Nv4500 Parts Diagram Guide for Easy Reference

The intricate workings of a vehicle’s gearbox play a crucial role in its overall performance. A comprehensive exploration of the various elements that comprise this essential system reveals the complexities involved in achieving smooth gear shifts and optimal power delivery. Each component contributes to the seamless operation of the transmission, highlighting the importance of a well-designed assembly.

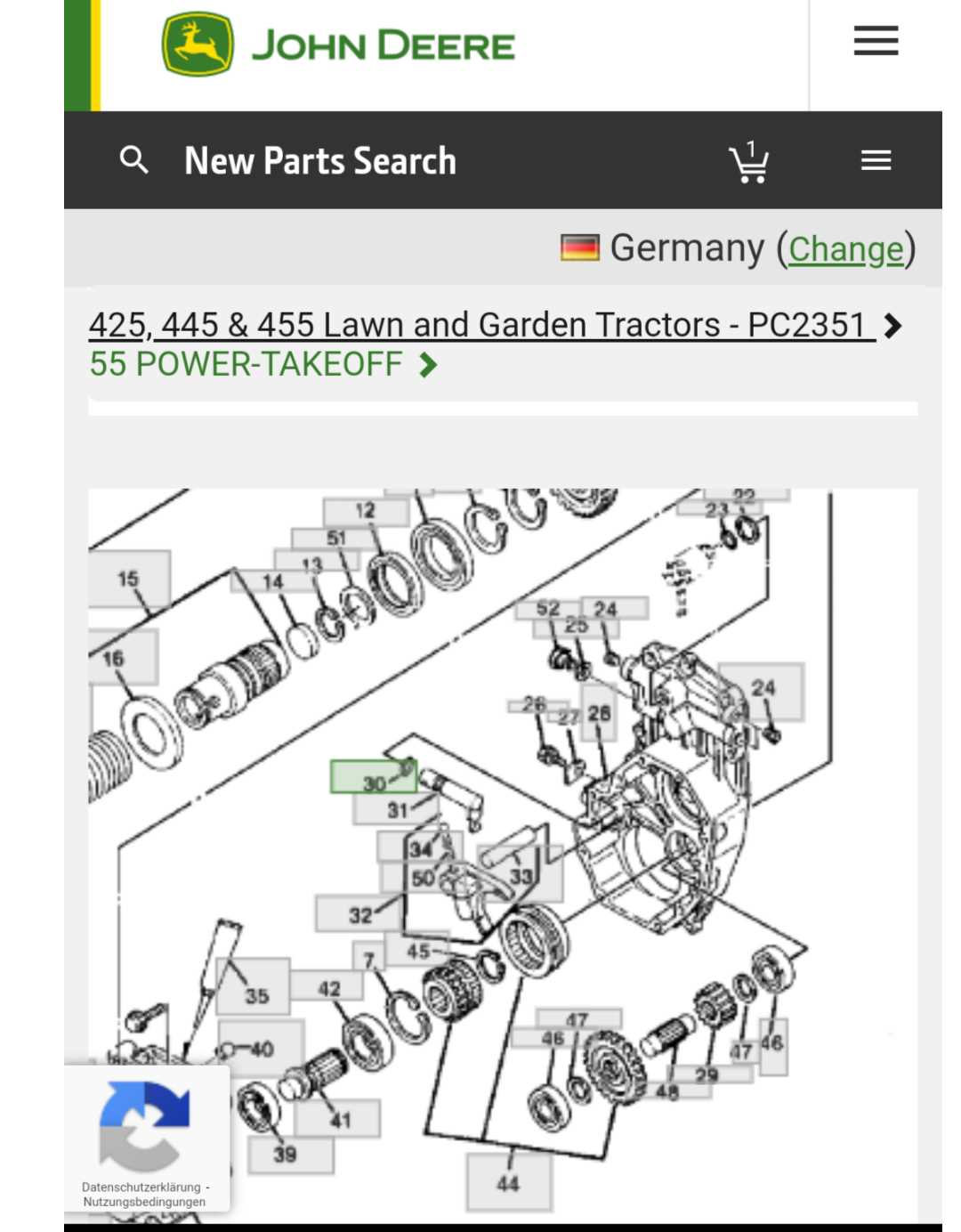

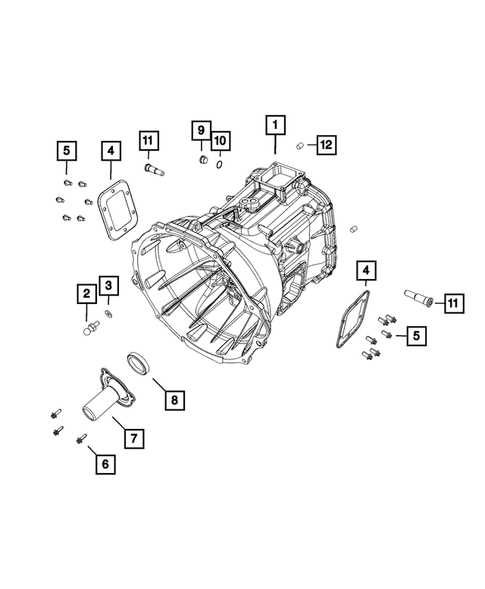

By examining a visual representation of the constituent parts, enthusiasts and mechanics alike can gain valuable insights into their functions and interrelationships. Such an overview not only facilitates better maintenance practices but also enhances the understanding of potential upgrades or repairs. Whether for educational purposes or hands-on projects, familiarity with the essential features of the system empowers users to make informed decisions.

Moreover, recognizing the specific roles of each segment helps identify common issues that may arise during operation. Armed with this knowledge, individuals can address problems effectively and ensure their vehicles remain in peak condition. A thorough comprehension of these mechanical intricacies is indispensable for anyone looking to deepen their expertise in automotive technology.

Nv4500 Parts Overview

This section provides a comprehensive look at the components essential for the manual transmission system. Understanding these elements is crucial for maintenance and performance enhancement, ensuring optimal functionality and longevity.

| Component | Description |

|---|---|

| Case | The outer structure that houses the internal mechanisms. |

| Gear Set | Includes various gears that facilitate speed and torque adjustments. |

| Shafts | Long cylindrical parts that transmit power and motion. |

| Bearings | Support rotating elements, reducing friction and wear. |

