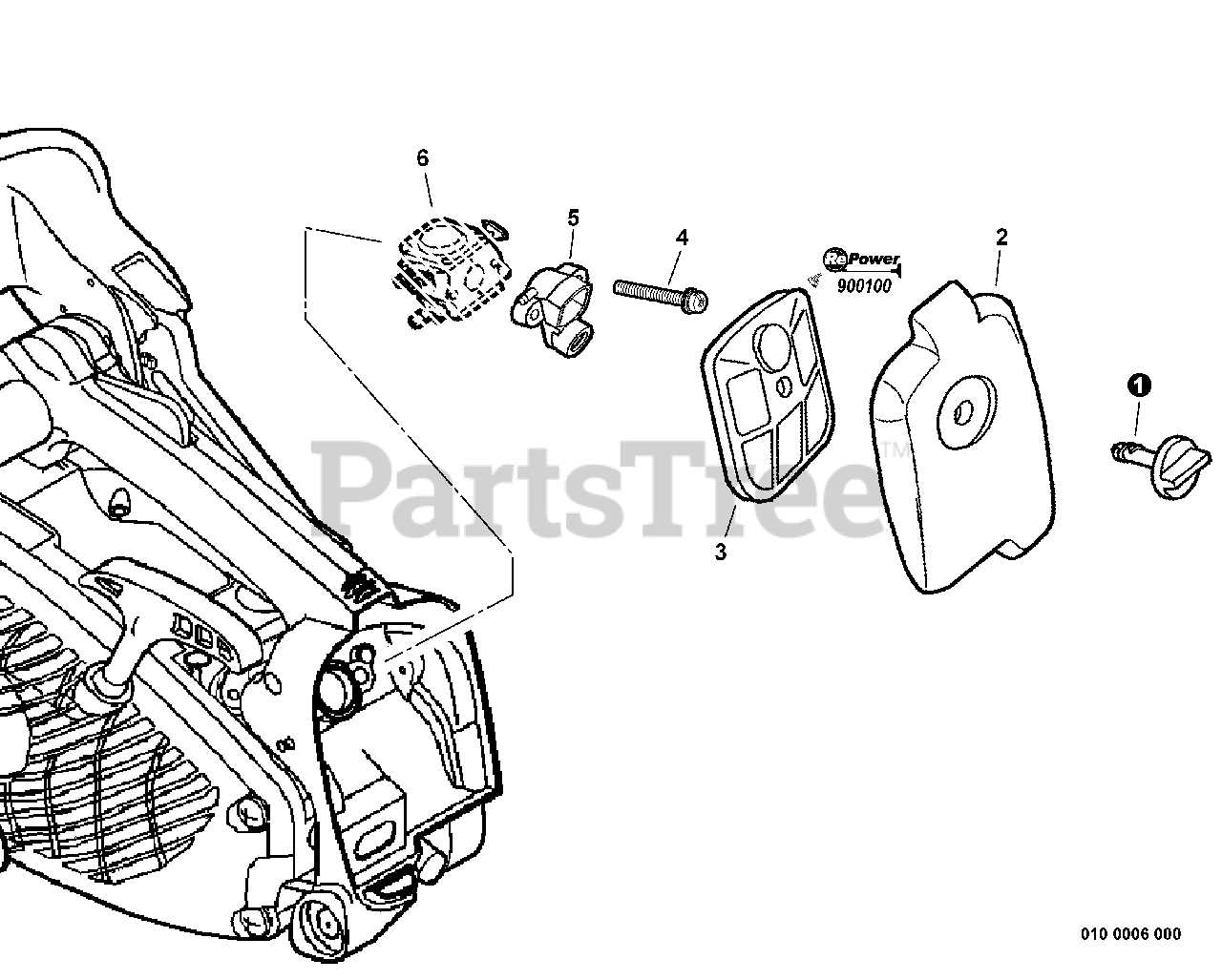

Interpreting Visual Guides

Reading these visual guides requires attention to detail. Each part is often numbered or labeled, aiding in identification and assembly. Understanding the layout will streamline repairs, allowing for quick referencing and improved efficiency. This knowledge empowers users to tackle mechanical challenges with ease.

Key Components of the Ms193t Model

Understanding the essential elements of this model is crucial for effective maintenance and optimal performance. Each component plays a significant role, contributing to the overall functionality and reliability of the system.

Primary Elements

- Engine: The heart of the device, providing the necessary power.

- Fuel System: Ensures efficient fuel delivery and combustion.

- Air Filter: Keeps contaminants out, maintaining air quality for combustion.

- Ignition System: Responsible for starting the engine and ensuring smooth operation.

Supportive Features

- Starter Mechanism: Facilitates easy ignition of the engine.

- Exhaust System: Manages emissions and directs exhaust gases away from the engine.

- Cooling System: Prevents overheating, ensuring longevity and reliability.

- Body Structure: Provides durability and houses all internal components securely.