| Forks | Devices that engage and disengage the gears during shifting. |

| Seals | Prevent fluid leaks and protect internal components from contaminants. |

Understanding the Transmission Components

The intricate system within a vehicle’s gearbox is essential for converting engine power into motion. Each element plays a crucial role in ensuring smooth shifts and optimal performance. By examining these components, we can appreciate their functions and interrelationships, which ultimately enhance the driving experience.

Gears are fundamental to this mechanism, allowing different torque levels and speeds. They work in harmony to provide the desired output, whether accelerating or cruising. Synchros, on the other hand, facilitate seamless engagement of gears, preventing grinding and ensuring a fluid transition during shifting.

Additionally, shifters enable the driver to control the gearbox, translating manual inputs into precise actions within the system. Bearings support rotating components, reducing friction and wear, which is vital for longevity. Understanding these elements provides insight into their collective significance in vehicle dynamics.

Key Features of the Nv4500

This transmission system is renowned for its robust design and impressive performance characteristics, making it a popular choice among enthusiasts and professionals alike. Its ability to handle high torque loads while maintaining smooth shifting is a standout feature, ensuring reliability in various driving conditions.

Durability and Strength

Engineered with heavy-duty components, this gearbox offers exceptional durability. The construction materials and design allow it to withstand the demands of both on-road and off-road driving, providing longevity and minimizing wear.

Smooth Operation

The system features advanced engineering that facilitates seamless gear transitions. This results in a driving experience that is both responsive and enjoyable, contributing to its reputation for excellence in performance.

Diagram Layout Explanation

This section aims to clarify the arrangement and relationships within the components of a transmission system. Understanding this layout is crucial for effective troubleshooting and maintenance, as it provides insight into how each element interacts and functions together.

| Component | Description |

|---|---|

| Housing | The outer shell that encases and protects internal mechanisms. |

| Gear Sets | Groups of gears that facilitate speed and torque variations. |

| Synchronizers | Devices that ensure smooth gear shifting by matching speeds. |

| Shifter Assembly | The mechanism used by the driver to select gears. |

| Input Shaft | The shaft that transmits power into the system. |

Common Parts and Their Functions

This section explores the essential components found within a specific transmission system, highlighting their roles in ensuring optimal performance and reliability. Understanding these elements is crucial for anyone looking to maintain or repair their vehicle’s transmission.

Key Components

- Gear Assembly: Facilitates the transfer of power between the engine and wheels, allowing for smooth acceleration and deceleration.

- Input Shaft: Connects the engine to the transmission, transmitting torque and rotational energy.

- Output Shaft: Transfers power from the transmission to the driveshaft, enabling movement of the vehicle.

- Clutch: Engages and disengages the engine from the transmission, allowing for gear changes.

- Shift Forks: Control the movement of gears, ensuring proper selection during shifting.

Supporting Elements

- Bearings: Reduce friction between moving parts, promoting longevity and smooth operation.

- Seals: Prevent fluid leaks and contamination, safeguarding the internal components.

- Synchronization Rings: Aid in aligning gears during shifting, ensuring a seamless transition between gears.

Repair and Replacement Guidelines

Maintaining the integrity of your transmission system is essential for optimal vehicle performance. Understanding the necessary procedures for repair and replacement can significantly enhance reliability and extend lifespan. This section offers essential insights into effective practices and considerations to ensure a smooth process.

Initial Assessment: Before proceeding with any repairs, conduct a thorough examination to identify the specific issues at hand. Look for signs of wear, leaks, or unusual noises that may indicate underlying problems.

Tools and Equipment: Having the right tools on hand is crucial. Ensure you are equipped with quality wrenches, sockets, and a reliable jack. Safety gear should also be considered to protect yourself during the process.

Replacement Components: When it comes to substituting damaged elements, select high-quality components that meet or exceed OEM specifications. This will ensure optimal performance and longevity of the system.

Step-by-Step Procedures: Follow a systematic approach for dismantling and reassembling parts. Document each step with notes or photos to aid in the reinstallation process. This will help avoid any potential errors.

Testing and Validation: After completing the repairs, conduct thorough testing to validate the functionality of the transmission. Pay attention to shifts, sounds, and overall performance to ensure everything operates seamlessly.

By adhering to these guidelines, you can effectively tackle repairs and replacements, ensuring your vehicle remains in peak condition for years to come.

Tools Required for Maintenance

Proper upkeep of your transmission system necessitates a selection of essential instruments and equipment. Having the right tools on hand not only facilitates the repair process but also ensures that each task is executed efficiently and safely. Below is an overview of the primary tools you will need for effective maintenance.

1. Socket Set: A comprehensive socket set is crucial for loosening and tightening various bolts and fasteners. Make sure to include both metric and standard sizes for versatility.

2. Wrenches: An assortment of wrenches, including adjustable and torque wrenches, will help you tackle different sizes and types of nuts and bolts.

3. Screwdrivers: Both flathead and Phillips screwdrivers are necessary for handling screws that secure various components.

4. Pliers: Needle-nose and slip-joint pliers are useful for gripping, bending, and cutting wires or small parts.

5. Fluid Extractor: A fluid extractor allows for the safe removal of transmission fluid, making fluid changes cleaner and more efficient.

6. Clean Rags: Keep a supply of clean rags or shop towels handy for wiping surfaces and cleaning up spills during maintenance tasks.

7. Safety Equipment: Always wear safety glasses and gloves to protect yourself while working on your equipment.

By equipping yourself with these essential tools, you can ensure that maintenance tasks are performed correctly, enhancing the longevity and performance of your system.