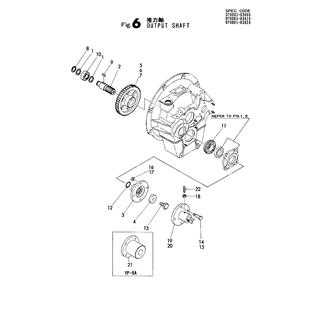

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective assembly, maintenance, and troubleshooting. These visual aids provide a detailed view of components and their relationships, allowing users to identify each element clearly. Familiarity with these representations can significantly enhance efficiency in any project.

First and foremost, it is crucial to recognize the symbols and notations used in these visuals. Each icon typically corresponds to a specific piece, and knowing what each symbol represents helps in quickly locating necessary items. Additionally, look for a legend or key that explains any abbreviations or unique symbols employed in the illustration.

Next, pay attention to the layout of the representation. Often, components are arranged in a way that indicates their placement or how they interact with one another. Understanding the flow of these illustrations can guide you in assembling parts in the correct order.

Finally, cross-reference the visual with any accompanying textual documentation. Detailed descriptions can offer insights that enhance comprehension of the visual information. By combining visual and textual data, you can develop a comprehensive understanding of the assembly or maintenance process.

Common Issues in Ms193t Parts

Understanding typical problems associated with components can significantly enhance the performance and longevity of your equipment. Various factors contribute to wear and tear, often leading to operational inefficiencies. Recognizing these issues early can prevent more extensive damage and costly repairs.

Here are some prevalent complications that users may encounter:

| Issue | Description | Potential Solution |

|---|---|---|

| Wear and Tear | Components may degrade over time, impacting functionality. | Regular inspections and timely replacements can mitigate this. |

| Improper Installation | Incorrect assembly can lead to malfunction or inefficiencies. | Follow manufacturer guidelines closely during installation. |

| Clogging | Debris accumulation can obstruct flow and reduce efficiency. | Routine cleaning and maintenance are essential to prevent this. |

| Incompatibility | Using non-compatible components may cause failures. | Ensure all parts are suitable for your specific model. |

| Overheating | Excessive heat can damage sensitive elements. | Check cooling systems and ensure proper airflow. |

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding in various fields. These detailed illustrations serve as essential tools for conveying complex information, allowing individuals to grasp intricate systems and components swiftly. Without high-quality visuals, misinterpretations can lead to errors and inefficiencies.

Benefits of Clear Illustrations

- Enhanced Clarity: Well-crafted visuals break down complex concepts, making them more accessible to a broader audience.

- Improved Efficiency: Accurate representations streamline processes, helping users locate components quickly and reducing the time spent on troubleshooting.

- Reduced Errors: Clear illustrations minimize the risk of mistakes, ensuring that instructions are followed correctly.

Applications Across Industries

- Manufacturing: Detailed schematics aid in assembly and maintenance, ensuring products are built and serviced correctly.

- Education: Visual aids enhance learning experiences by providing tangible references to theoretical concepts.

- Engineering: Precise blueprints are vital for designing systems and structures, allowing for accurate planning and execution.

Tips for Identifying Parts Quickly

Efficiently recognizing components can significantly enhance your workflow, whether in maintenance or assembly. Understanding how to swiftly determine the necessary elements ensures a smoother process and minimizes downtime. Here are some effective strategies to help you locate and identify each item with ease.

Firstly, familiarize yourself with the nomenclature used in the industry. Knowing the terminology associated with each component allows for faster communication and reduces confusion. Additionally, creating a reference guide that outlines common names and their functions can serve as a handy tool during your tasks.

Secondly, utilize visual aids whenever possible. High-quality images or labeled illustrations can expedite the identification process. If available, consider using interactive resources that allow you to zoom in on specific areas or rotate images for a better view.

Another useful approach is to categorize elements based on their functionality. Grouping similar items together helps you quickly narrow down options when searching for a specific part. Maintaining an organized workspace also contributes to a more efficient identification process.

Finally, practice makes perfect. Regularly working with different components enhances your familiarity and speeds up recognition. As you gain experience, you’ll find that identifying each piece becomes almost instinctive, further streamlining your operations.

Comparing Ms193t to Similar Models

This section explores the differences and similarities between a specific power tool and its counterparts in the market. Understanding these distinctions can help users make informed decisions based on their needs and preferences.

Key Features Overview

When evaluating the tool in question alongside similar models, it’s essential to focus on critical aspects such as performance, design, and user-friendliness. Below is a comparative table highlighting these features.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 2.0 kW | 1.8 kW | 2.2 kW |

| Weight | 4.5 kg | 5.0 kg | 4.3 kg |

| Fuel Efficiency | High | Medium | High |

User Experience

Feedback from users highlights various strengths and weaknesses across models. Key considerations include ease of handling, maintenance requirements, and overall satisfaction. Such insights are invaluable for those seeking the ultimate tool for their tasks.

Where to Find Parts Diagrams Online

Locating detailed schematics for machinery and equipment can greatly enhance maintenance and repair efforts. Various online resources provide access to these valuable illustrations, making it easier for users to understand the components and their relationships.

Here are some effective ways to find these resources:

- Manufacturer Websites: Many manufacturers offer downloadable resources directly on their official sites, ensuring the most accurate and up-to-date information.

- Online Retailers: E-commerce platforms that specialize in equipment often have sections dedicated to user manuals and schematics, allowing customers to view or download relevant information.

- Forums and Community Groups: Online communities dedicated to specific brands or types of equipment can be a goldmine for shared resources, including diagrams and maintenance tips.

- Technical Libraries: Some websites curate extensive libraries of technical documents, making them a valuable resource for detailed visuals and specifications.

Utilizing these sources can significantly streamline the repair process and improve understanding of the equipment in question.

Maintenance Practices for Ms193t Users

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Implementing systematic care practices can prevent potential issues and enhance performance, ultimately saving time and resources. This section outlines key strategies to keep your machinery in optimal condition.

Routine Inspections

Conducting frequent checks is vital for identifying wear and tear early. Consider the following steps:

- Examine all components for signs of damage or corrosion.

- Ensure all moving parts are lubricated adequately.

- Verify that safety mechanisms are functioning correctly.

Cleaning Procedures

Maintaining cleanliness is crucial for operational efficiency. Follow these cleaning guidelines:

- Remove debris from all surfaces and openings.

- Use appropriate cleaning agents to avoid damaging sensitive areas.

- Regularly clean air filters to ensure optimal airflow.

By adhering to these maintenance practices, users can significantly enhance the reliability and performance of their equipment.

DIY Repairs Using Parts Diagrams

Engaging in self-repairs can be a rewarding experience, allowing individuals to save money and develop practical skills. By utilizing visual guides that outline components, you can better understand the assembly and disassembly processes. This section will explore how these resources empower enthusiasts to tackle maintenance tasks effectively.

Understanding Component Layouts

Having a clear visual reference can simplify complex repairs. Recognizing the arrangement and function of each element enables more efficient troubleshooting and replacement. Familiarity with these layouts helps in identifying potential issues before they escalate.

Tools and Techniques

To facilitate successful repairs, having the right tools is essential. Ensure you have a comprehensive toolkit that includes various screwdrivers, pliers, and wrenches. Additionally, employing systematic methods will streamline the process, making it easier to follow along with the visual guides.

| Tool | Purpose |

|---|---|

| Screwdriver Set | Removing screws and fastening parts |

| Pliers | Gripping and manipulating components |

| Wrenches | Tightening or loosening nuts and bolts |

| Multimeter | Testing electrical connections |

Understanding Manufacturer Specifications

When dealing with complex machinery, comprehending the specifications set by the producer is crucial for optimal performance and maintenance. These guidelines provide essential information that ensures the equipment operates efficiently and safely, preventing unnecessary complications.

Manufacturer specifications typically encompass various aspects, including:

- Dimensions: Exact measurements that guarantee compatibility with other components.

- Materials: Details about the substances used, which influence durability and functionality.

- Performance Standards: Benchmarks that indicate the expected output and efficiency levels.

- Maintenance Requirements: Recommended practices to ensure longevity and reliability of the equipment.

Understanding these specifications can lead to several benefits:

- Enhanced Safety: Adhering to guidelines minimizes the risk of accidents or equipment failure.

- Improved Efficiency: Knowledge of operational standards aids in maximizing productivity.

- Cost Savings: Proper maintenance according to recommendations can reduce repair costs and extend the lifespan of the machinery.

Ultimately, a thorough understanding of producer guidelines is fundamental for anyone involved in the operation, maintenance, or repair of machinery. It fosters informed decisions and promotes effective use of resources.

Ordering Replacement Parts Efficiently

Acquiring essential components for equipment maintenance can often be a complex task. However, streamlining this process can save time and resources. By following strategic steps, you can ensure a smooth and effective procurement experience.

Steps to Consider

To enhance your ordering process, start by compiling a comprehensive list of the items needed. This should include specific models, quantities, and any unique specifications. Next, research reliable suppliers who offer the required items at competitive prices.

Organizing Information

Maintain clarity in your orders by documenting all necessary details. A well-structured table can help you track information efficiently.

| Item | Quantity | Supplier | Cost |

|---|---|---|---|

| Component A | 2 | Supplier 1 | $50 |

| Component B | 1 | Supplier 2 | $30 |

| Component C | 3 | Supplier 1 | $15 |

By organizing your requests and maintaining communication with suppliers, you can significantly improve your efficiency in obtaining necessary items.

Resources for Ms193t Owners

For enthusiasts and users of specific models, having access to quality information and support is essential. This section highlights valuable materials and platforms that can enhance the ownership experience, offering insights into maintenance, troubleshooting, and upgrades.

Online Communities

Engaging with fellow users through forums and social media groups can provide real-time advice and shared experiences. These communities often discuss common issues and effective solutions, making them a great resource for learning from others’ journeys.

Technical Manuals and Guides

Comprehensive manuals and instructional guides are indispensable for proper care and operation. These documents typically cover essential aspects such as assembly, maintenance schedules, and troubleshooting tips, ensuring owners have the ultimate support at their fingertips.