Identifying Common Issues

Understanding the frequent challenges that arise within a particular mechanical system is crucial for effective maintenance and troubleshooting. By recognizing these common problems, owners can take proactive measures to ensure longevity and performance.

Signs of Wear and Tear

Over time, components may exhibit signs of deterioration, such as unusual noises or difficulty in shifting. These symptoms often indicate that certain parts need attention or replacement. Regular inspection can help in catching issues early.

Fluid Leaks and Contamination

Another prevalent issue is the presence of fluid leaks, which can lead to serious damage if not addressed promptly. Checking for leaks and ensuring that fluids remain clean is essential for optimal function and reliability. Regular maintenance plays a key role in preventing these complications.

Upgrading Nv4500 Components

Enhancing the efficiency and performance of your transmission system can significantly impact your vehicle’s overall functionality. By selecting high-quality upgrades, you can optimize power delivery, improve shifting capabilities, and extend the lifespan of critical components.

Key Upgrades to Consider

- Transmission Fluid: Opt for synthetic fluids to enhance lubrication and reduce wear.

- Gearing Changes: Altering gear ratios can improve acceleration or fuel efficiency, depending on your needs.

- Clutch Upgrades: A performance clutch can provide better grip and smoother engagement.

Installation Tips

- Ensure you have the necessary tools and safety equipment.

- Follow manufacturer guidelines for each component.

- Consider professional installation for complex upgrades to ensure optimal results.

Aftermarket Parts vs. OEM Options

When it comes to vehicle components, consumers often face a choice between alternatives that promise cost savings and those that ensure factory quality. Each option has distinct advantages and considerations, making it essential to weigh the implications of your selection carefully.

Aftermarket components can offer competitive pricing and availability, appealing to those looking for budget-friendly solutions. However, the quality and compatibility can vary significantly, necessitating thorough research and understanding of the product specifications.

On the other hand, OEM (Original Equipment Manufacturer) options provide peace of mind with guaranteed fit and performance, as they are made to the same standards as the original components. This reliability often comes at a higher price, which may deter some buyers.

Ultimately, the decision hinges on individual needs, budget constraints, and long-term vehicle goals. Delve into the specifics of both types to determine which path aligns best with your requirements.

Tips for Efficient Assembly

When undertaking the assembly of complex machinery, attention to detail and organization can significantly enhance the process. A systematic approach not only ensures that each component fits together seamlessly but also minimizes the likelihood of errors. Below are some strategies to improve efficiency and effectiveness during assembly tasks.

Preparation is Key

Before beginning, it is crucial to gather all necessary components and tools. Create a checklist to verify that everything is on hand. Organizing items in a logical manner can save valuable time during the assembly process. Additionally, familiarizing yourself with the specifications and layout beforehand will provide a clearer understanding of how parts interact.

Follow a Methodical Approach

Implementing a step-by-step method can lead to a smoother assembly experience. Start with the foundational elements and progressively work towards the more intricate components. Using visual aids, such as assembly guides or instructional videos, can further clarify the process. Remember to periodically check your progress to ensure alignment with the intended design.

Lastly, maintaining a clean workspace is essential. A tidy environment reduces distractions and helps keep track of smaller components, ultimately streamlining the entire assembly operation.

Resource Links for Further Reading

This section offers valuable references for those seeking a deeper understanding of manual transmission systems. The curated links provide insights into components, maintenance practices, and enhancements that can optimize performance.

Essential Resources

| Resource | Description |

|---|---|

| Transmission Manuals | Comprehensive guides detailing the operation and servicing of manual gearboxes. |

| Online Forums | A community space for discussions and troubleshooting among enthusiasts and experts. |

| Video Tutorials | Visual step-by-step instructions for installation and repair processes. |

Further Insights

For those interested in performance tuning, several articles and reviews explore modifications and upgrades that enhance efficiency and responsiveness. Engaging with these resources will ultimately enrich your knowledge and skill set in working with these systems.